Glass manufacturing process

A glass manufacturing and crafting technology, applied in the field of glass processing, can solve problems such as the inability to install threaded pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

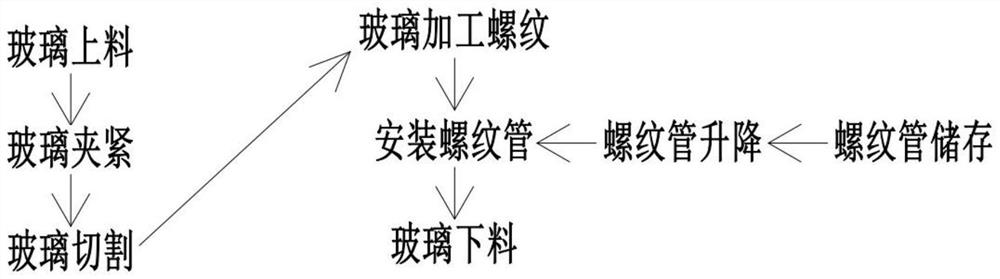

[0024] reference Figure 1 , detailing the process flow for the manufacture of glass:

[0025] A glass manufacturing process that includes the following steps:

[0026] Step 1: Clean the glass to ensure that there will be no processing errors due to debris during processing, and the glass after cleaning is clamped, and the glass is prepared for processing to prevent the glass from deviating;

[0027]Step 2: Cut the clamped glass, cut a round hole in the geometric center of the glass, and knock down the glass in the center of the cut round hole to achieve the removal after glass cutting;

[0028] Step 3: Thread the edge of the glass incision, process the thread on the inner wall of the removed round hole, and prepare for the installation of the threaded pipe;

[0029] Step four: the threaded pipe is installed at the thread of the processing, and remove the glass, after the installation of the threaded pipe glass in use, can be located through the threaded pipe in the middle of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com