High-strength rivet and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the direction of rivets, can solve problems such as the limitation of the connection space structure, the lengthening of the structure size of the connection part, and the inability to meet the structural strength requirements, so as to improve the riveted connection strength, meet the space position requirements, and be economical. Effects of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

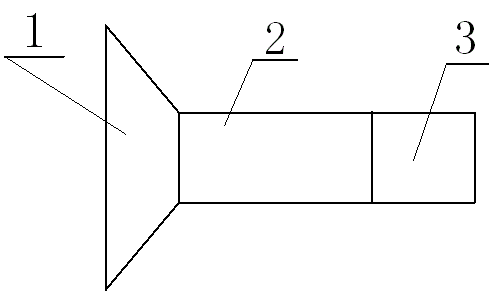

[0009] figure 1 As shown, a high-strength rivet is designed in sections, and its structure is divided into rivet head 1, high-strength end 2 and riveting end 3. The high-strength end 2 is located between the rivet head 1 and the riveting end 3, and is the main stress-bearing part; the riveting end 3 is the riveting part. The material of the high-strength rivet of the present invention is selected from materials such as high-strength structural steel, titanium alloy, and stainless steel. The rivet head 1 is formed by upsetting, and the length of the shank is processed according to the requirements of different interlayer thicknesses. It is strengthened by heat treatment first, and the tensile strength σb reaches more than 1100MPa; the strength of the riveting end 3 is reduced by local degradation, and its length is determined according to the size of the rivet h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com