Developing machine film drying device

A technology of a drying device and a film processor, applied in the field of film processors, which can solve problems such as uneven drying, unreasonable control of the drying wind speed, and traces left on the film surface, so as to ensure the drying quality and Dries evenly and thoroughly, drying thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

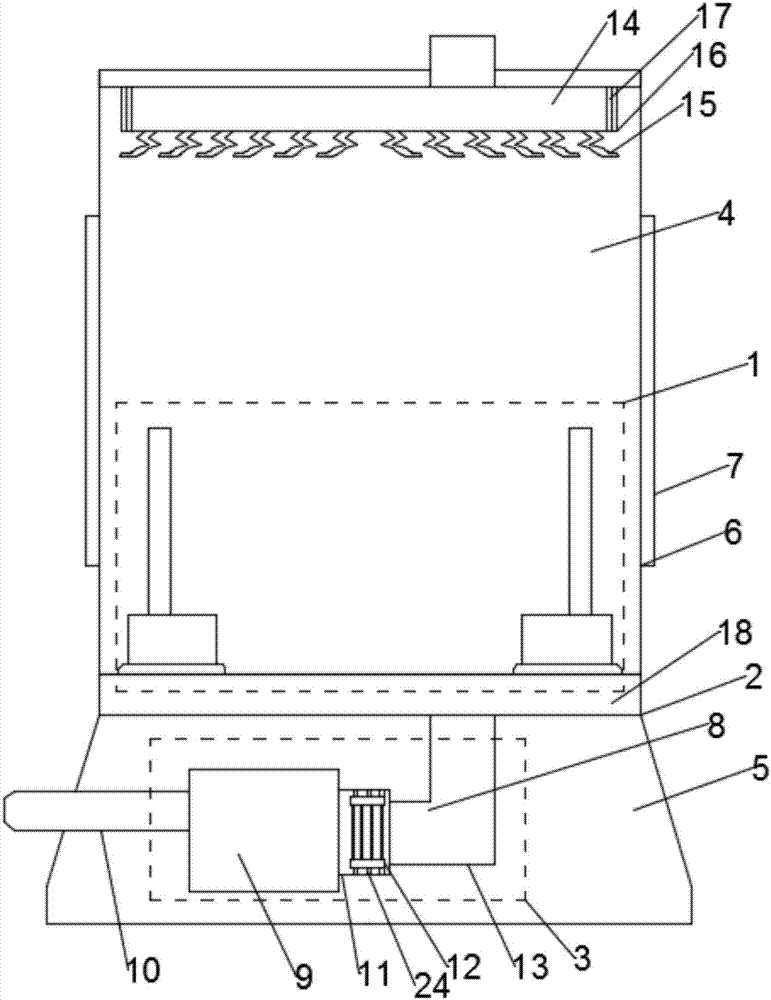

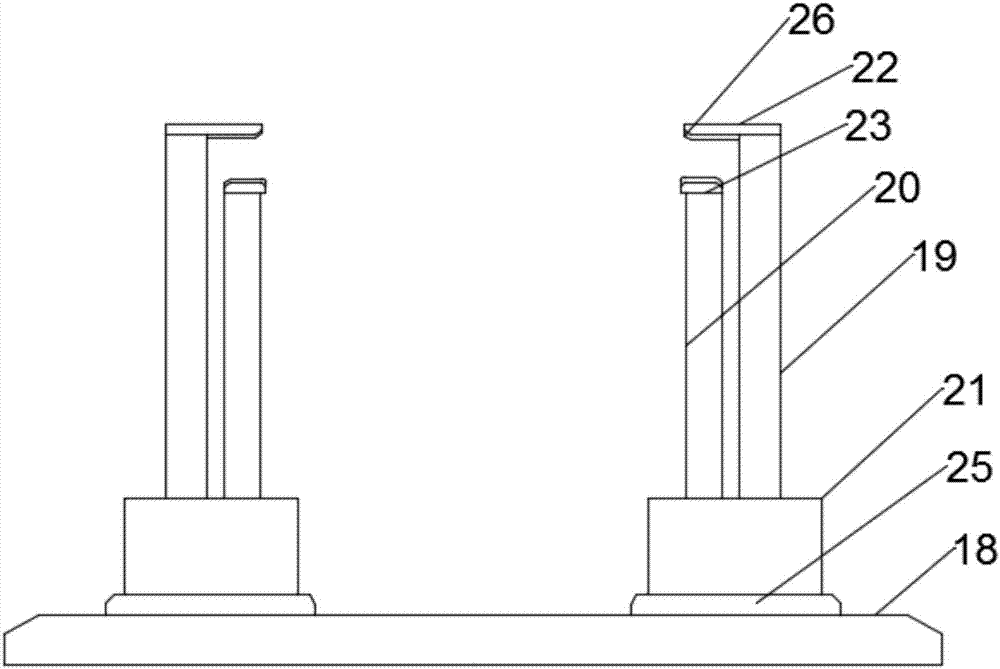

[0020] see figure 1 , figure 2 , the present invention provides a technical solution: a film drying device of a film processor, including a fixing device 1, a drying device 2 and a heating device 3, and the drying device 2 includes a drying box 4, a base 5 and a feed port 6 , the feed port 6 is arranged on both sides of the drying box 4, the film is put into the film through the feeding port 6, the base 5 is arranged at the bottom of the drying box 4, and the fixing device 1 is arranged inside the drying box 4, so The heating device 3 includes an electric heating wire 8 and an exhaust fan 9, and the exhaust fan 9 draws in air through an external air inlet pipe 10, and a fixed ring 11 is provided at the curved pipe of the exhaust fan 9, and the fixed ring 11 is provided with a metal frame 12 inside, the electric heating wire 8 is connected together through the metal frame 12 and the fixed ring 11, the exhaust fan 9 discharges the gas into the drying box 4 through the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com