X-ray film developing and drying integrated device for imaging department

A film and imaging technology, applied in the field of medical imaging, can solve the problems of troublesome operation, insufficient continuous operation, low time utilization rate, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

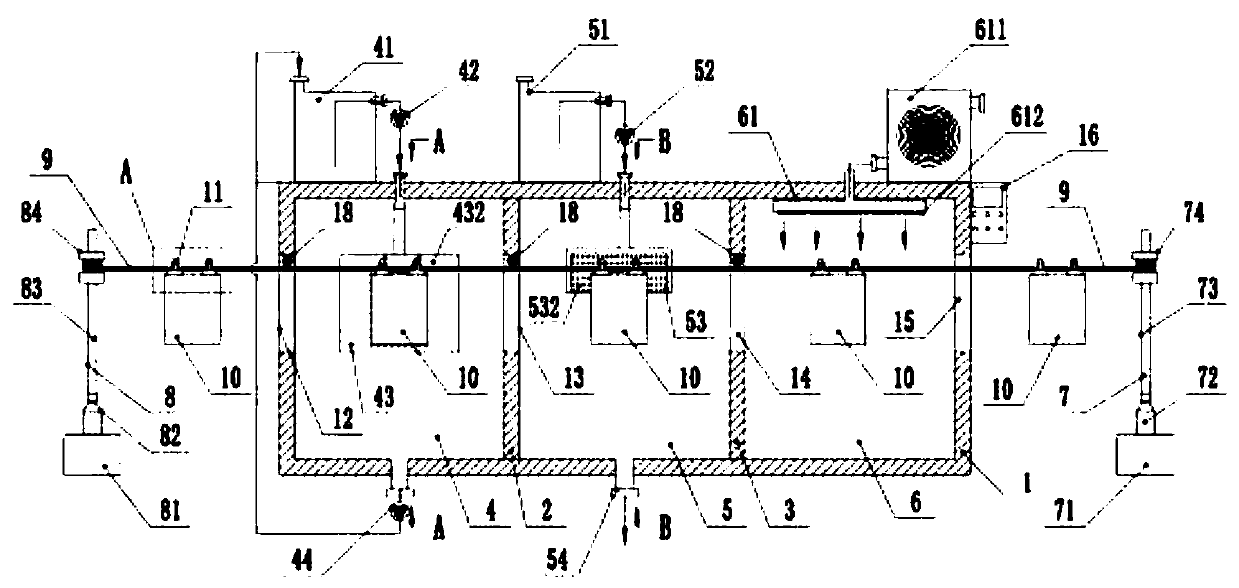

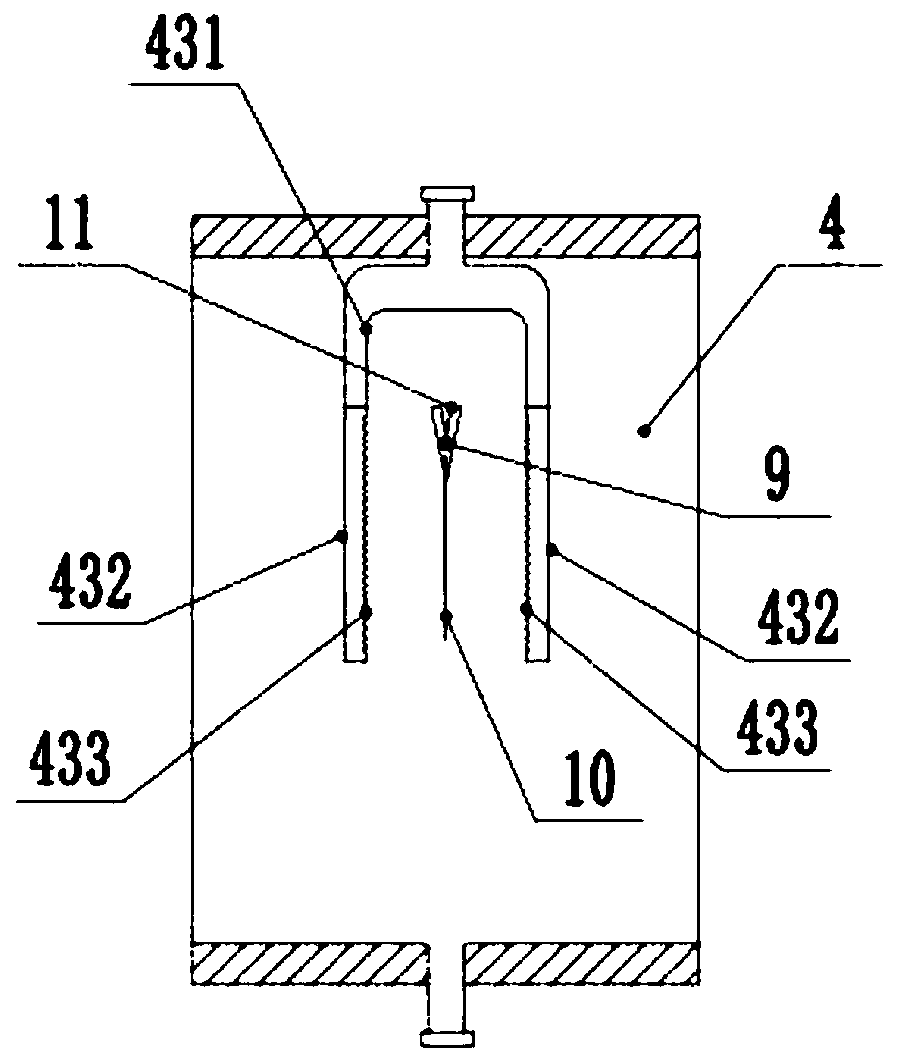

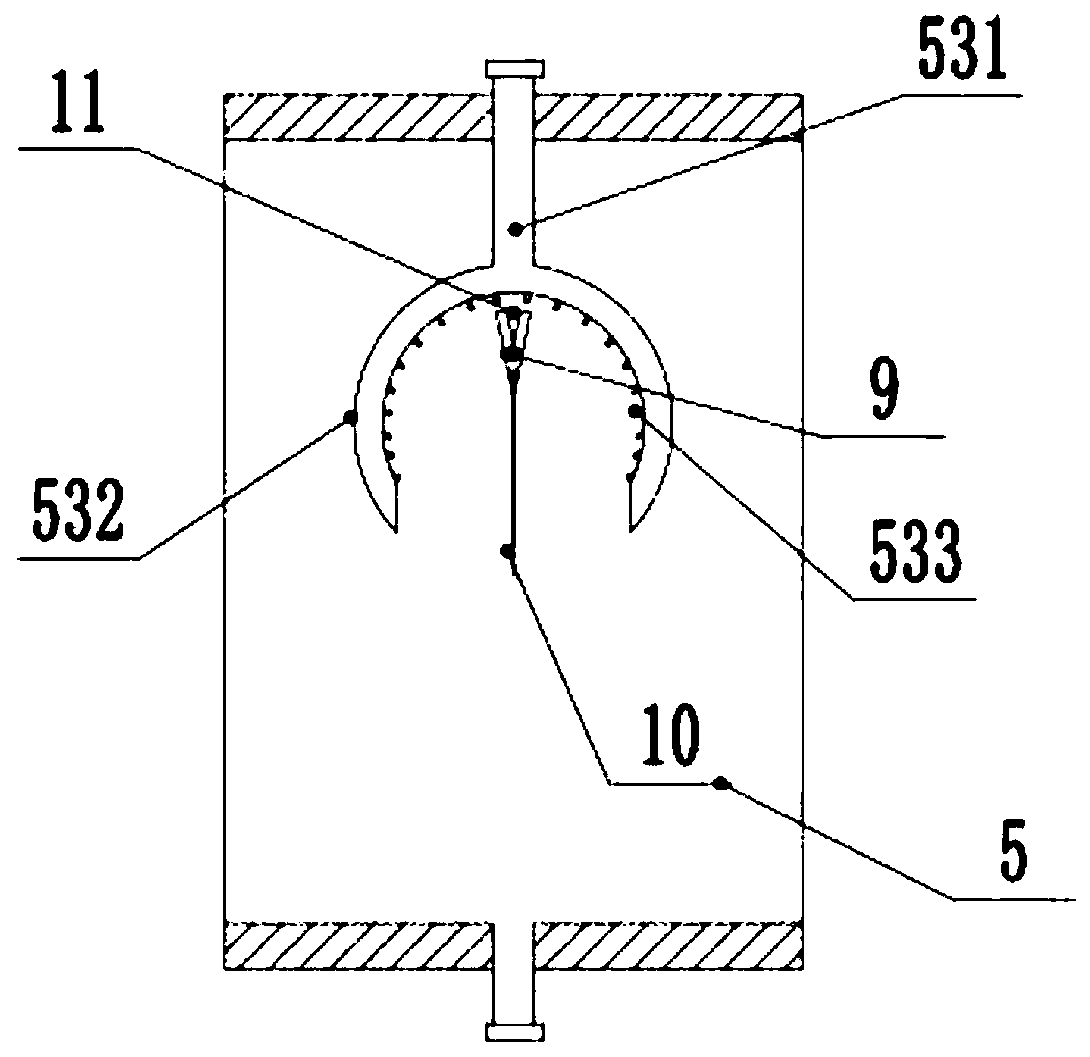

[0032] Such as figure 1 As shown, an integrated device for developing and drying X-ray films used in imaging departments includes: a box body 1, and the inside of the box body 1 is divided into a developing room 4 by a first partition 2 and a second partition 3 arranged vertically , the film developing chamber 5 and the drying chamber 6; the first notch 12 and the second notch respectively provided on the left side wall of the box body 1, the first partition plate 2, the second partition plate 3 and the right side wall of the box body 1 in sequence 13. The third notch 14 and the fourth notch 15, the first notch 12, the second notch 13, the third notch 14 and the fourth notch 15 are located on the same horizontal line, and are used to clamp the traction rope 9 holding the X-ray film 10 in the Free shuttle inside and outside the cabinet 1;

[0033] Such as figure 1 As shown, the main winding mechanism 7 and the auxiliary winding mechanism 8 located on the left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com