Patents

Literature

63results about "Drying/glazing processed material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drying device

InactiveUS7073274B2Avoid adjustmentSmooth trafficDrying gas arrangementsDrying machines with progressive movementsWaste management

Owner:FUJIFILM CORP +1

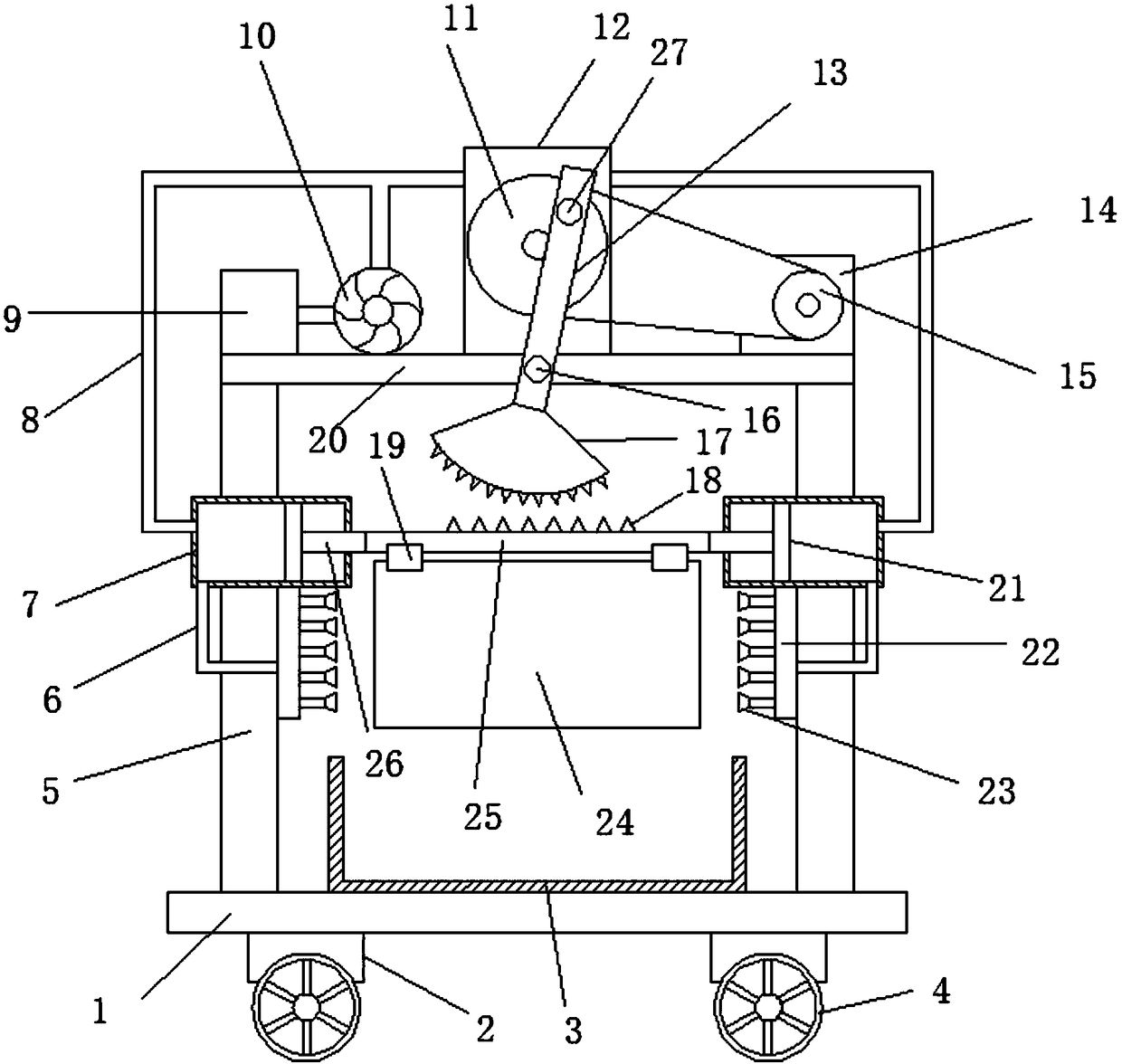

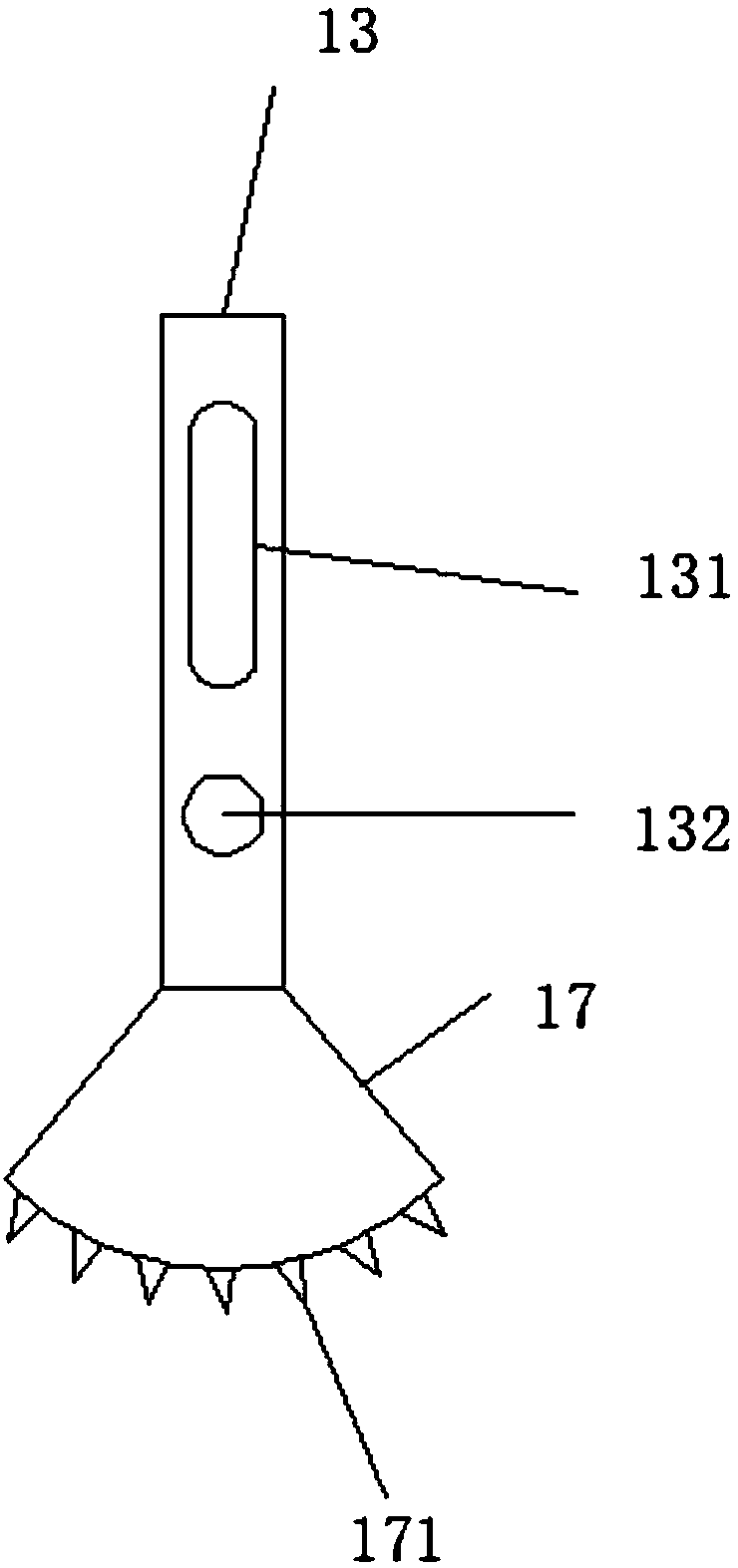

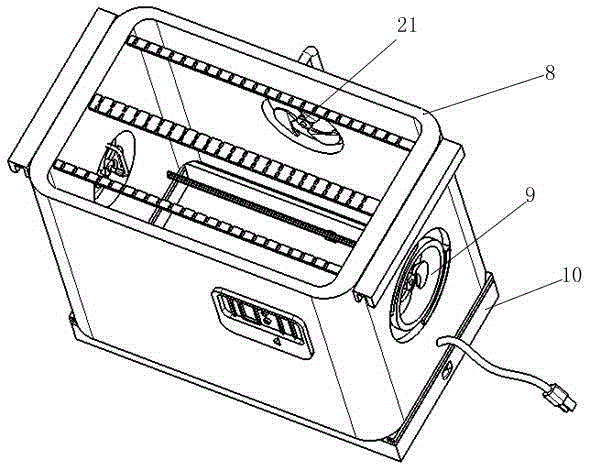

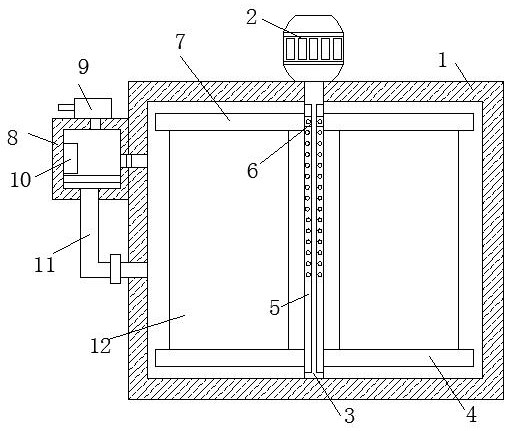

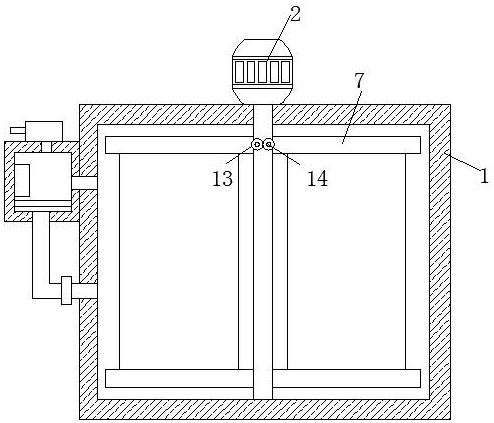

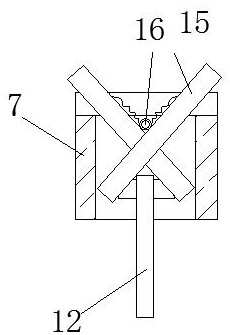

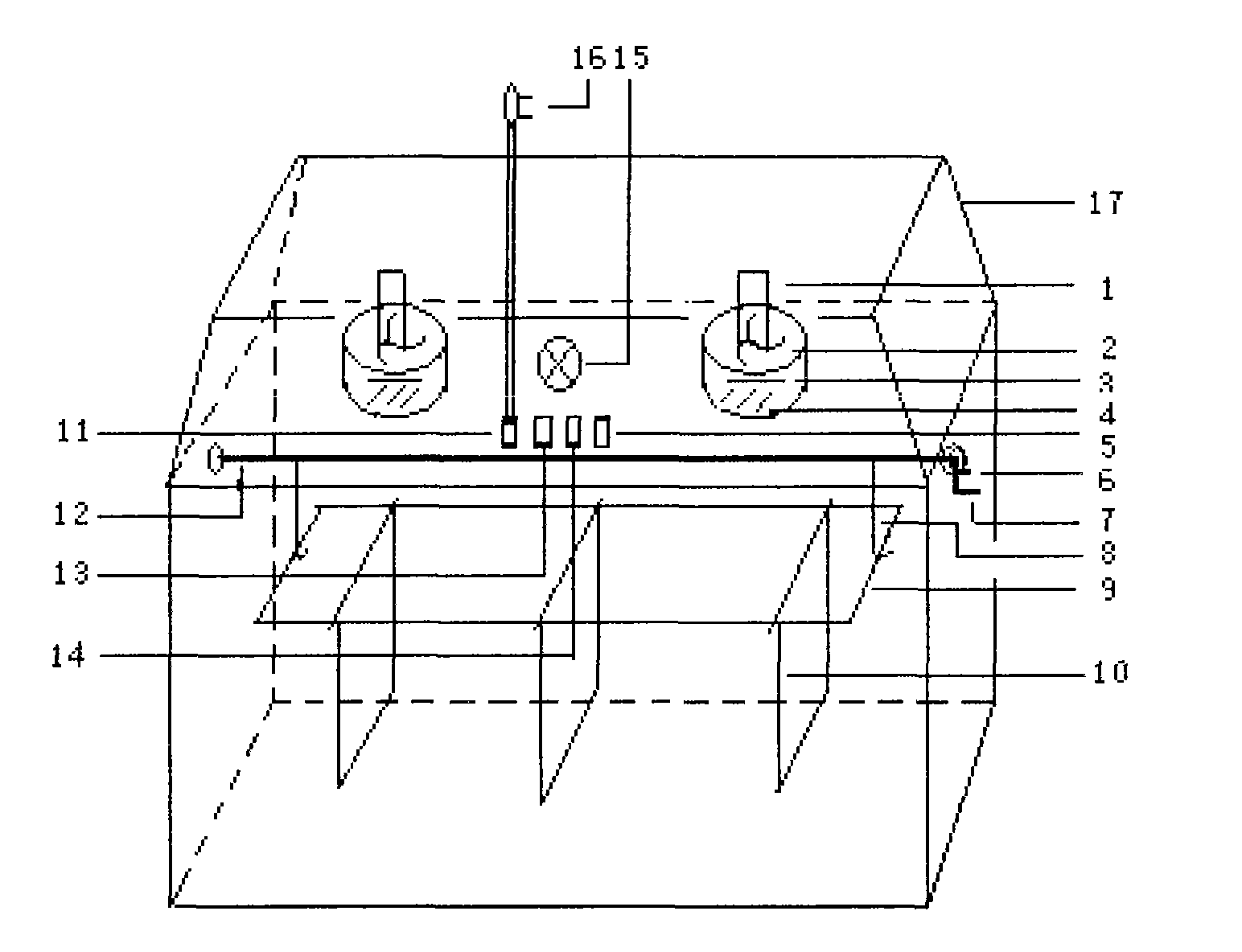

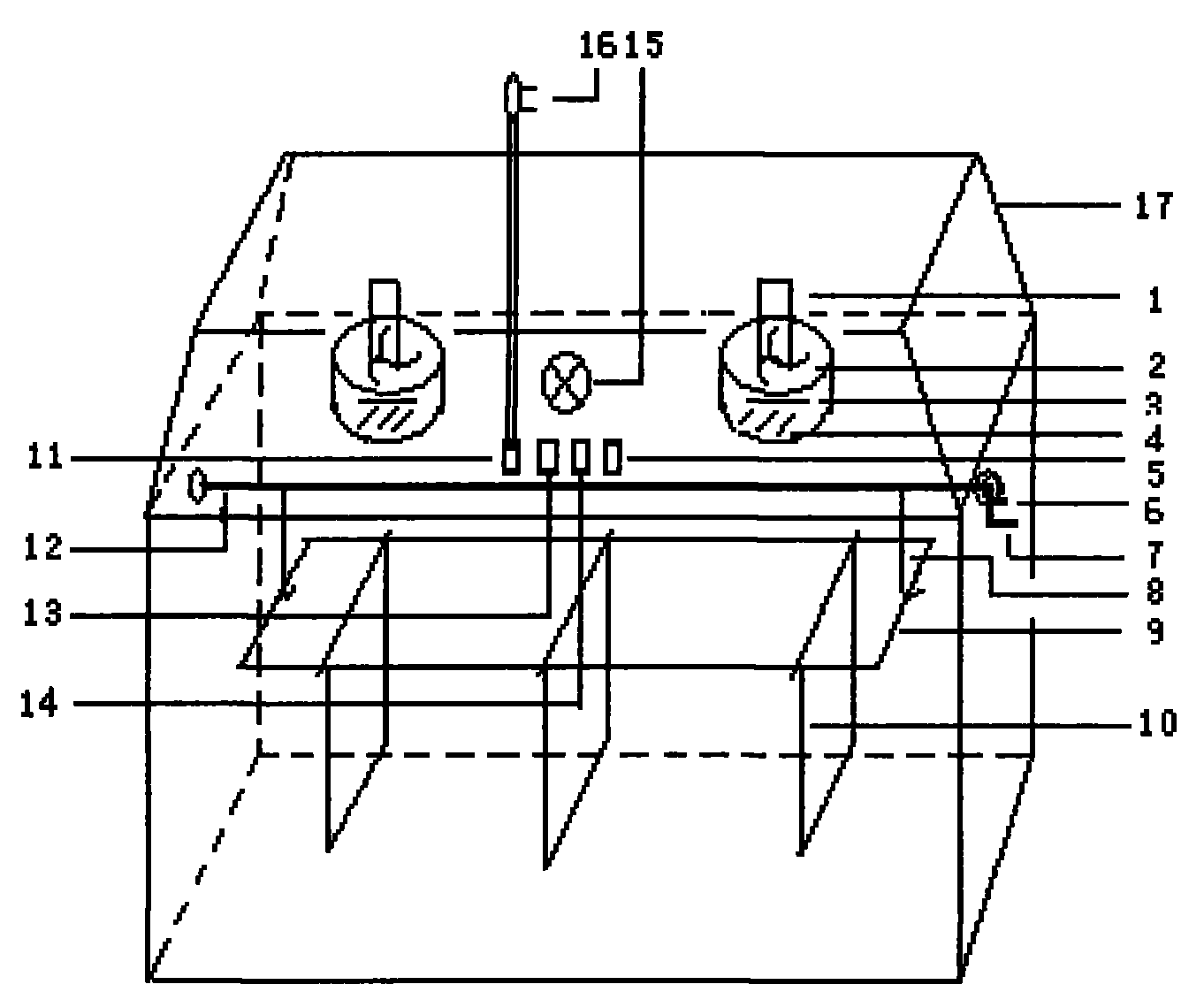

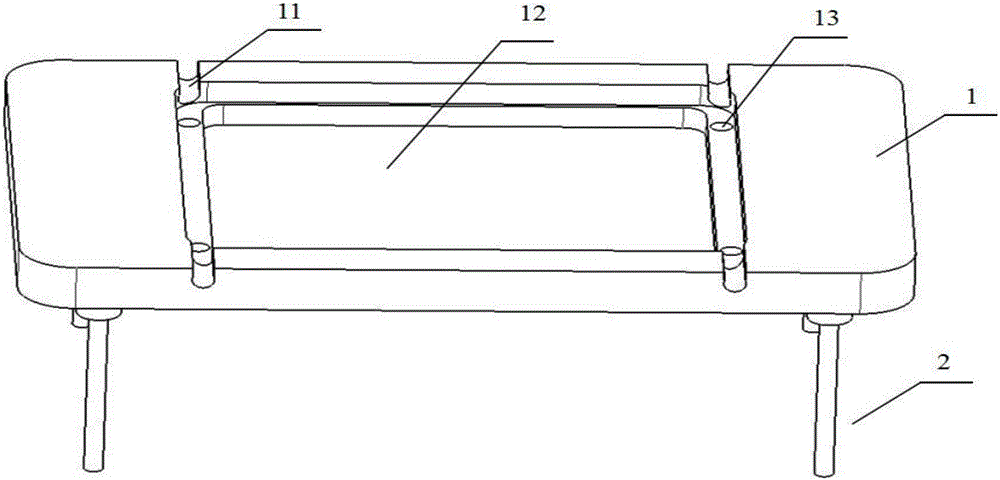

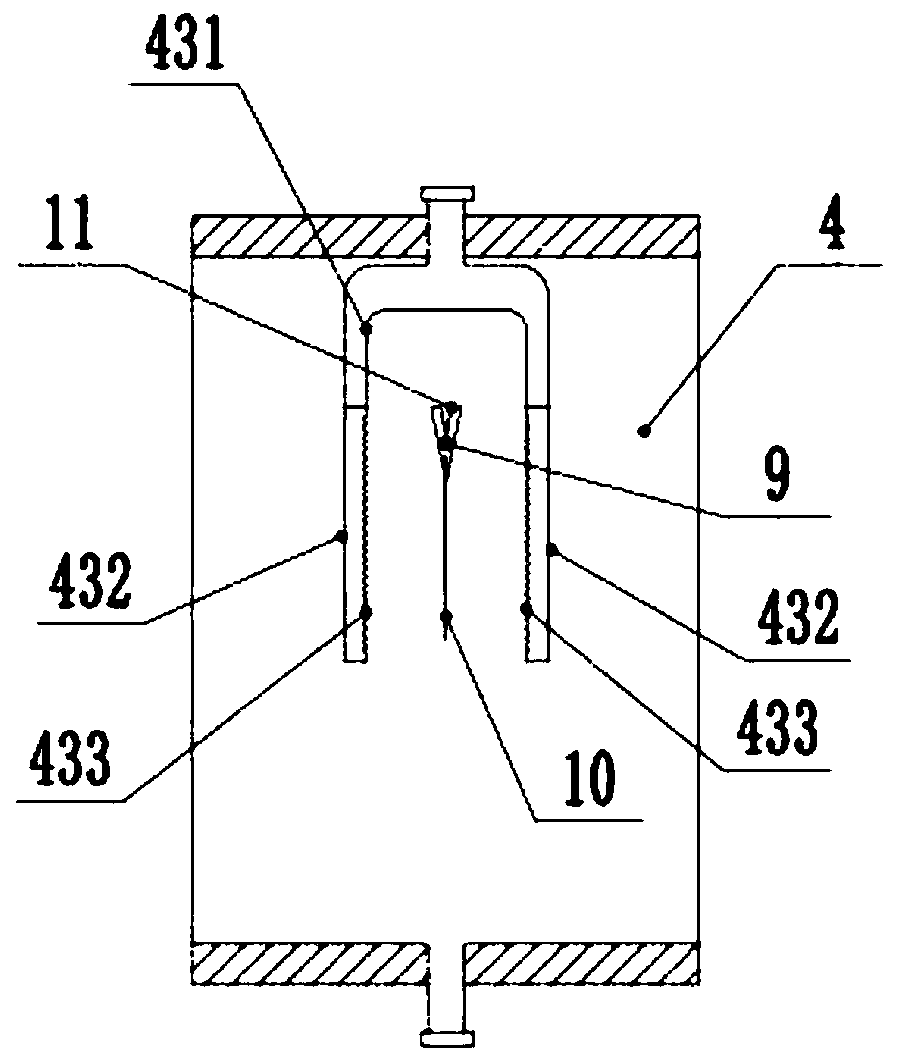

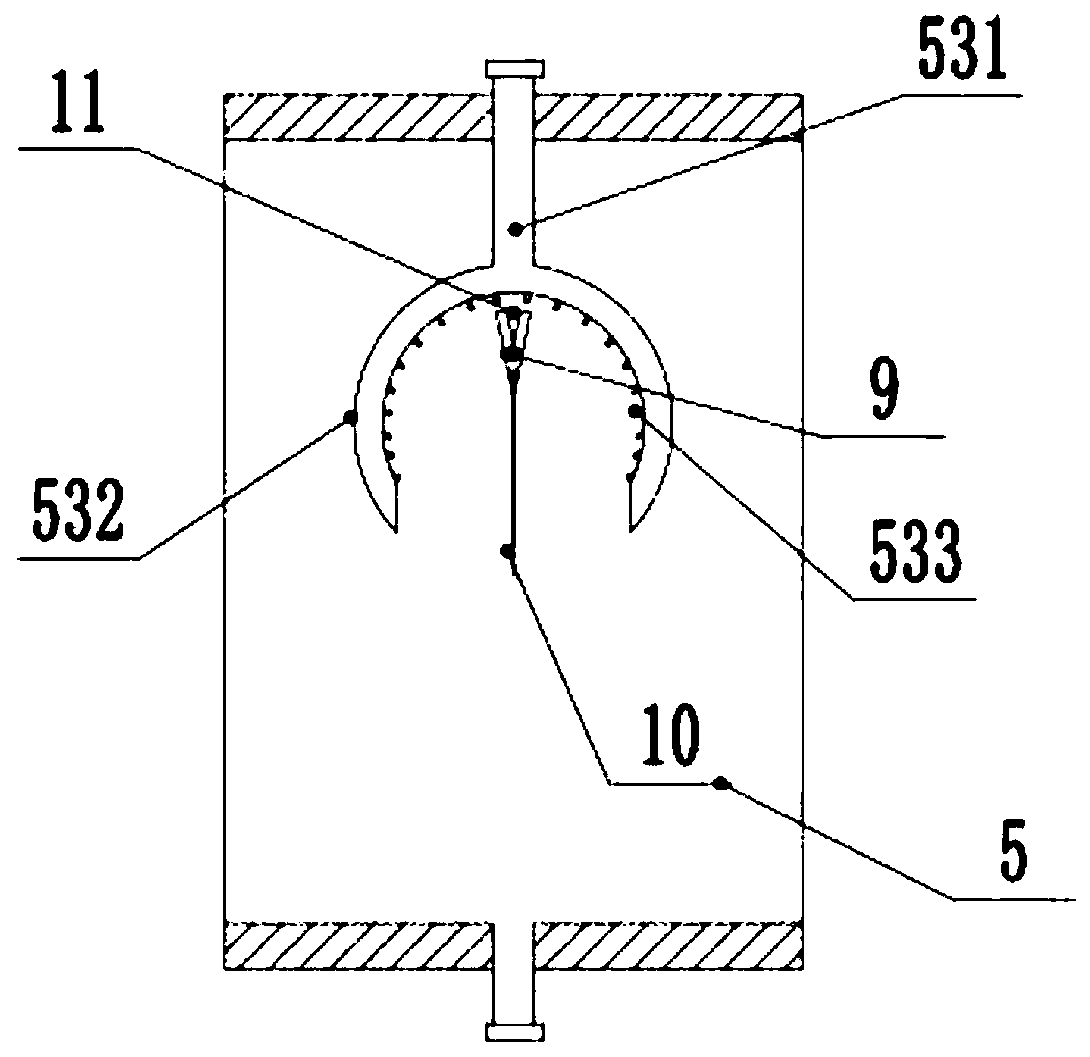

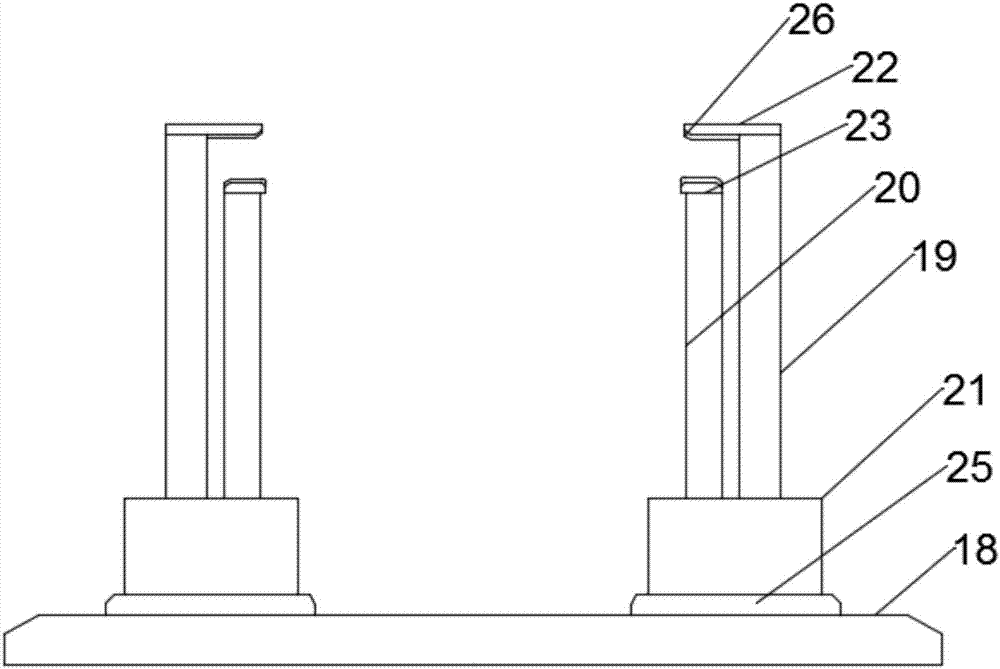

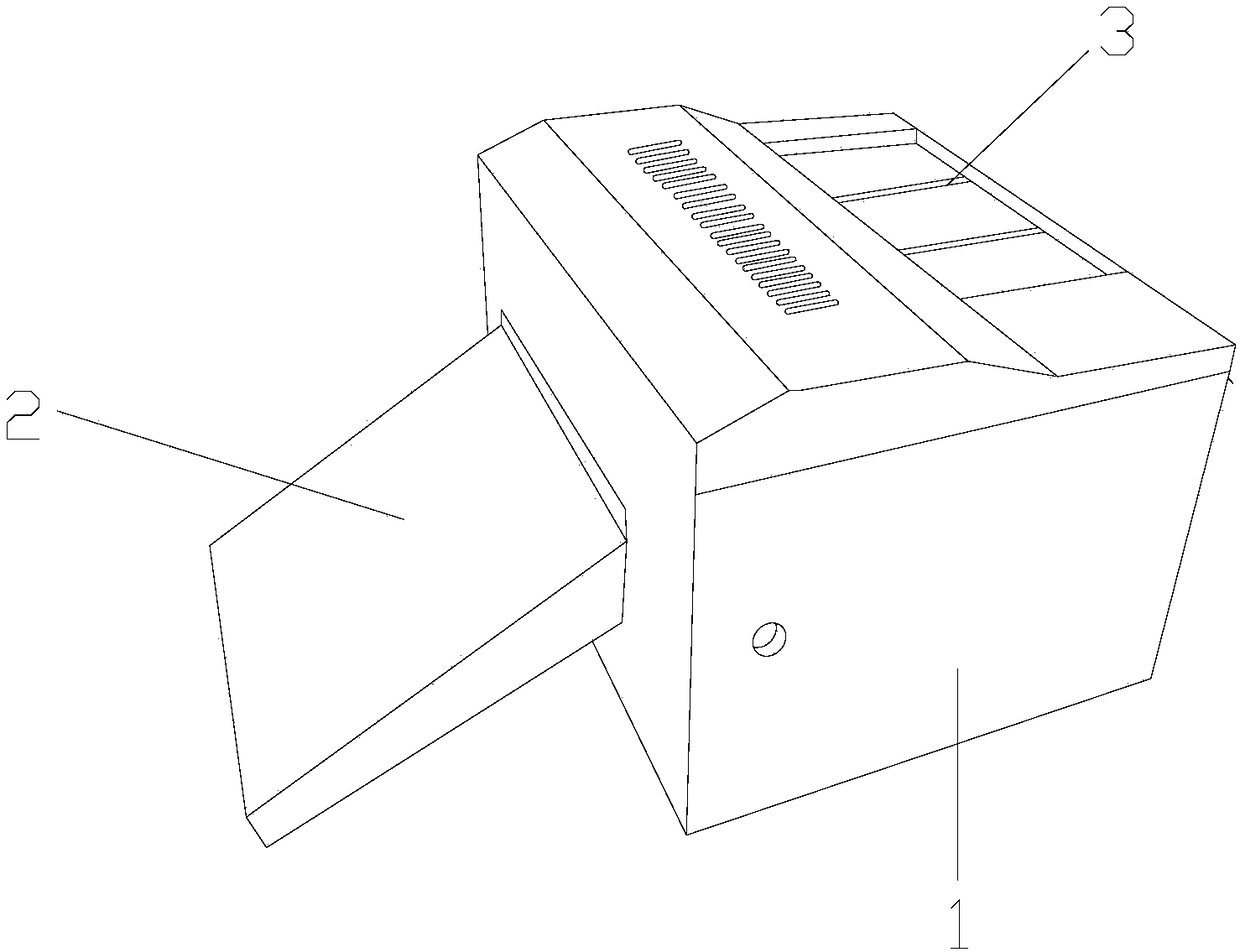

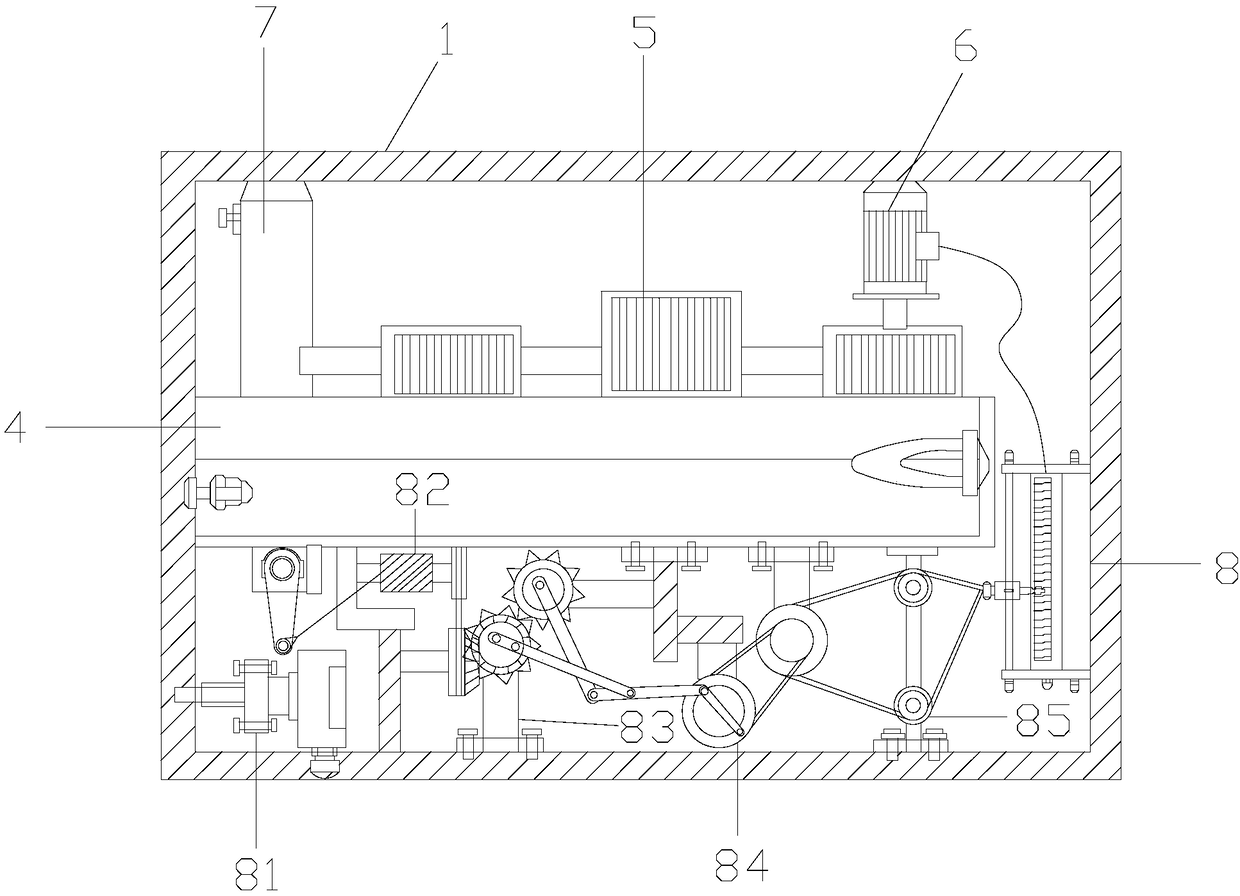

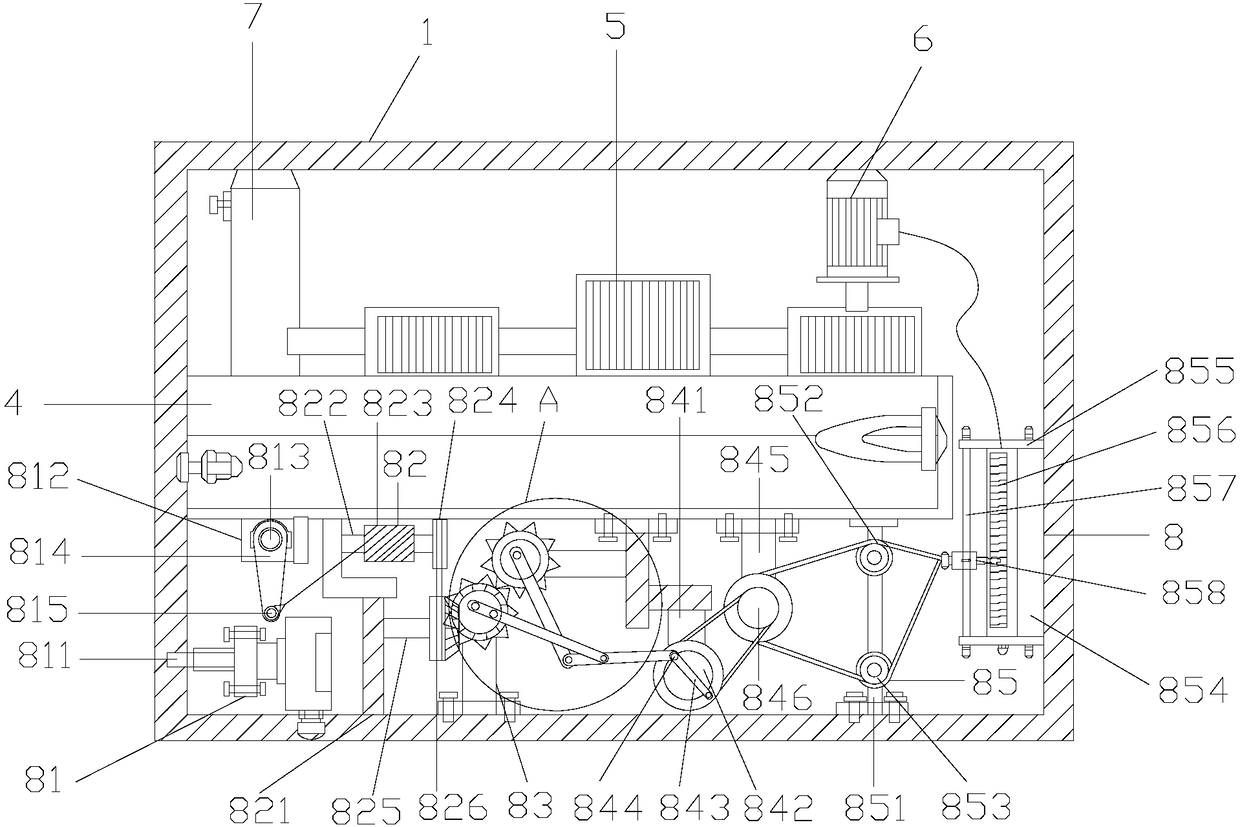

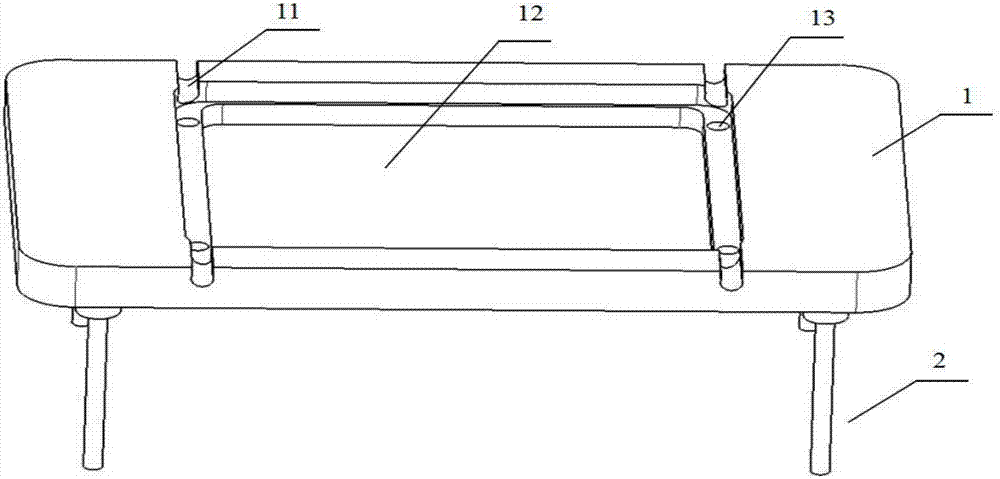

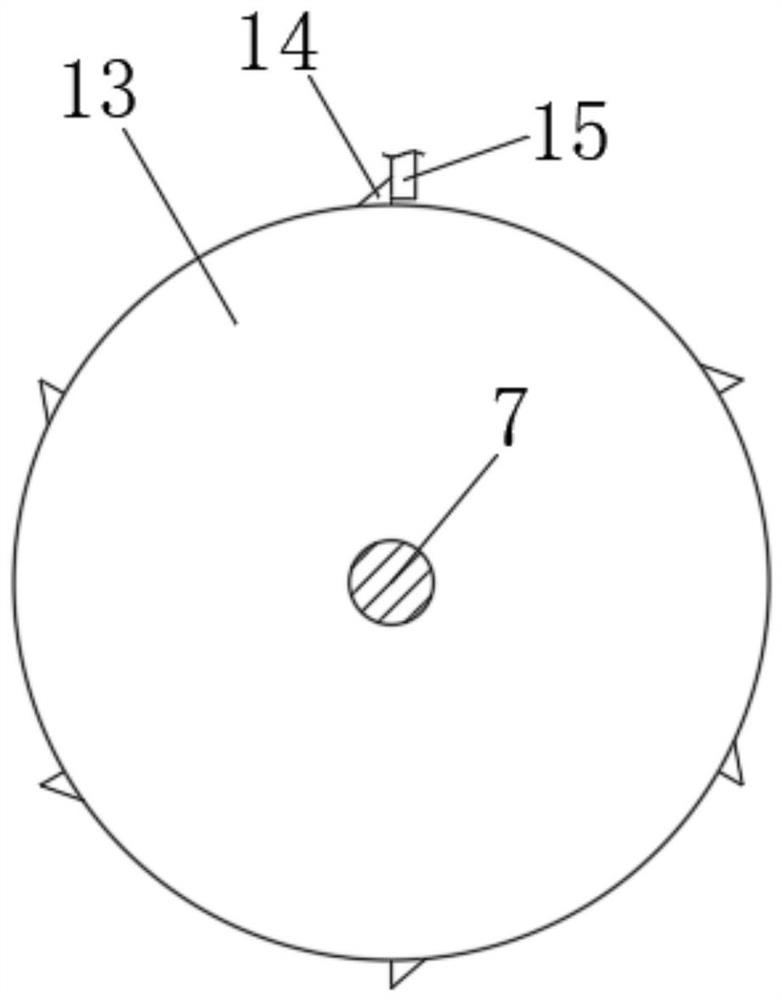

Semi-gear rack-meshed type drying device of X-ray medical image film

ActiveCN108089395AReasonable structureInnovative designDrying/glazing processed materialX-rayEngineering

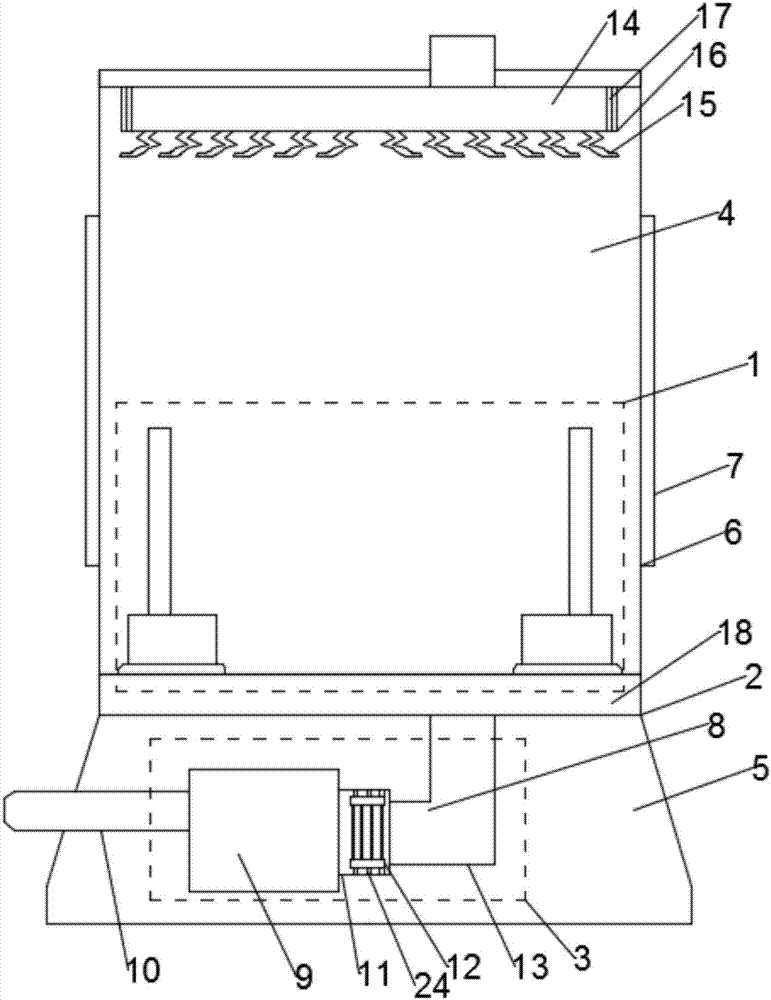

The invention discloses a semi-gear rack-meshed type drying device of an X-ray medical image film. The semi-gear rack-meshed type drying device comprises a pedestal; support frames are installed at the two sides of the upper end of the pedestal; a cross rack is installed on the tops of the support frames; and a fixed plate is installed in the middle of the upper end of the cross rack. A driven belt wheel is installed in the middle of the front end of the fixed plate; and a rotation post is installed at the front end of the driven belt wheel. A fixed post is installed in the middle of the crossrack; a swinging rack is hinged to the front end of the fixed post; and a swinging wheel is installed at the lower end of the swinging rack. Air bleeding cylinders are installed at the middle part ofthe support frames; pistons are installed inside the air bleeding cylinders; piston rods are installed between the pistons; a guide plates is installed between the piston rods; and sliding clamps areinstalled uniformly at the lower end of the guide plate. Dividing cavities are installed at the inner sides of the lower ends of the support frames; and gas ejector pipes are connected to the outer sides of the dividing cavities. Besides, a heating device is installed at the left of the upper end of the cross rack. According to the invention, an X-ray film can be shaken left and right and the airblowing effect on the X-ray film by the air bleeding cavity is realized; and the drying efficiency of the X-ray film after developing is increased.

Owner:江苏泰科医疗科技有限公司

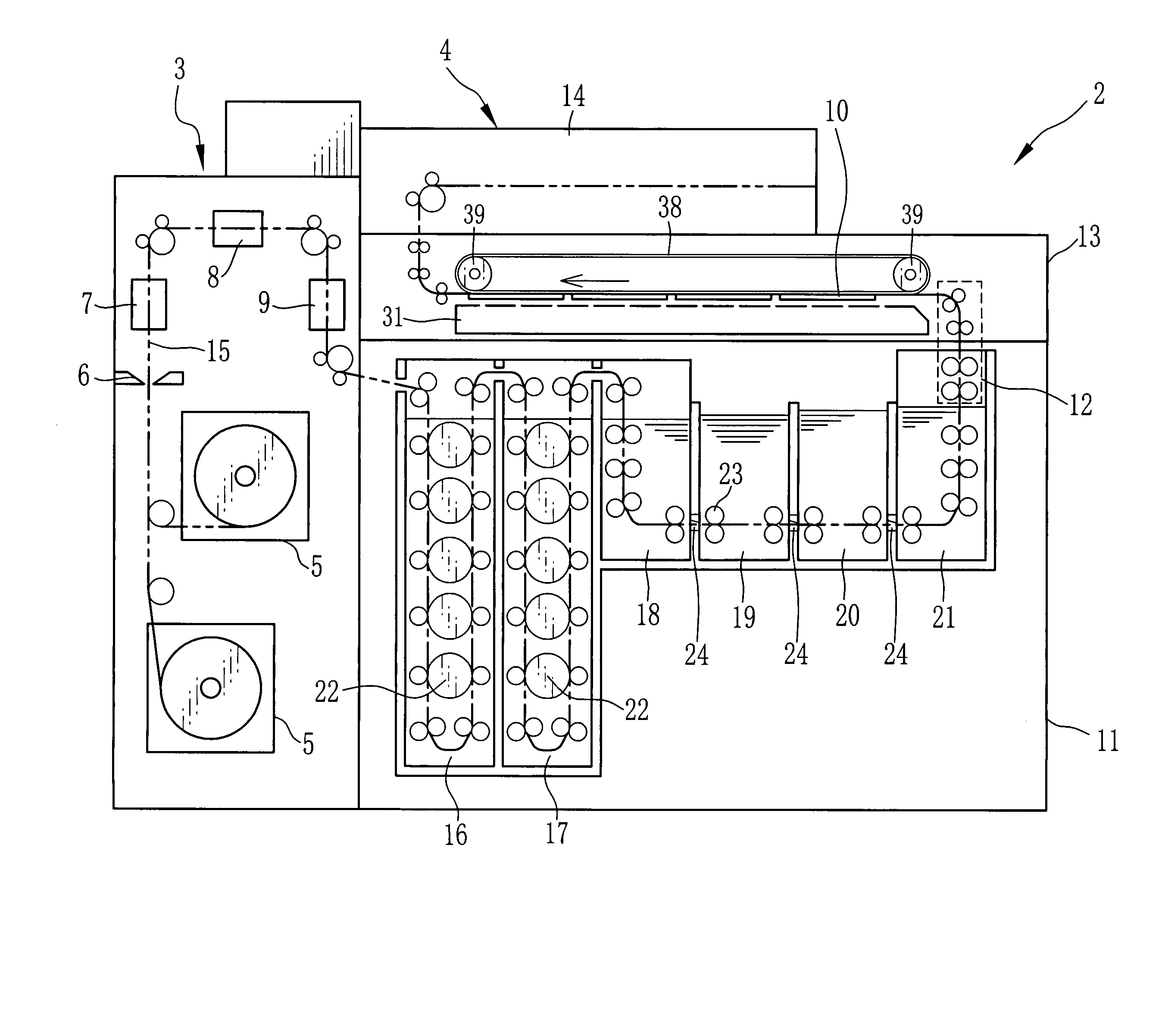

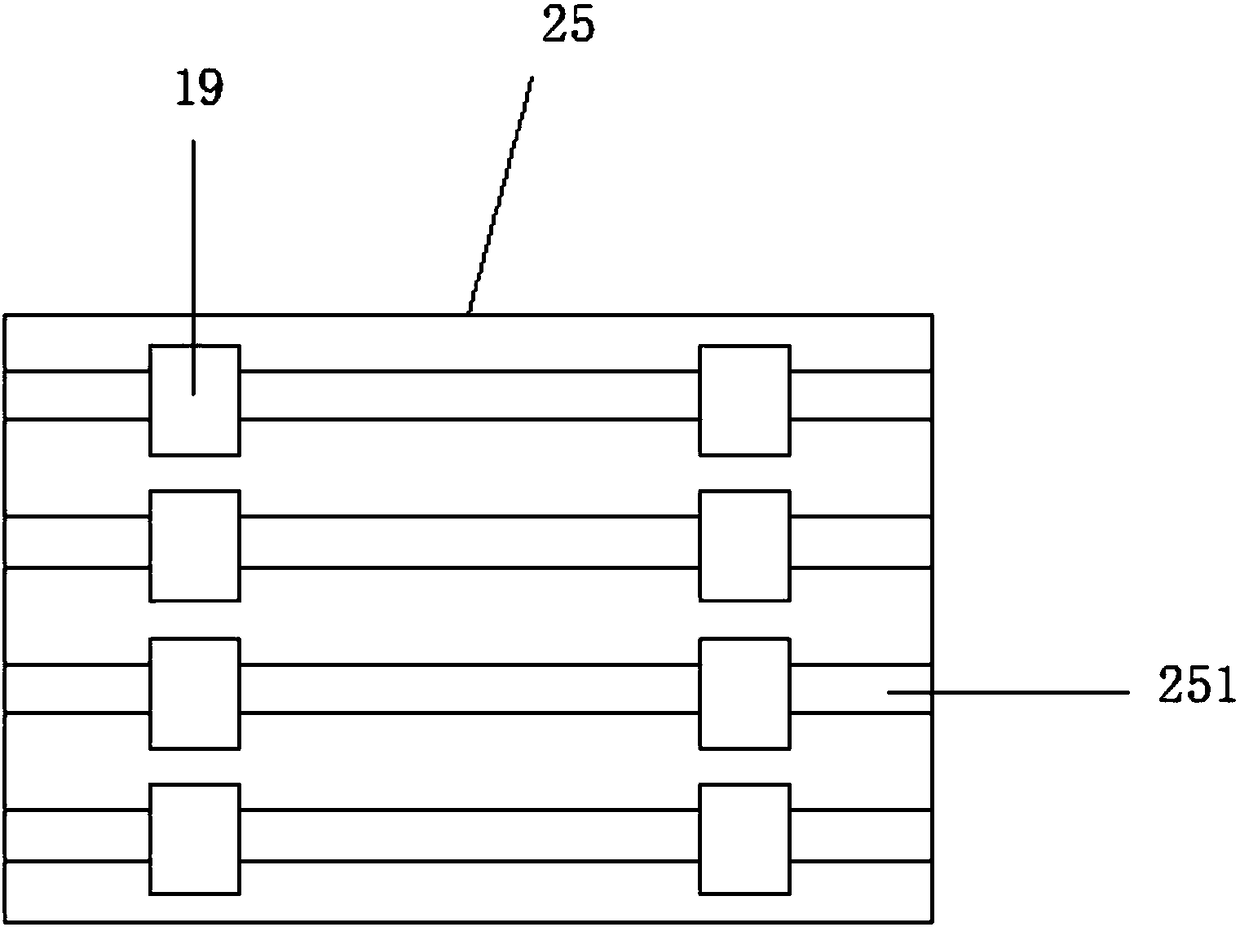

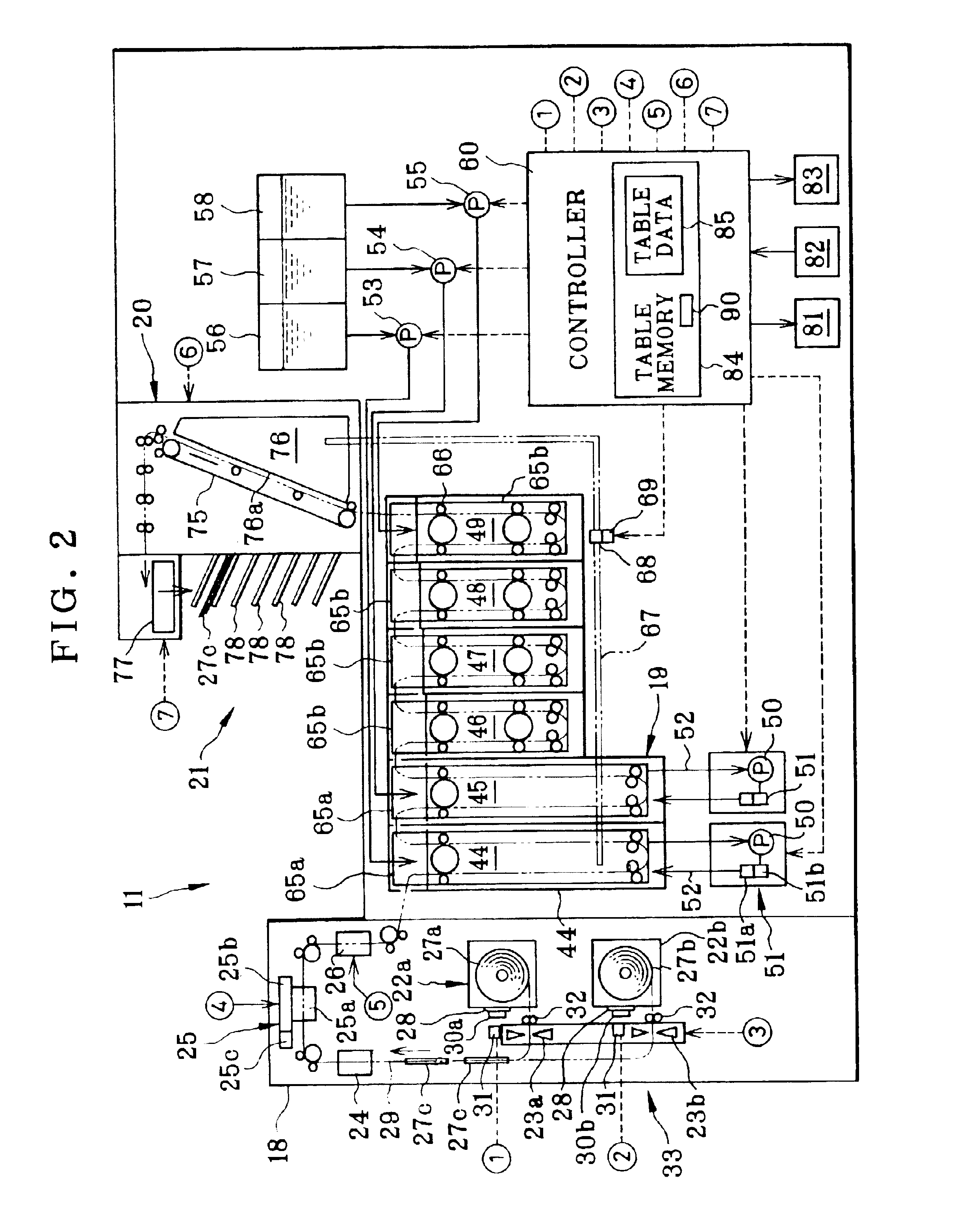

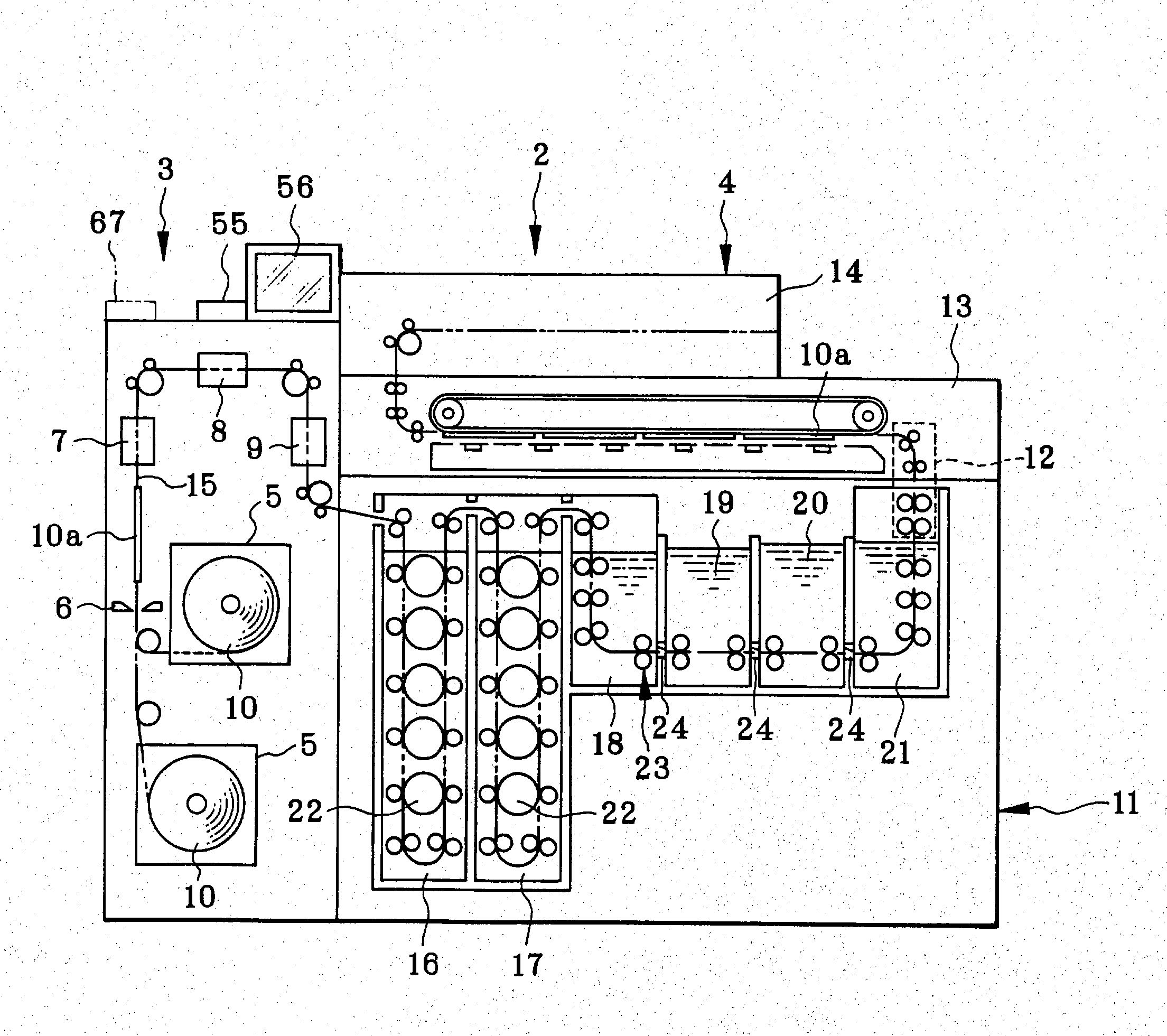

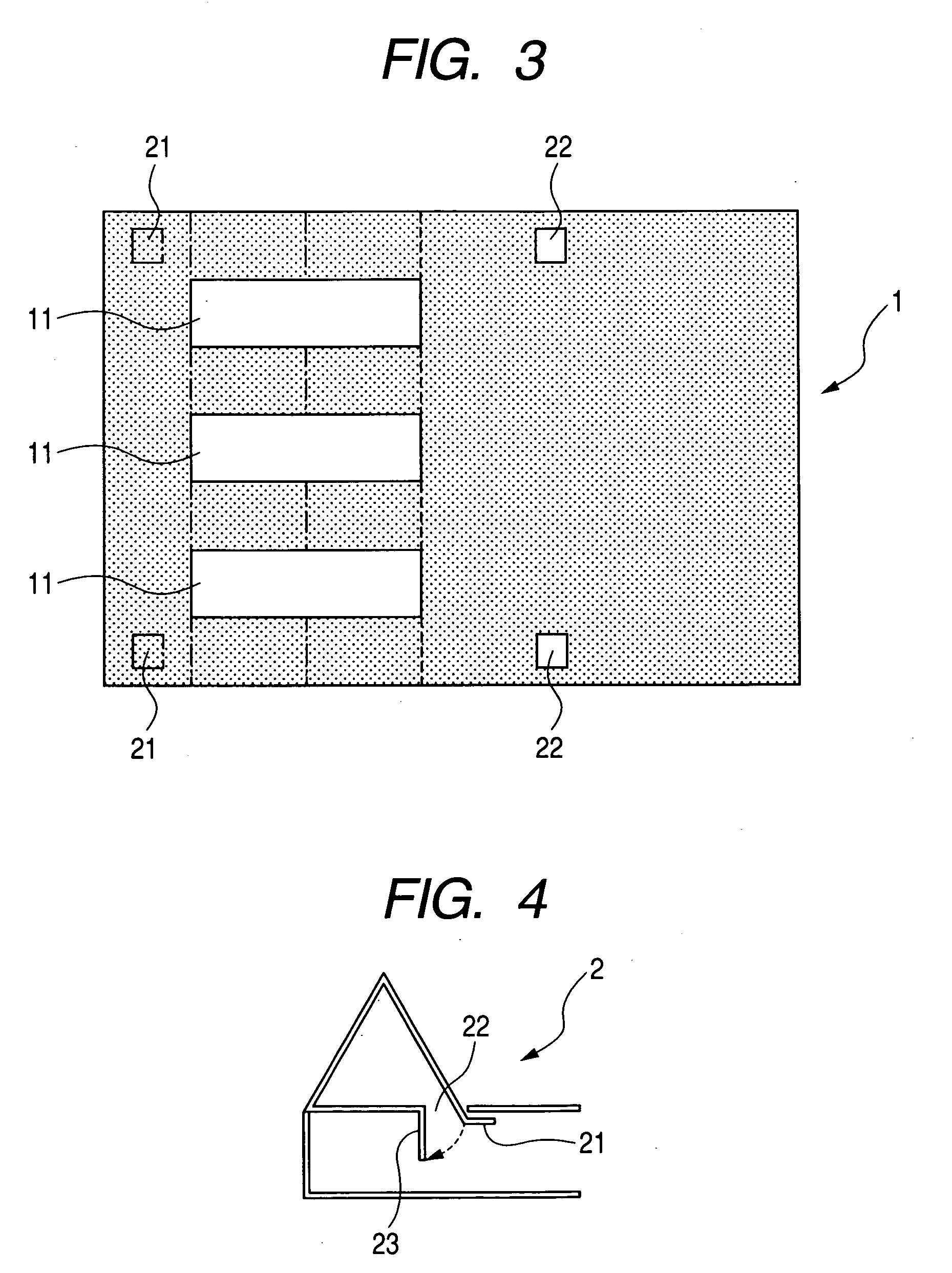

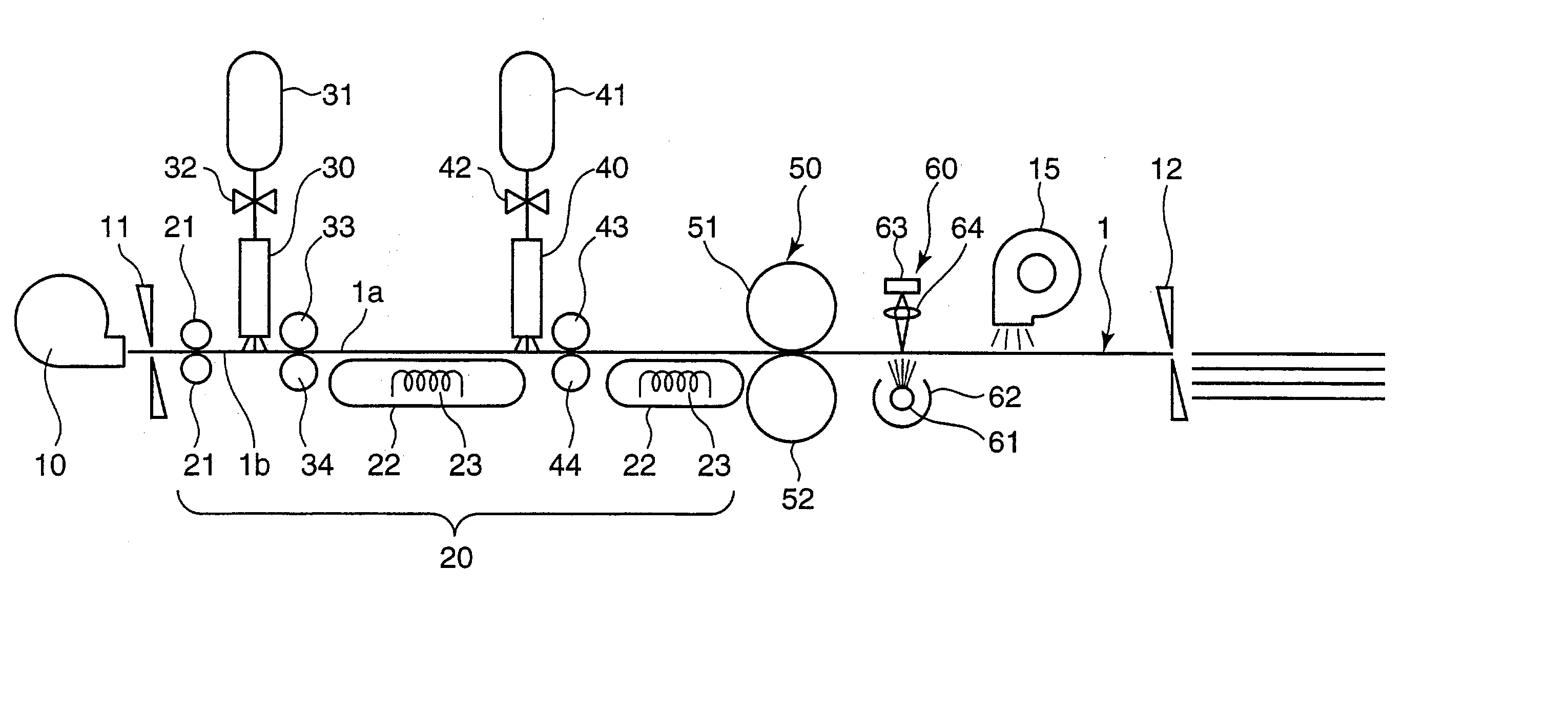

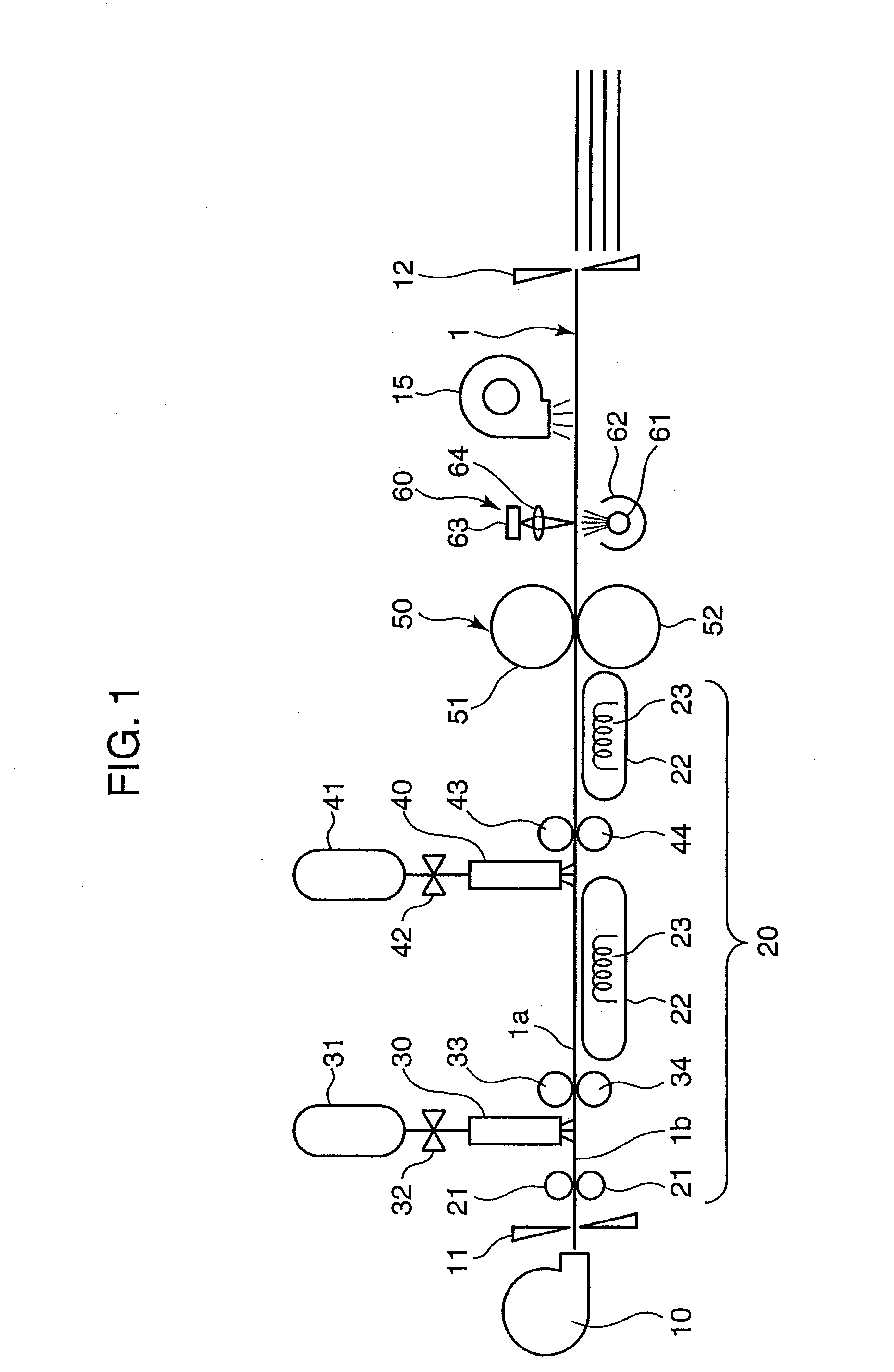

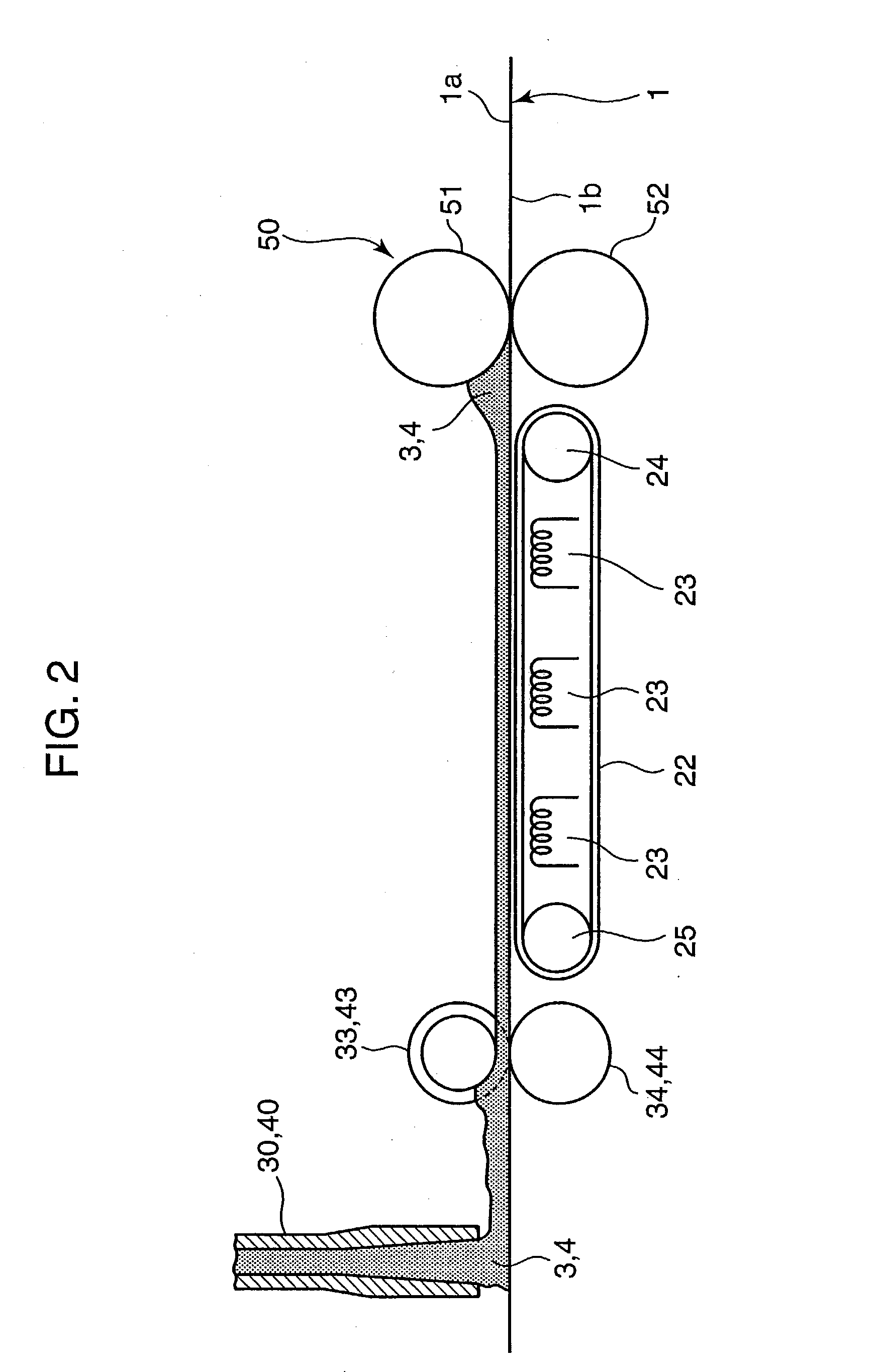

Drier device for photosensitive material

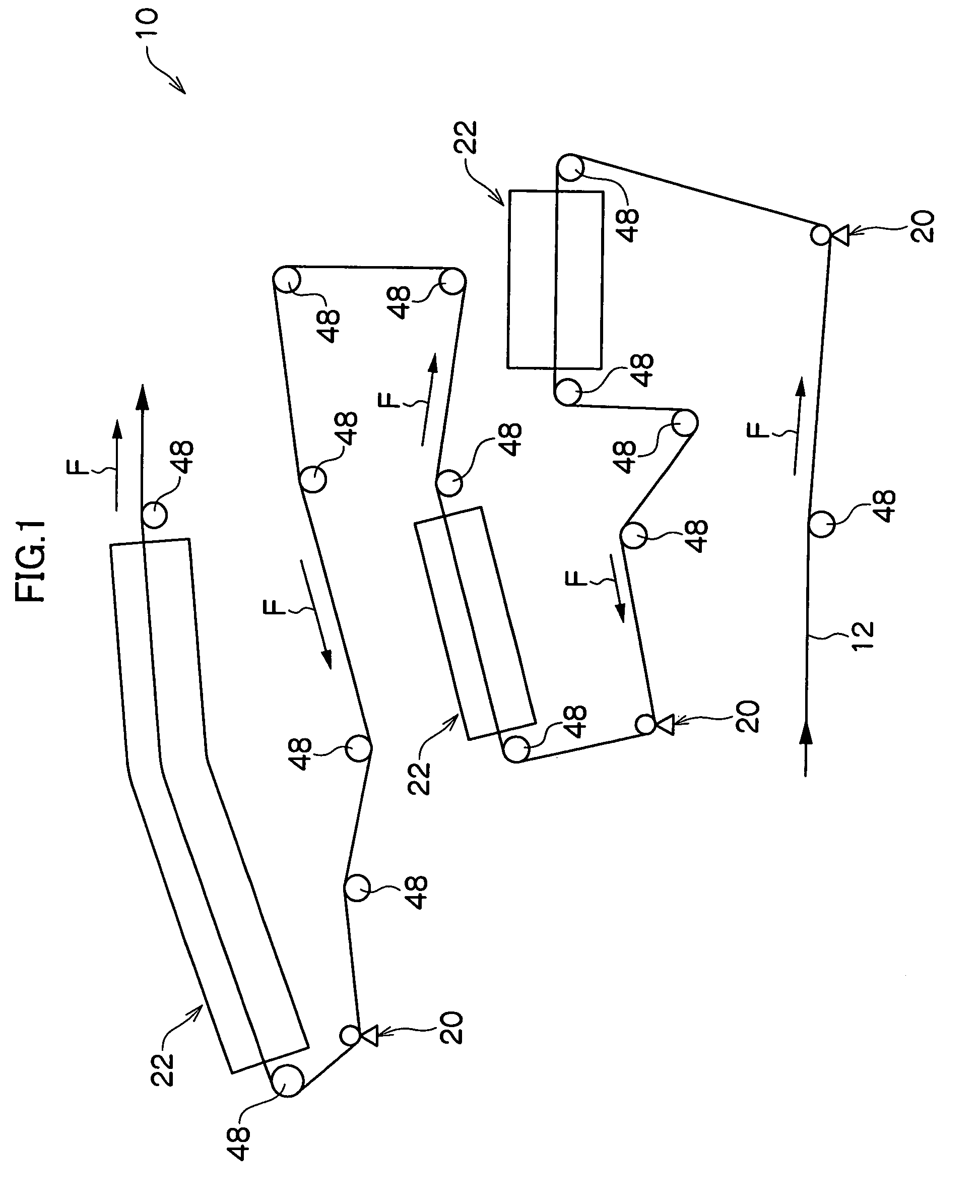

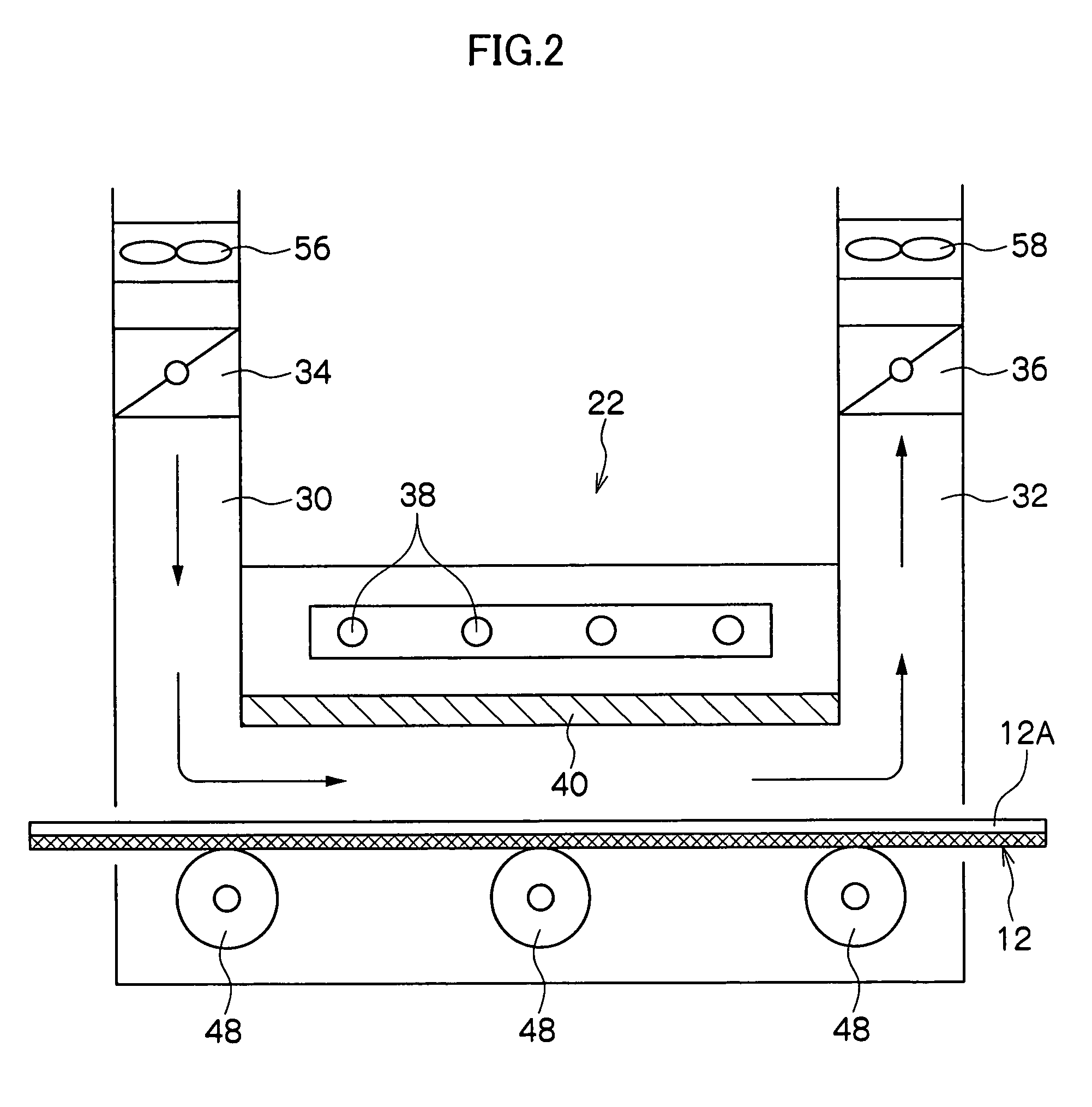

InactiveUS6183146B1Drying machines with progressive movementsDrying/glazing processed materialPhotographic paperAir blower

A photographic paper drier device includes a conveyor belt for conveying the photographic paper along a conveying path. A fan or blower dries the photographic paper by application of air thereto while the photographic paper is conveyed along the conveying path. The fan or blower sends the air into an air blow case, which has an air blow wall extending along the conveying path, and being positioned opposite to the photographic paper. Plural outlet slits are formed through the air blow wall, and blow the photographic paper with the air. Each of the outlet slits extends in a crosswise direction crosswise to the conveying path. The outlet slits are arranged in 18 trains arranged along the conveying path. Each of the outlet slits has a length smaller than a width of the photographic paper.

Owner:FUJIFILM CORP +1

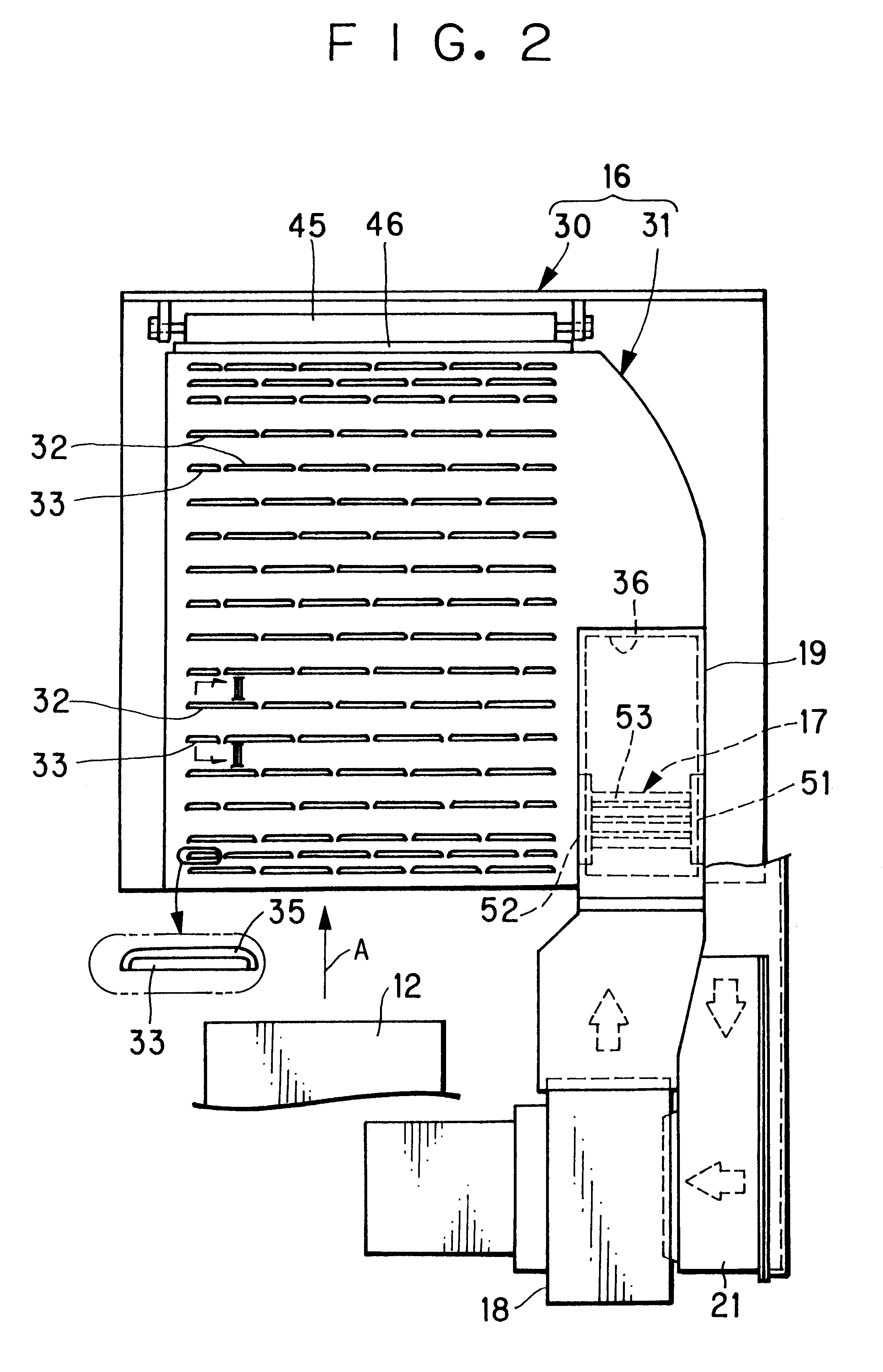

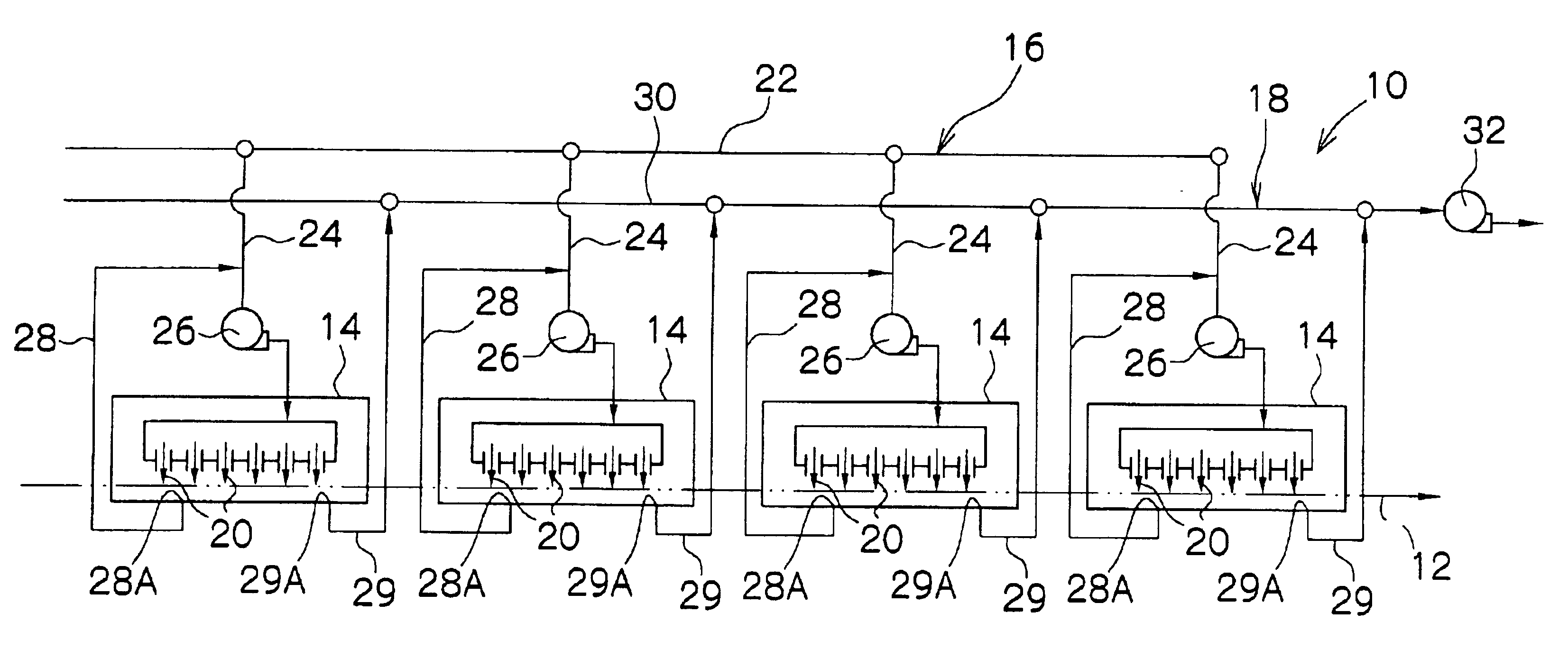

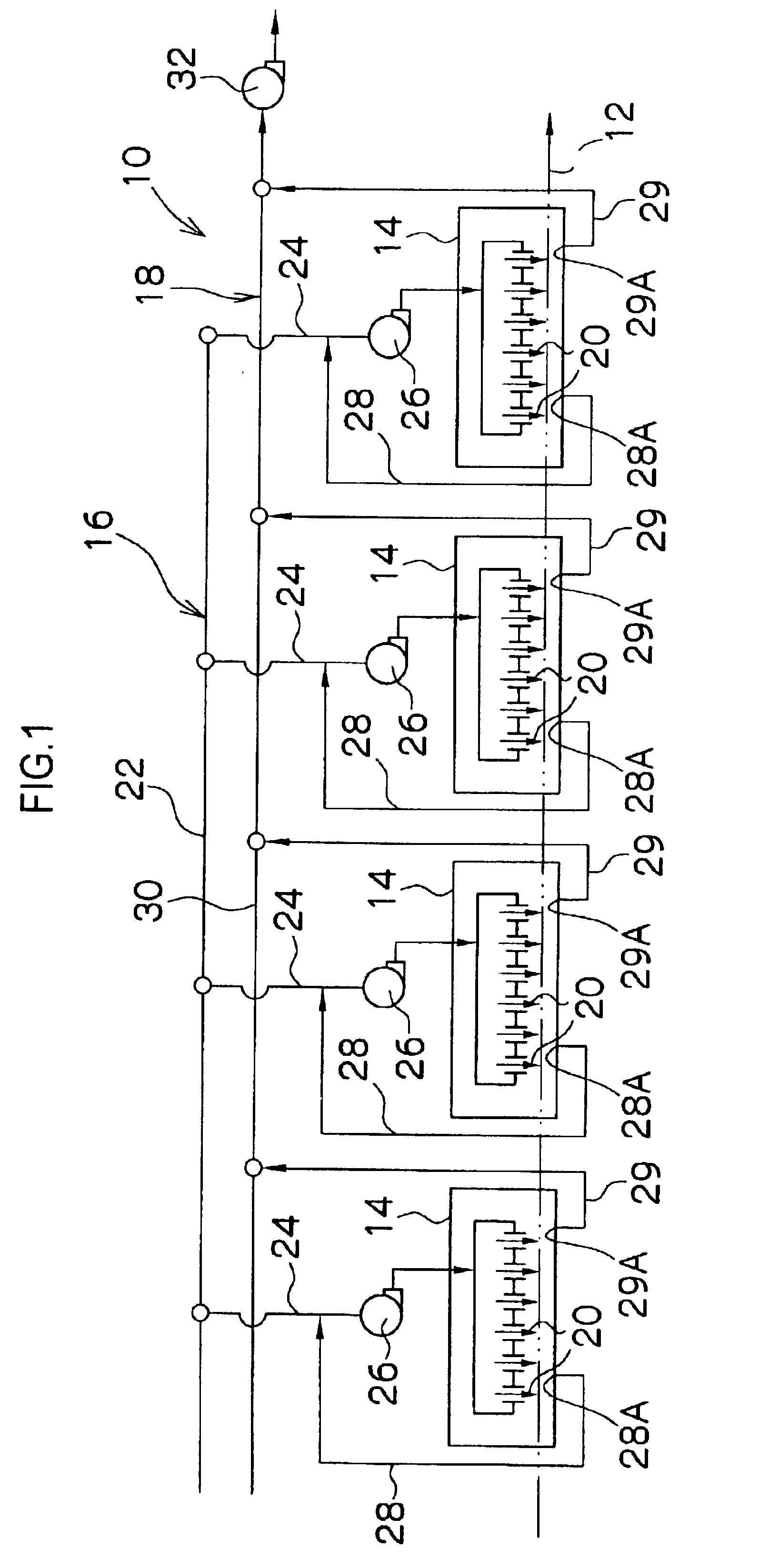

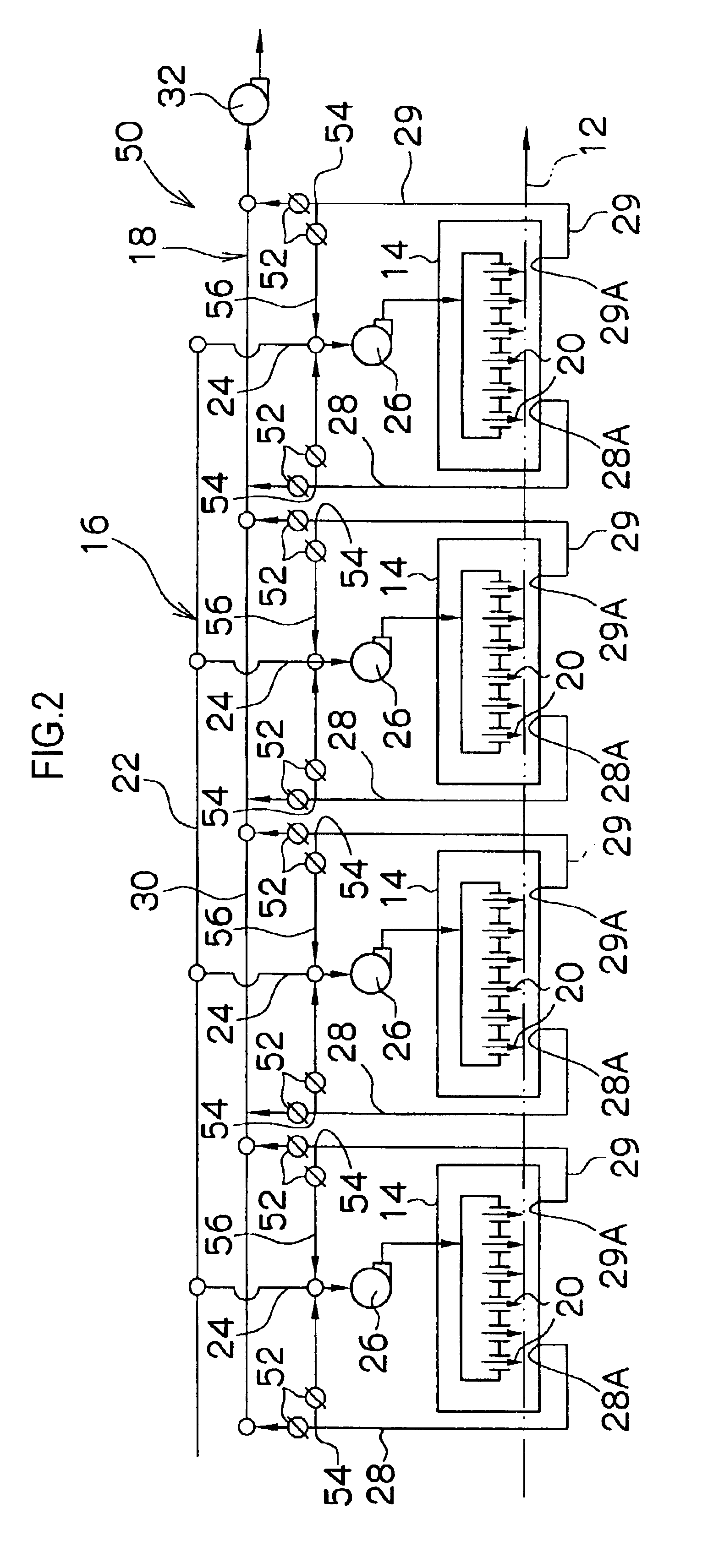

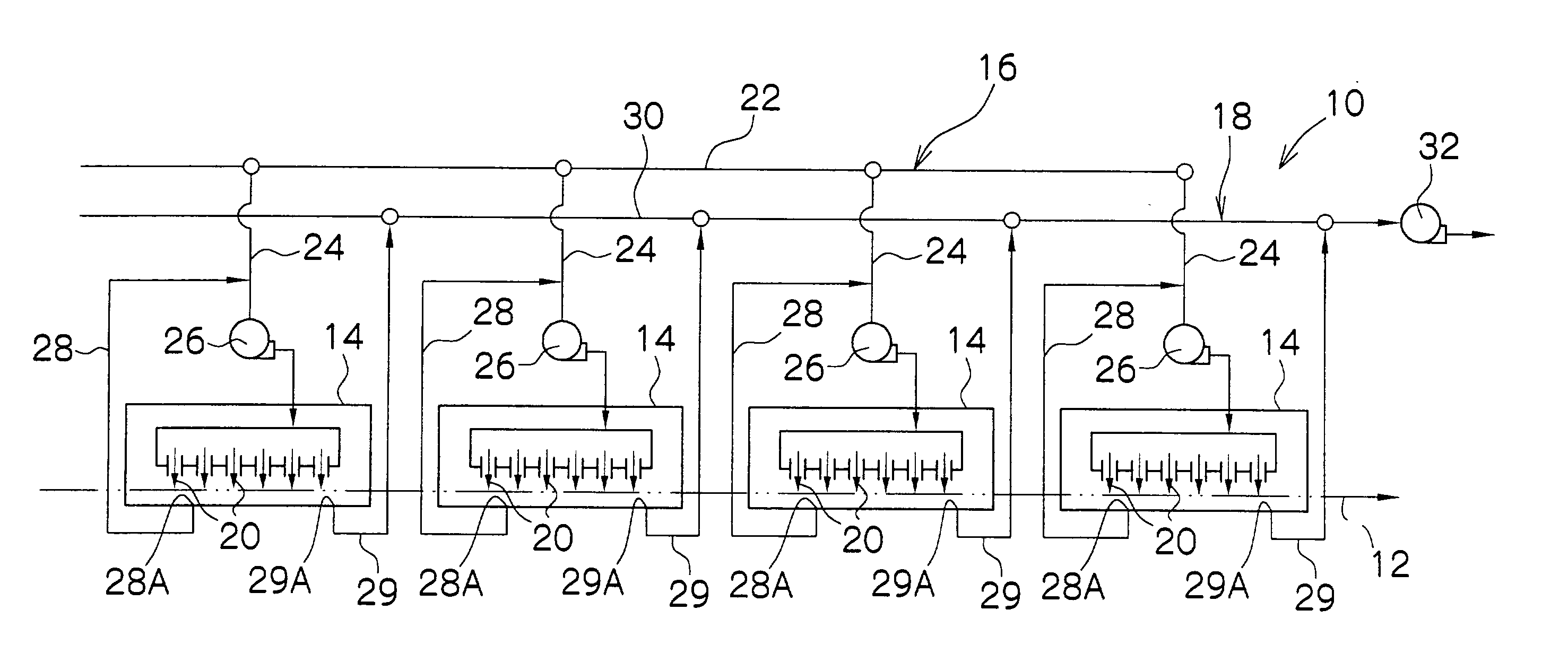

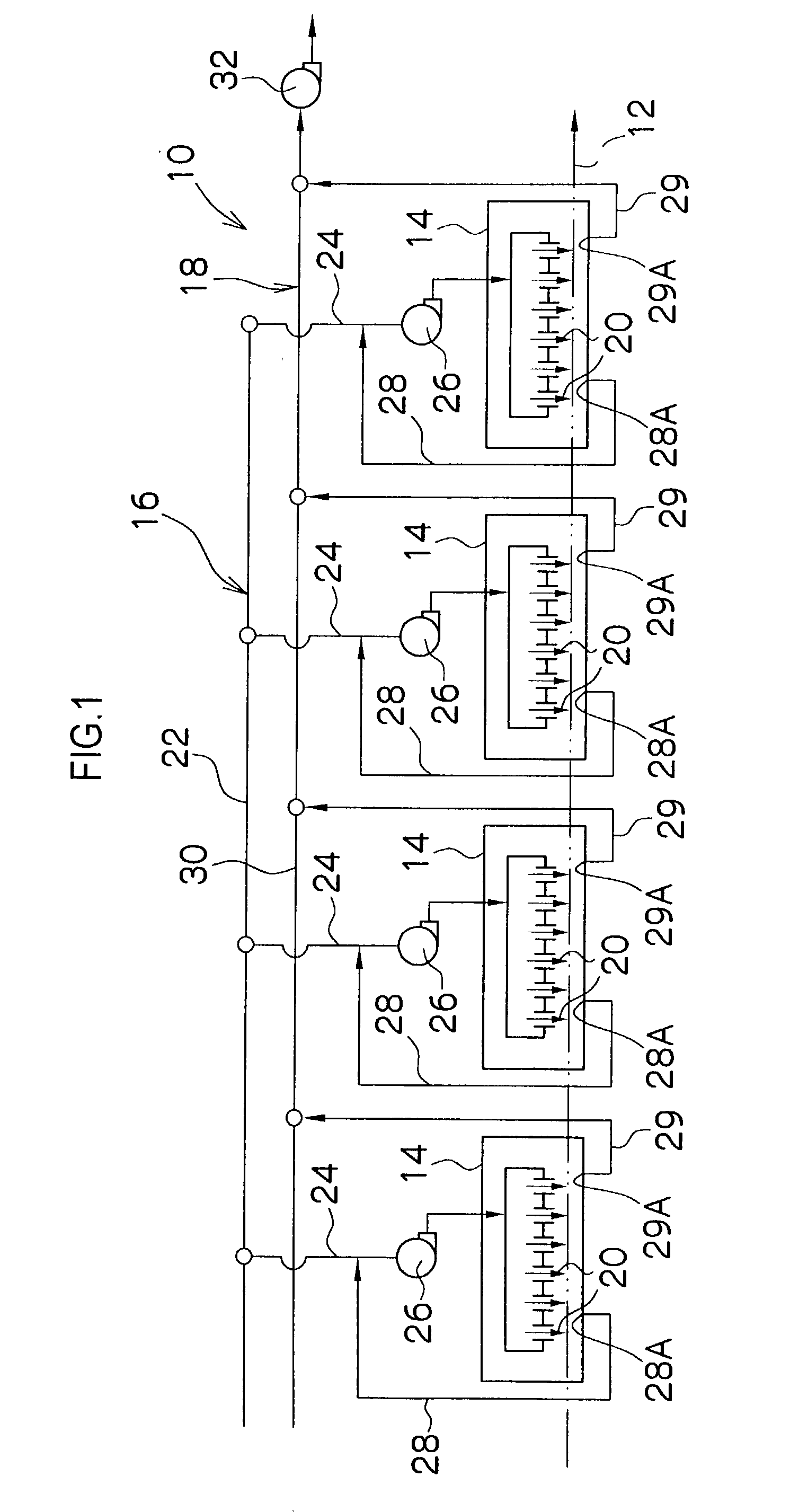

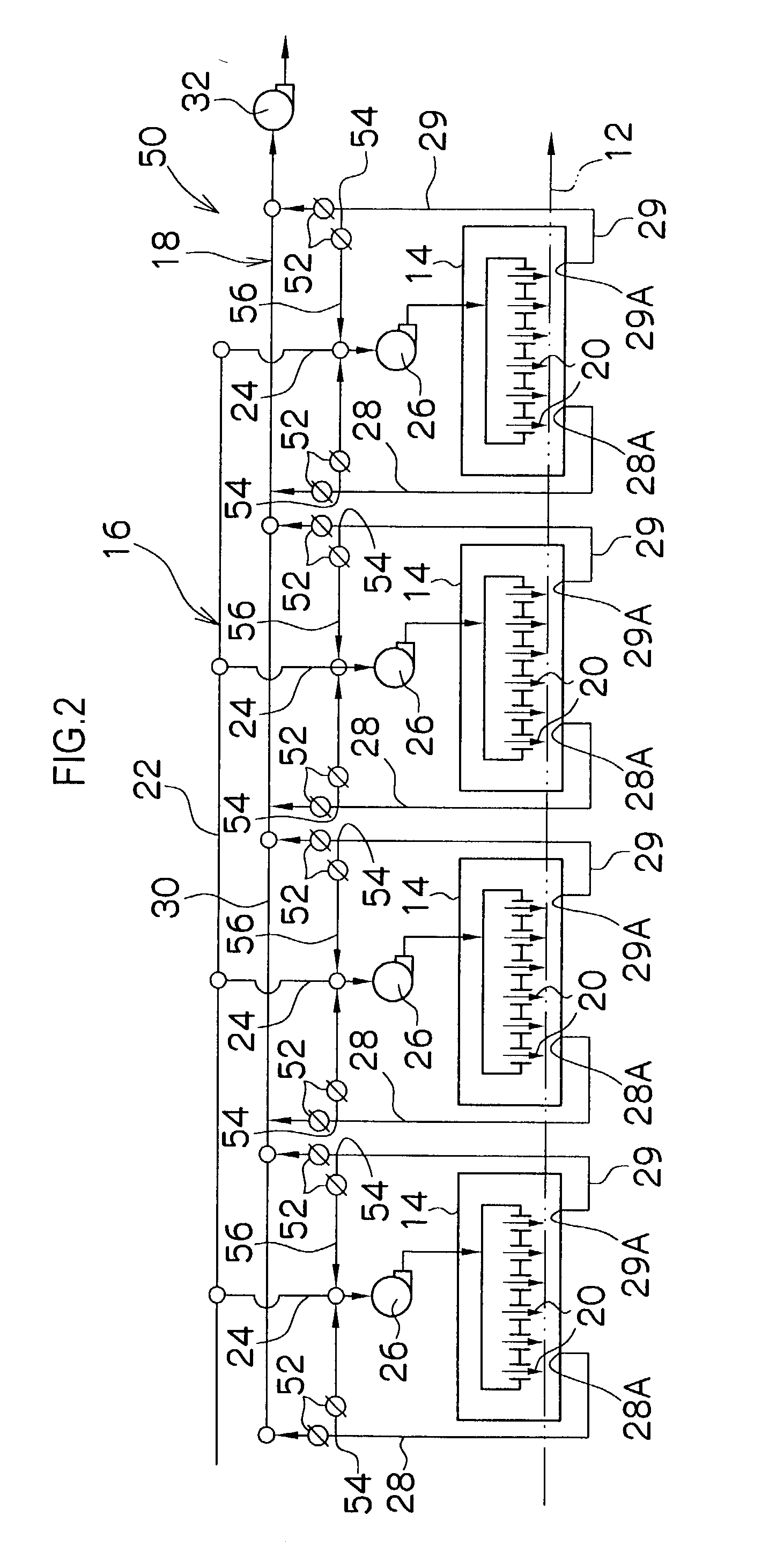

Drying apparatus

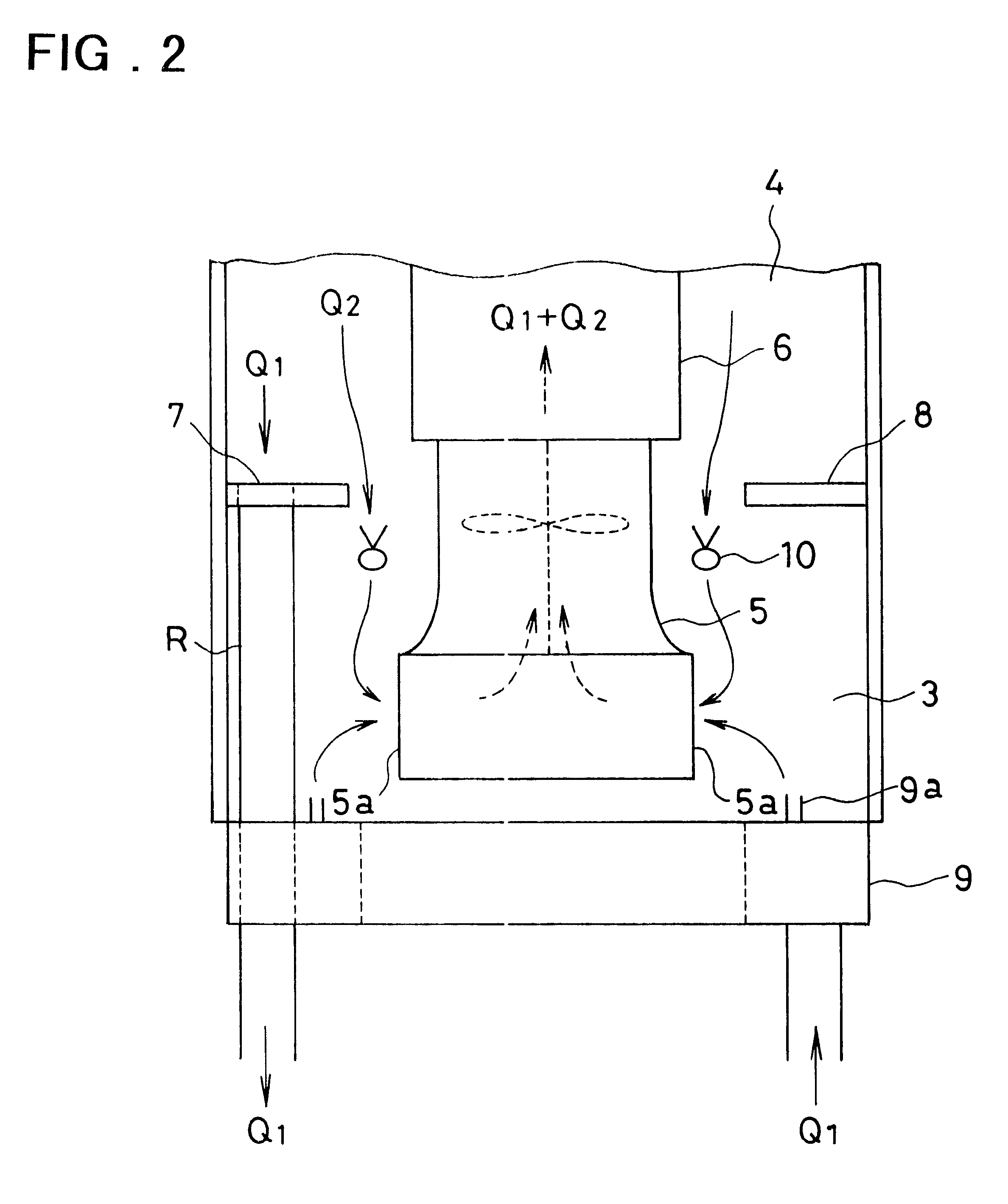

InactiveUS6735882B2Explosion proofing safetySimple configurationDrying gas arrangementsDrying chambers/containersExhaust fumesProduct gas

A concentration of a gas introduced into a circulation blower and an exhaust blower is reduced with a simple apparatus configuration. In an exhaust system, exhaust gases from a plurality of drying chambers are joined to a joining duct to be then exhausted by an exhaust blower. A plurality of exhaust ducts having inlets at different positions in each drying chamber are provided, and the exhaust duct having the inlet in the lowest gas concentration area is used as a duct for an exhaust gas circulated to a circulation blower.

Owner:FUJIFILM CORP +1

Drying apparatus

InactiveUS20030079372A1Explosion proofing safetySimple configurationDrying gas arrangementsDrying chambers/containersExhaust fumesGas concentration

A concentration of a gas introduced into a circulation blower and an exhaust blower is reduced with a simple apparatus configuration. In an exhaust system, exhaust gases from a plurality of drying chambers are joined to a joining duct to be then exhausted by an exhaust blower. A plurality of exhaust ducts having inlets at different positions in each drying chamber are provided, and the exhaust duct having the inlet in the lowest gas concentration area is used as a duct for an exhaust gas circulated to a circulation blower.

Owner:FUJIFILM CORP +1

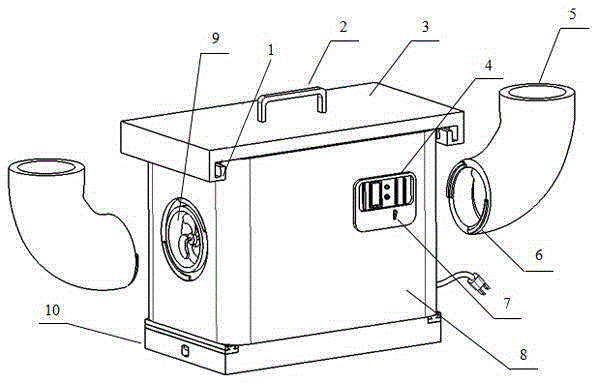

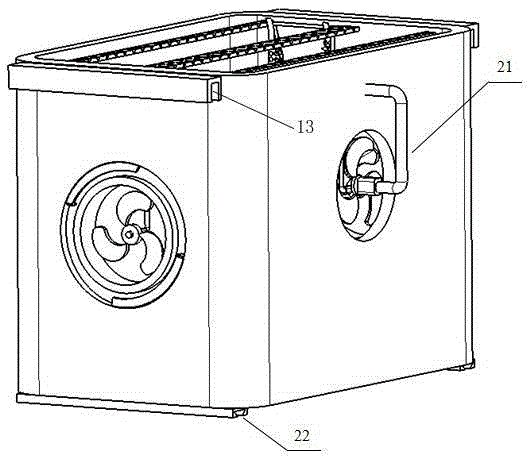

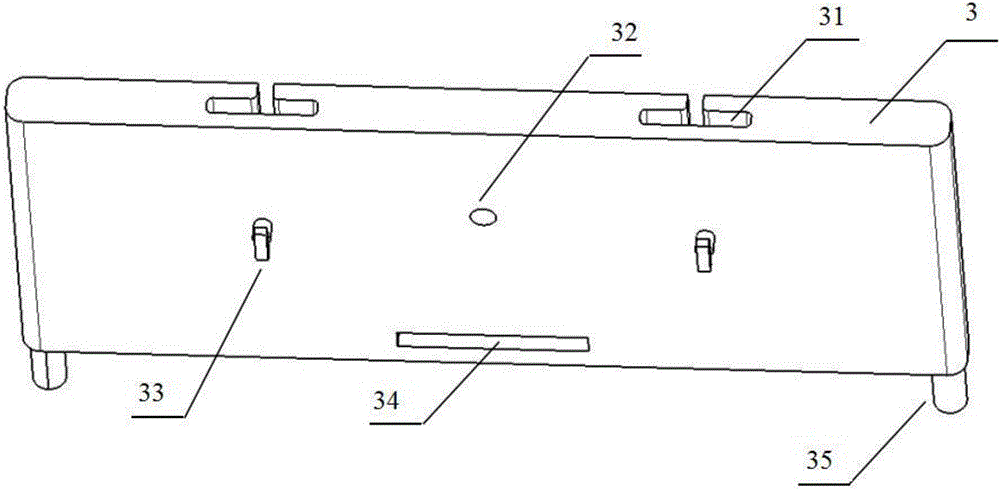

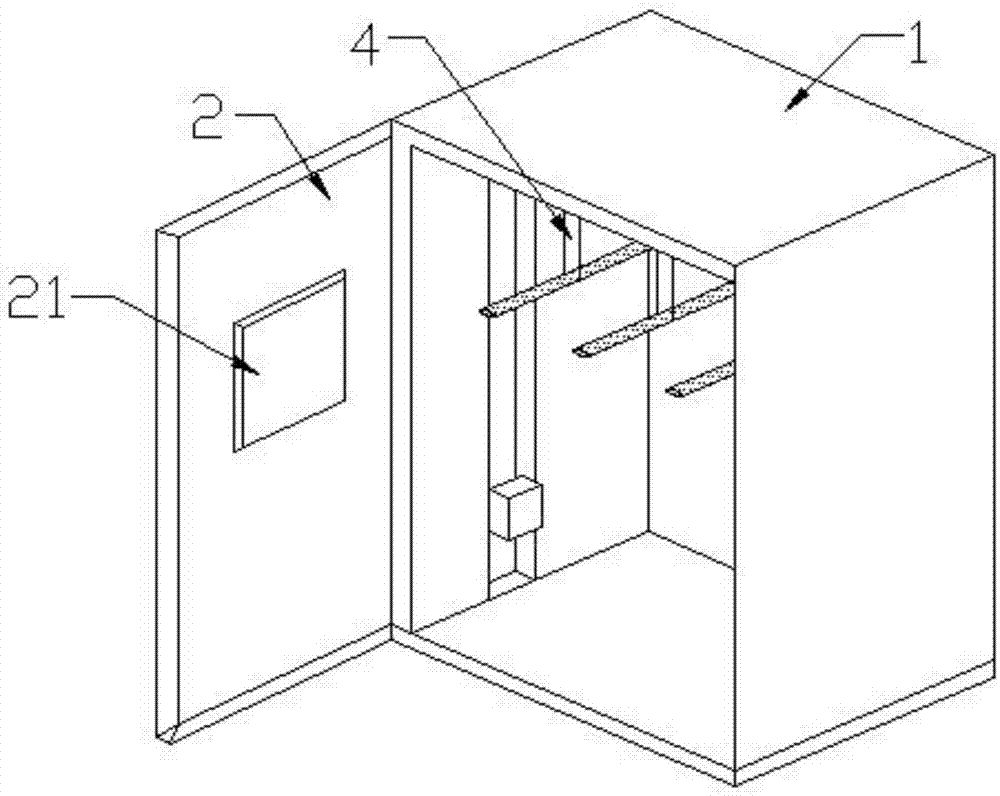

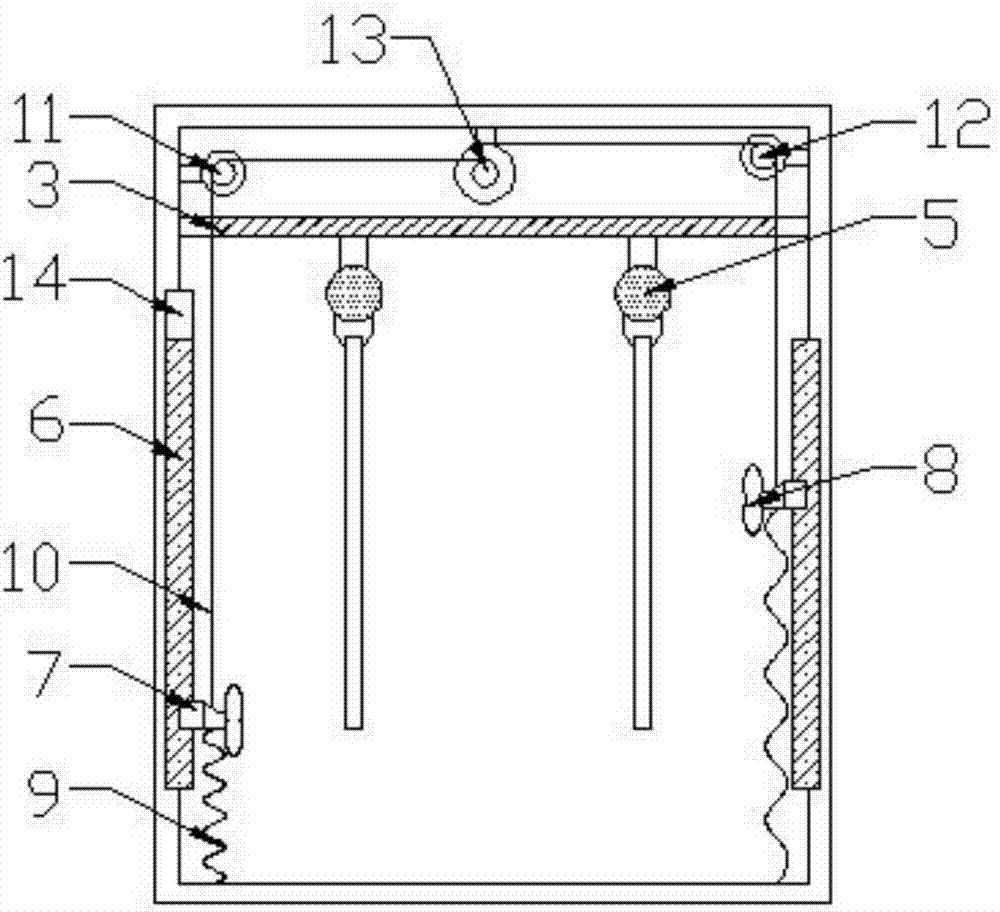

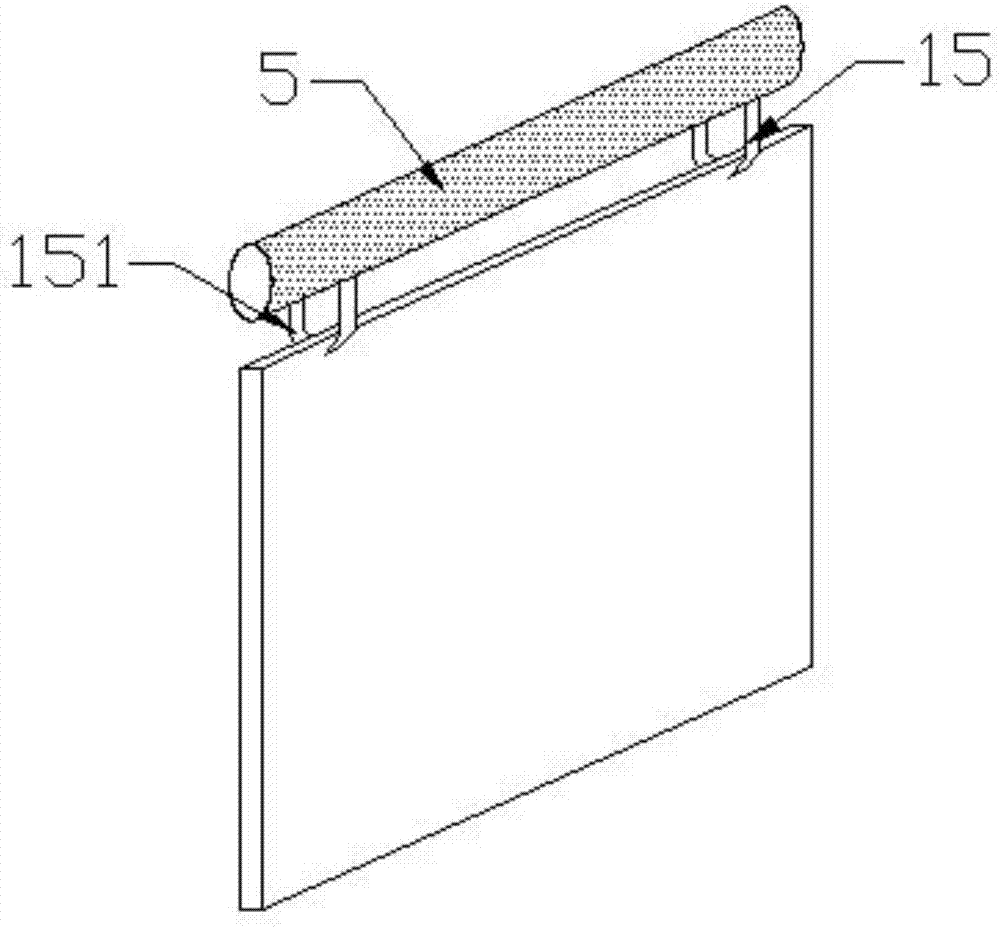

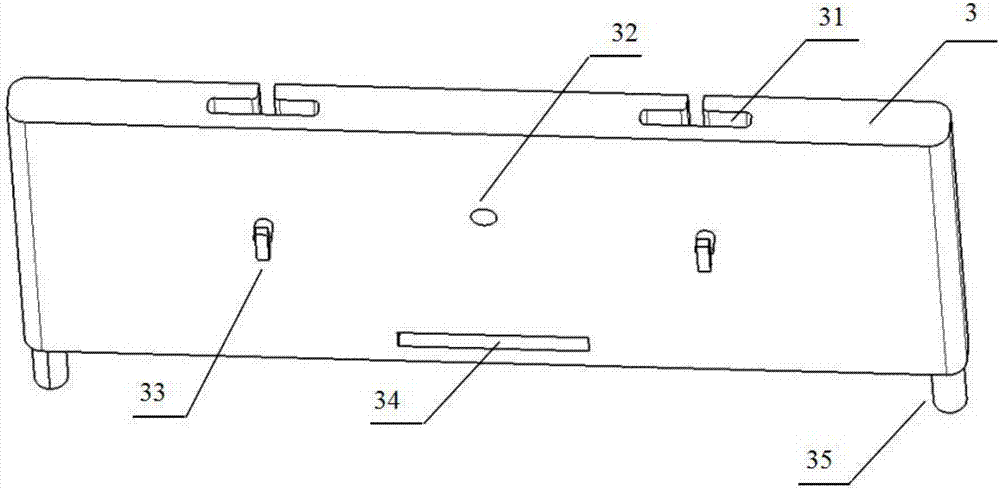

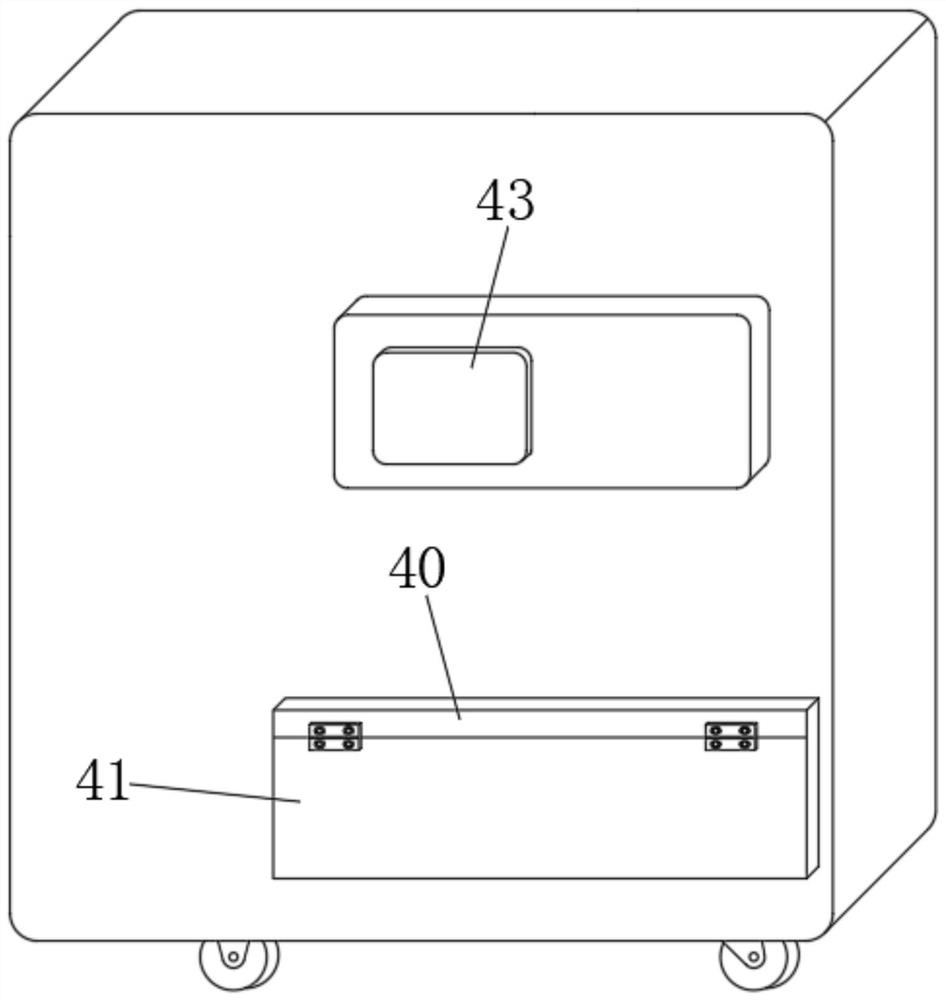

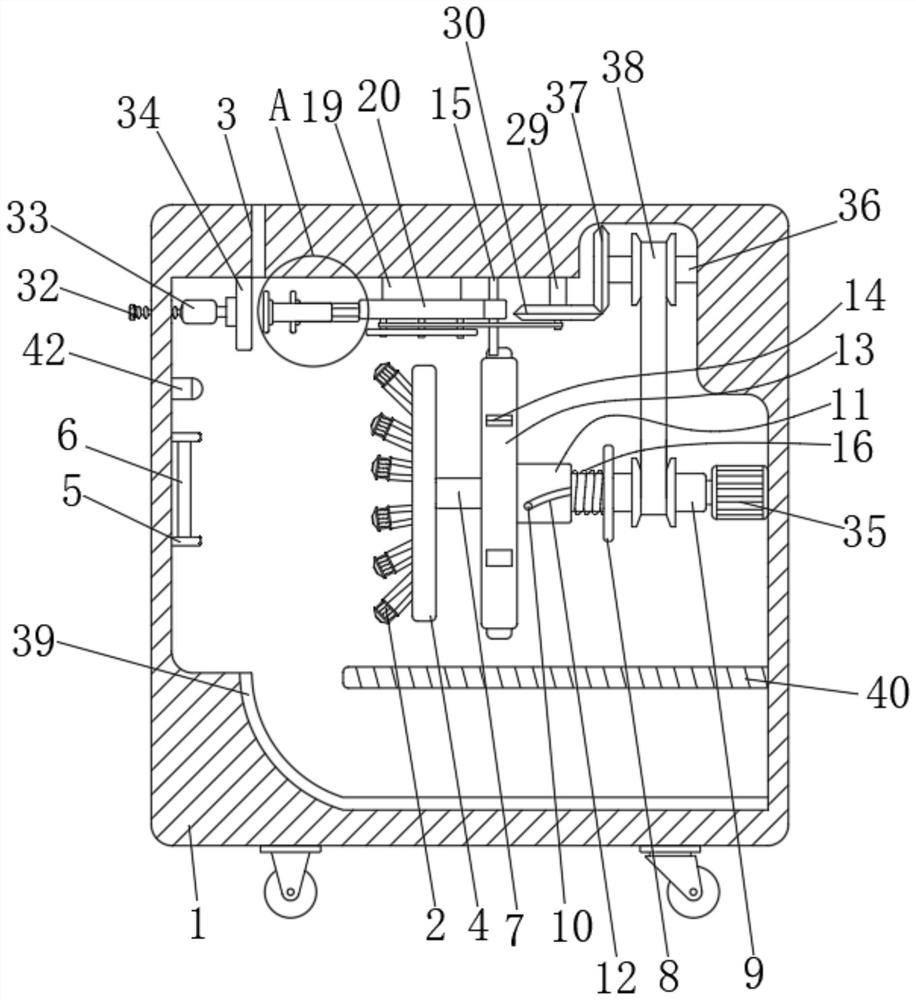

Portable air cooling film drying apparatus

InactiveCN105425531AEasy to assemble and disassembleEasy to carryDrying/glazing processed materialWastewaterRejection rate

The present invention discloses a portable air cooling film drying apparatus. The drying apparatus comprises: a drying oven housing, wherein both the upper and lower ends of the drying oven housing are of an open shape; a bracket structure for placing a film cartridge is arranged in the drying oven housing; at least one air blowing apparatus and at least one air suction apparatus are arranged on the drying oven housing; a drying oven cover, which is detachably mounted on an upper opening of the drying oven housing; and a wastewater containing apparatus, which is detachably mounted on a lower opening of the drying oven housing. The film cartridge filled with films is put on the bracket structure inside the drying oven housing; and the air blowing apparatus is used for blowing the outside air into the drying oven housing, and the air suction apparatus is used for sucking out the air inside the drying oven housing. The portable air cooling film drying apparatus provided by the present invention is convenient to use, simple in operation method, and easy to carry, so that working efficiency is improved, a rejection rate of the films is reduced, and the portable air cooling film drying apparatus has a certain environment protection function.

Owner:SHANGHAI INST OF TECH

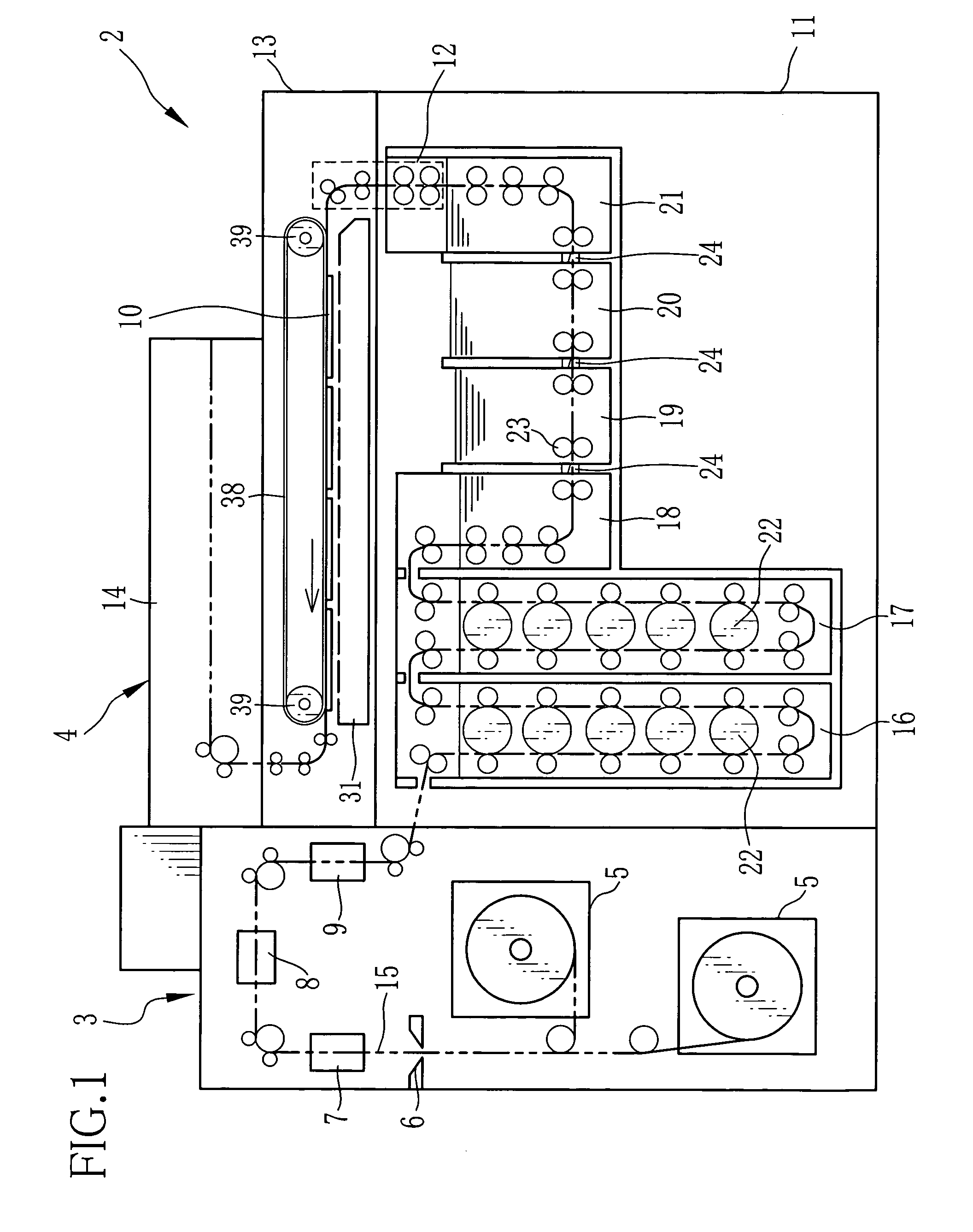

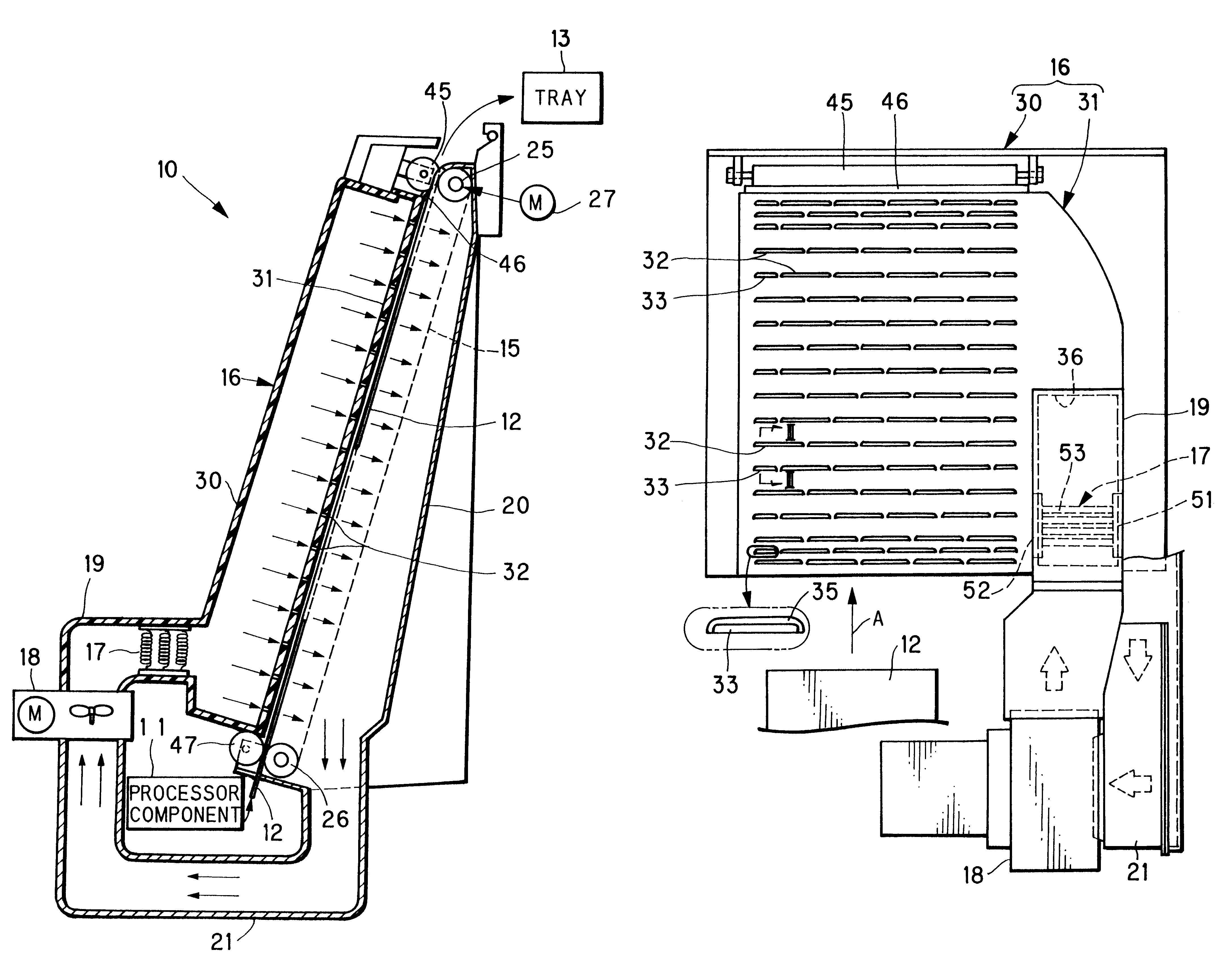

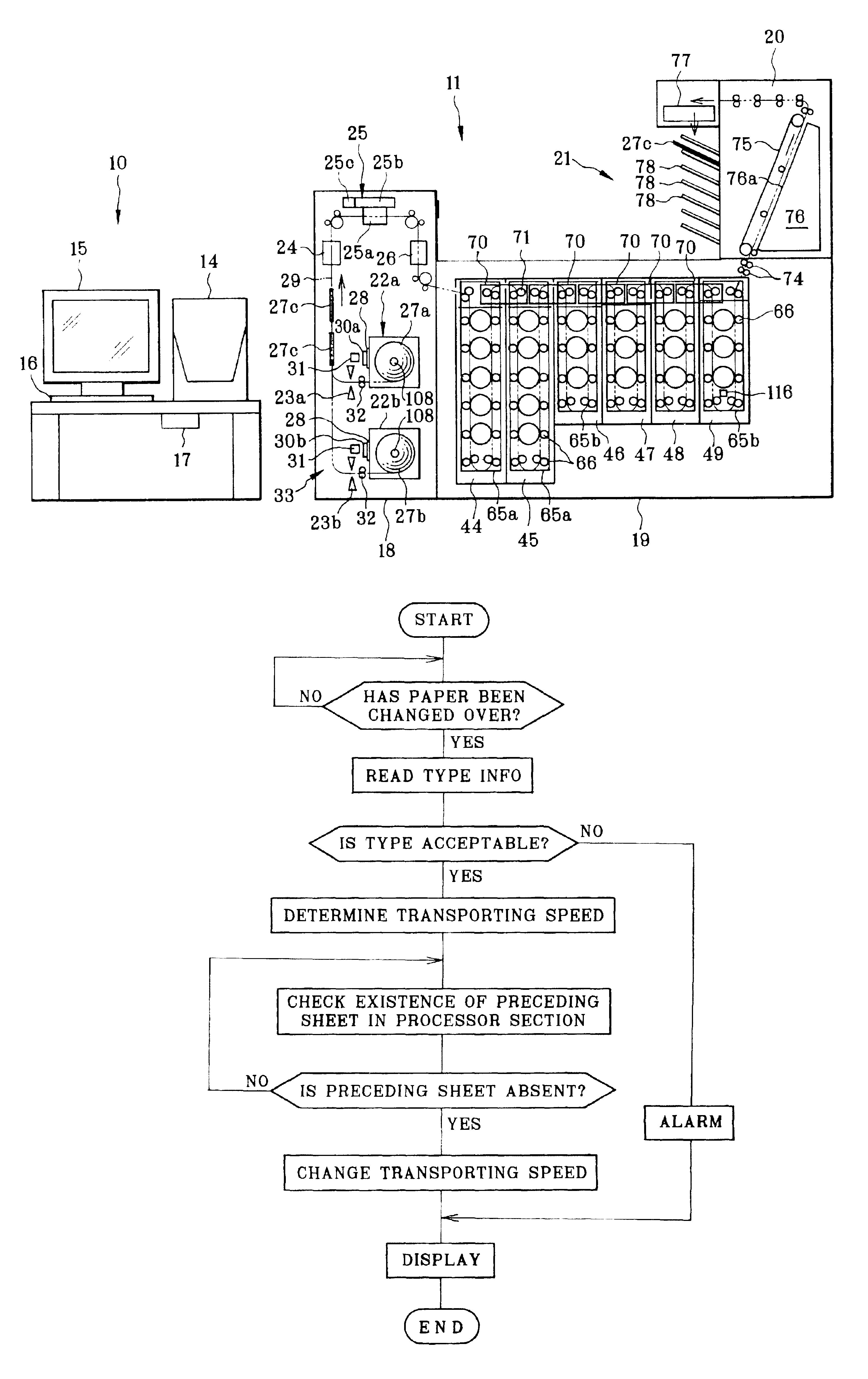

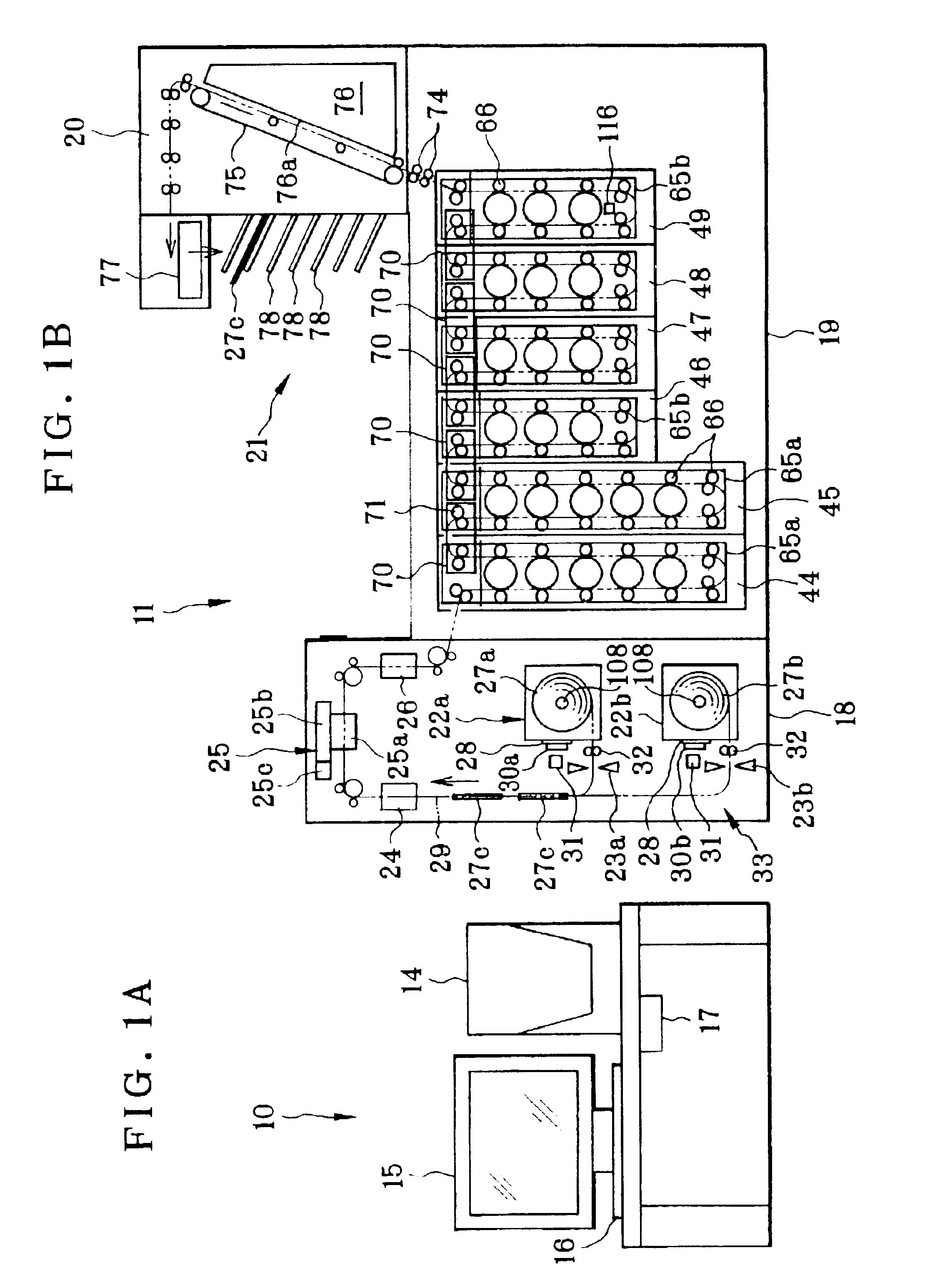

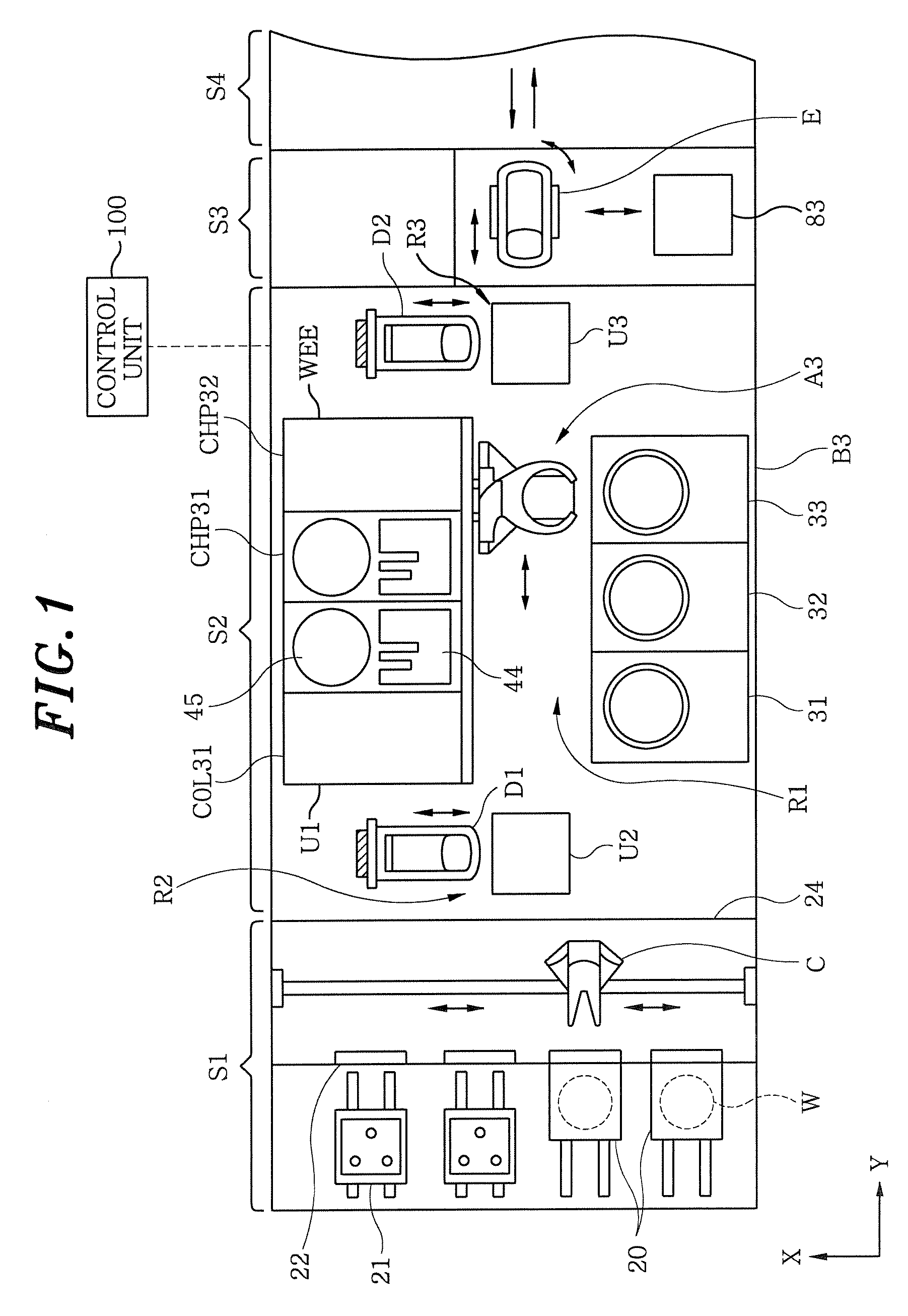

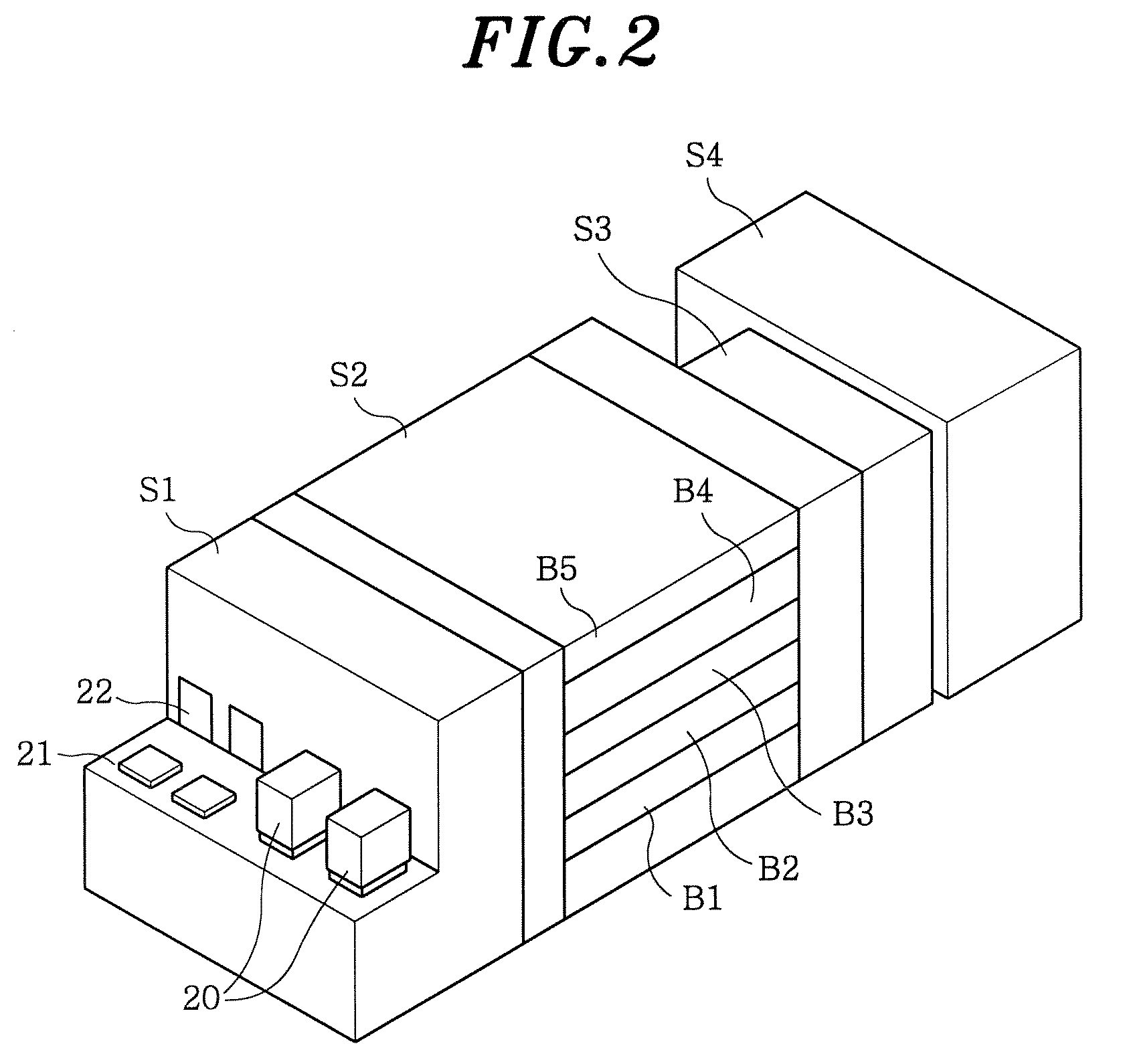

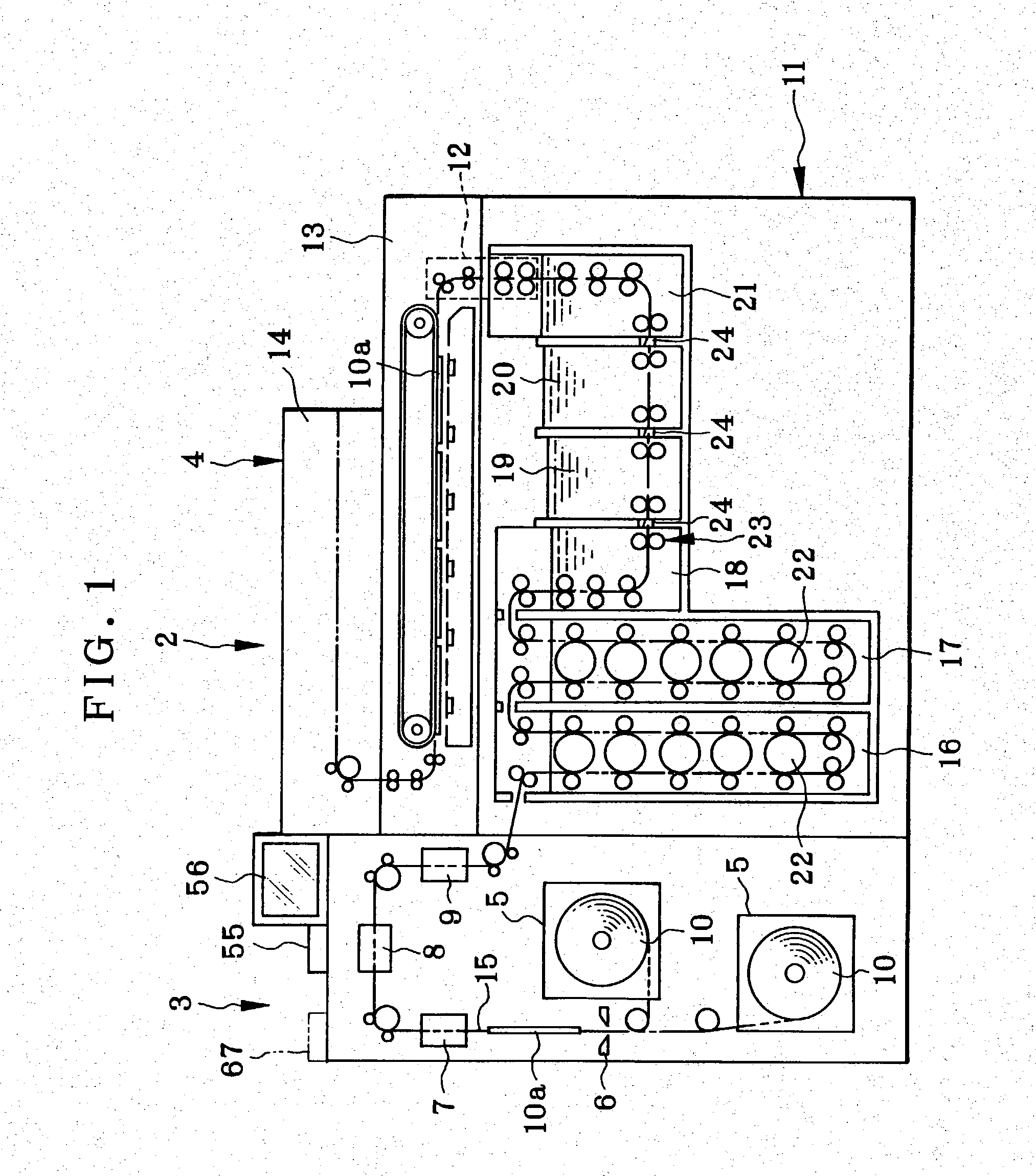

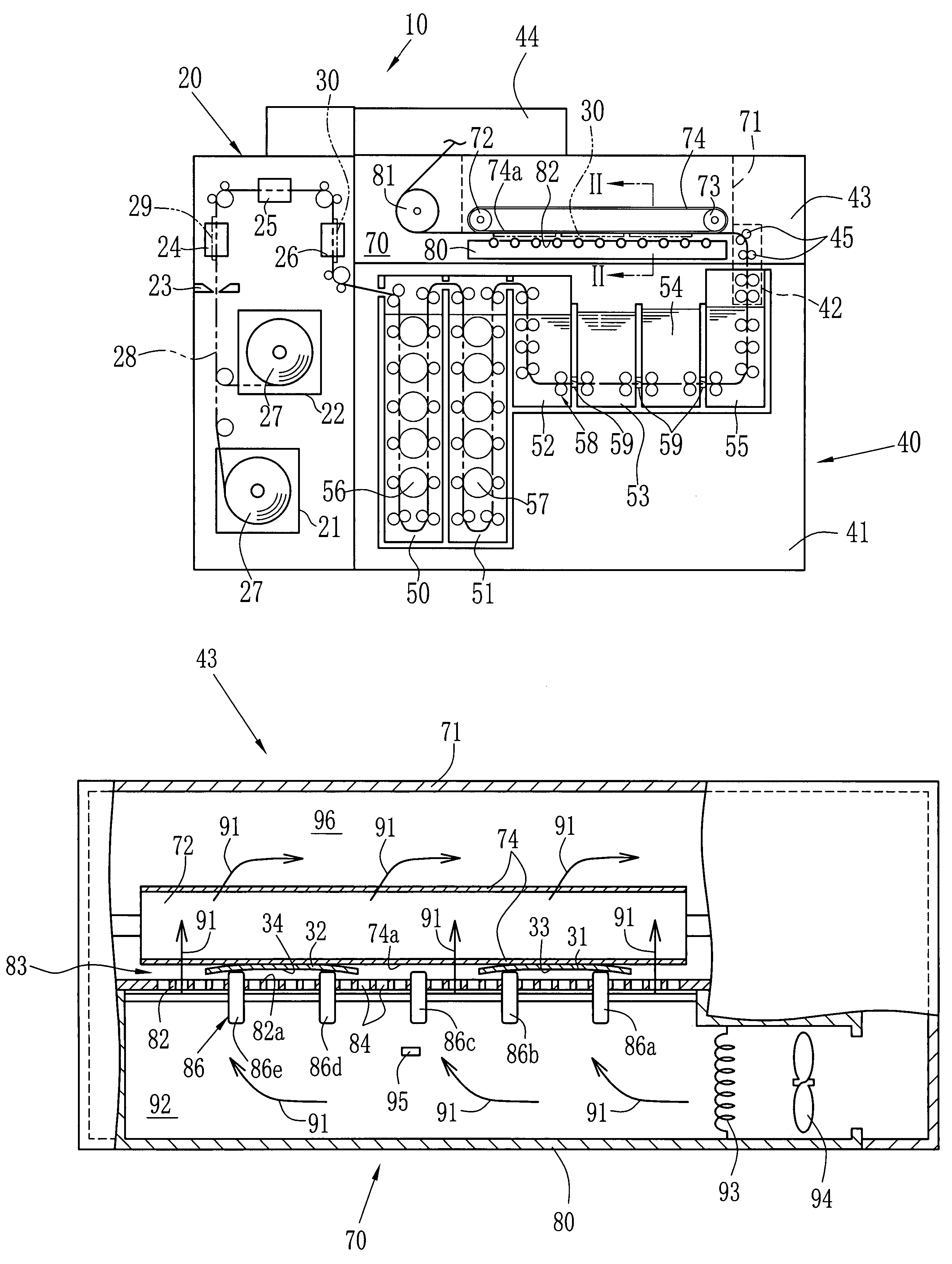

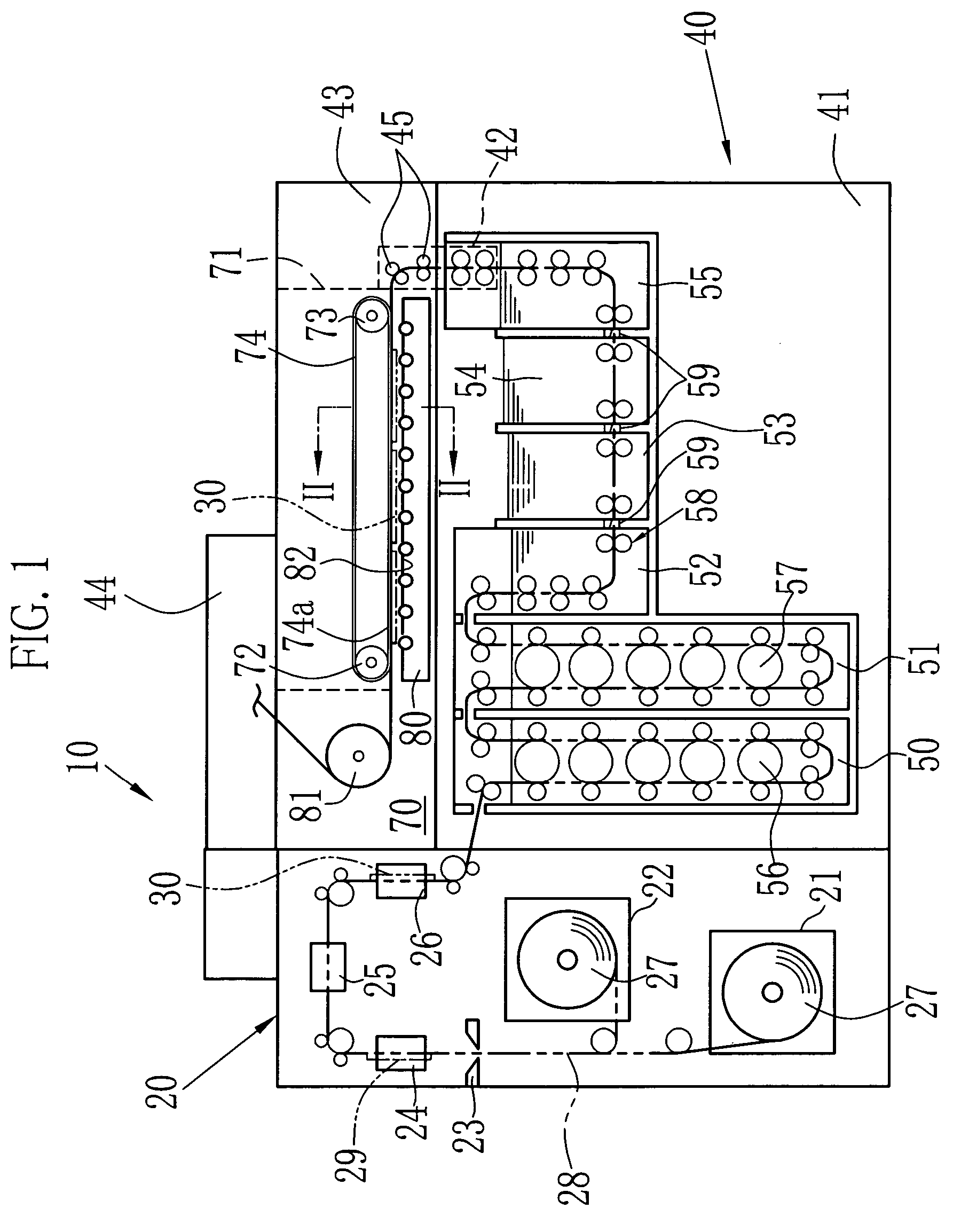

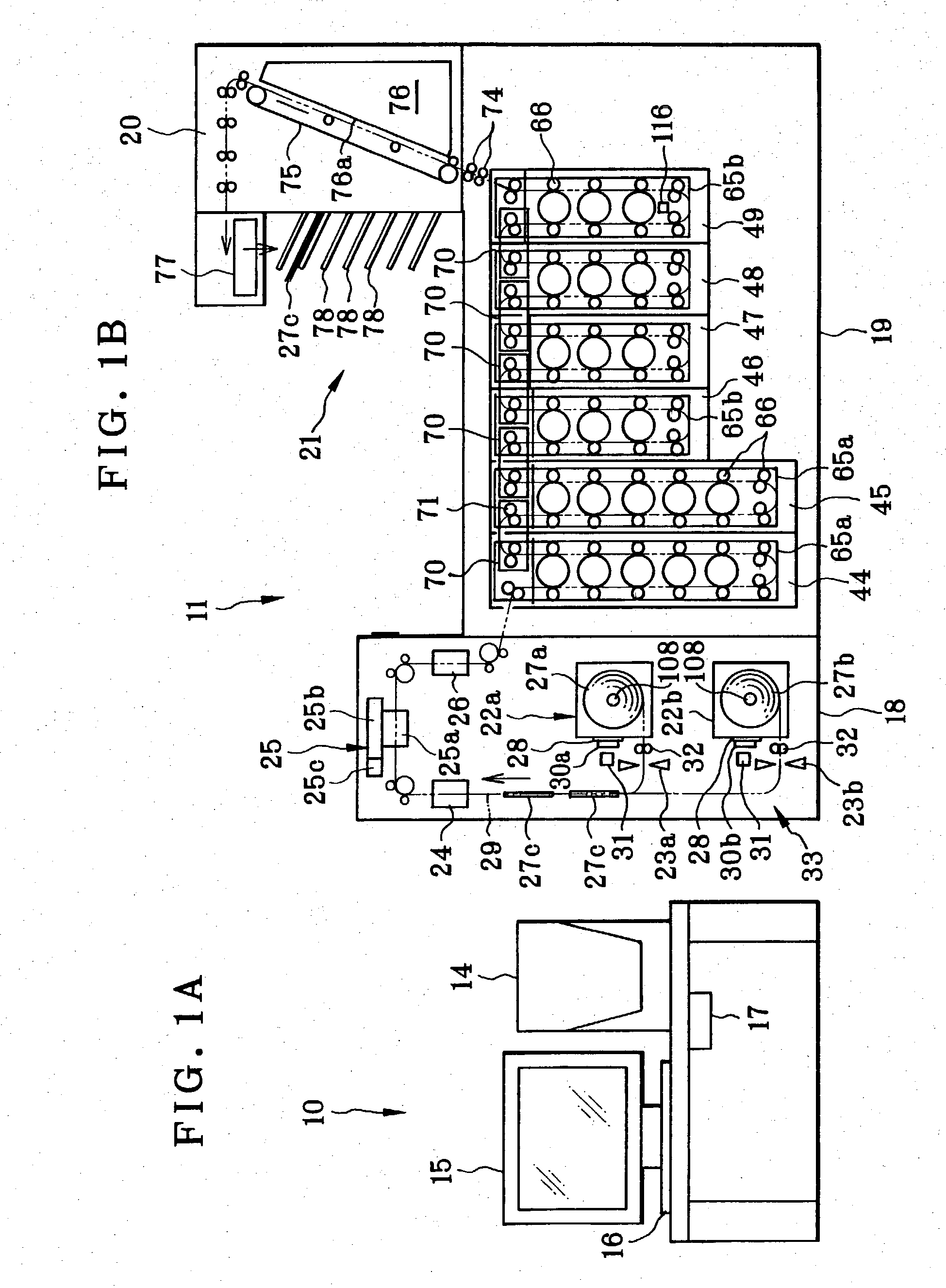

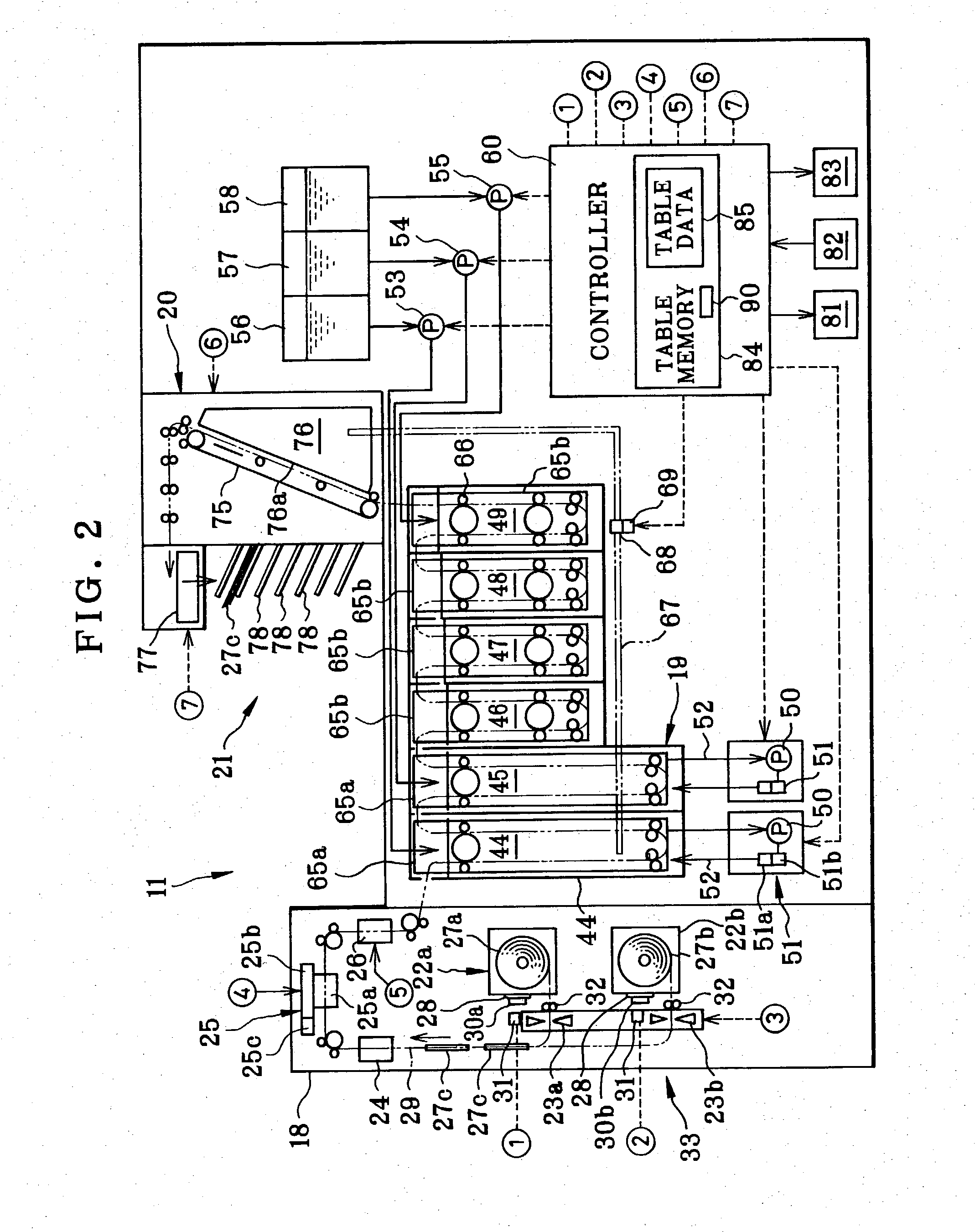

Photosensitive material processing apparatus and photosensitive material

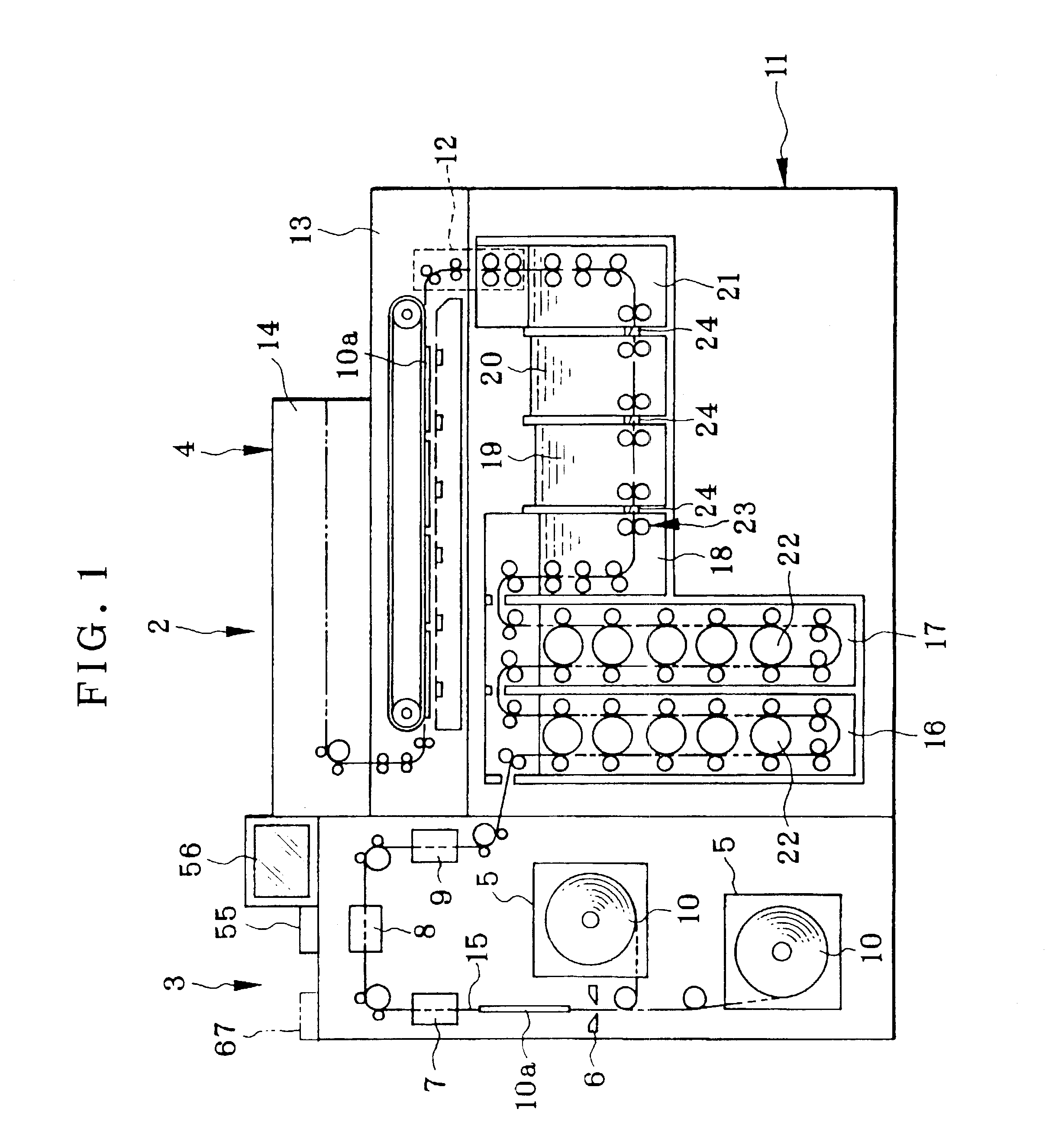

InactiveUS6817789B2Easy to processEasy to changeLiquid processing with progressive mechanical movementDrying/glazing processed materialEngineeringPhotographic paper

A photosensitive material processing apparatus includes a printer section for recording an image on photographic paper by exposure. There is a processor section for photographic development of the photographic paper. A drier section dries the photographic paper. A type bar code reader reads and inputs type information of a type of the photographic paper. A condition table memory is used to generate information of a transporting speed of the photographic paper and other processing conditions according to the type information being input, so as to control at least one of the printer section, the processor section and the drier section.

Owner:FUJIFILM CORP +1

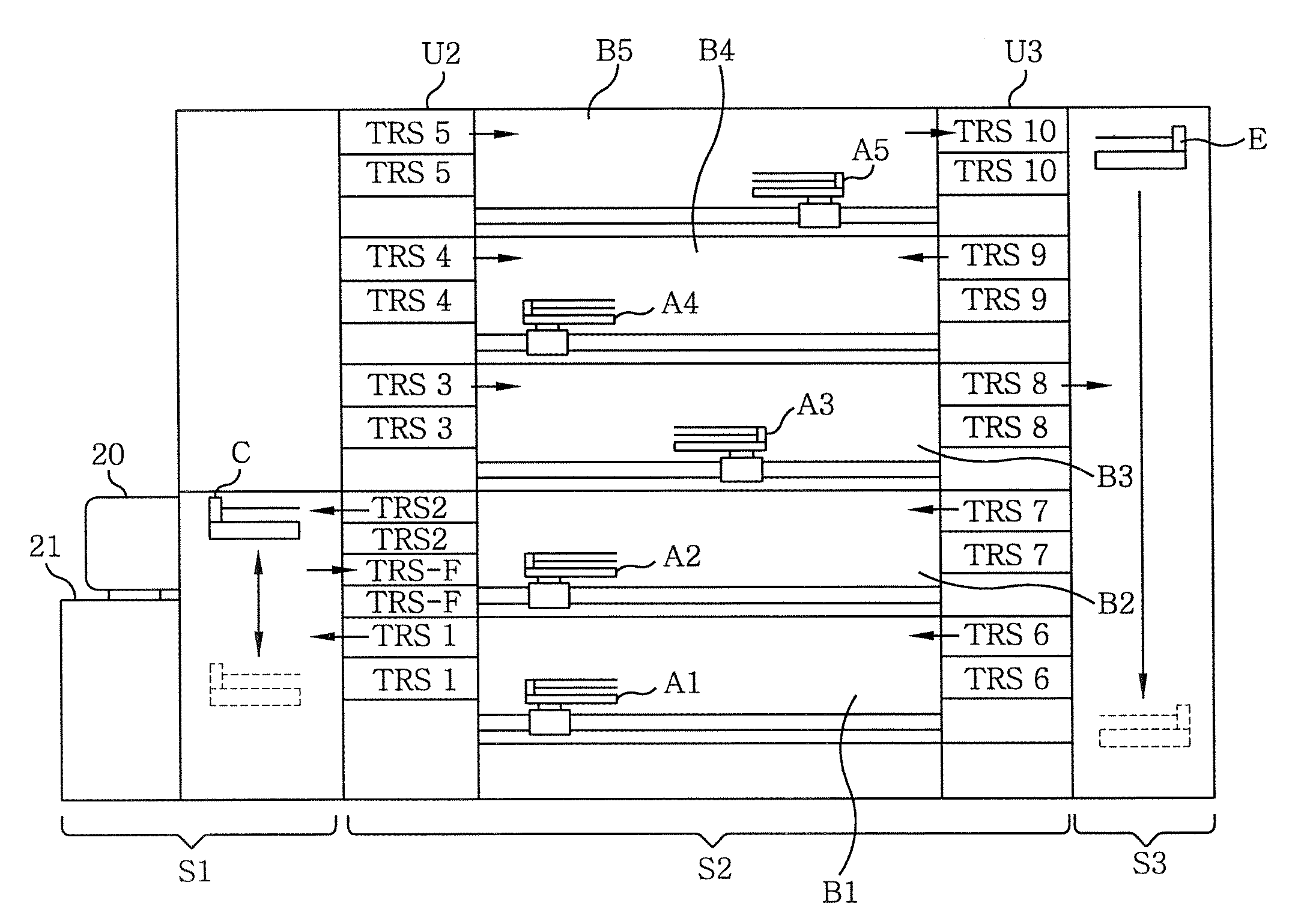

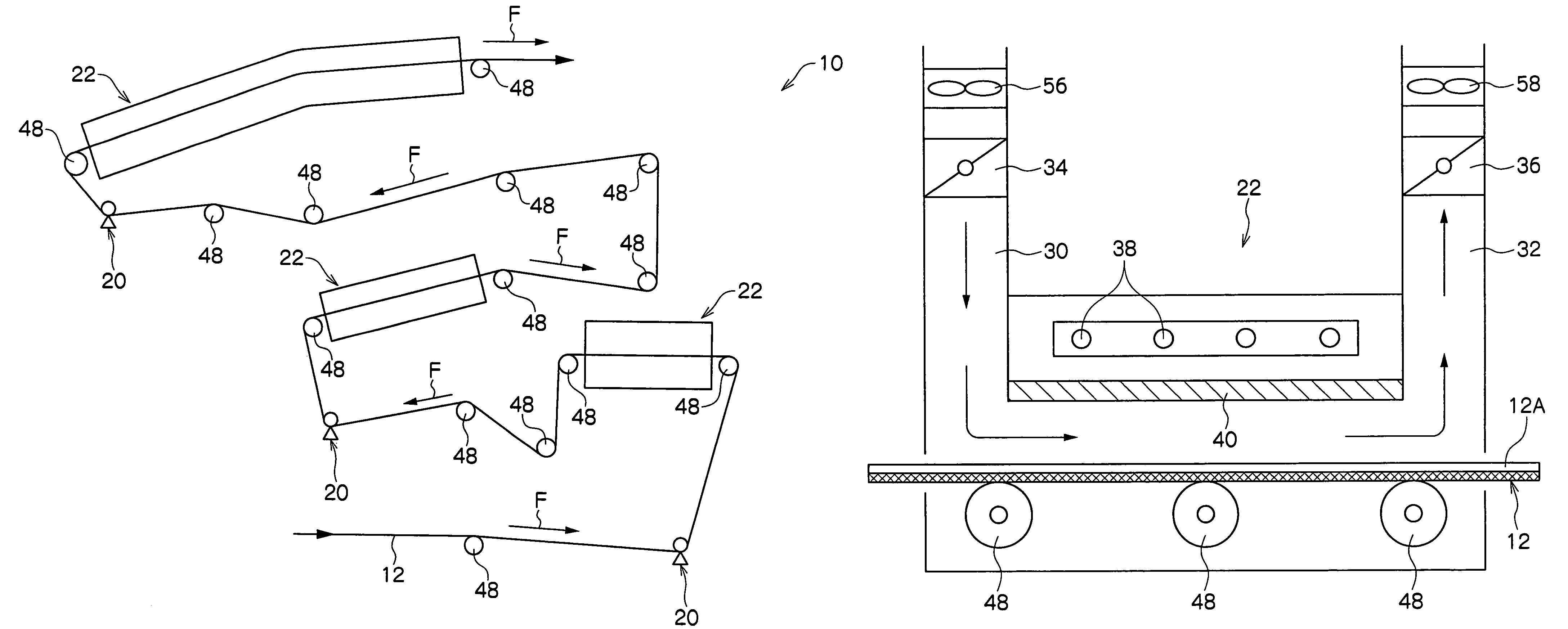

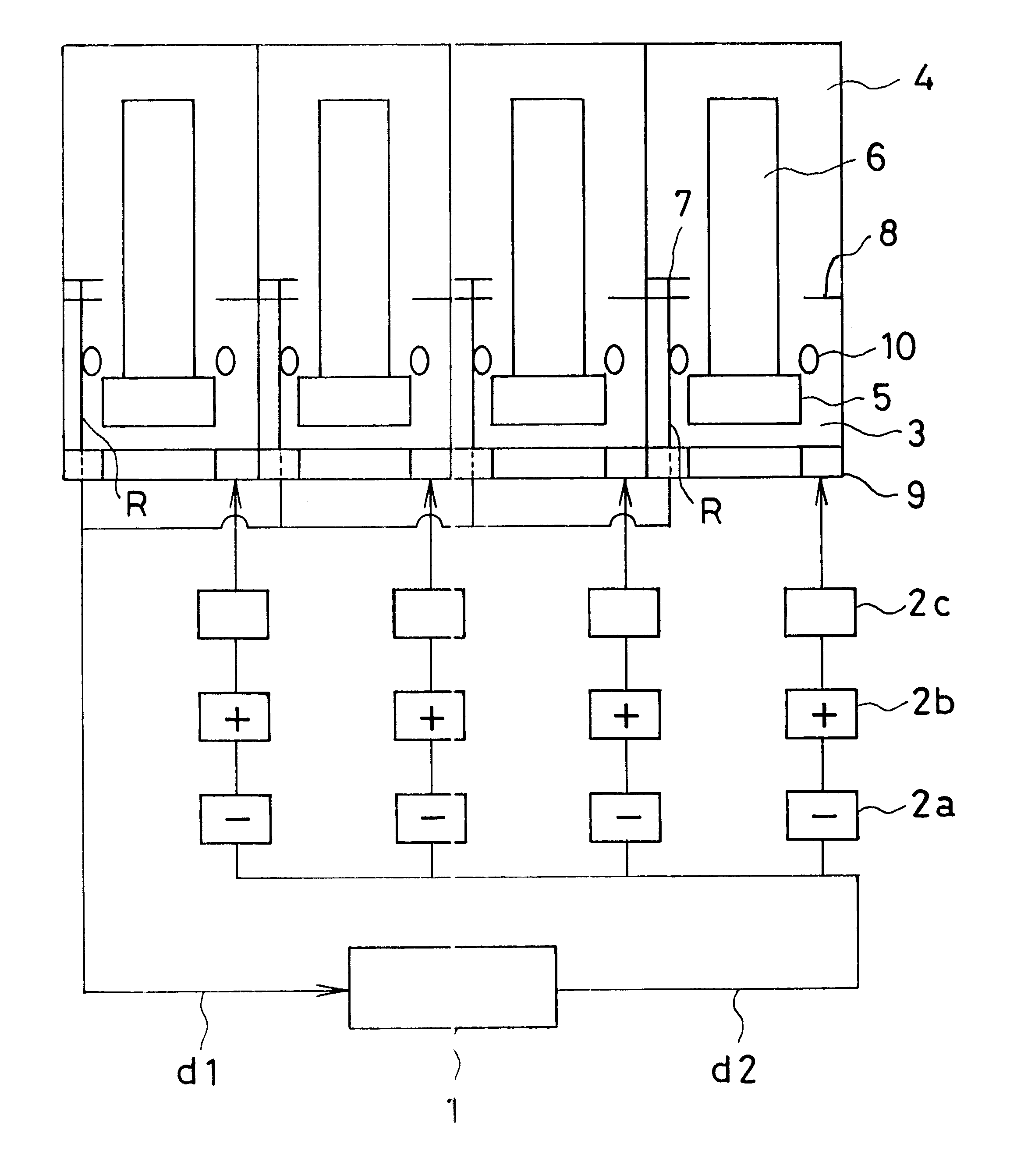

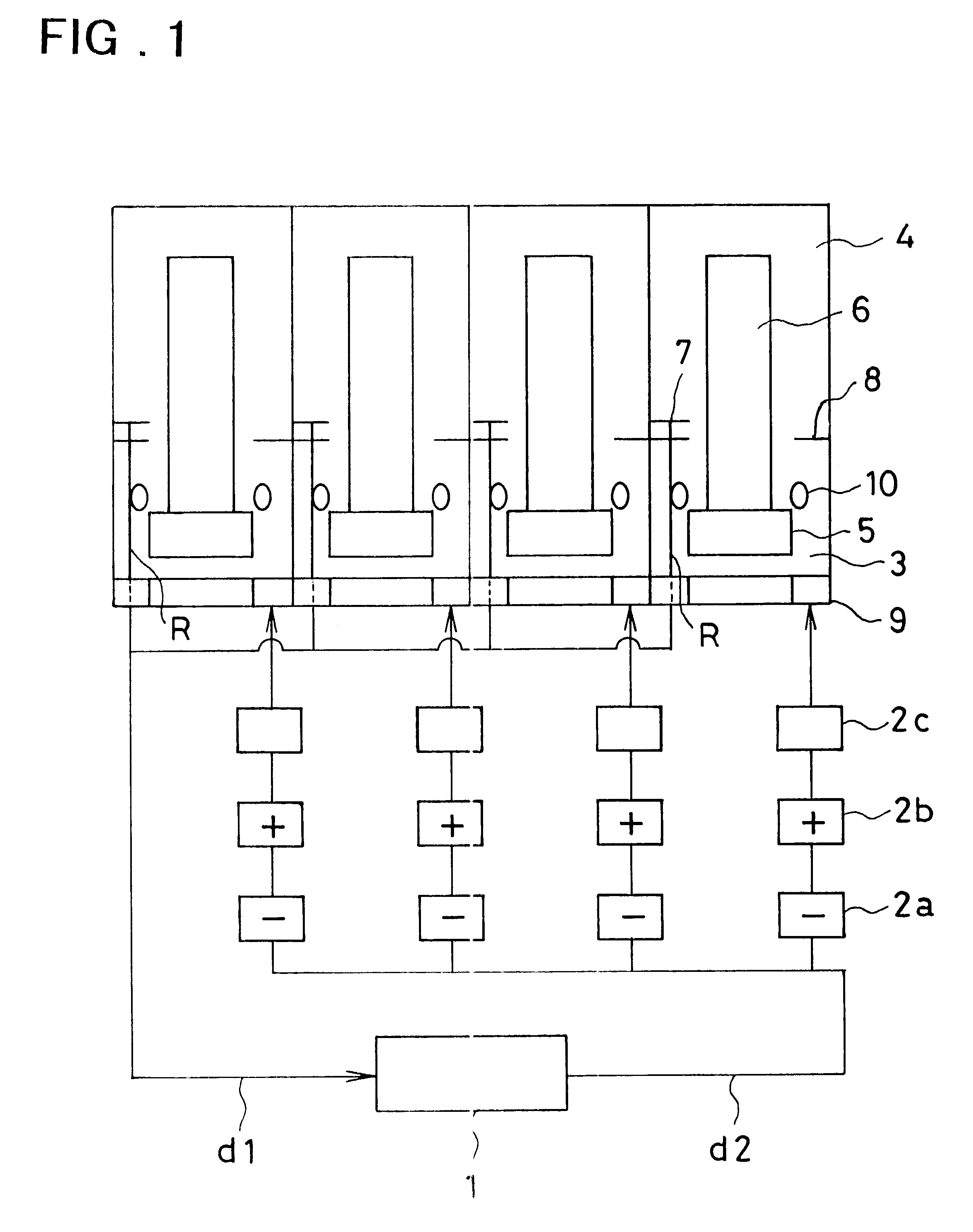

Coating/developing device and method

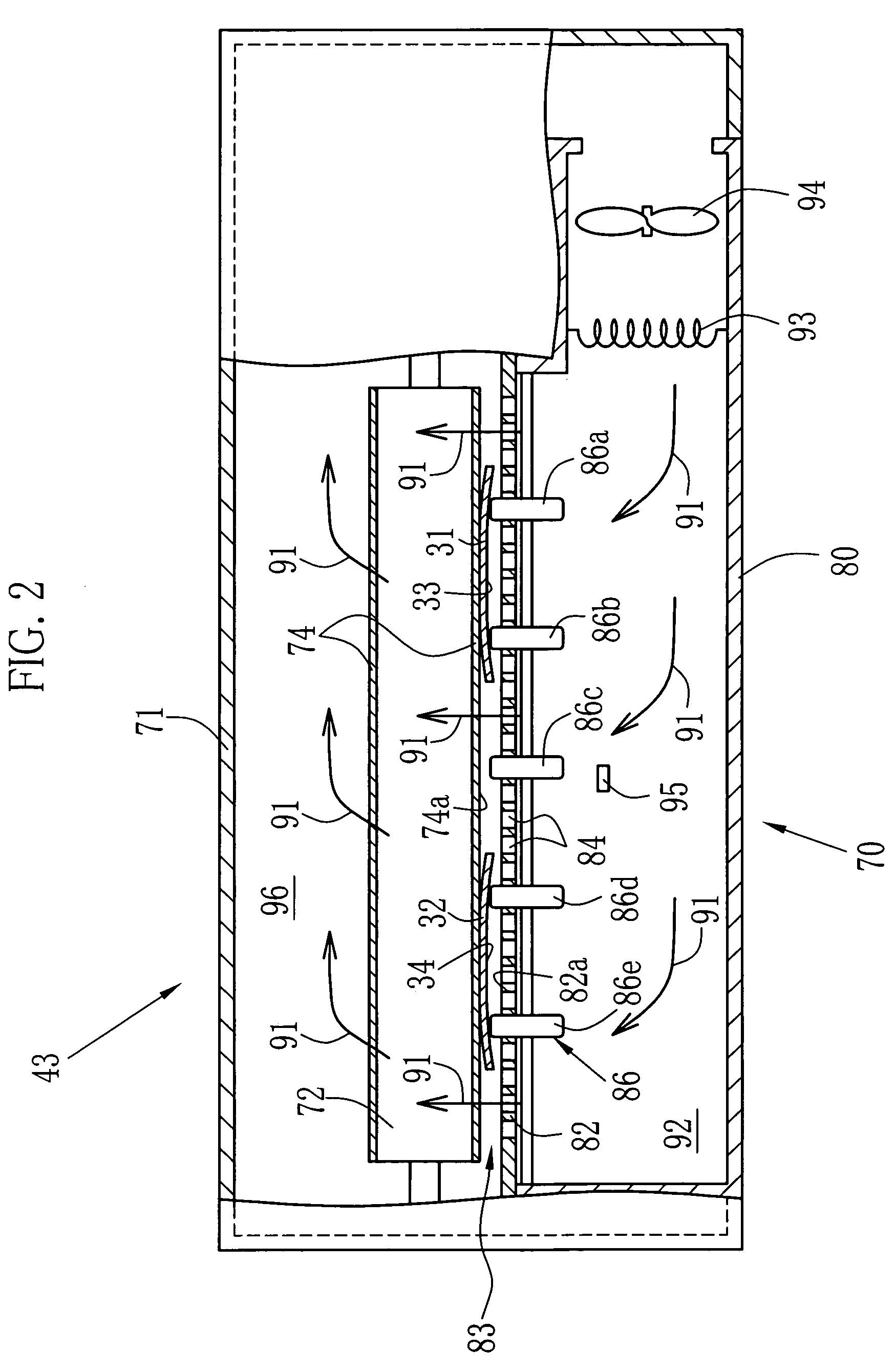

ActiveUS8408158B2Suppressing deterioration of throughputSave spaceLiquid processing by liquid spraysPhotomechanical apparatusResistEngineering

A coating / developing device includes a processing block having a plurality of coating unit blocks stacked and a developing unit block stacked on the coating unit blocks. Each of the unit blocks is provided with a liquid processing unit for coating a liquid chemical on a substrate, a heating unit for heating the substrate, a cooling unit for cooling the substrate and a transfer unit for transferring the substrate between the units. The liquid processing unit is provided with a coating unit for coating a resist liquid on the substrate, a first bottom antireflection coating (BARC) forming unit for coating a liquid chemical for a BARC on the substrate before the resist liquid is coated thereon, and a second BARC forming unit for coating a liquid chemical for the BARC on the substrate after the resist liquid is coated thereon.

Owner:TOKYO ELECTRON LTD

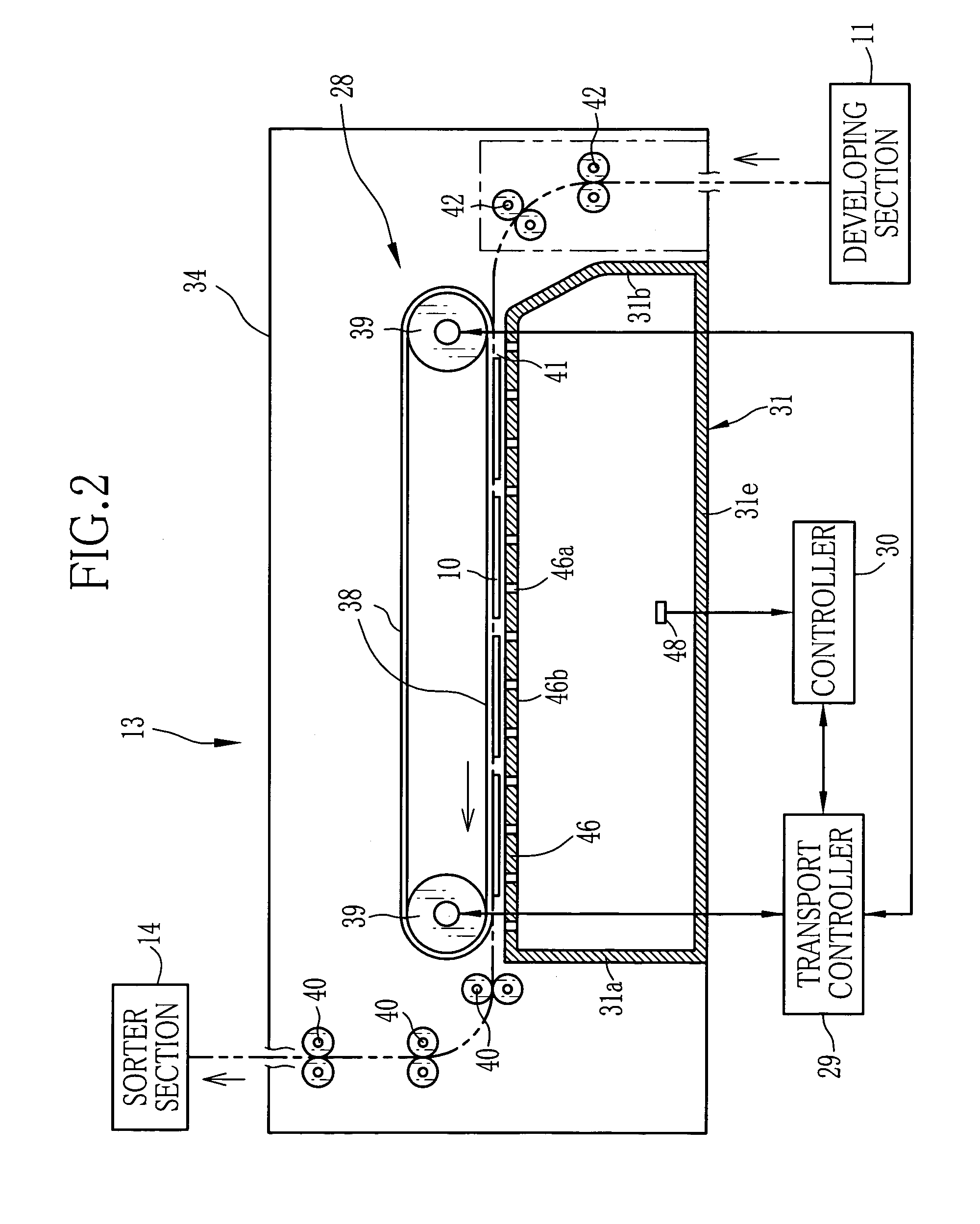

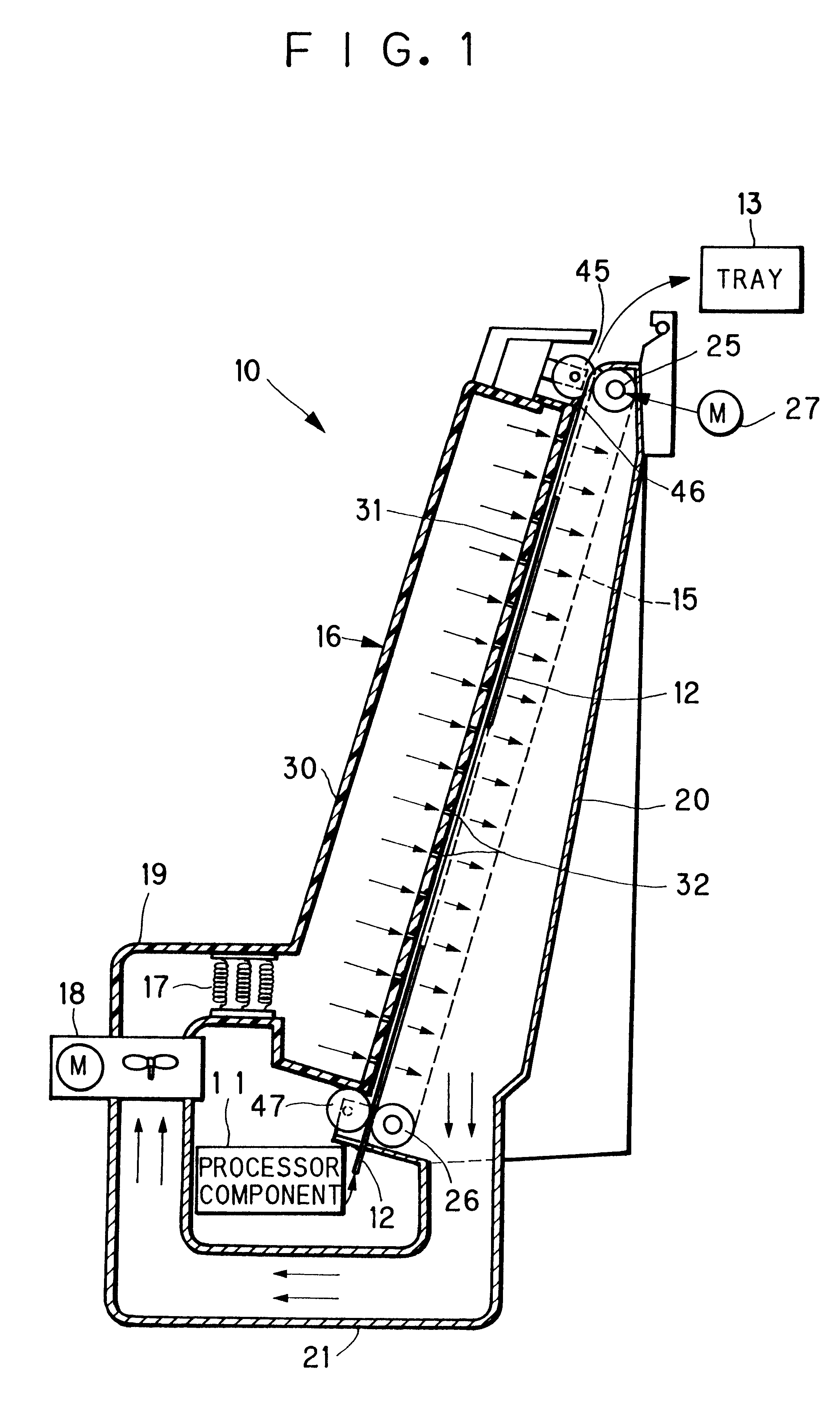

Photographic processing apparatus for photosensitive material

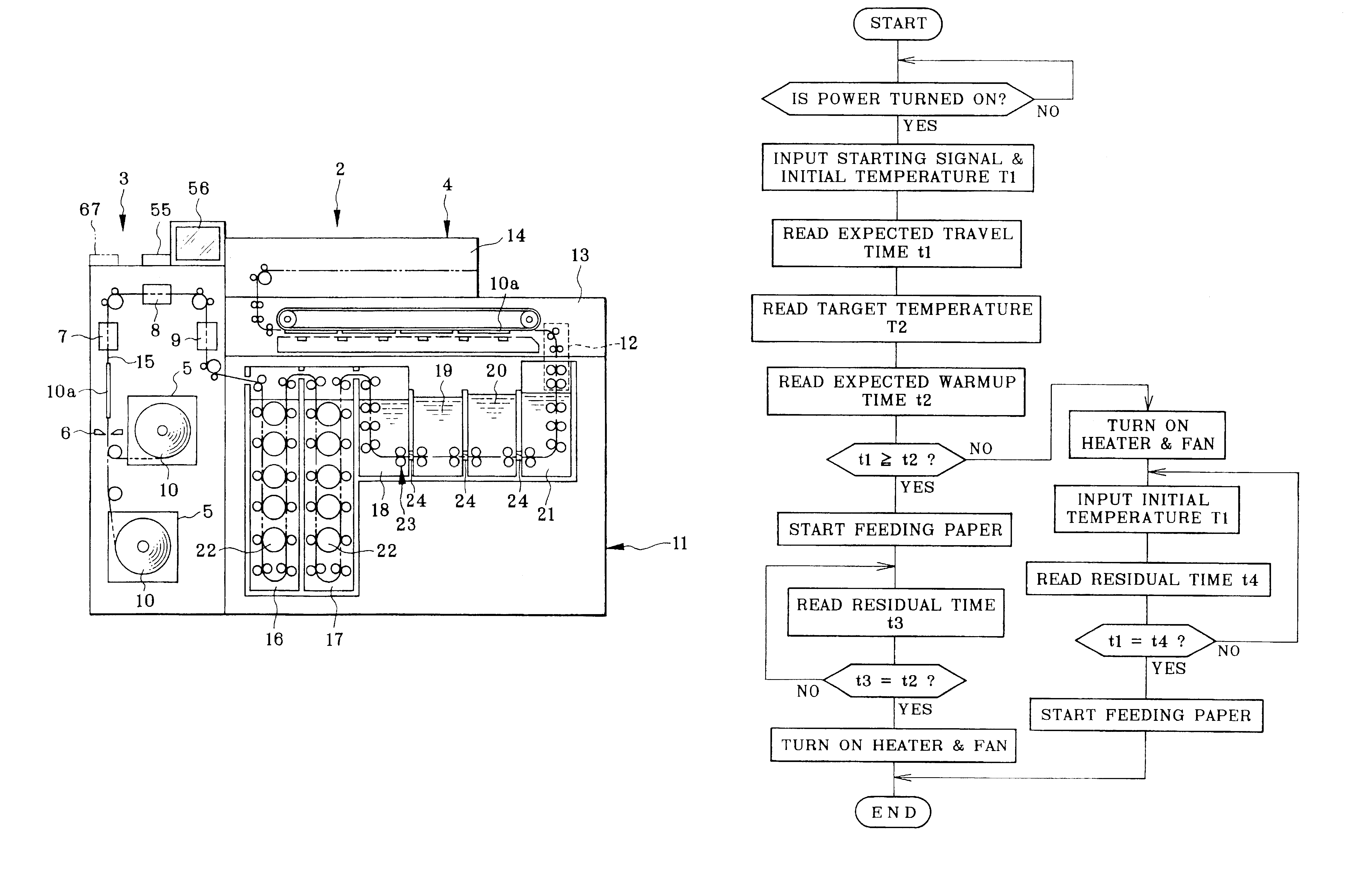

InactiveUS20030185559A1PrintersDrying solid materials with heatPhotographic processingPhotographic paper

A photographic processing apparatus includes a processing bath train, which processes photographic paper. A drier is positioned downstream from the processing bath train, for heating air and for drying the photographic paper by blowing the photographic paper with the heated air. Feeding racks feed the photographic paper in a predetermined travel path which begins on an upstream side of the processing bath train, extends through the processing bath train, and ends at the drier. A memory is accessed to estimate expected travel time t1 for passing of the photographic paper through the predetermined travel path in feeding of the feeding racks. The memory is accessed to estimate expected warmup time t2 for warming up the air in the drier up to a target temperature T2. A controller compares the expected travel time t1 and the expected warmup time t2, initially starts heating in the drier if the expected warmup time t2 is longer than the expected travel time t1, and starts actuation of the feeding racks when time of a difference (t2-t1) elapses after start of the heating in the drier. So warmup of the drier to the target temperature T2 is synchronized with a reach of the photographic paper to the drier.

Owner:FUJIFILM CORP +1

Drying device and drying method

InactiveUS7344322B2Satisfactory heating efficiencyPrevent foggingDrying solid materials with heatPhotomechanical coating apparatusInfraredMid infrared

Owner:FUJIFILM HLDG CORP +1

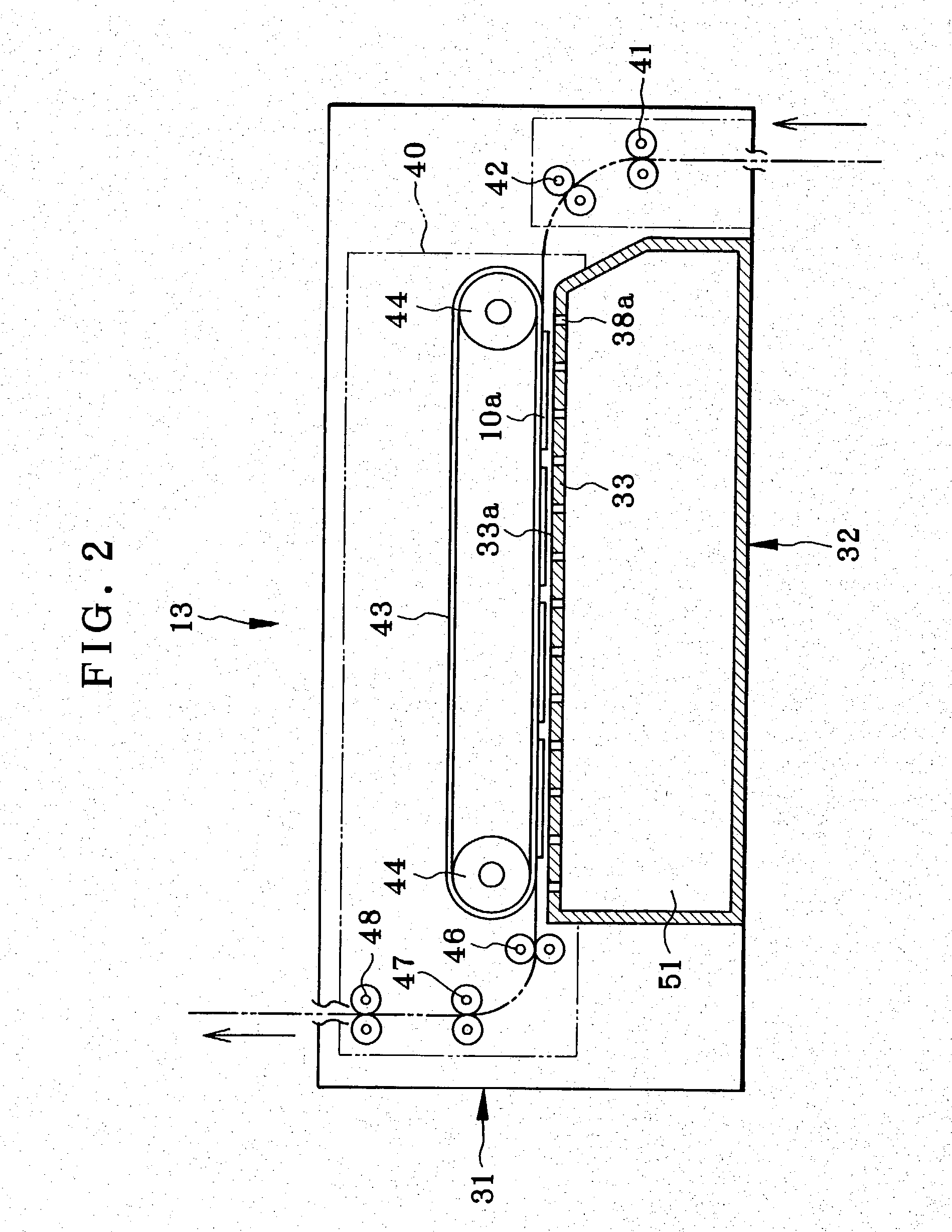

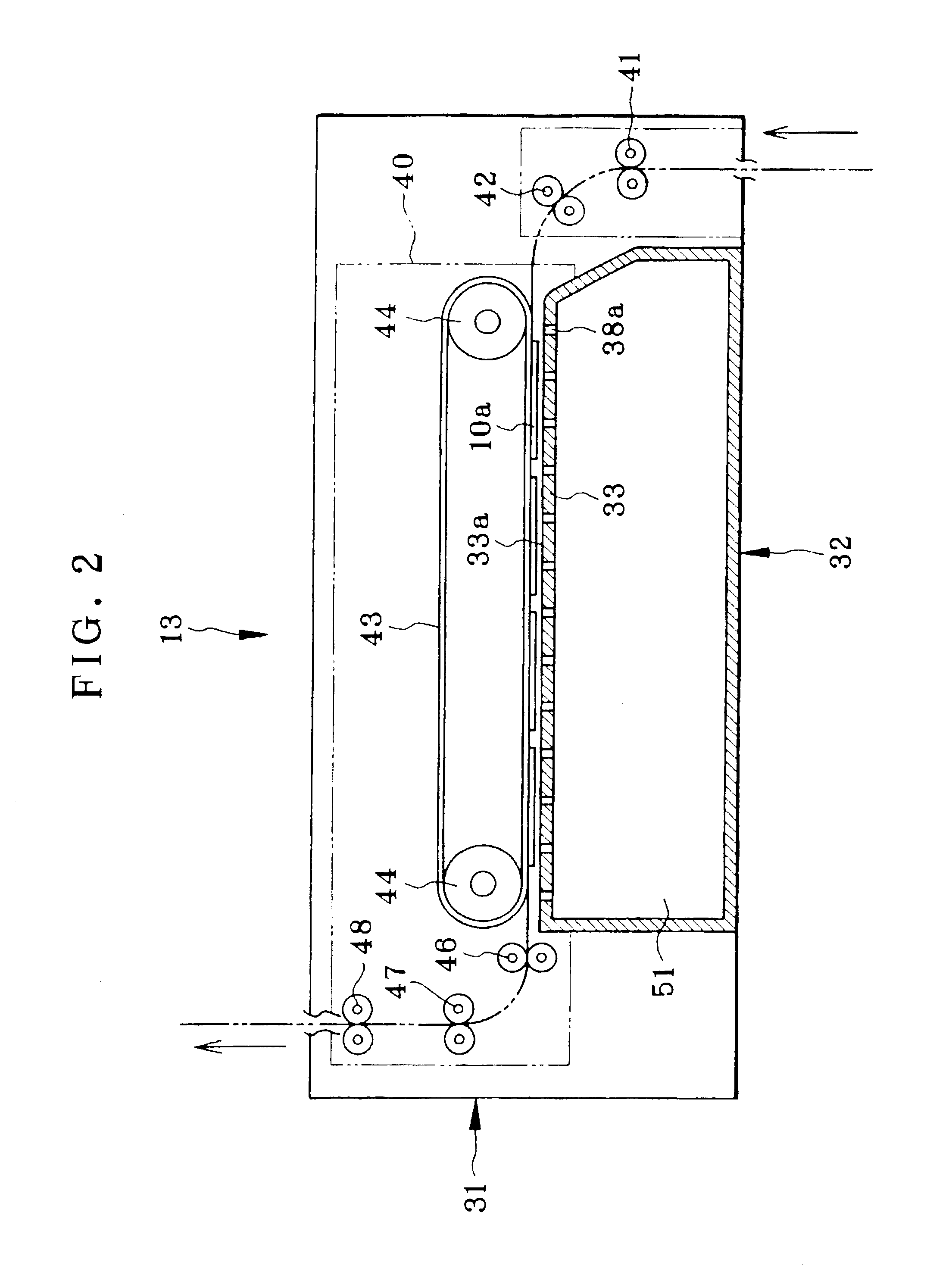

Dryer for a recording medium

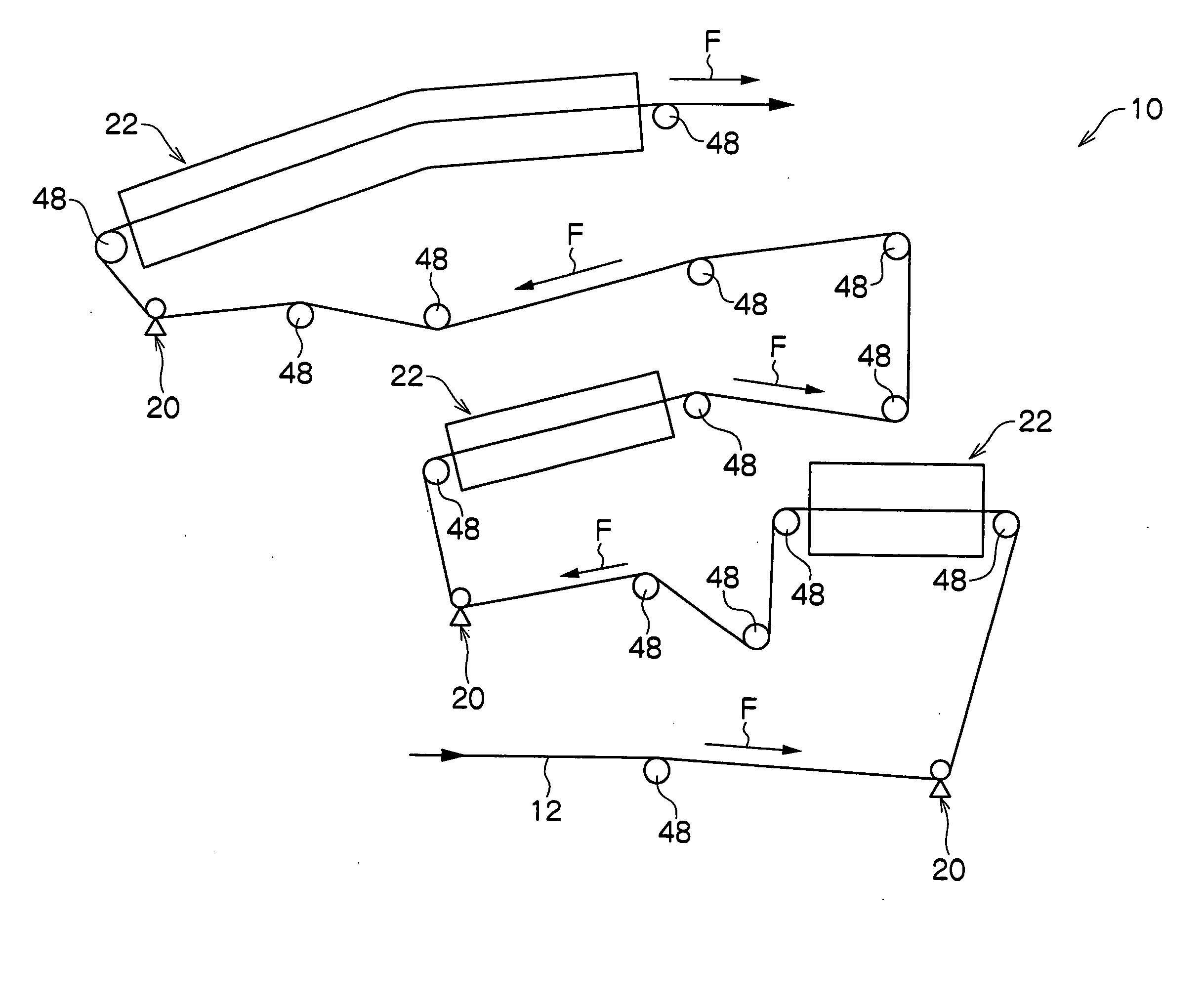

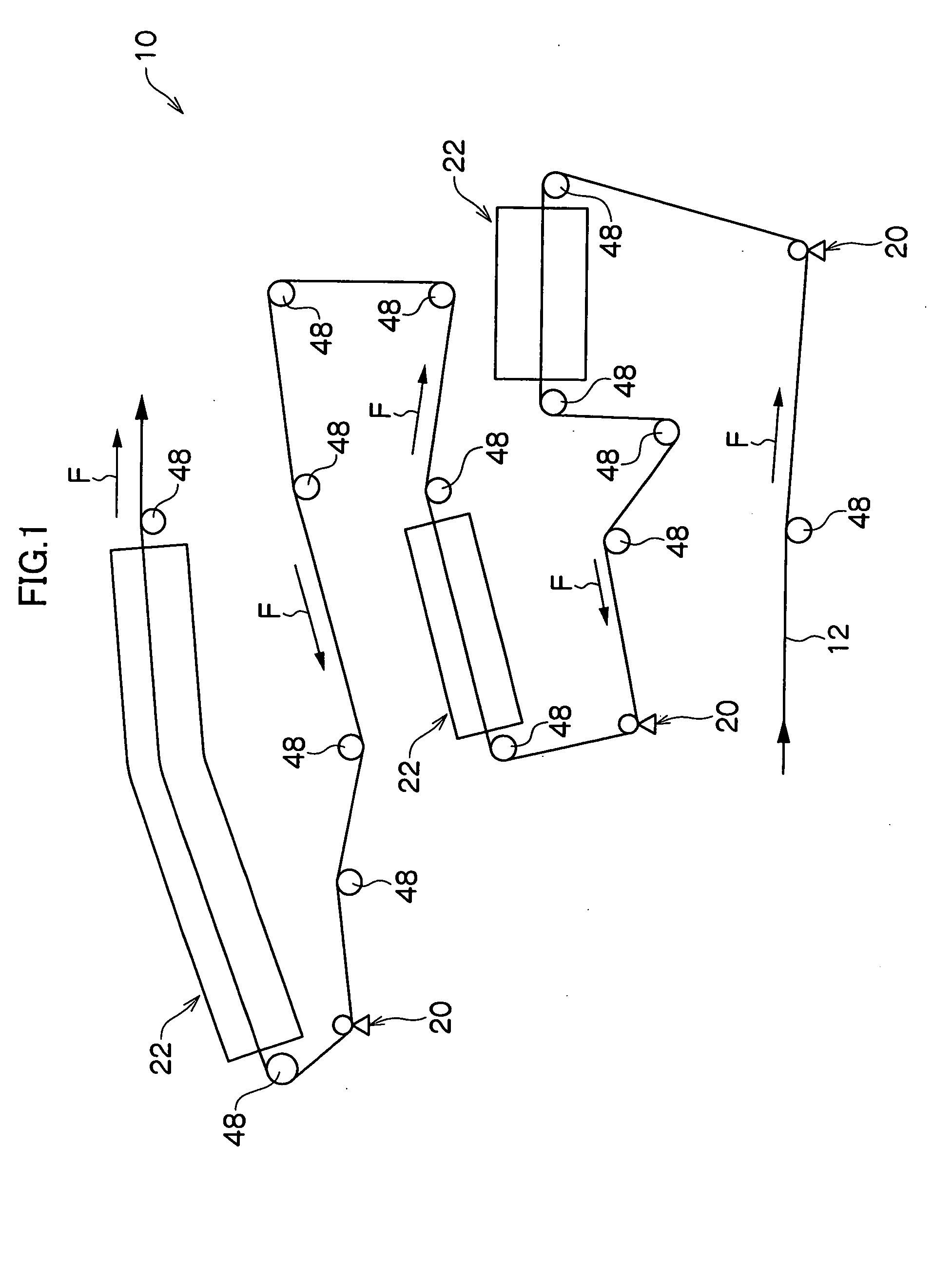

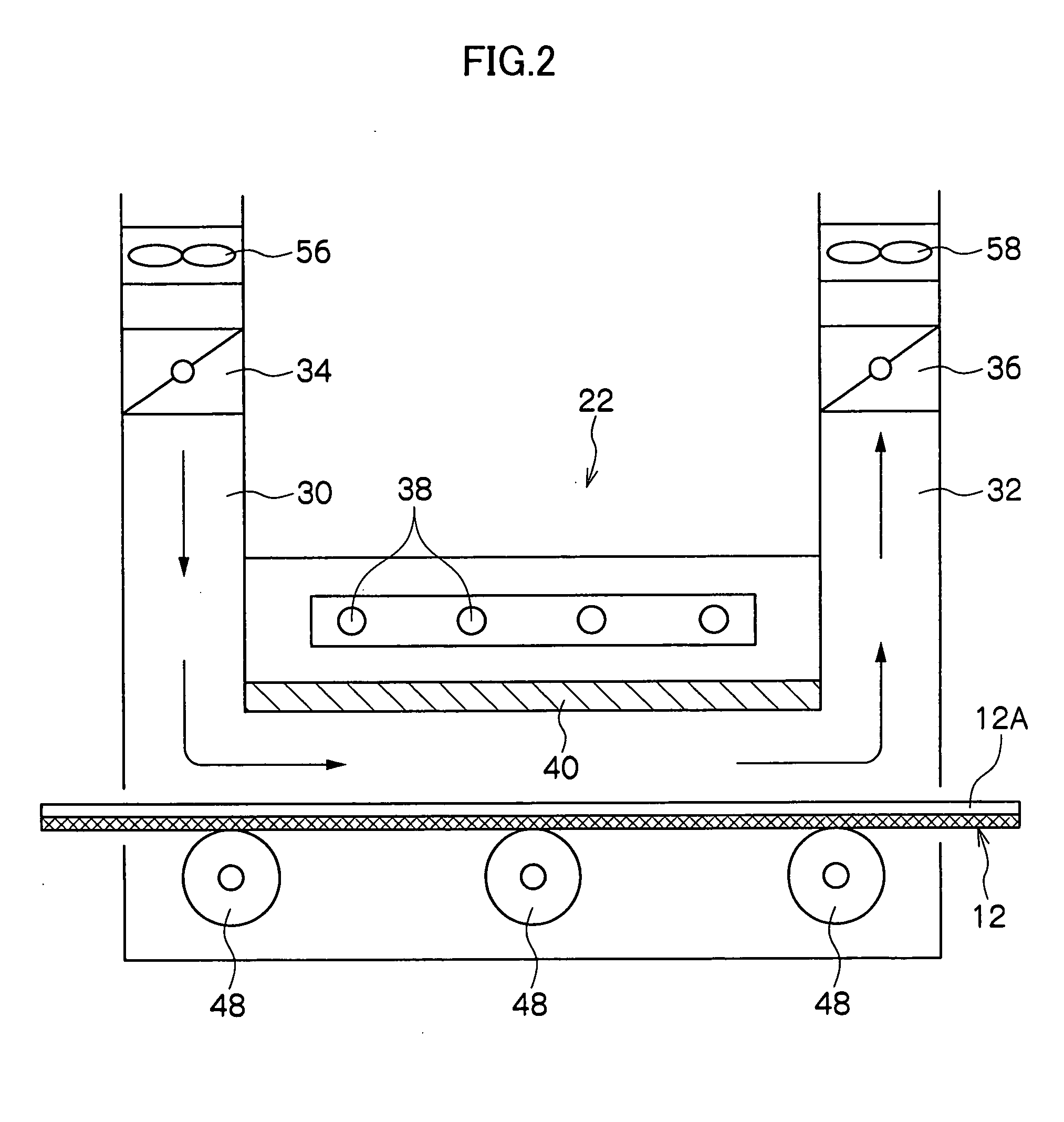

InactiveUS7077584B2Blocking may occurDefective carry is preventedDrying solid materials with heatLiquid processing with progressive mechanical movementConveyor beltRecording media

Dry air is jetted from jet holes of a guide plate toward a conveyor belt to levitate a photosensitive sheet and to press it against the conveyor belt. The photosensitive sheet is supported and carried by the conveyor belt. The dry air dries the photosensitive sheet. A projection amount h of a guide roller projecting from the guide plate is defined so as to satisfy an expression of h≧H×(W−P) / W. H is a gap between the guide plate and the conveyor belt. P is a length from a center line of the carried photosensitive sheet to an outer edge of the guide roller. W is a length from the center line to a lateral end of the photosensitive sheet. Even if a curl occurs on the photosensitive sheet, an edge thereof is prevented from contacting with the guide plate.

Owner:FUJIFILM CORP +1

Film drying box for imaging department

InactiveCN111752084AEasy clampingReduce humidityDrying/glazing processed materialActivated carbonElectric machinery

The invention discloses a film drying box for the imaging department. The film drying box comprises a drying box, wherein a motor is fixedly mounted on the top surface of the drying box; the output end of the motor is fixedly connected with a rotating rod penetrating through the drying box; sliding grooves are formed in the left wall and the right wall of the rotating rod; sliding bases are installed in the sliding grooves in a sliding mode; a plurality of fixed through holes are formed in the sliding grooves; a lower clamping block is fixedly connected to the left lower wall and the right lower wall of the rotating rod, and an upper clamping block is fixedly connected to the two sliding bases; and clamping mechanisms are arranged on the upper clamping block and the lower clamping block and used for clamping films. By means of a fixing mechanism, a T-shaped pull rod is pulled to be disengaged from the through holes, limiting blocks extrude compression springs and enable the sliding bases to move to proper positions, so films with different lengths can be clamped; and humidity in the drying box is reduced through a circulating pipe and activated carbon, so drying effect is good, andimaging is more reliable.

Owner:宋洛伟

Photographic processing apparatus for photosensitive material

A photographic processing apparatus includes a photographic paper processing bath train. A drier, positioned downstream from the train, heats air and dries the photographic paper. Feeding racks feed the paper in a predetermined travel path which begins on an upstream side of the train, extends therethrough, and ends at the drier. A memory is accessed to estimate expected travel time t1 for passing of the paper through the travel path. The memory is accessed to estimate expected warmup time t2 for warming up the air in the drier to a target temperature T2. A controller compares the time t1 and the time t2, initially starts heating in the drier if the time t2 is longer than the time t1, and starts actuation of the feeding racks when a time difference (t2-t1) elapses after start of the heating to synchronize drier warmup to temperature T2 with paper reaching the drier.

Owner:FUJIFILM CORP +1

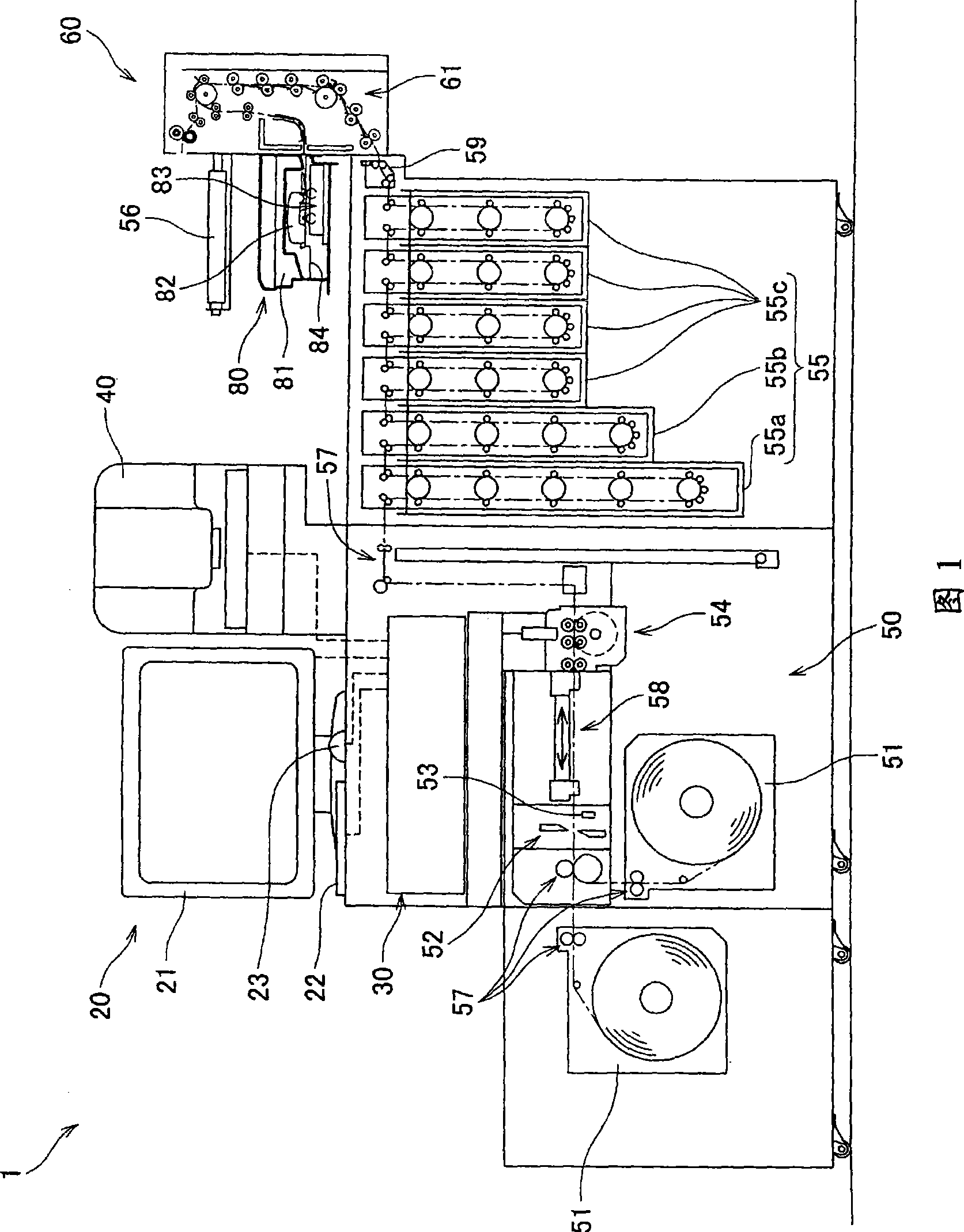

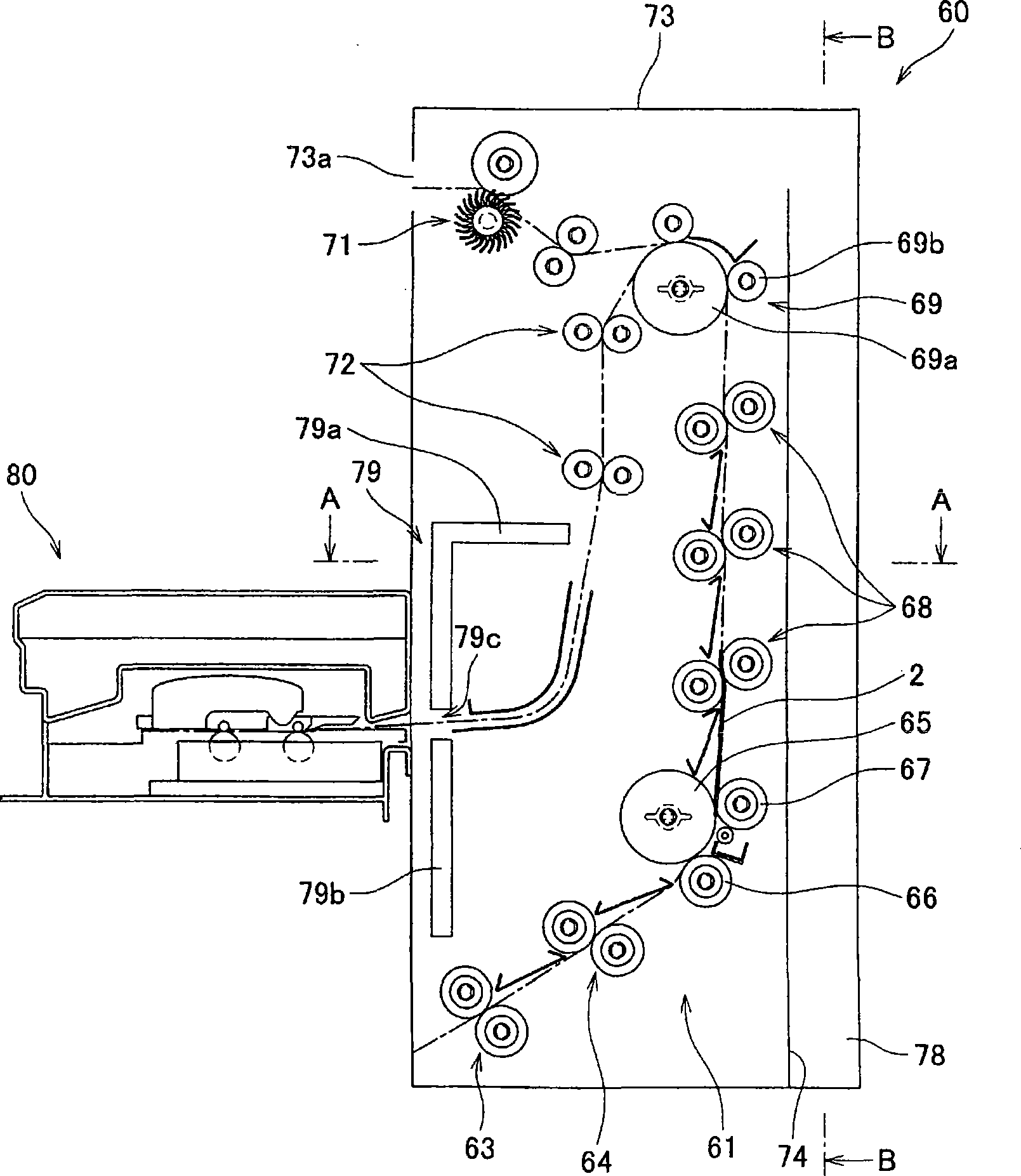

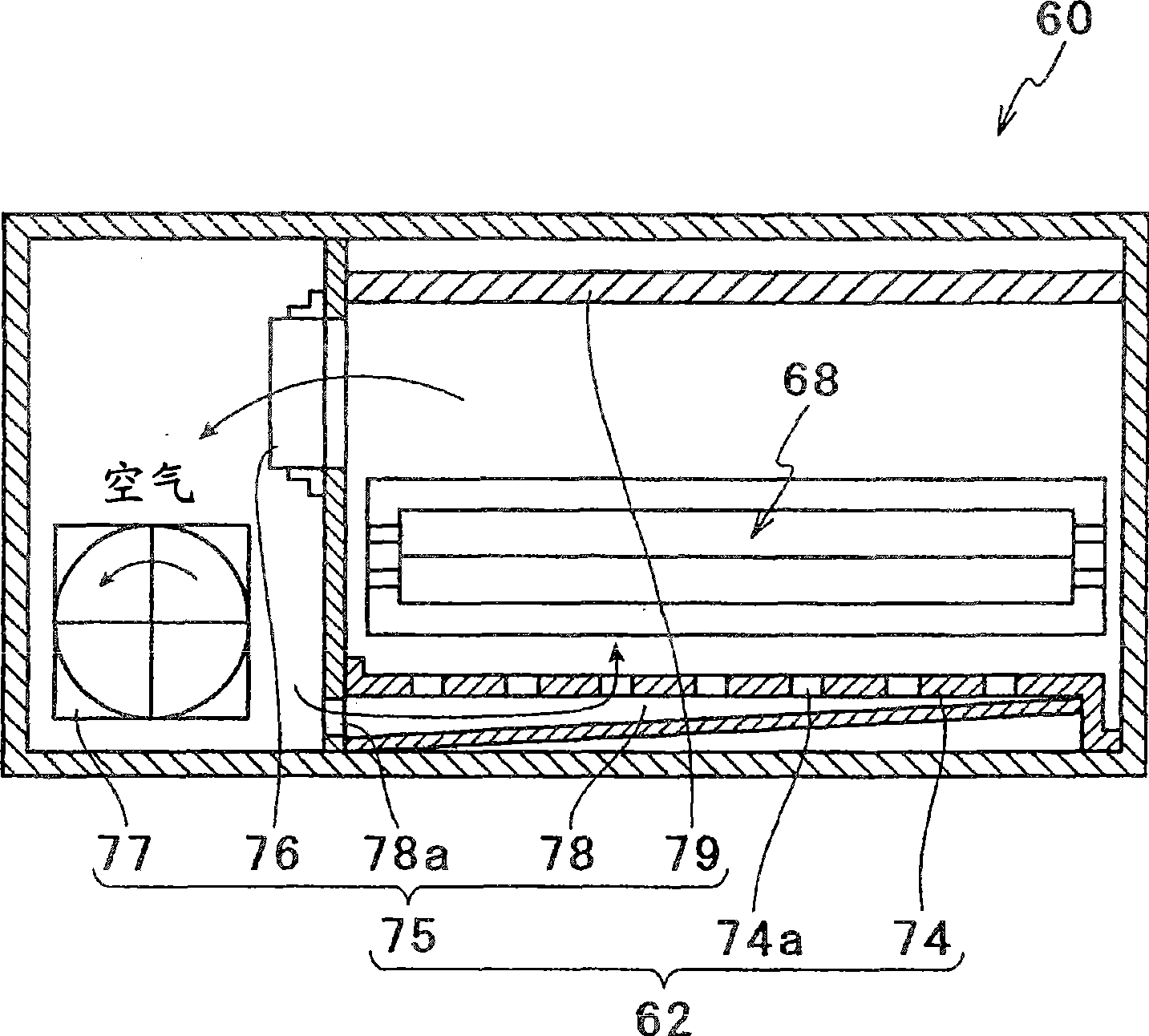

Drying apparatus

InactiveCN101419395AHigh thermal efficiencyAvoid heat transferDrying gas arrangementsDrying machines with progressive movementsThree levelEngineering

The invention discloses a drying apparatus. The drying apparatus (60) comprises a conveying portion (61) conveying printing paper (2) inside a housing (73), a partition board with holes (74) of a conveying path carrying out conveying spraying heated air to the conveying portion (61), and a circulating mechanism (75) circulating the air sprayed from the partition board with holes (74) facing the partition board with holes (74) through a heating chamber (78) and the air (WB) sprayed to the conveying path without facing the partition board with holes (74). One side opposite to the partition board with holes (74) inside the housing (73) from the conveying path is provided with a partition component (79) having horizontal wall portion (79a). The horizontal wall portion (79a) is configured to between a four-level hole (74a) at the lower part corresponding to the partition board with holes (74) and a three-level hole (74a) at the upper part. Therefore, a drying portion (60) (drying apparatus) with very good thermal efficiency can be obtained.

Owner:NORITZ CORP

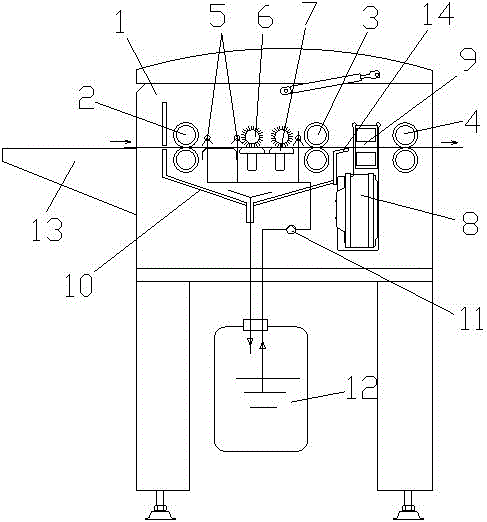

Pneumoconiosis film air drying processor

InactiveCN101968604AGuaranteed dry handlingEasy to dryDrying/glazing processed materialTemperature controlPneumoconiosis

The invention relates to a pneumoconiosis film air drying device for a washed film in pneumoconiosis detection. The air drying processor mainly comprises a temperature-control air drying device and a film suspension device. The temperature-control air drying device consists of a motor and a fan and is fixed arranged at the upper part of the cabinet body, wherein the fan is driven by the motor. The film suspension device consists of a shaft lever, a crank, a locking device, a wire rope and a film-carrying frame, wherein the shaft level is arranged on the cabinet body; at least one end of the shaft level is provided with a crank provided with a locking device; the wire rope is wound on the shaft level; the outer end of the wire rope is connected with the film-carrying frame for accommodating a film clip. The pneumoconiosis film air drying device can rapidly dry the film, and avoids the problems of scratching, adhesion and the like when the film is not dried.

Owner:莱芜钢铁集团有限公司医院

Photosensitive material processing apparatus and photosensitive material

InactiveUS20030152382A1Easy to processEasy to changeLiquid processing with progressive mechanical movementDrying/glazing processed materialPhotographic paperEngineering

A photosensitive material processing apparatus includes a printer section for recording an image on photographic paper by exposure. There is a processor section for photographic development of the photographic paper. A drier section dries the photographic paper. A type bar code reader reads and inputs type information of a type of the photographic paper. A condition table memory is used to generate information of a transporting speed of the photographic paper and other processing conditions according to the type information being input, so as to control at least one of the printer section, the processor section and the drier section.

Owner:FUJIFILM CORP +1

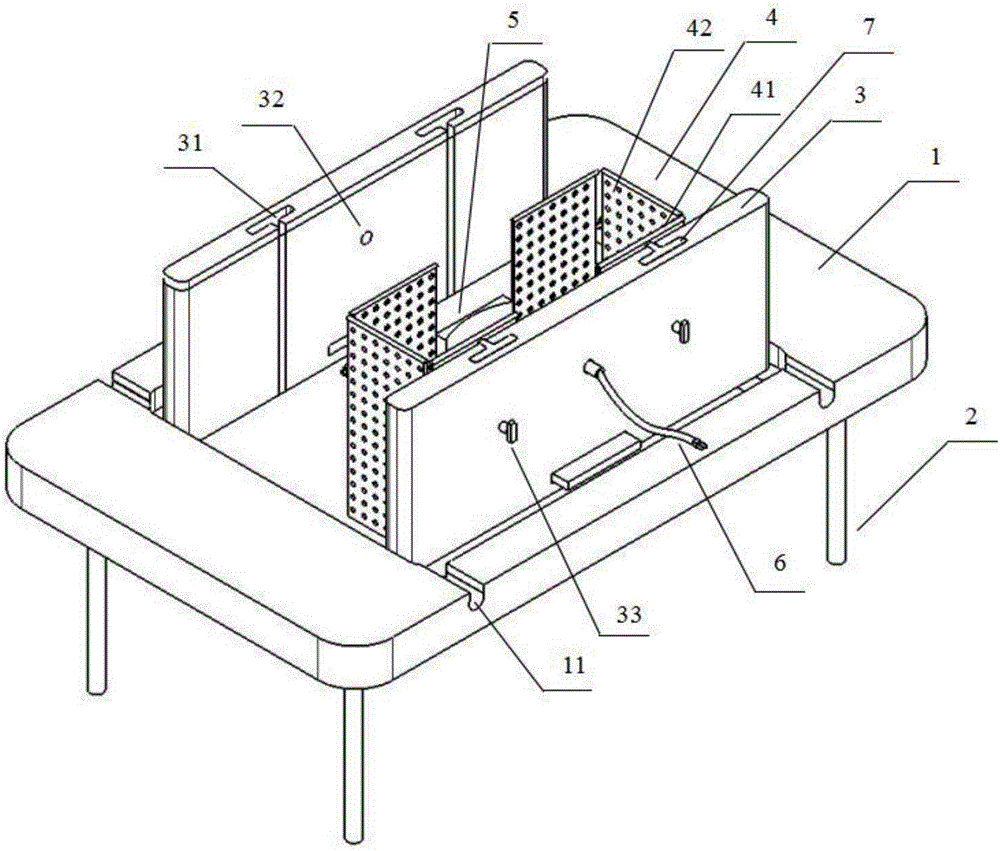

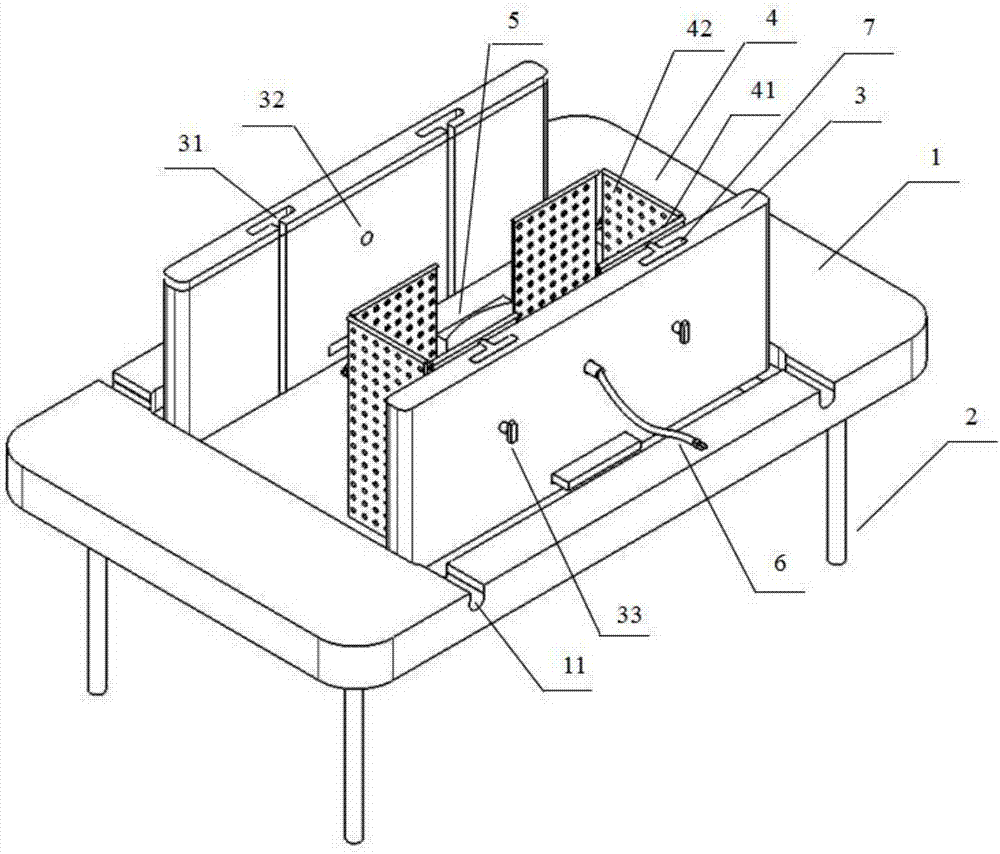

Portable film rack drying device

InactiveCN106154734ASolve the problem of being dry and not portableAvoid sorting workDrying/glazing processed materialAgricultural engineering

The invention relates to a portable film rack drying device which comprises a supporting platform, a detachable plate, a film rack, a wind spreading plate, a fan and a T-shaped slide block, wherein the detachable plate is arranged at the upper end of the supporting platform; the film rack is mounted on one side of the detachable plate; the wind spreading plate is connected with the detachable plate and is located on one side of the film rack; the fan is arranged in the middle of the detachable plate; the detachable plate is connected with the film rack through the T-shaped slide block; the T-shaped slide block is mounted in the detachable plate and used for driving the film rack to slide up and down to a proper position. The portable film rack drying device involved by the invention overcomes shortcomings of the existing device, solves a problem that the ordinary electric drying oven is not portable when being used for drying films, solves the classification work of different tank film racks, is good in supporting effect and convenient to disassemble, saves space, improves the work efficiency, and enhances the convenience.

Owner:SHANGHAI INST OF TECH

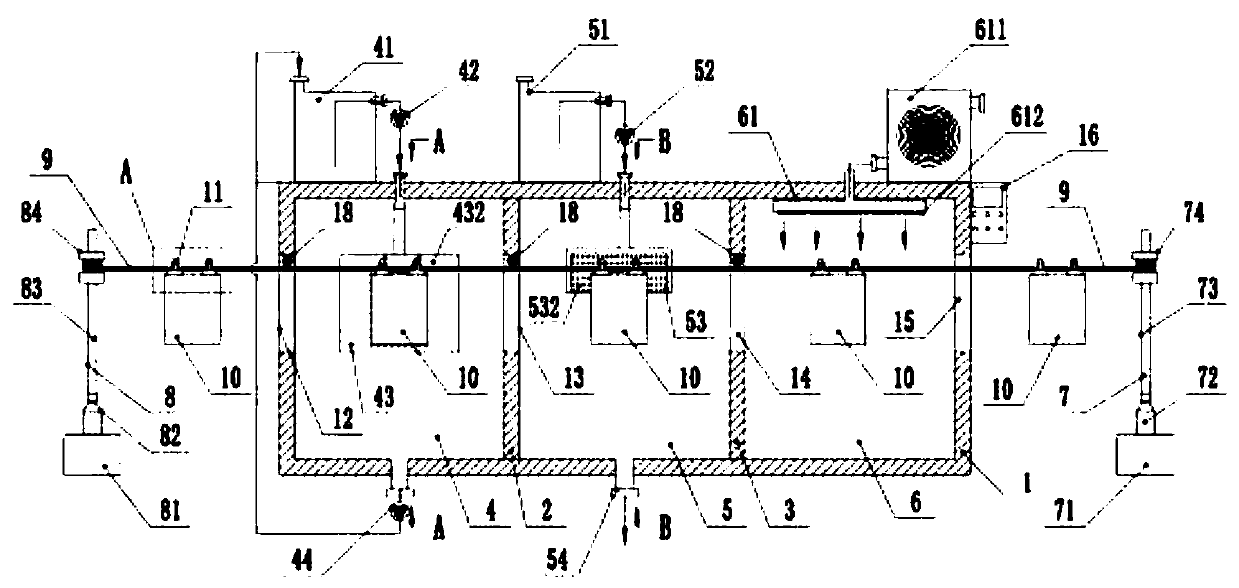

Linear plate processor and linear plate processing technology thereof

ActiveCN104102088ANot easy to scratchNot easy to wearDrying/glazing processed materialAgricultural engineeringSpare part

The invention discloses a linear plate processor which comprises a rack, and a guide mechanism, a spray mechanism and a dryer which are arranged in the rack, wherein the guide mechanism comprises a first rubber shaft group, a second rubber shaft group and a third rubber shaft group which are arranged in parallel; the spray mechanism is arranged between the first rubber shaft group and the second rubber shaft group; the dryer is arranged between the second rubber shaft group and the third rubber shaft group; cleaning hairbrushes are arranged on the rack between the first rubber shaft group and the second rubber shaft group; support plates are arranged on the rack corresponding to the cleaning hairbrushes; a feed port and a discharge port are formed in the rack corresponding to the first rubber shaft group and the third rubber shaft group respectively; and sensors are arranged on the rack at the feed port and the discharge port. With the adoption of the mode, the linear plate processor is simple in structure, low in manufacturing cost, and uniform and stable in gluing; spare parts are easy to clean and replace; and the surface of a plate is not easy to scratch and wear.

Owner:虎丘影像(苏州)股份有限公司

X-ray film developing and drying integrated device for imaging department

InactiveCN111580337AEvenly stainedSave energyLiquid processing with progressive mechanical movementDrying/glazing processed materialMechanical engineeringIntegrated devices

The invention discloses an X-ray film developing and drying integrated device for the imaging department. The X-ray film developing and drying integrated device comprises a box body. The box body is internally divided into a developing chamber, a film washing chamber and a drying chamber through a first partition plate and a second partition plate which are longitudinally arranged. A main windingmechanism and an auxiliary winding mechanism which are connected through a traction rope are arranged on the two sides of the box body; a plurality of clamping pieces used for clamping X-ray films arearranged on the traction rope; and a notch allowing the traction rope with the clamped X-ray films to freely shuttle inside and outside the box body is formed in the box body. The X-ray films are sequentially brought into the developing chamber, the film washing chamber and the drying chamber in the box body through the moving traction rope to complete developing-washing-drying integrated assembly line operation, and convenience and rapidness are achieved.

Owner:昌乐县妇幼保健院

Drying device

InactiveUS6332279B1Drying solid materials with heatDrying gas arrangementsProcess engineeringHumidity

A drying device in which temperature and humidity of a gas flow fed into each of plural helical dryers in the form of a cylinder (i.e., temperature and humidity of an exhausted gas flow) can be each controlled independent of the other dryers. The drying device, is equipped with a casing. The casing includes therein at least a helical dryer 6 in the form of a cylinder for exhausting a drying gas flow fed therein out of gas distributed on its outer periphery to feed on a drying object, and an axial-flow blower 5 connected to an entrance side of the helical dryer for inspiring a gas flow exhausted out of the helical dryer into the casing inside the same casing and feeding into the helical dryer again to circulate said gas flow, in which a part of a gas flow inspired by the axial-flow blower serves as a gas flow having a depressed dew point which results from splitting a gas flow exhausted out of the helical dryer and depressing the dew point of the split gas flow in a dehumidifying facility 1 located outside the casing.

Owner:FUJIFILM HLDG CORP +1

Drying device and drying method

InactiveUS20050163502A1Satisfactory heating efficiencyPrevent foggingDrying solid materials with heatPhotomechanical coating apparatusInfraredEngineering

A drying device, which dries a photosensitive layer of a photosensitive planographic printing plate using infrared rays, includes an infrared emitting device and a filter that is arranged between the photosensitive planographic printing plate conveyed through the drying device and the infrared emitting device and that blocks a predetermined range of wavelength. More specifically, the filter is arranged between a web that is conveyed through the drying device and a mid-infrared radiator, so as to block 30% or more of wavelengths of 1 μm or less. As a result, fogging on a photosensitive coating layer can be prevented, and high heating efficiency can be achieved.

Owner:FUJIFILM HLDG CORP +1

Radiograph drying machine

InactiveCN107479322AAvoid development blurDevelopment effectDrying/glazing processed materialTemperature controlEngineering

The invention discloses a radiograph drying machine. The machine includes a drying machine shell, a machine door, radiograph hanging rods and a temperature control hot-air machine, wherein one side of the drying machine shell is provided with the machine door, and the top of the drying machine shell is provided with a cross plate through a connecting rod; the bottom of the cross plate is provided with the multiple radiograph hanging rods, and the two opposite sides of the interior of the drying machine shell are provided with side guide rails. According to the radiograph drying machine, through the arrangement of the temperature control hot-air machine, temperature control drying can be conducted on radiographs inside the drying machine shell so as to avoid that radiograph developing is vague since the temperature is higher than 55 DEG C, which effectively improves the drying quality of the drying machine to the radiographs; moreover, the temperature control hot-air machine can move in the drying machine; on the one hand, the drying efficiency of the radiographs is improved, the drying cost of the radiographs is reduced, and the caused pollution to the radiographs when the radiographs are dried is prevented; on the other hand, the radiograph drying uniformity of the drying machine is improved, and it is avoided that uneven drying caused by heating source fixing influences developing.

Owner:武汉时代金丰仪器有限公司

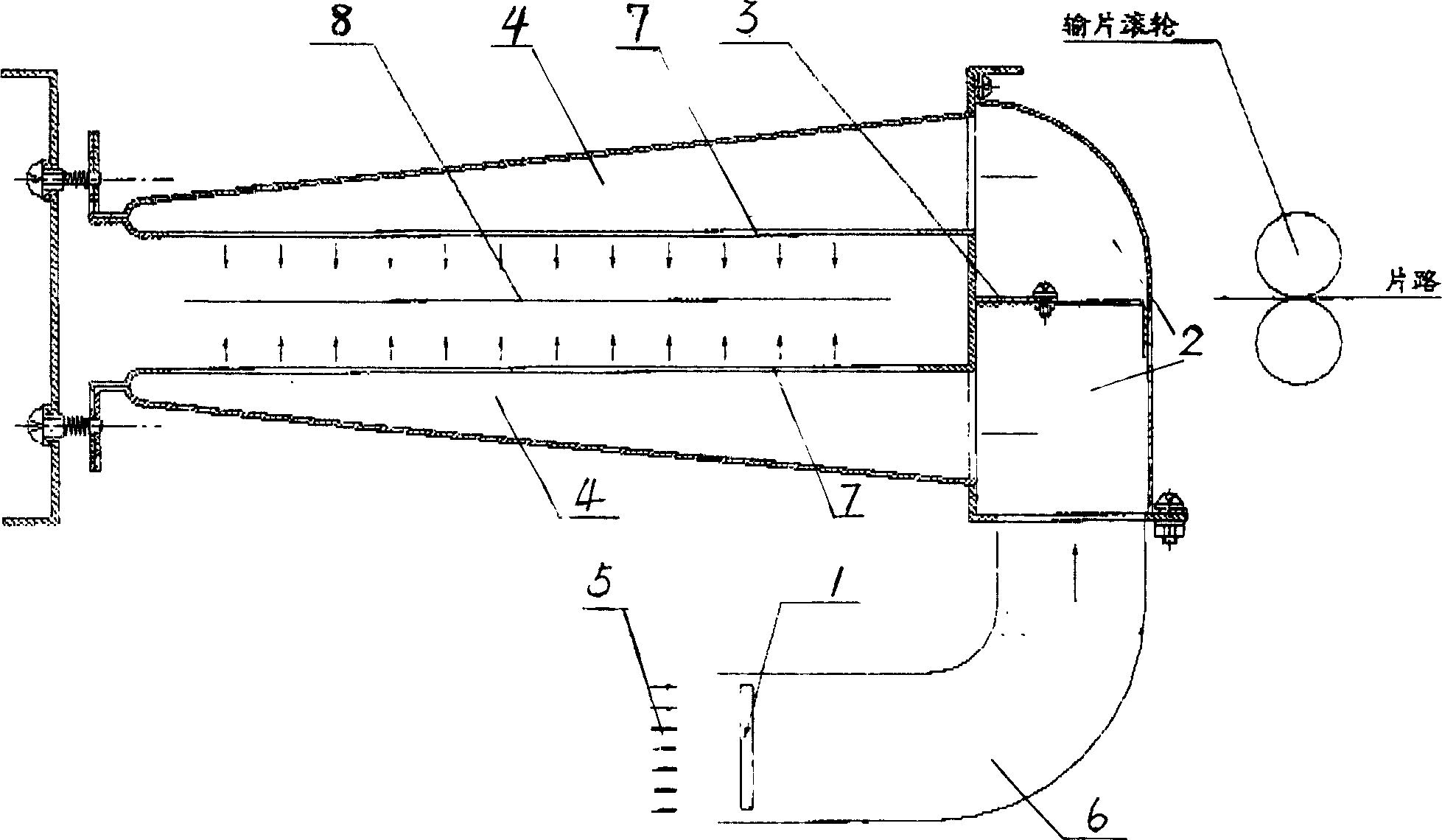

Drying system of film developing machine

The present invention relates to one drying system to dry film homogeneously inside one conic air duct by means of the heat effect of heating PTC ceramic element. The drying system consists of blower, air duct, heating element, hot blast tank and air pipes. The blower blows blast via air duct to the heating PTC ceramic element via air duct to generate heat effect. Hot blast entering the hot blast tank from the air duct is divided into two parts to enter separately to the upper and the lower conic air pipes from their large ports and the two parts, after passing through the conic surface of the air pipes, blow to the films through the air outlet slits. The present invention has no damage of film and the peripheral parts owing to the conic air pipes to make the films to obtain homogeneous wind and heat.

Owner:SHANGHAI SHENBEI OFFICE MASCH CO LTD

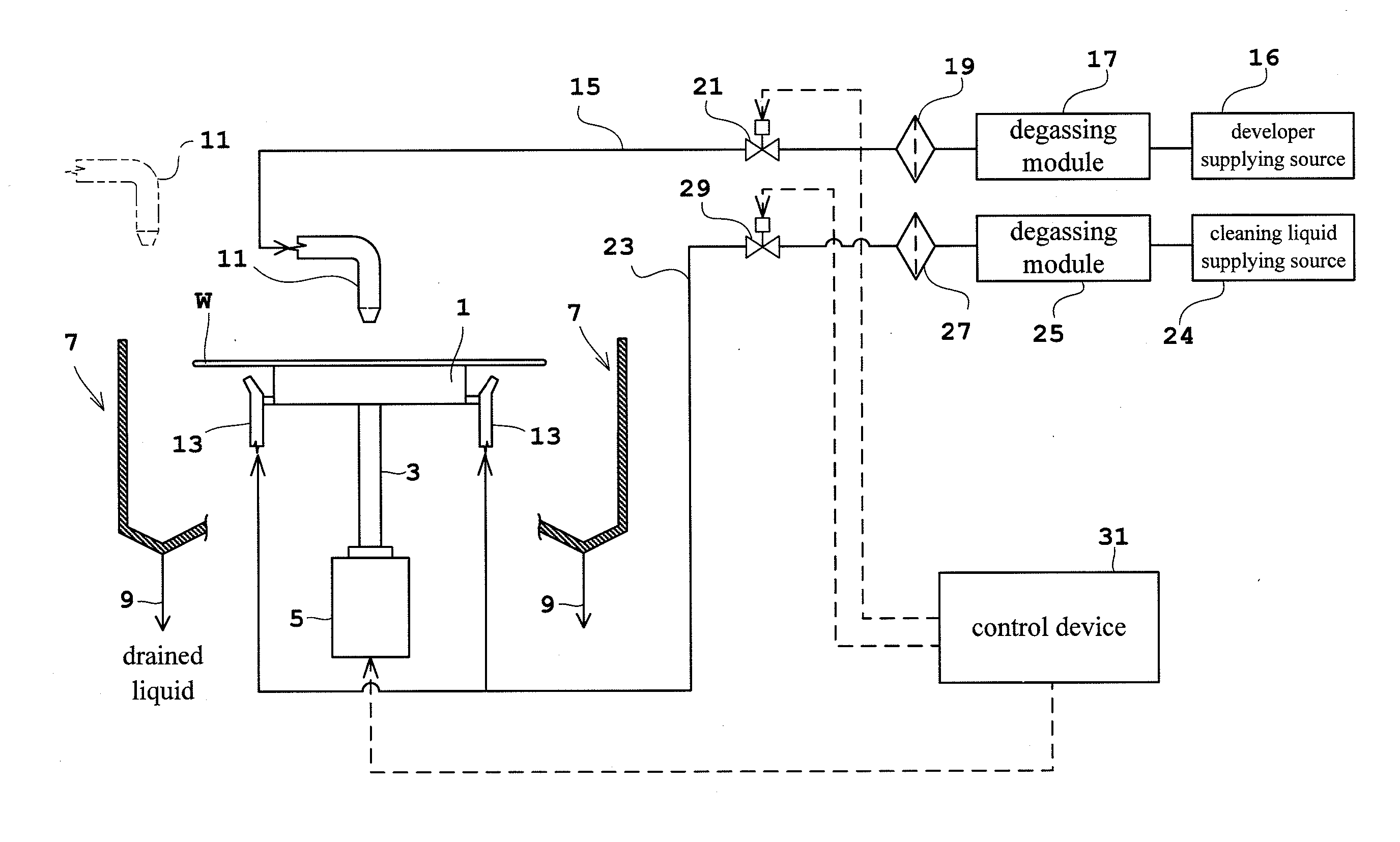

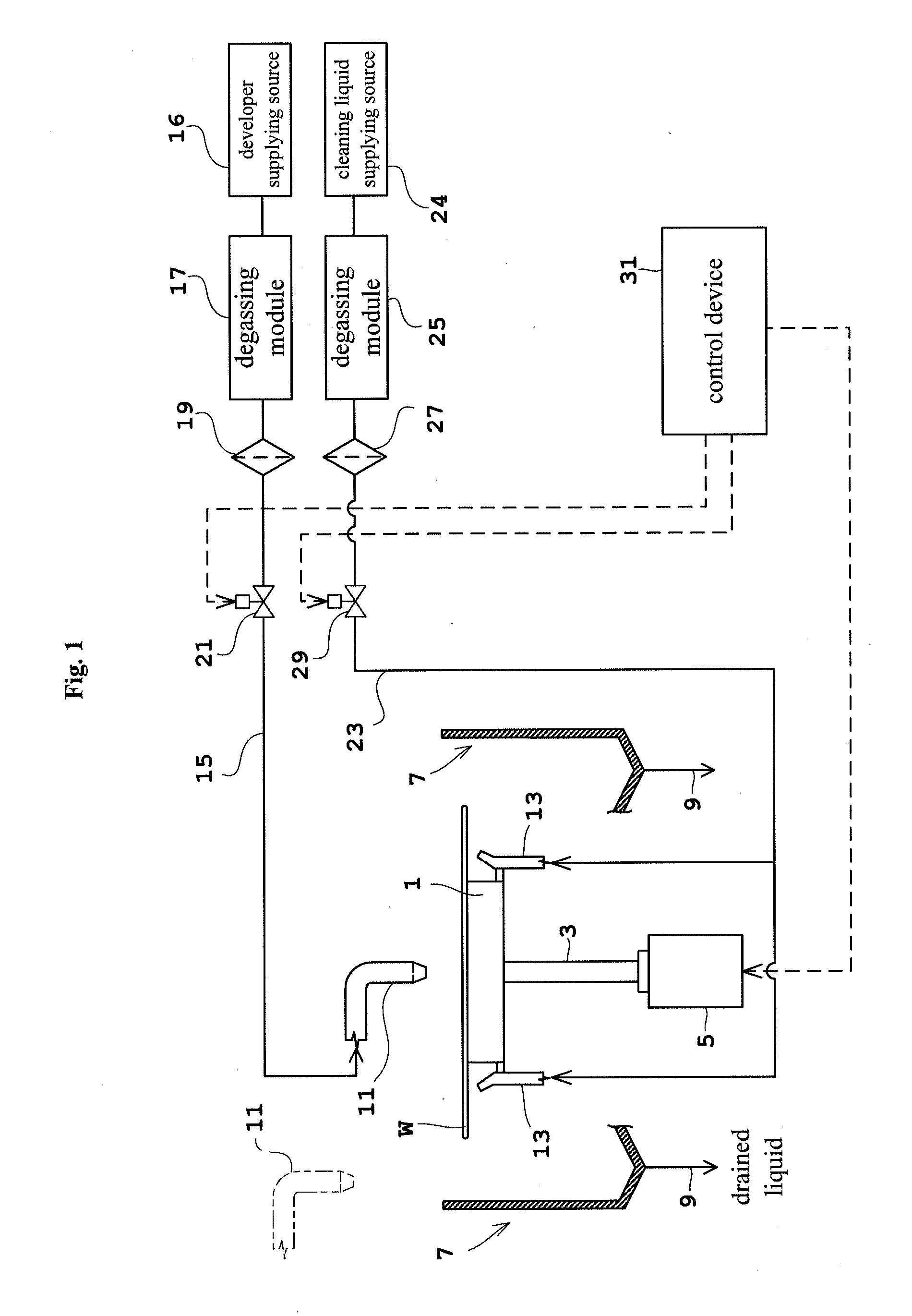

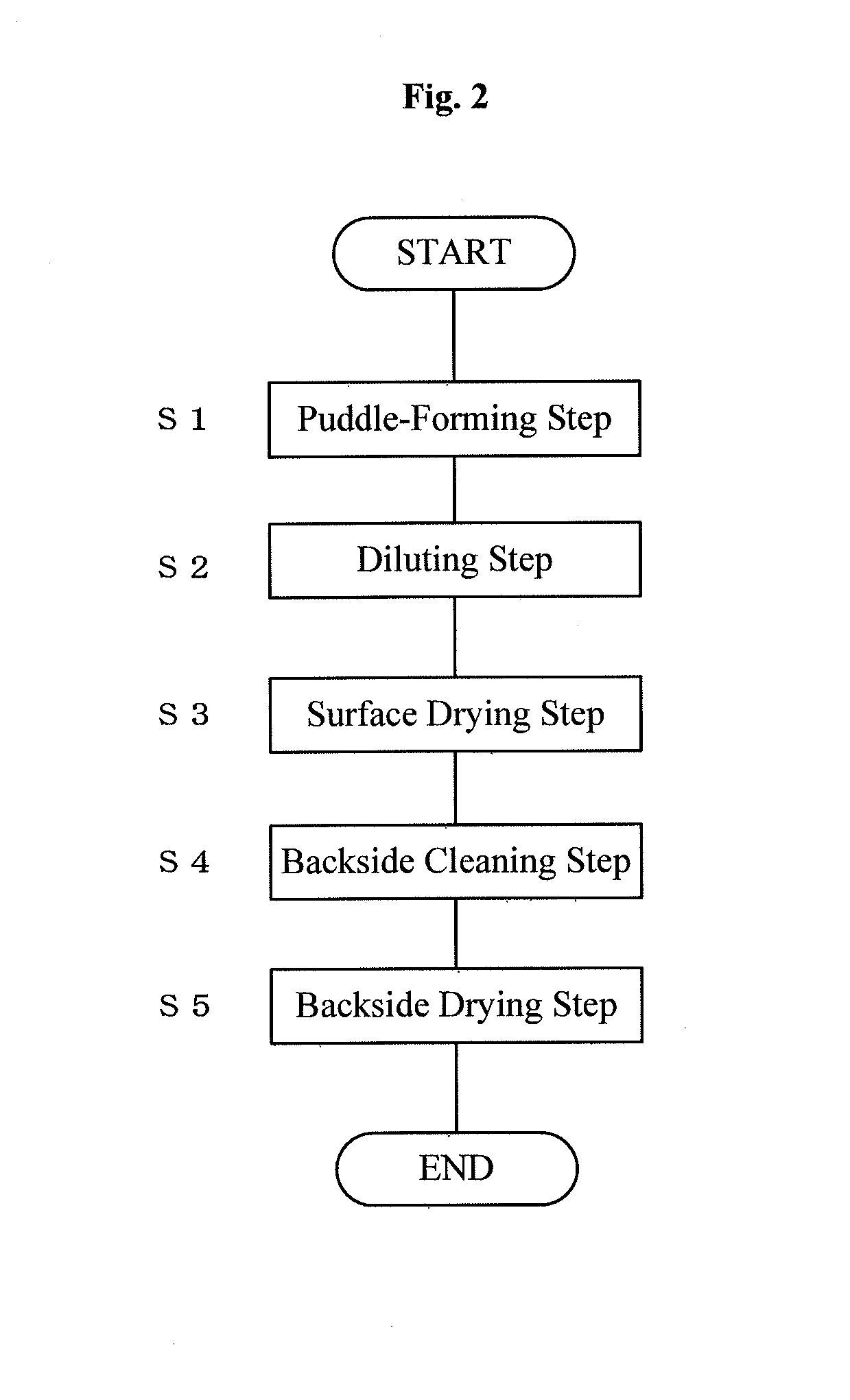

Negative developing method and negative developing apparatus

ActiveUS20160282722A1Quality improvementDrying/glazing processed materialPhotosensitive material processingResistOrganic solvent

Disclosed is a negative developing method including a puddle-forming step, a diluting step, and a surface drying step. In the puddle-forming step, developer containing an organic solvent is supplied to a resist film formed on a surface of the substrate and keeping a puddle of the developer on the resist film. In the diluting step, a concentration of a dissolution product dissolved in the developer on the resist film is diluted by additionally supplying the developer containing the organic solvent to the resist film after the puddle-forming step. In the surface drying step, the surface of the substrate is dried by rotating the substrate after the diluting step.

Owner:DAINIPPON SCREEN MTG CO LTD

Developing machine film drying device

InactiveCN107290927AFast imagingIncrease the areaDrying/glazing processed materialPulp and paper industryExhaust pipe

The invention discloses a film drying device of a film processor, which includes a fixing device, a drying device and a heating device. The drying device includes a drying box, a base and a feeding port. It is arranged at the bottom of the drying box, and the fixing device is arranged inside the drying box. The heating device includes an electric heating wire and an exhaust fan. A fixing ring is arranged at the curved pipe of the exhaust fan, and the electric heating wire is connected together through a metal frame and the fixing ring. There is an air outlet plate on the top of the drying box, the top of the air outlet plate is connected to the exhaust pipe, and there are several curved pipes on the bottom of the air outlet plate. The fixing device includes a mounting seat, a hydraulic rod and a fixing rod. Reduce the drying wind speed, so that the hot air overflows slowly, the drying quality is higher, and it is not easy to leave marks. At the same time, the corners of the film can be fixed, and the drying is more uniform and thorough, which is conducive to the rapid imaging of the film. It is worth promoting.

Owner:房立洲

Film drying box for imaging department

InactiveCN108519724AGuaranteed drying effectImprove reliabilityDrying/glazing processed materialAmbient humidityEngineering

Owner:庄素藤

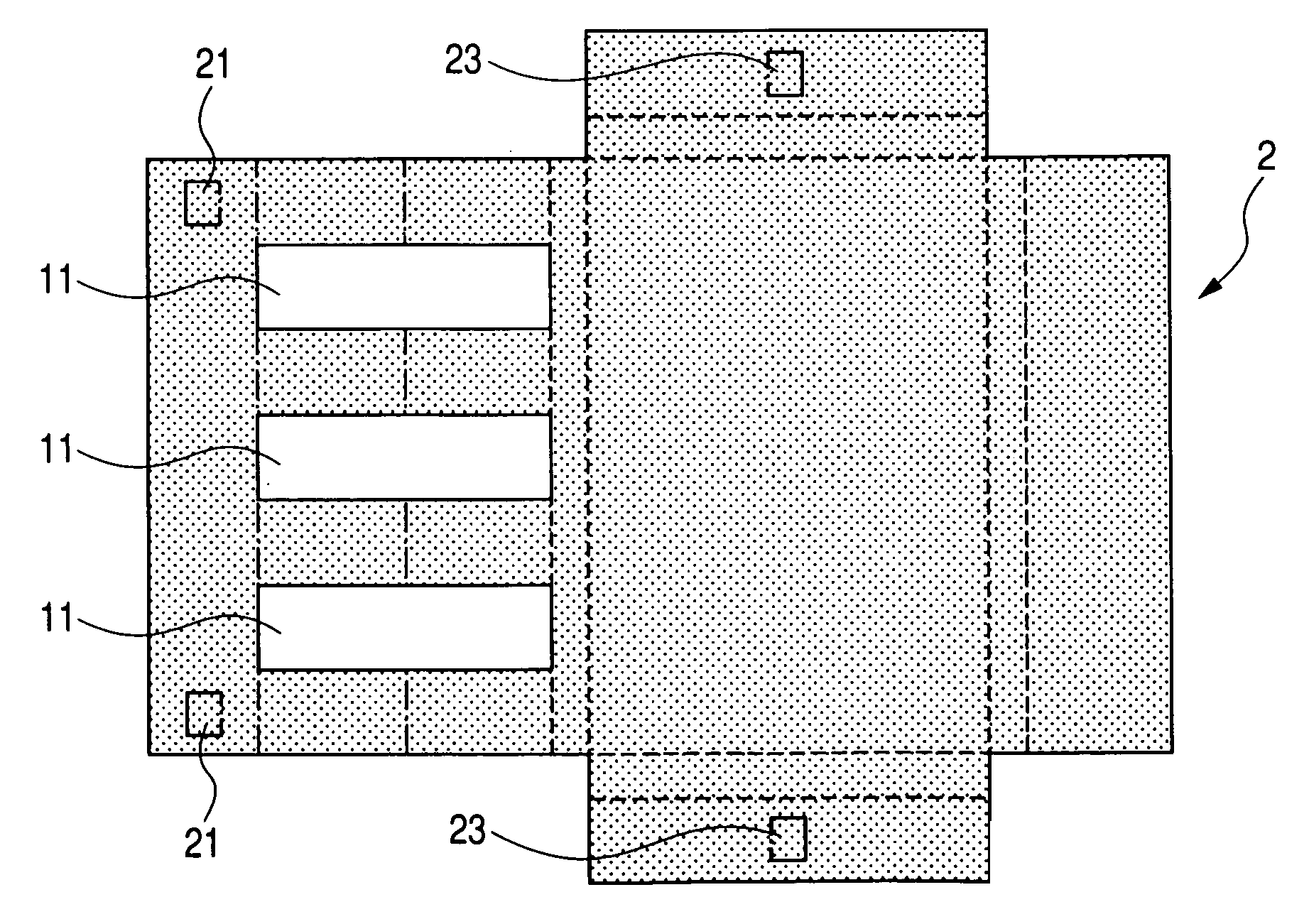

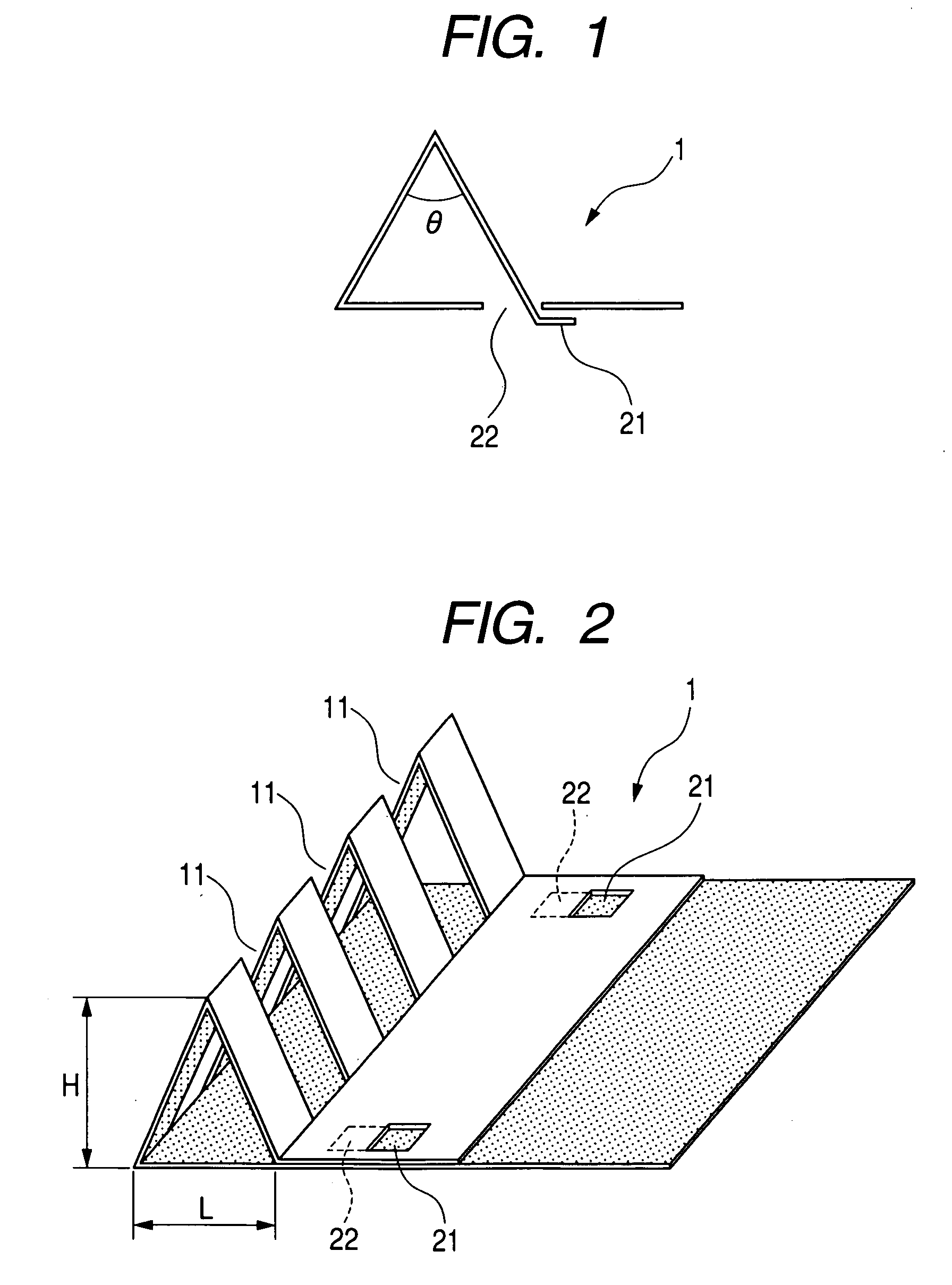

Tool, method for drying recording sheet using the same and package with tool

InactiveUS20050275703A1Simply and stably driedStably stand the recording sheetsDrying/glazing processed materialOther printing apparatusEngineeringRestoring force

Disclosed herein is a tool having an opening capable of holding a recording sheet by being raised in a gable form, which comprises a hook capable of retaining the gable form utilizing a restoring-force when formed in the gable form, and a hook hole into which the hook can fit. The tool is used to stand the recording sheets subjected to recording in the opening raised in the gable form, thereby drying the recording sheet.

Owner:CANON KK

A portable film rack drying device

InactiveCN106154734BSolve the problem of being dry and not portableAvoid sorting workDrying/glazing processed materialEngineeringMechanical engineering

Owner:SHANGHAI INST OF TECH

Medical thermosensitive film drying device

ActiveCN113934106AAvoid damageGuaranteed drying qualityDrying/glazing processed materialRadiationComposite materialAir blower

The invention discloses a medical thermosensitive film drying device, and relates to the technical field of medical instruments. The medical thermosensitive film drying device comprises a body and an air blower, the top surface of the body is provided with a through hole, the air blower is arranged on the left side of a displacement plate, and the body is internally provided with a displacement part used for driving the displacement plate to stably displace towards a thermosensitive film, and being quickly far away when being far away from the thermosensitive film. A driving mechanism used for driving the displacement part to operate is arranged on the inner wall of the body, two fixed short plates are fixedly connected to the inner wall of the body, and the opposite sides of the two fixed short plates are jointly and fixedly connected with a disinfection lamp. Through mutual cooperation of the structures, the device has the effects of drying a thermosensitive film in a variable-pitch manner, preventing the film from being damaged and disinfecting the thermosensitive film, and solves the problems that in a traditional mode, the fixed-point temperature of the film is rapidly increased along with the continuous drying process, the film is prone to being damaged, and the disinfection function is not achieved.

Owner:深圳市柯尼达医疗设备有限公司

Photographic film developing apparatus

InactiveUS20030113113A1Liquid processing by liquid spraysLiquid processing with progressive mechanical movementEmulsionBiochemical engineering

A photographic film developing apparatus maintains a photographic film, a developer solution and a second processing solution at a specific temperature while performing film development operation by directly applying the individual solutions to an emulsion side of the photographic film. After the developer solution and the second processing solution have been applied from respective processing solution application heads to the emulsion side of the photographic film, the quantity of each solution on the emulsion side is adjusted to form a layer of a specified thickness. While transfer belts advance each successive portion of the photographic film up to a processing solution wipe-out device, heaters provided close to the transfer belts heat the individual solutions applied to the photographic film through the transfer belts to maintain the solutions at the specific temperature.

Owner:NORITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com