System for installing and adjusting adjustable reflection type optical object lens

An optical objective lens and reflective technology, which is applied in the field of adjustable reflective optical objective lens assembly and adjustment system, to achieve the effects of reducing mechanical deformation of the mirror surface, enhancing flexibility, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

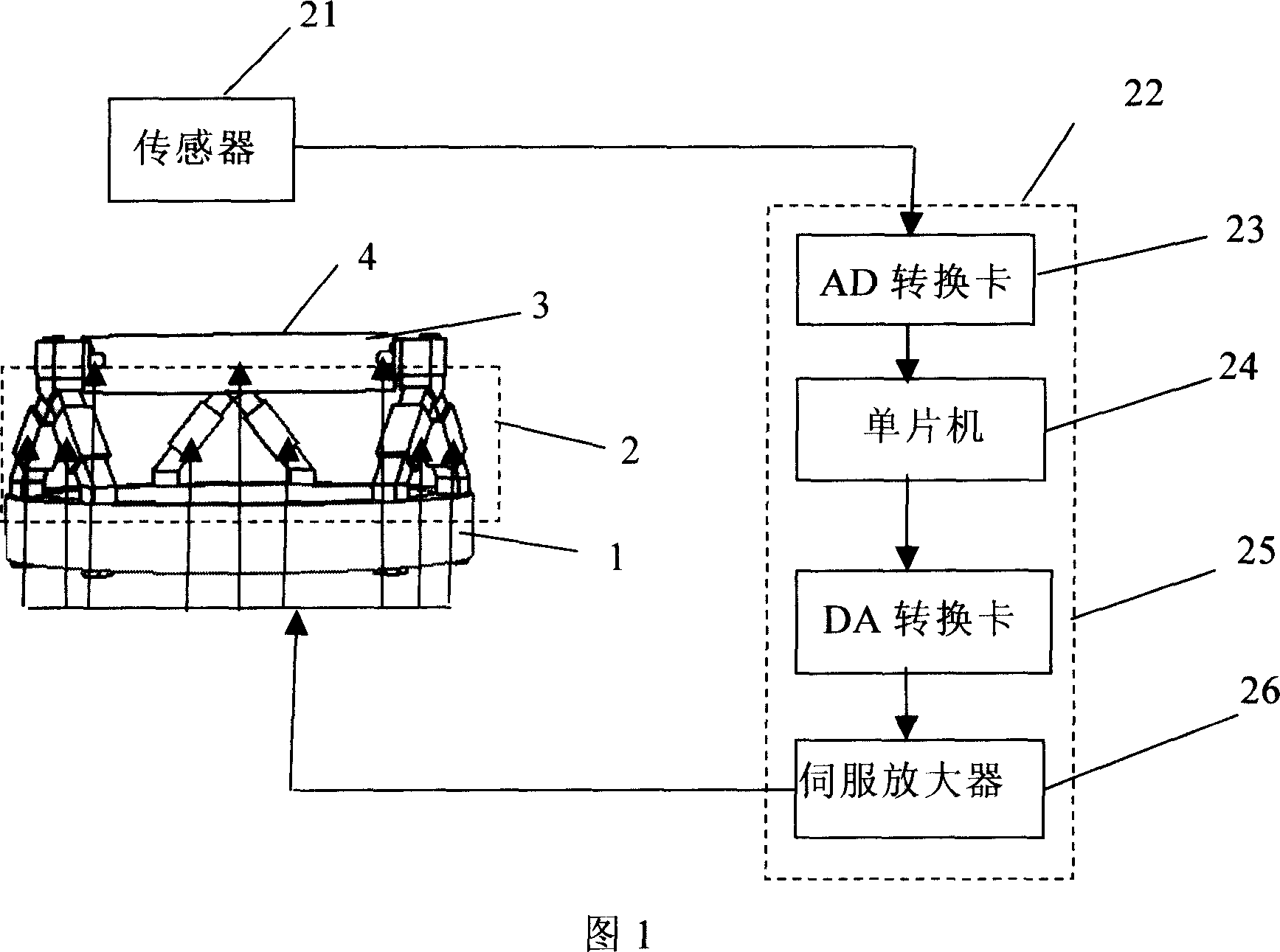

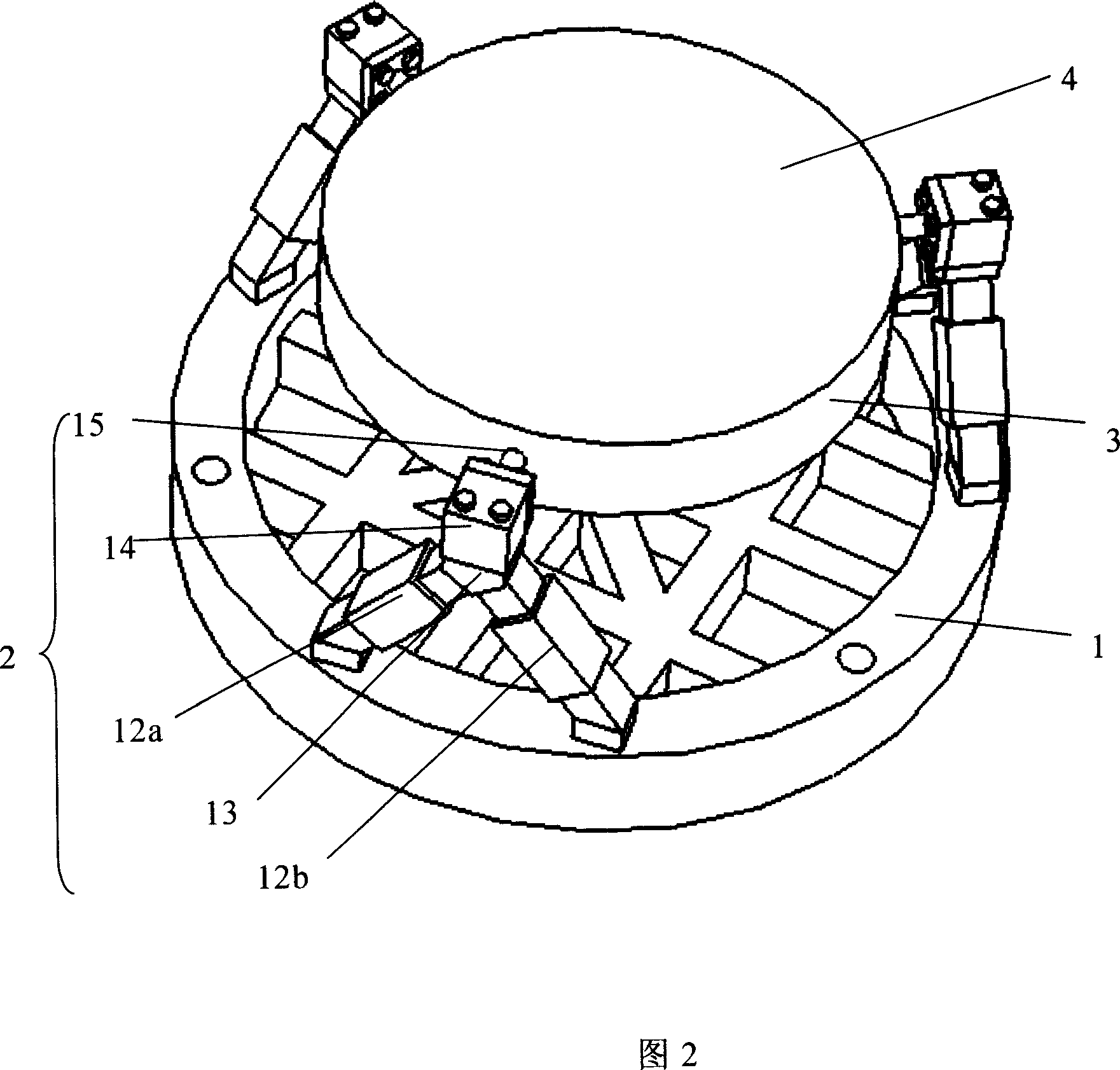

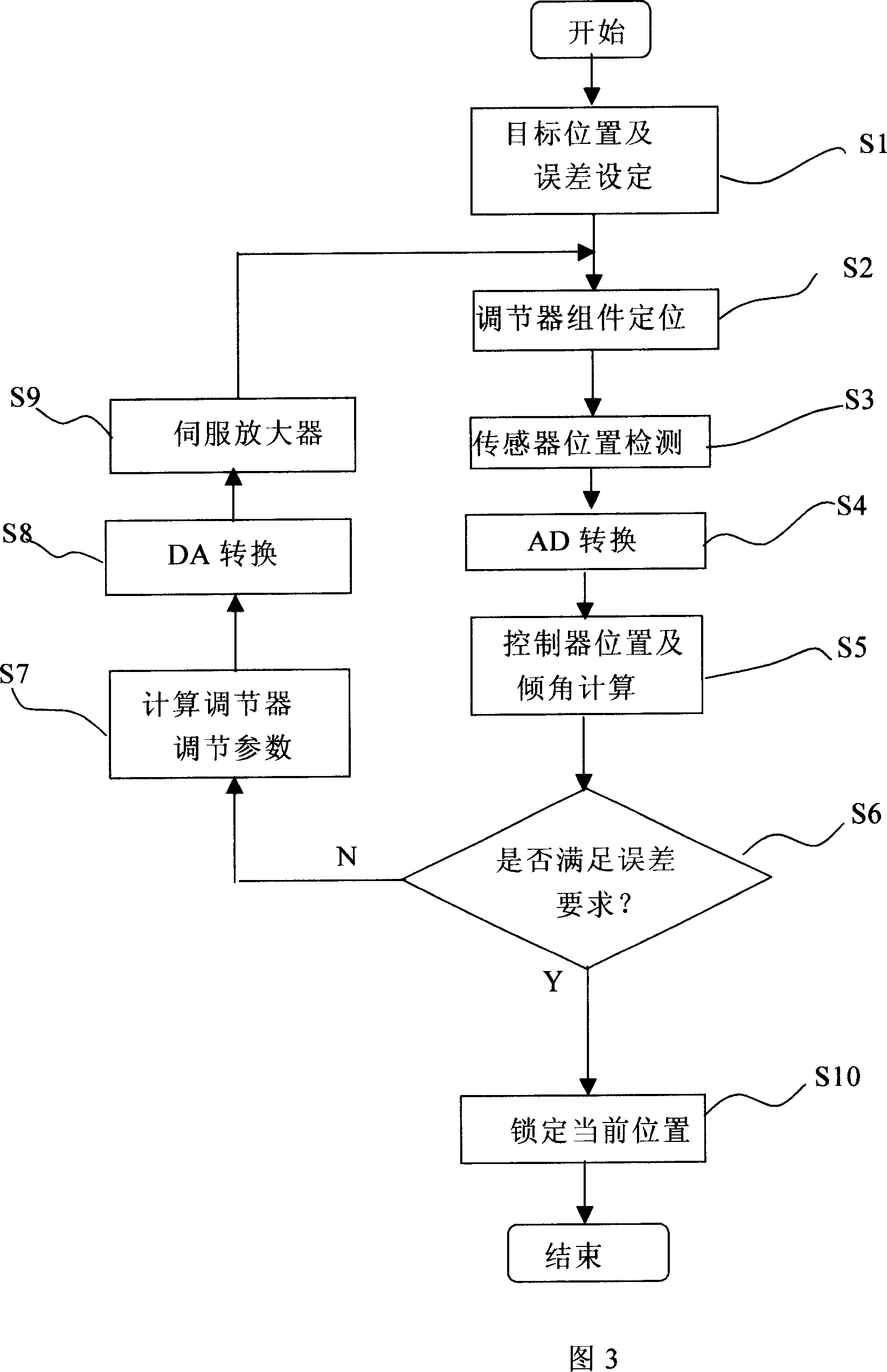

[0020] The objective lens assembly and adjustment system of the present invention comprises a base 1 , an adjuster assembly 2 , an objective lens 3 , a sensor 21 , a controller 22 , an AD conversion card 23 , a single-chip microcomputer 24 , a D / A conversion card 25 and a servo amplifier 26 .

[0021] As shown in Fig. 1 and Fig. 2, the base 1 is located at the bottom end, which is the fixed part of the whole assembly and adjustment mechanism. Three sets of regulator assemblies 2 are evenly distributed on the base 1 along the circumference at intervals of 120°. Each set of adjuster assemblies 2 includes two adjusting rods 12a, 12b and a radial adjuster 15, the lower ends of the adjusting rods 12a and 12b are fixedly connected to the base 1 by bolts, and the upper ends of the two adjusting rods 12a and 12b are fixedly connected to the connector 13 on. The latter is bolted to the fixing plate 14 and connected to the radial adjuster 15 . The adjusting rods 12a and 12b are retrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com