Hydraulic oil treatment device for hydraulic equipment

A processing device and hydraulic equipment technology, applied in the hydraulic field, can solve problems such as easy blockage of radiator pipes, easily damaged oil leakage, and increased oil return resistance, so as to reduce equipment operating costs, reduce installed capacity, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

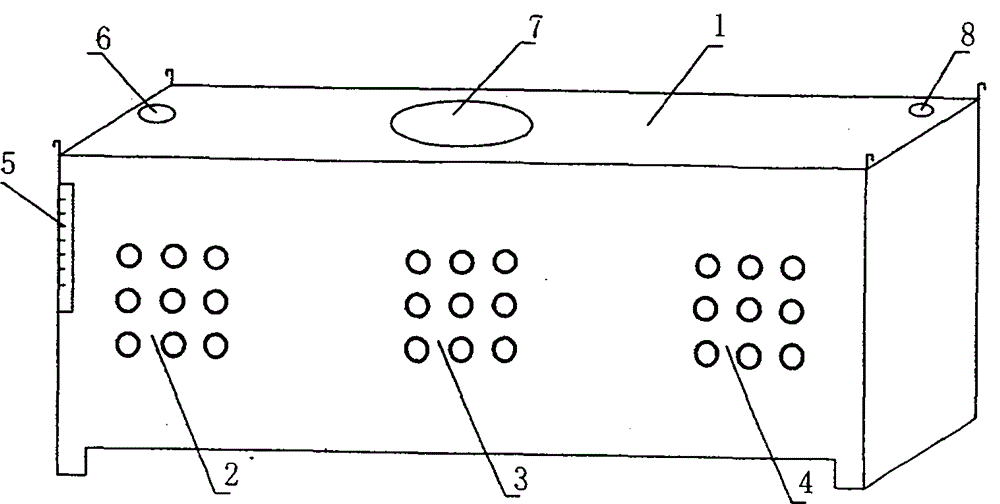

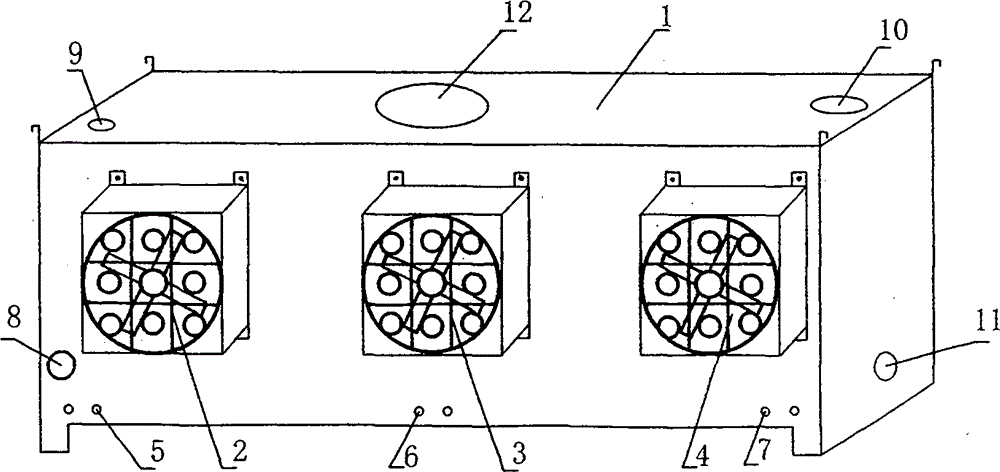

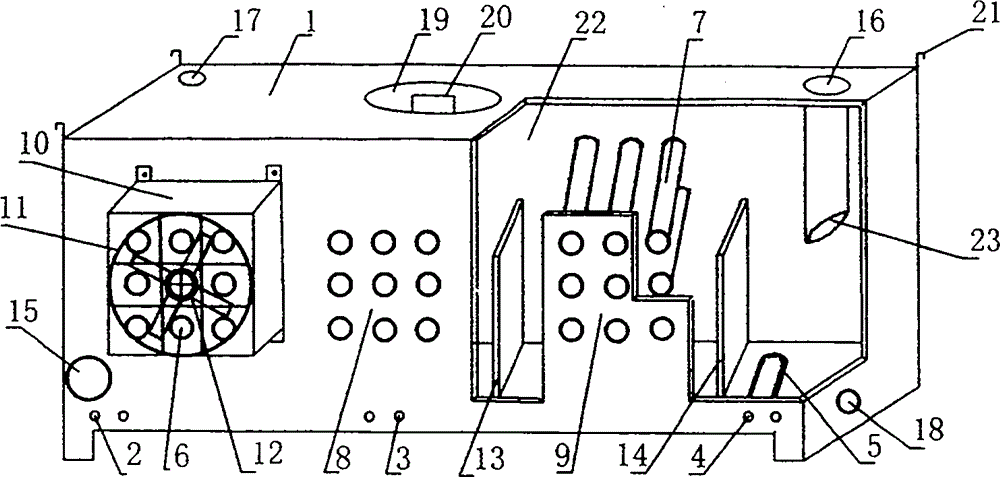

[0034] The hydraulic oil treatment device of the hydraulic system of the 200-ton CNC hydraulic press and the Figure 4 , Figure 5 , Figure 6 The present invention is further described.

[0035] 1. Calculate the total amount of oil in the hydraulic system

[0036] The cylinder of this hydraulic machine has a diameter of 360mm, a stroke of 500mm, a 22KW-6 motor, and a 190L Rexroth constant power electronically controlled proportional variable pump.

[0037] 2. Determine the cabinet parameters

[0038] According to the condition of the main engine, the parameters of the box are determined to be 1400mm in length, 660mm in width, and 740mm in height. The total volume is about 680L, the effective volume is about 540L, and 500L of oil can be filled.

[0039] 3. Purchasing materials and accessories.

[0040]The thickness of the box plate is 5mm, 2 pieces in total of 660 in width and 1400 in length, 2 pieces in total of 740 in width and 1400 in length, and 2 pieces in total of 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com