Road wheel for tracked vehicle

A road wheel and vehicle technology, applied to tracked vehicles, wheels, vehicle parts, etc., can solve the problems of poor track stability, low service life, large dynamic load, etc., and achieve the effects of stable driving, improved service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

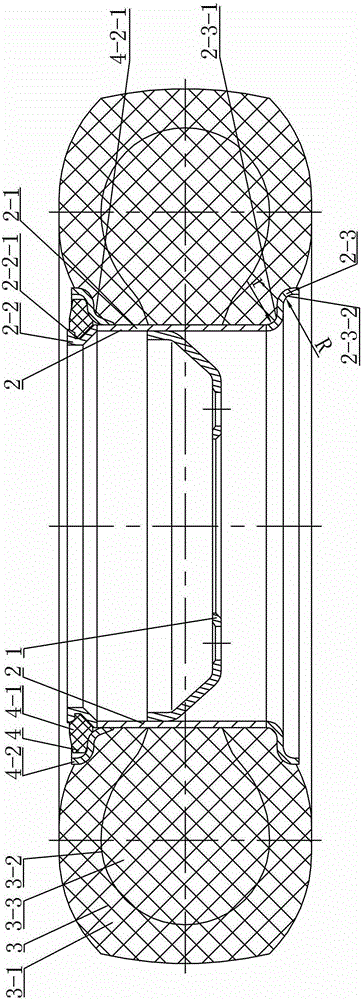

[0008] Specific implementation mode one: combine figure 1 This embodiment is described. A road wheel for a crawler vehicle in this embodiment includes a hub 1, a rim 2, a tire 3, and a side ring 4. The cross section of the hub 1 is shaped like a 〔, and the large end of the hub 1 is inserted into the On the rim 2 and the two are made into one, the side ring 4 is composed of a snap ring 4-1 and a retaining ring 4-2, the snap ring 4-1 and the retaining ring 4-2 are made into one, one side of the rim A snap ring 4-1 is installed, and a tire 3 is inserted between the other side of the rim 2 and the side ring 4. The tire 3 is a solid tire, and the tire 3 includes an outer layer 3-1 and an intermediate layer 3-2. And the inner layer 3-3, the material of the outer layer 3-1 is ply material, the material of the middle layer 3-2 is carbon fiber rubber material, and the material of the inner layer 3-3 is natural rubber or synthetic rubber material.

[0009] The outer layer of the tire o...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the rim 2 in this embodiment is composed of a cylinder body 2-1, a card body 2-2 and a support body 2-3, the card body 2-2 is a rotating body, and the support body 2-3 It is a rotating body, one end of the cylinder 2-2 is connected with the card body 2-2, the other end of the cylinder 2-1 is connected with the support body 2-3, and the cylinder body 2-1, the card body 2-2 and the support body 2-3 The three are made into one body, the end surface of the card body 2-2 away from the axis of the cylinder body 2-1 is provided with a circle of first grooves 2-2-1, and the snap ring 4-1 is installed in the first groove 2 - In 2-1, the shape of the retaining ring 4-2 is consistent with the shape of the supporting body 2-3, and a ring of second grooves is arranged on the end face of the retaining ring 4-2 away from the first groove 2-2-1 4-2-1, a third groove 2-3-1 is provided on the end surfa...

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the second groove 4-2-1 in this embodiment is an arc-shaped groove, and the third groove 2-3-1 is an arc-shaped groove. Such arrangement facilitates tire insertion and meets actual needs. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com