Pneumoconiosis film air drying processor

A processing machine and film technology, applied in the direction of drying/glazing processing materials, etc., can solve the problems of inconvenient work, long drying time, affecting the quality of the film, etc., and achieve the effect of reducing the workload and promoting the application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

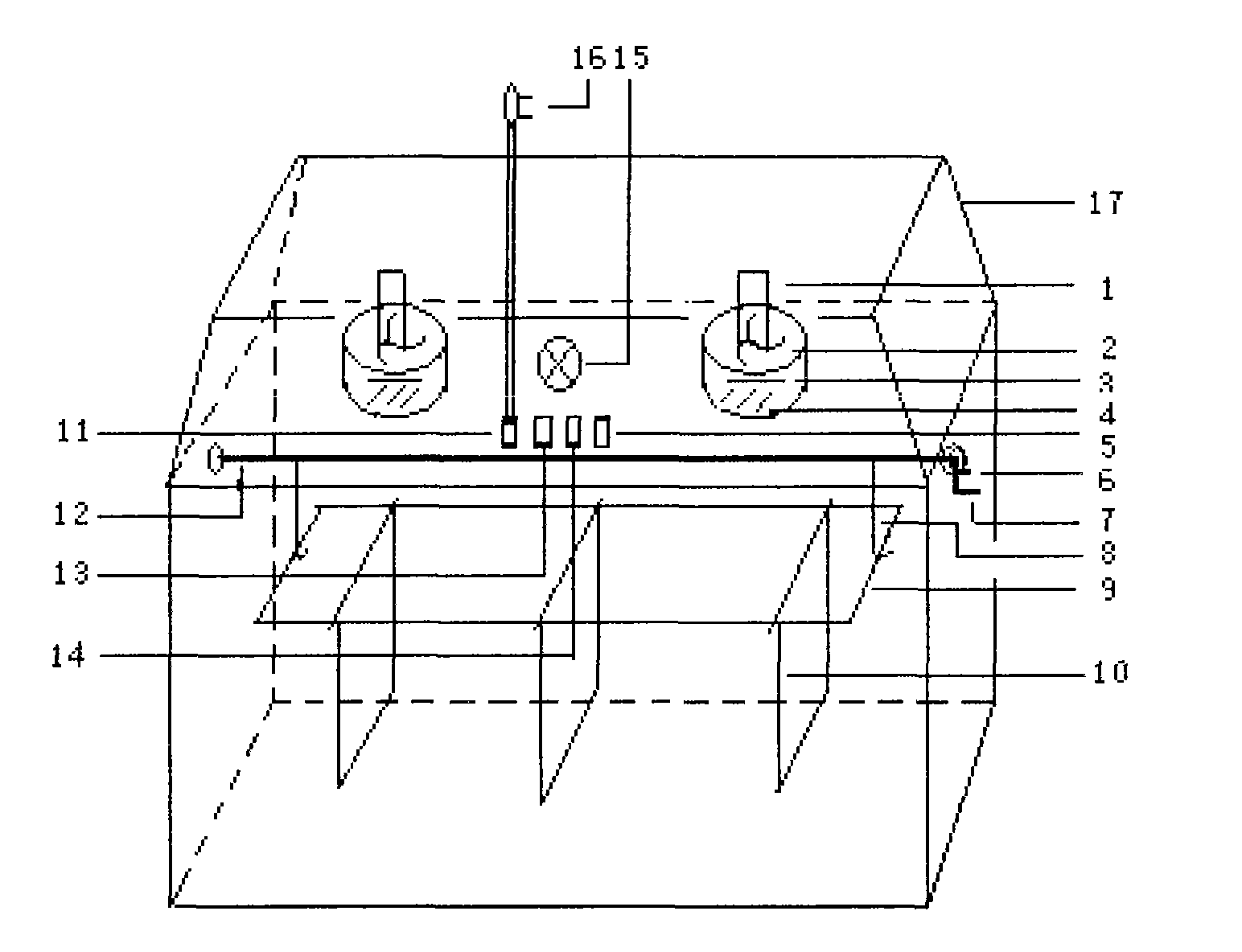

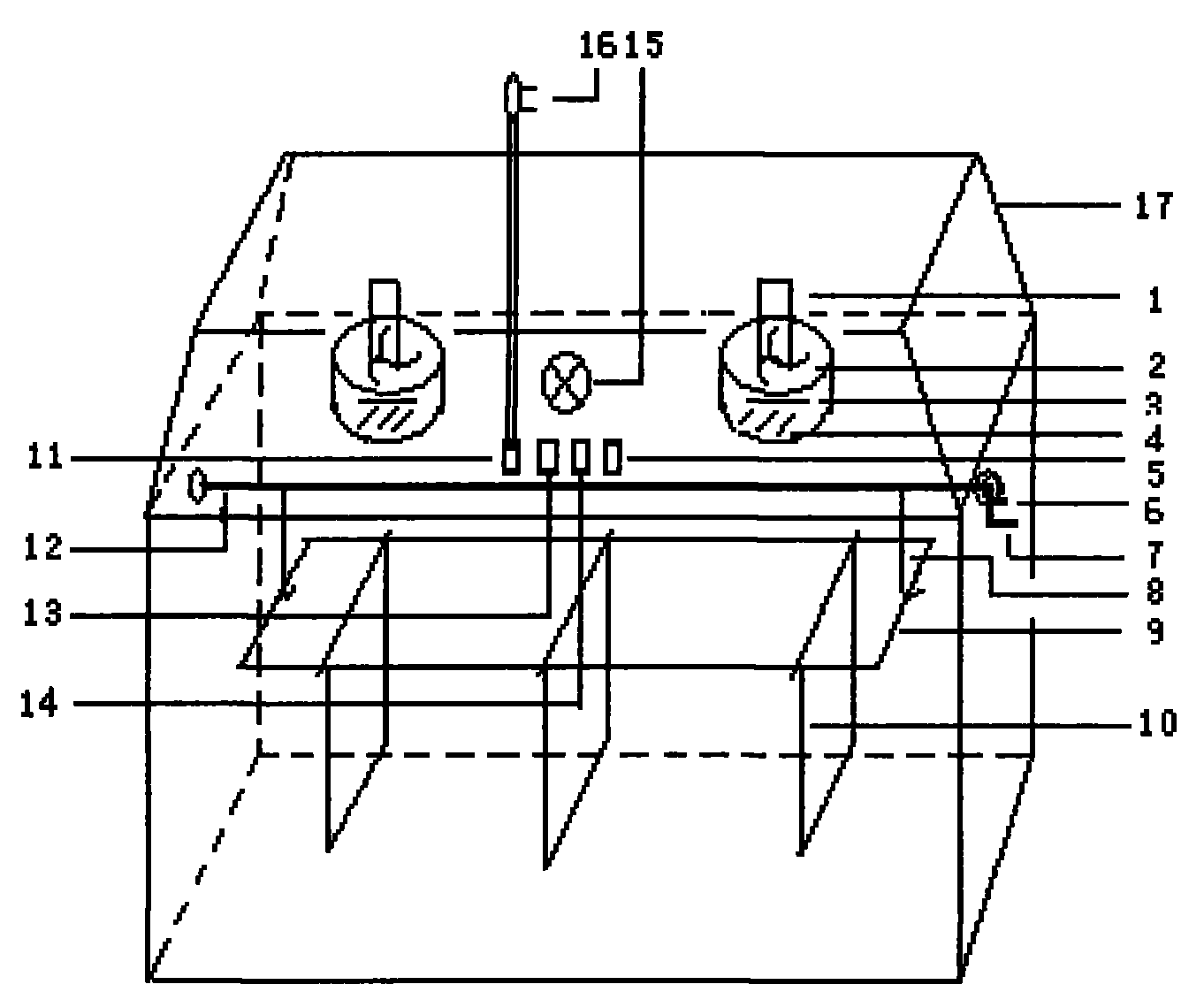

[0008] This air-drying processing machine mainly is made up of two parts of temperature-controlled air-drying device and film suspension device, and its temperature-controlled air-drying device is made of fan 2 driven by motor 1, and this device is fixedly installed on the top of cabinet body 17. The film suspension device is composed of a shaft rod 12, a crank 7, a locking device 6, a wire rope 8, and a film carrier 9, wherein the shaft rod 12 is installed on the chassis body 17, and at least one end of the shaft rod 12 is equipped with a locking device. The crank handle 7 of 6, the steel wire rope 8 is wound on the shaft rod 12, and the outer end of the steel wire rope 8 is connected with the film carrier 9 where the film clip 10 is installed to form.

[0009] In order to expand the wind-passing area of the fan 2 and increase the softness of the wind, a wind guide vane 4 is installed on the support in front of the fan 2 to continuously change the flow direction and size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com