Drying apparatus

A drying device and air technology, applied in the direction of drying gas arrangement, progressive dryer, drying, etc., can solve the problems of inaccurate measurement of concentration, poor thermal efficiency, long time required for temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

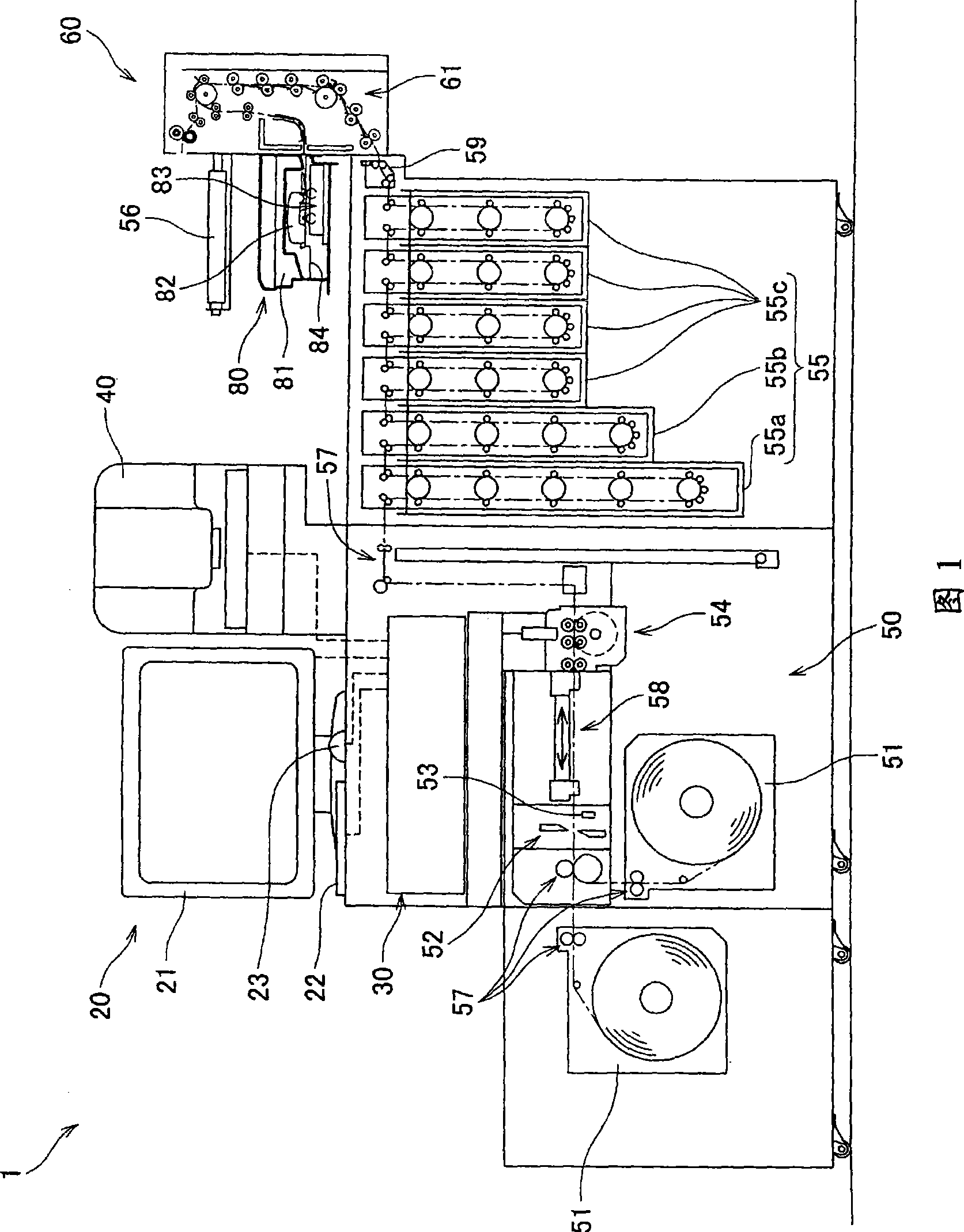

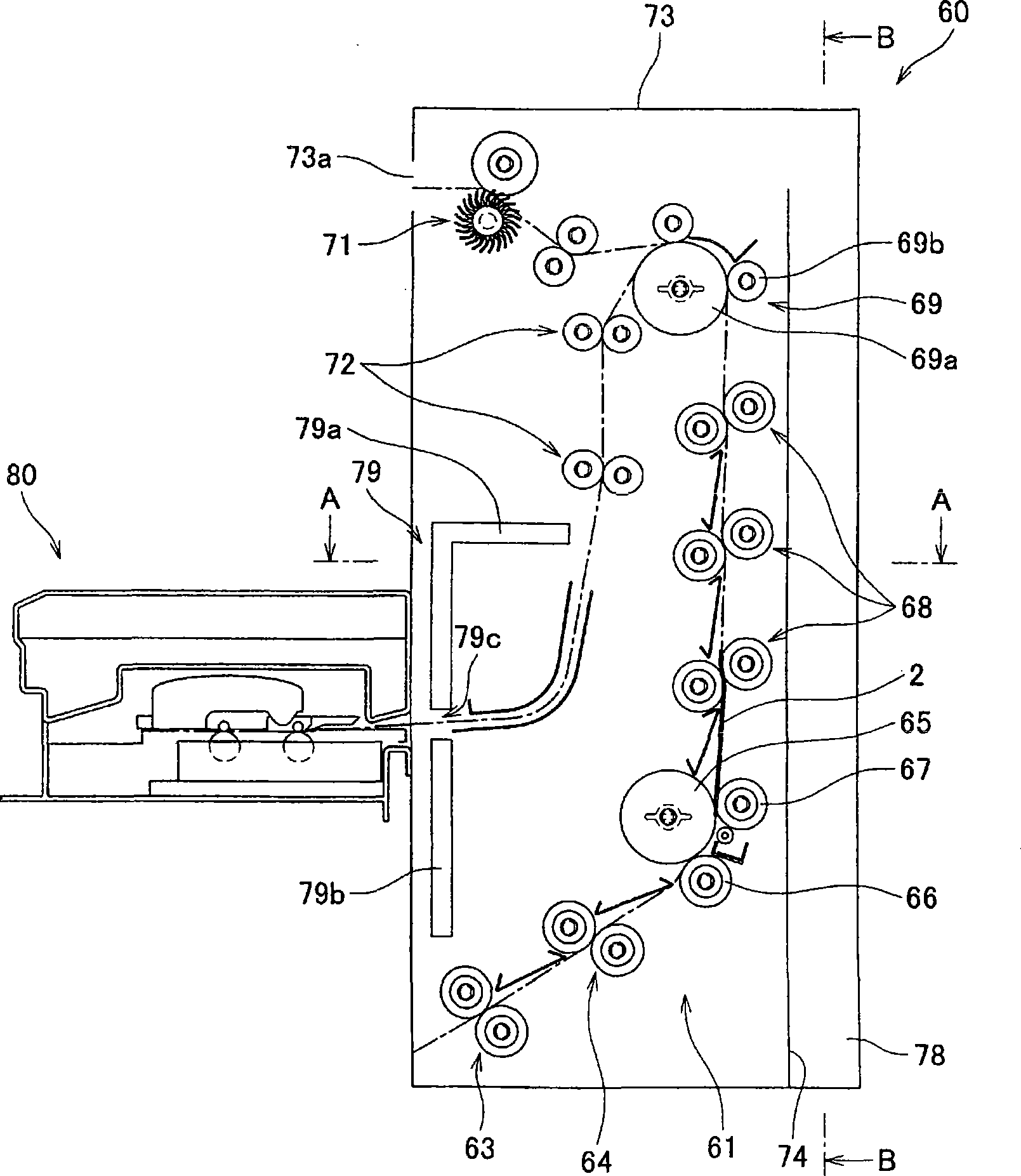

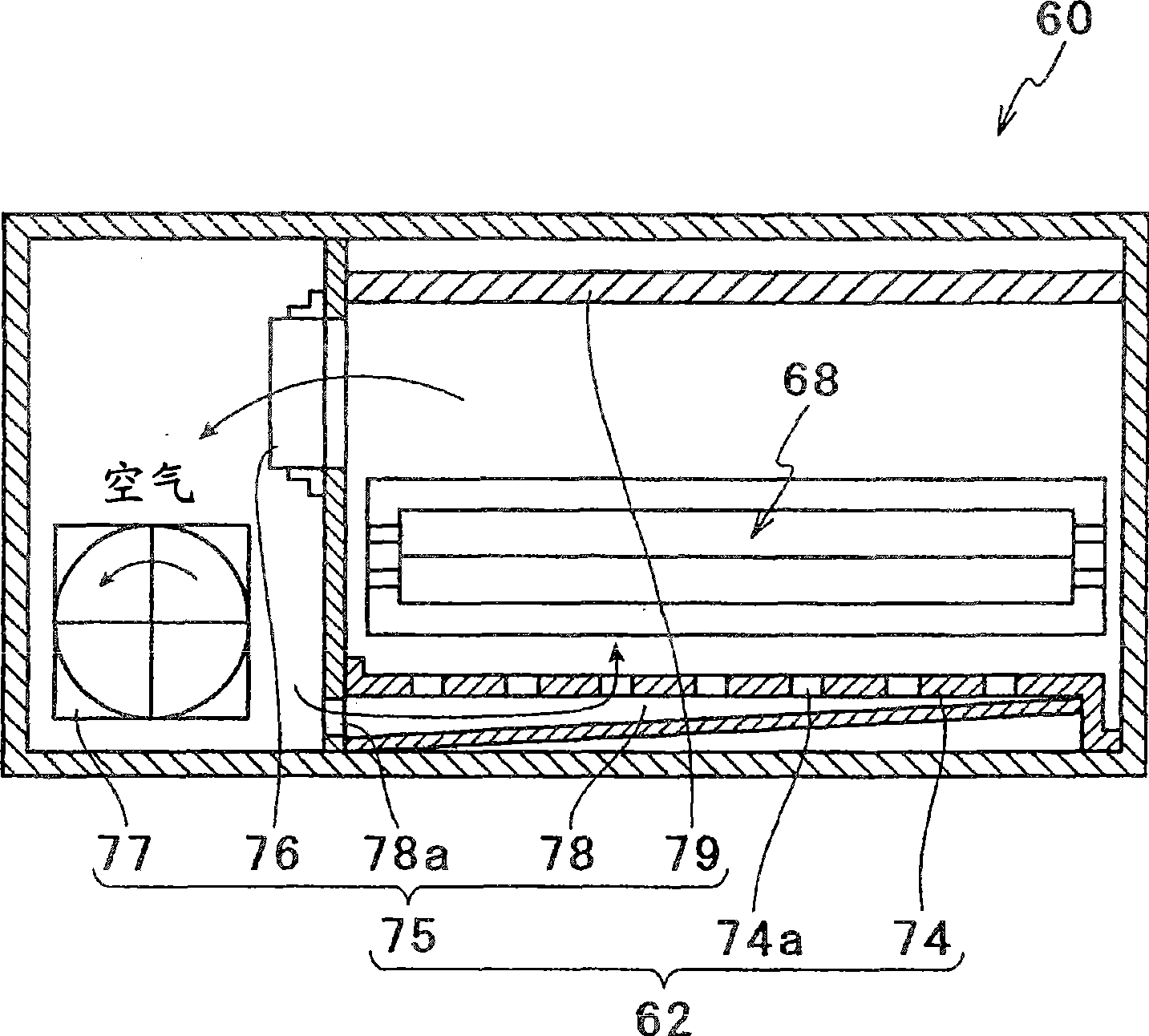

[0017] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a schematic configuration diagram of a photograph processing apparatus 1 including a drying unit 60 (drying device) according to an embodiment of the present invention.

[0018] As shown in Figure 1, the photo processing apparatus 1 comprising the drying section 60 involved in the present embodiment is a photo processing apparatus utilizing a digital scanning exposure method of a laser beam, and includes an image input section 20, a printing section 50, a drying section 50, and a drying section 60. part 60, concentration measuring part (concentration measuring device) 80.

[0019] In the image input section 20, the processing of reading the image recorded in each frame of the developed film, the processing of digitally converting the read image data, and the recording of the image data recorded in the flash memory etc. are carried out. The digital ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com