Transmitter for measuring ultrasonic cavitation intensity

An intensity measurement and ultrasonic technology, which is applied in the direction of measuring ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as difficulty in meeting the measurement requirements of cavitation intensity measuring instruments, complex ultrasonic action mechanism, and low measurement accuracy. The effect of low power consumption, small size and reliable signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

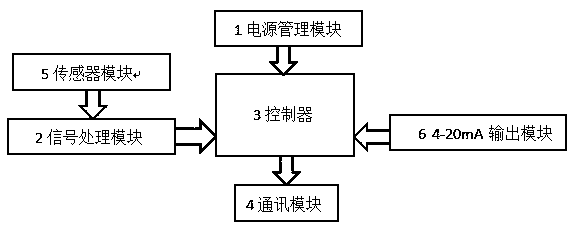

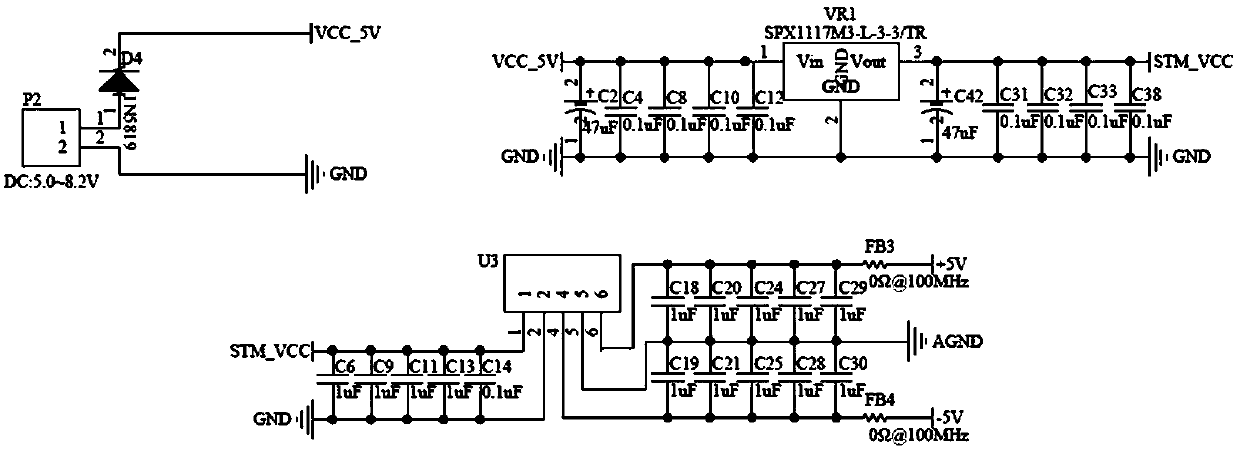

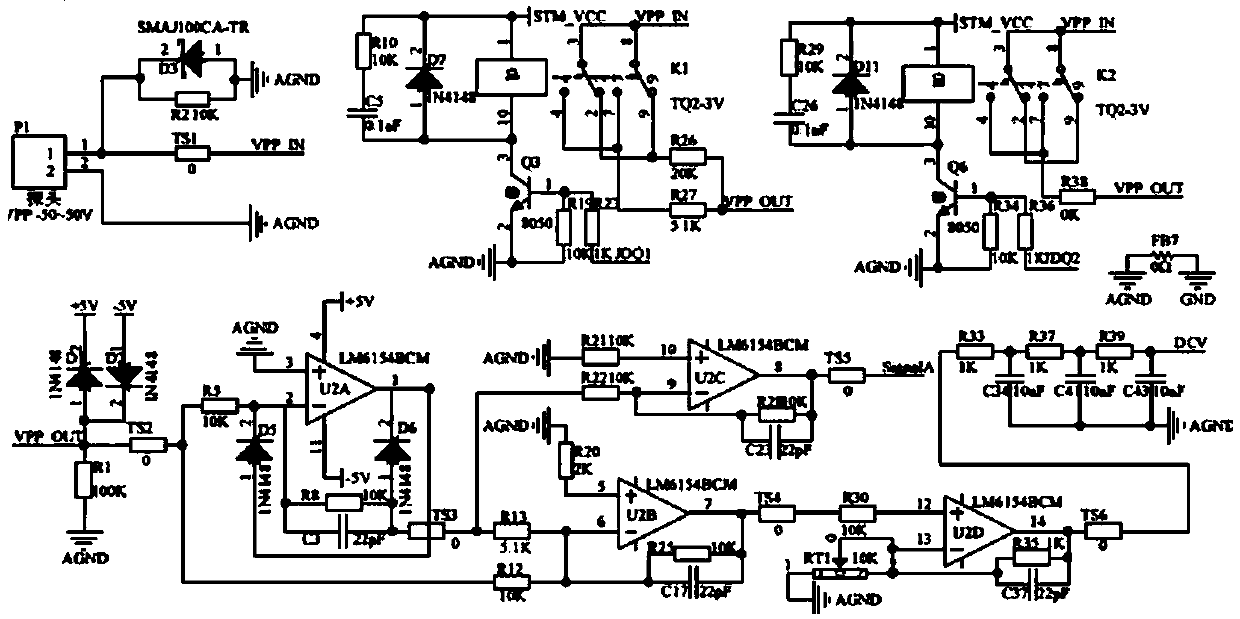

[0024] Such as figure 1 As shown, the present invention includes a sensor module, a power management module 1 , a signal processing module 2 , a control module 3 , a communication module 4 and an input and output module 5 . Each module adopts the existing mature technology. Among them, the sensor module is composed of dual hydrophone modules based on the piezoelectric effect. The dual hydrophone method uses two hydrophones in opposite directions and close to each other to measure two points respectively. The sound pressure value, and the cavitation intensity can be obtained indirectly by selecting the optimal filtering algorithm. The power management module 1 includes an 8.5V power input module and a 3.3V voltage conversion module. The signal processing module 2 includes a voltage amplification module. The input signal is reversed by an operational amplifier and then the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com