Single-blade mounting hanging tool for fan blade

A single-blade and spreader technology, which is applied to the clamping mechanism of the installation spreader and the installation spreader of the wind blade, can solve the problem that the wind turbine installation equipment cannot keep up with the speed of industry development, which is unfavorable to the construction economy of wind power projects, and the model difference cannot be too large Major problems, to achieve the effect of reducing the risk of adjustment, reducing the risk of injury, and reducing the probability of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

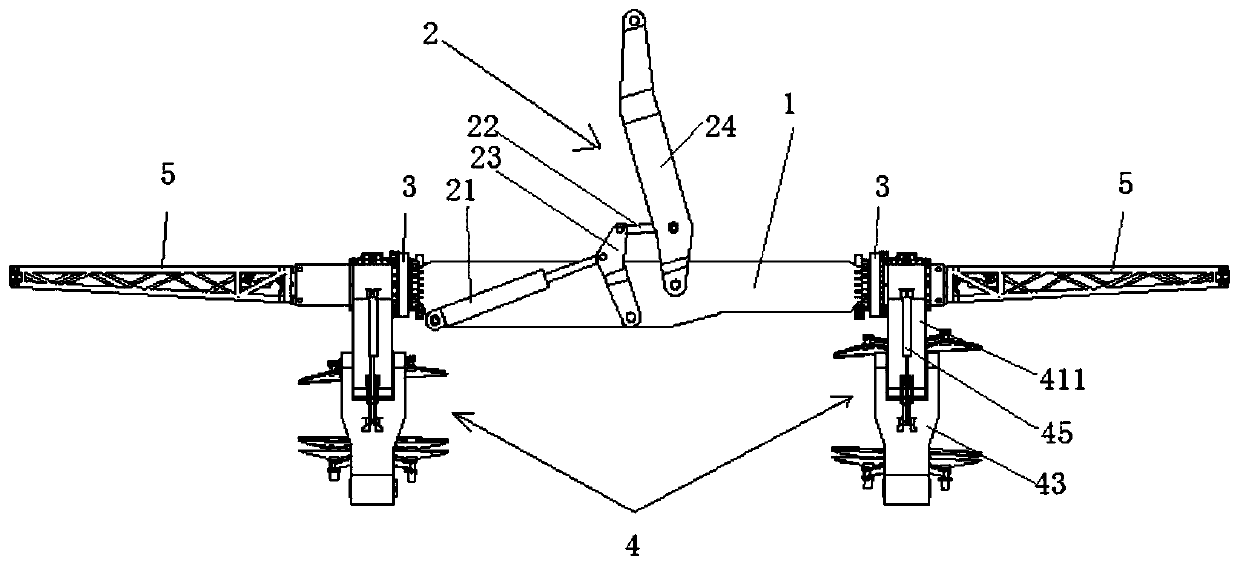

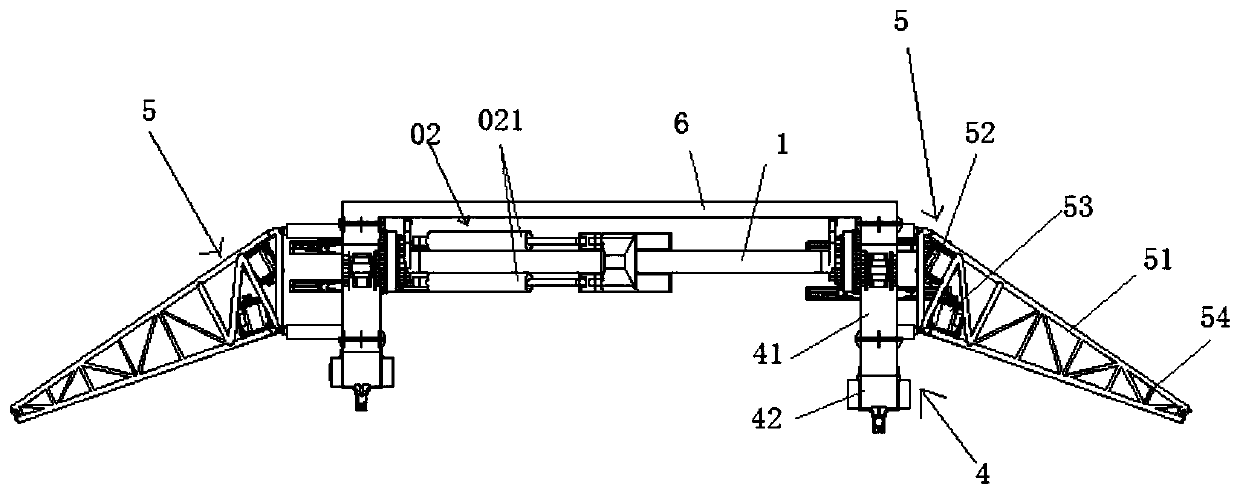

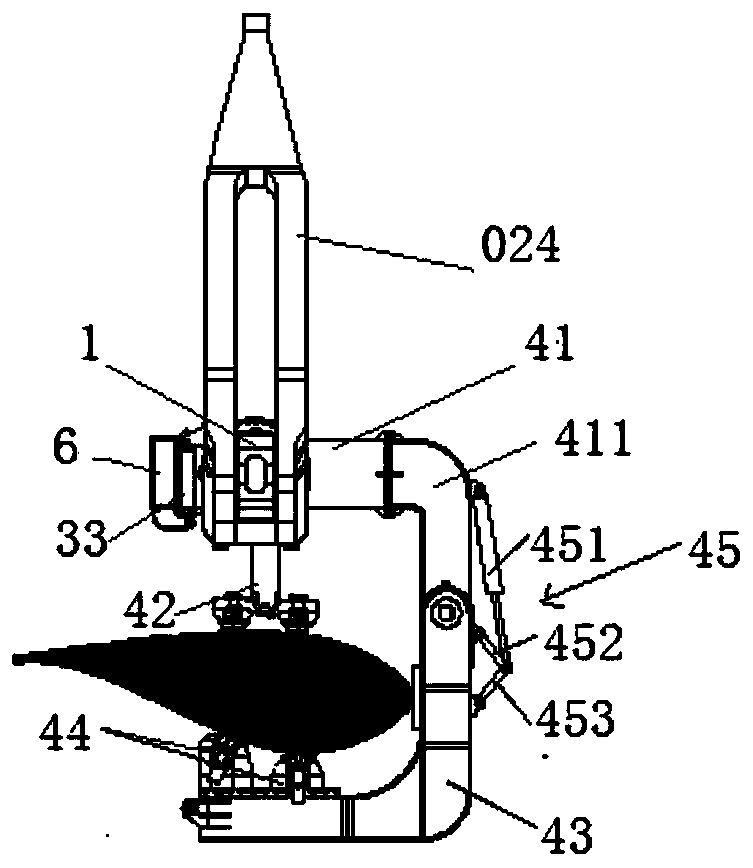

[0067] The cylinder 021 of the pitch mechanism 2 is hinged with the main beam 1 and the second link 023 to drive the four-link mechanism composed of the rocker arm 024, the first link 022, the second link 023 and the main beam 1 as a rocker. The action changes the angle between the rocker arm 024 and the main beam 1. In order to maintain the overall longitudinal stability, the spreader makes the longitudinal center of gravity of the blade 01 automatically coincide with the lifting point on the top of the rocker 024 to a vertical line. When the cylinder 021 is retracted to the shortest process, the whole machine will slow down under the action of the center of gravity. Slowly longitudinally rotate clockwise to +32°; when the cylinder 021 is extended to the longest, the whole machine will slowly rotate longitudinally and counterclockwise to -62° under the action of the center of gravity.

[0068] The implementation mode of the present invention adapting to different types of blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com