Baked corn beverage and preparation method thereof

A corn and beverage technology, applied in food ingredients as taste improver, function of food ingredients, food science, etc., can solve the problems of unstable corn beverage quality, general taste, poor drinking experience, etc., and achieve rich varieties and storage time. Long, long shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

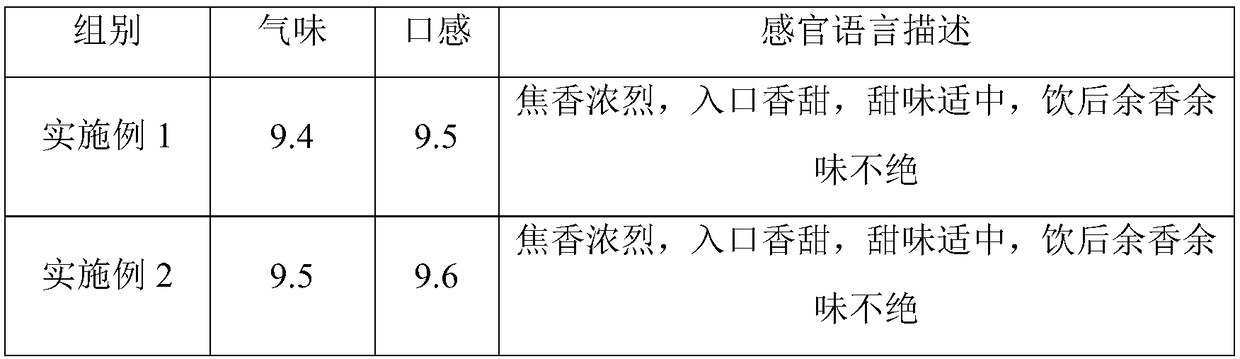

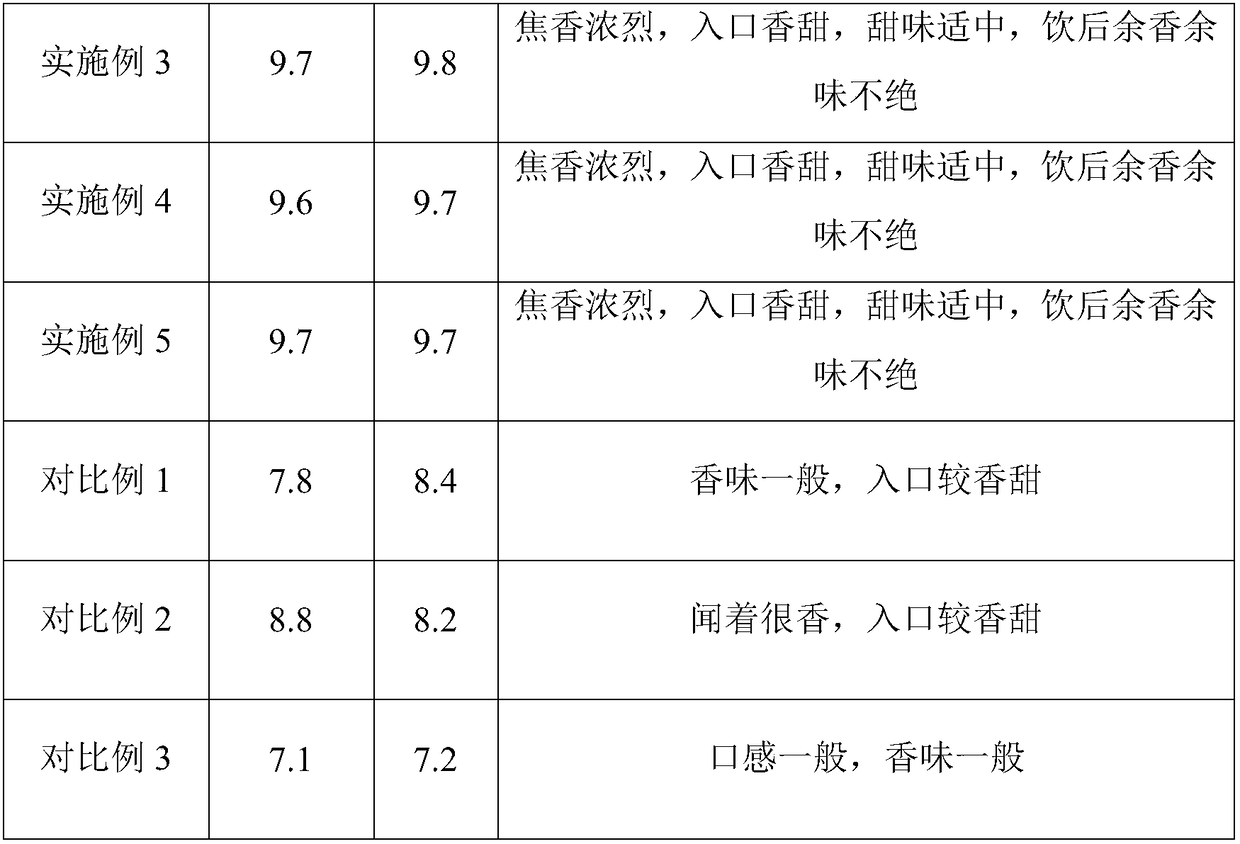

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing a roasted corn beverage, wherein the roasted corn beverage is the above-mentioned roasted corn beverage, and the preparation method comprises:

[0047] (1) Grinding roasted corn to obtain roasted corn flour.

[0048] Preferably, the roasted corn is prepared at a temperature of 120-170°C such as 120°C, 130°C, 140°C, 150°C, 160°C or 170°C after washing and drying selected high-quality dry corn kernels. It can be obtained by lower baking for 20-40 minutes, such as 20 minutes, 25 minutes, 30 minutes, 35 minutes or 40 minutes. Among them, the preferred corn is selected dry corn kernels without moths, mildew, deterioration, impurities, plumpness, and no cracks.

[0049] It should be noted that the present invention uses a superfine pulverizer to pulverize the roasted corn, preferably, the particle size of the pulverized roasted corn flour is 80-150 mesh, such as 80 mesh, 100 mesh, 120 mesh or 150 mesh, etc. .

[00...

Embodiment 1

[0062] (1) Screen out high-quality dry corn kernels that are free from insects, mildew, no deterioration, no impurities, plump, and no cracks.

[0063] (2) Wash the selected high-quality dry corn kernels, dry them naturally, put them into an oven, bake them at 120° C. for 40 minutes, and take them out to obtain roasted corn.

[0064] (3) Take 4 parts of roasted corn as the main raw material, and pulverize it with an ultrafine pulverizer to obtain roasted corn flour with a particle size of 80 mesh.

[0065] (4) Add the roasted corn flour prepared in step (3), 0.4 part of emulsification stabilizer, 2 parts of white granulated sugar, 0.01 part of sodium carbonate and 85 parts of pure water into the batching bucket, stir well, and then mix the obtained The mixed solution is injected into the SRH3-100 emulsification pump for emulsification to obtain a slurry; wherein, the emulsion stabilizer is gum arabic.

[0066] (5) Pour the slurry obtained in step (4) into a 150-mesh filter ba...

Embodiment 2

[0069] (1) Screen out high-quality dry corn kernels that are free from insects, mildew, no deterioration, no impurities, plump, and no cracks.

[0070] (2) Wash the selected high-quality dry corn kernels, dry them naturally, put them into an oven, bake them at 130° C. for 35 minutes, and take them out to obtain roasted corn.

[0071] (3) Take 4.5 parts of roasted corn as the main raw material, and pulverize it with an ultrafine pulverizer to obtain roasted corn flour with a particle size of 100 mesh.

[0072] (4) Add the roasted corn flour prepared in step (3), 0.5 parts of emulsification stabilizer, 2.5 parts of white granulated sugar, 0.012 parts of sodium carbonate and 86 parts of pure water into the batching bucket, stir well, and then mix the obtained The mixed liquid is injected into the SRH3-100 emulsification pump for emulsification to obtain a slurry; wherein, the emulsification stabilizer is mono-diglyceride fatty acid ester.

[0073] (5) Pour the slurry obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com