A multifunctional steel structure cutting and drilling device

A drilling device and steel structure technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of consuming manpower and material resources, low work efficiency, etc., and achieve the effect of improving work efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

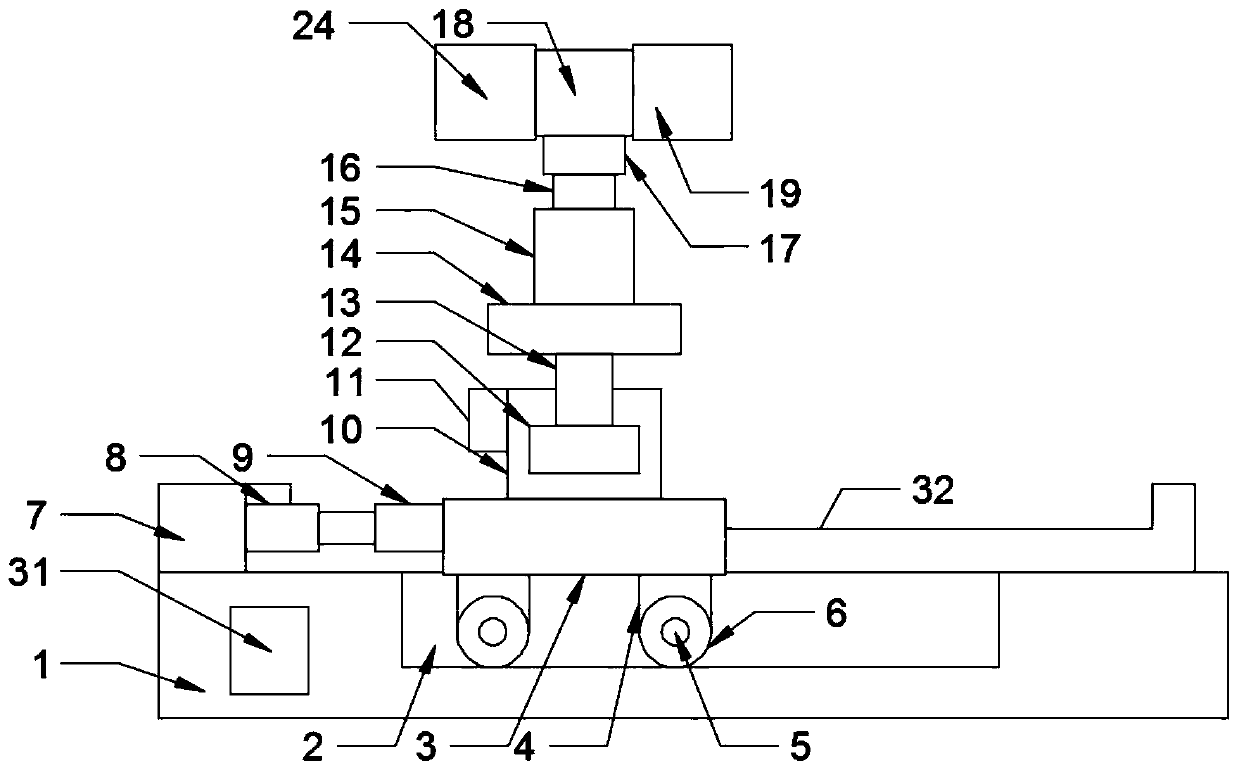

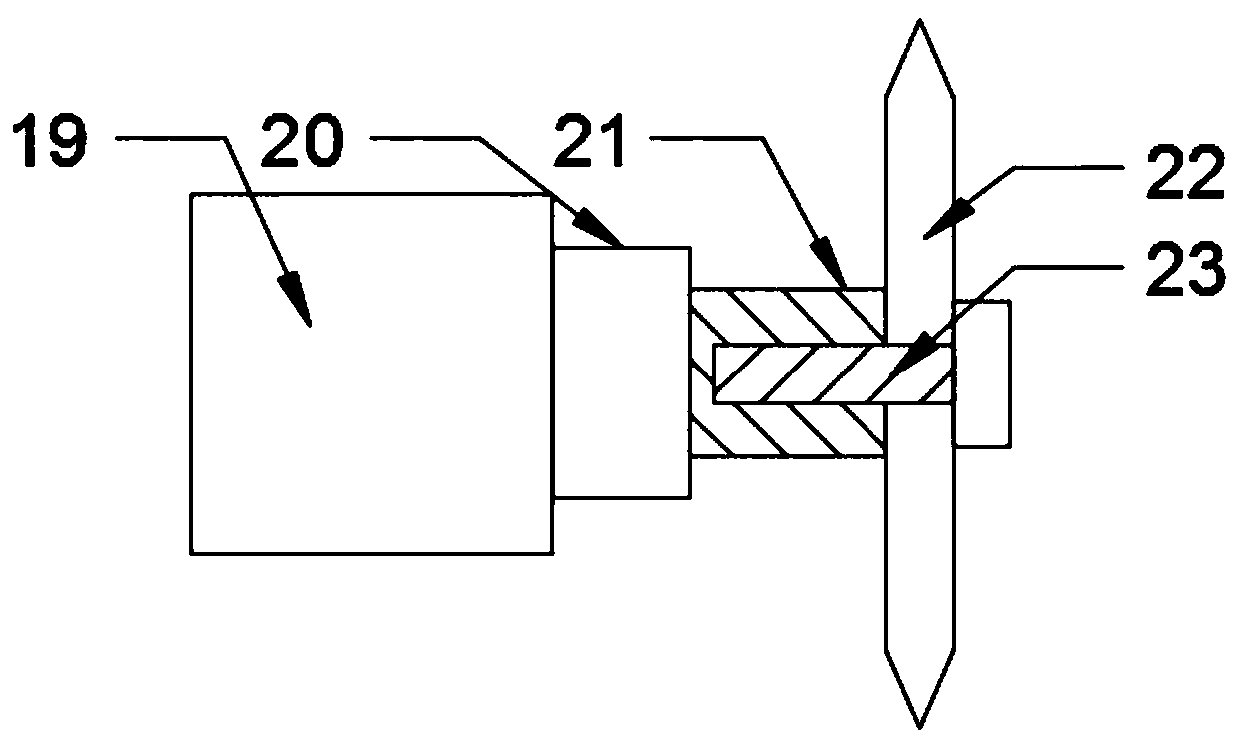

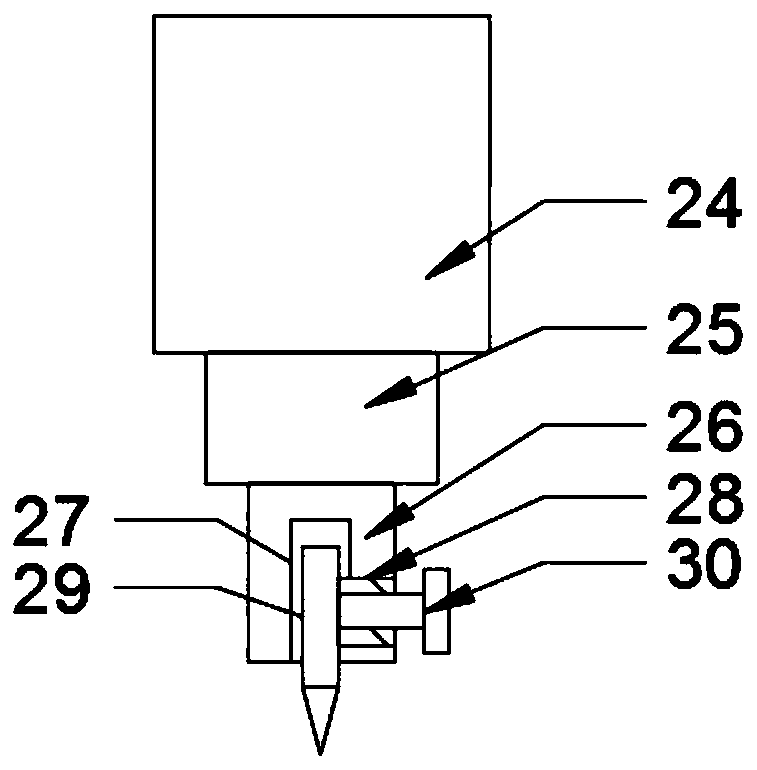

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a multifunctional steel structure cutting and drilling device includes a workbench body 1, the workbench body 1 is fixedly installed on the ground, and the workbench body 1 is provided with a cutting and drilling mobile lifting device. The mobile lifting device for cutting and drilling consists of a groove 2 fixed on the front end of the upper surface of the workbench body 1, a mobile base 3 located on the upper surface of the workbench body 1 and at the upper end of the groove 2, and a multi-layer fixedly mounted on the lower surface of the mobile base 3. A roller fixing frame 4, a roller shaft 5 inserted in the roller fixing frame 4, a roller 6 set in the roller shaft 5 and located on the upper surface of the groove 2, fixedly installed on the upper surface of the workbench body 1 and located in the groove 2 The linear motor 7 on one side, the teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com