Method for precisely grinding small roller of bearing with automatic grinding device

A high-precision, grinding technology, which is applied in the direction of grinding drive devices, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the contact instability of the pallet working surface, grinding wheel and guide wheel And other parts wear, affect the machining accuracy and consistency and other issues, to achieve the effect of stable and reliable quality, low grinding cost, and improve grinding accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is a method for high-precision grinding of small bearing rollers by an automatic grinding device. The outer diameter of the small bearing rollers is less than 10mm. The automatic grinding device of the present invention realizes the centerless grinding of the small bearing rollers. grinding, and the grinding accuracy of the small roller of the bearing is greatly improved.

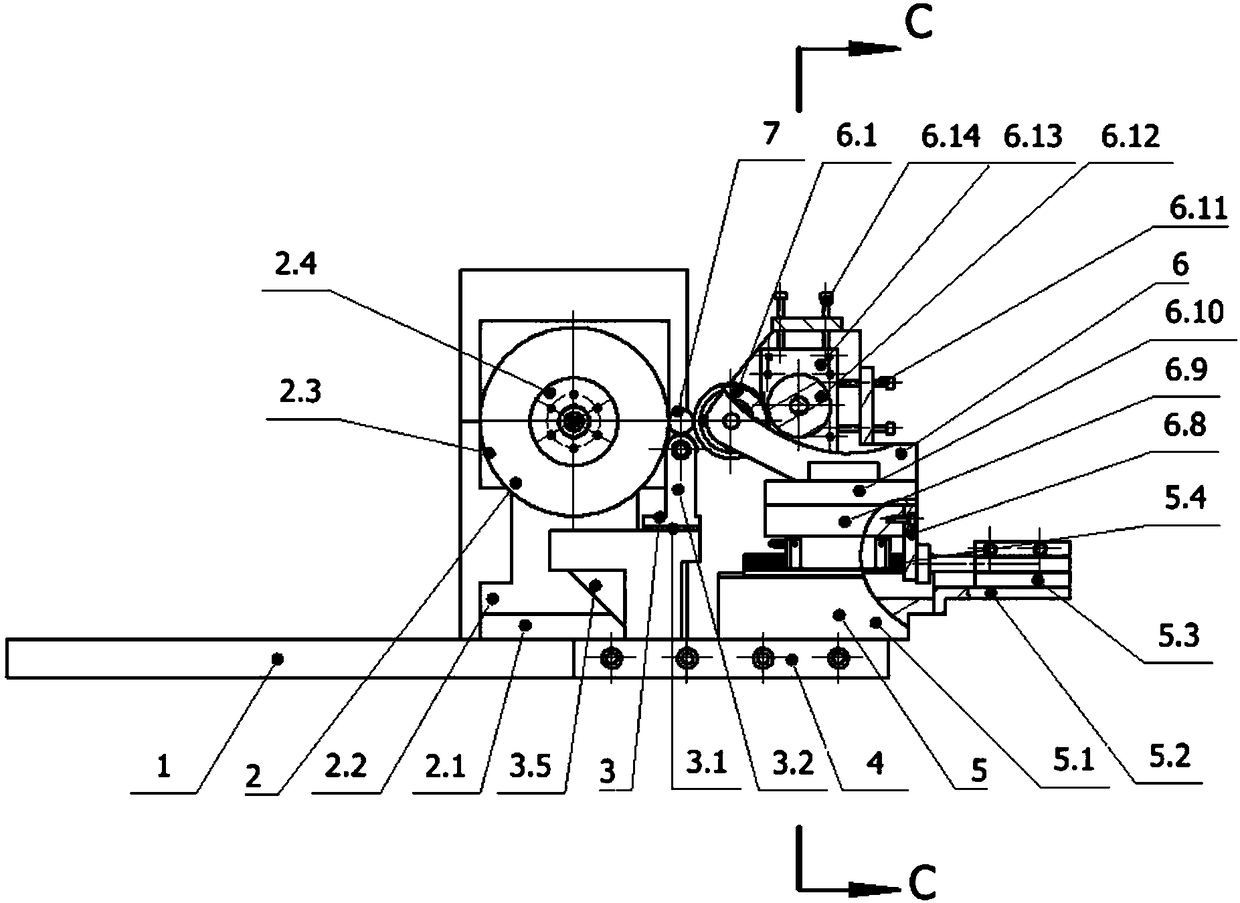

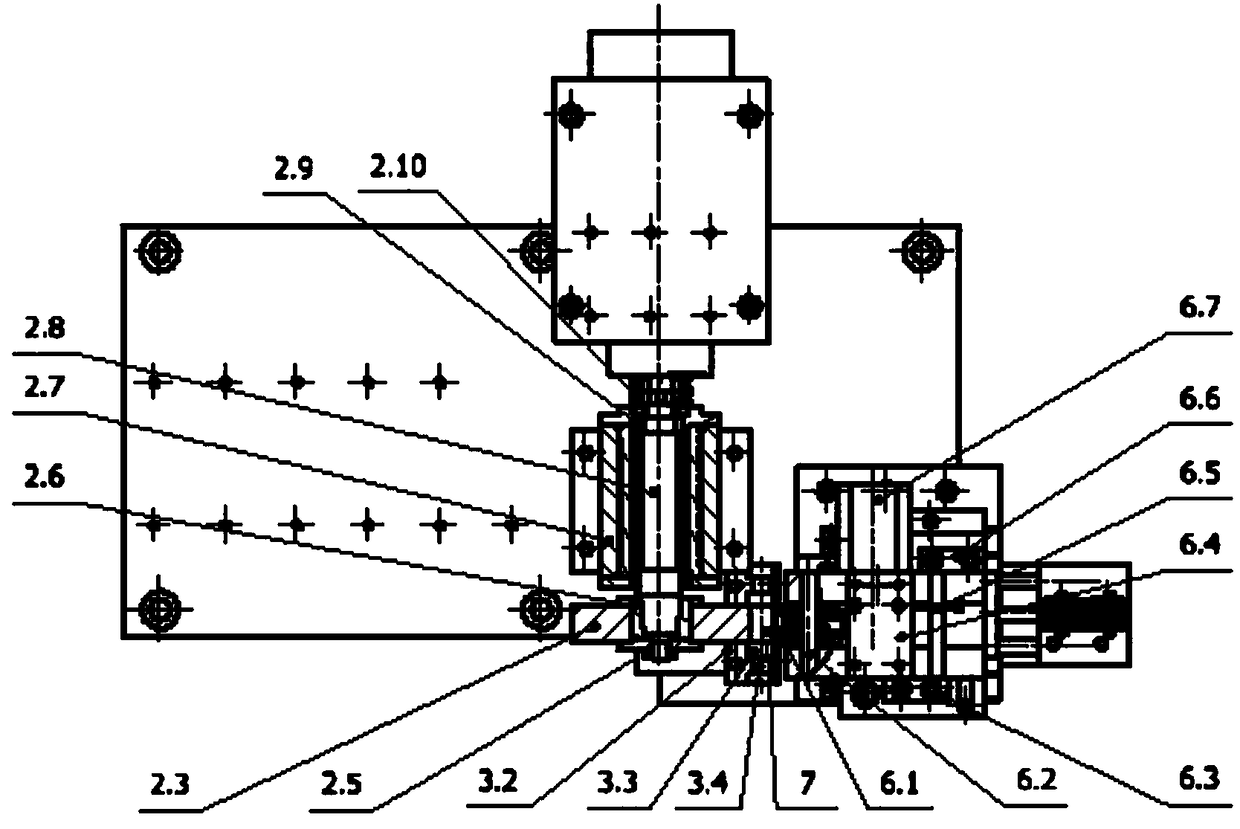

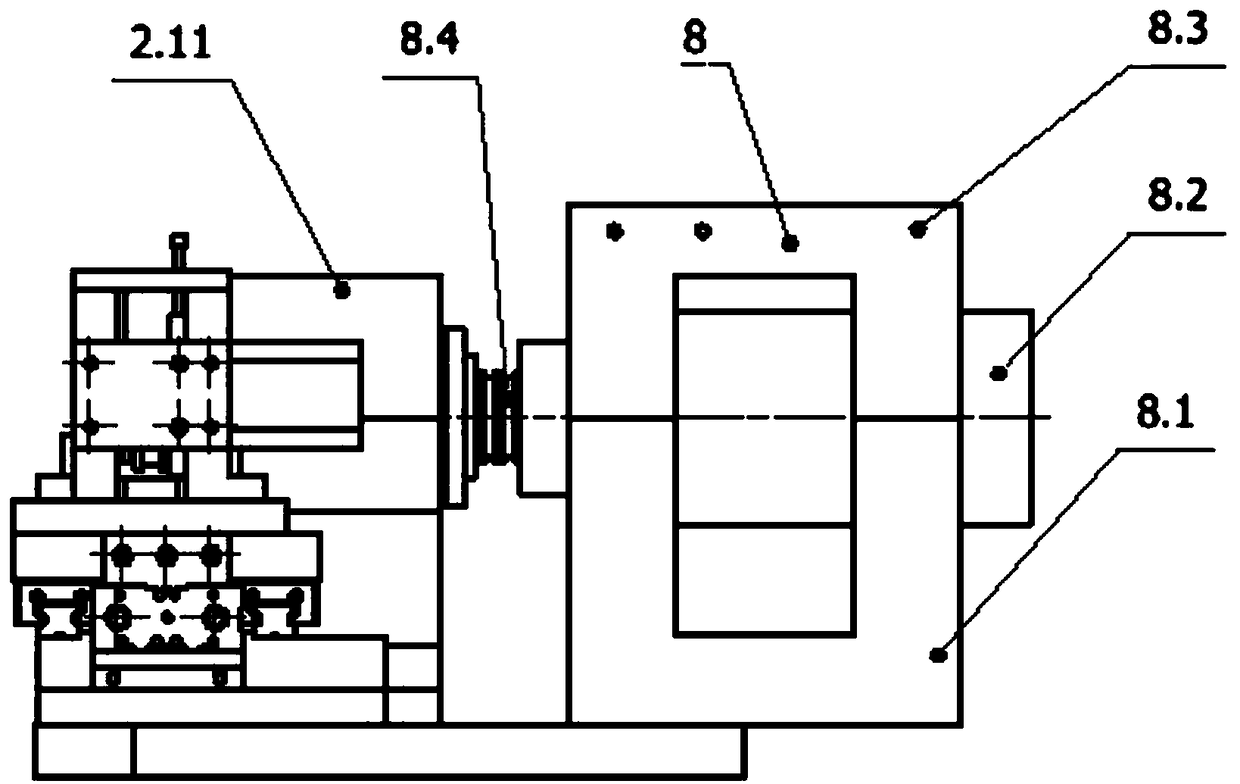

[0023] combine Figure 1-4 , the automatic grinding device of the present invention includes a base plate 1, a grinding wheel device 2, a support wheel device 3, an additional plate 4 for the base plate, a guide wheel lateral feed device 5, a guide wheel driving device 6 and an electric spindle device 8, wherein the grinding wheel device 2 Contains insulating plate 2.1, grinding wheel spindle support 2.2, grinding wheel 2.3, grinding wheel gland 2.4, nut 2.5, grinding wheel taper sleeve 2.6, bearing seat 2.7, grinding wheel spindle 2.8, lock nut 2.9, grinding wheel spindle conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com