All deflection propeller vector boost mechanism and underwater navigation vehicle

A technology of vector propulsion and propeller, applied in the direction of propulsion device engines, ship propulsion, propulsion components, etc., can solve the problems of destroying the structural continuity of the aircraft, reducing the structural strength of the aircraft, and limiting the layout of the aircraft to achieve compact structure and maintenance. Convenient, simple, and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

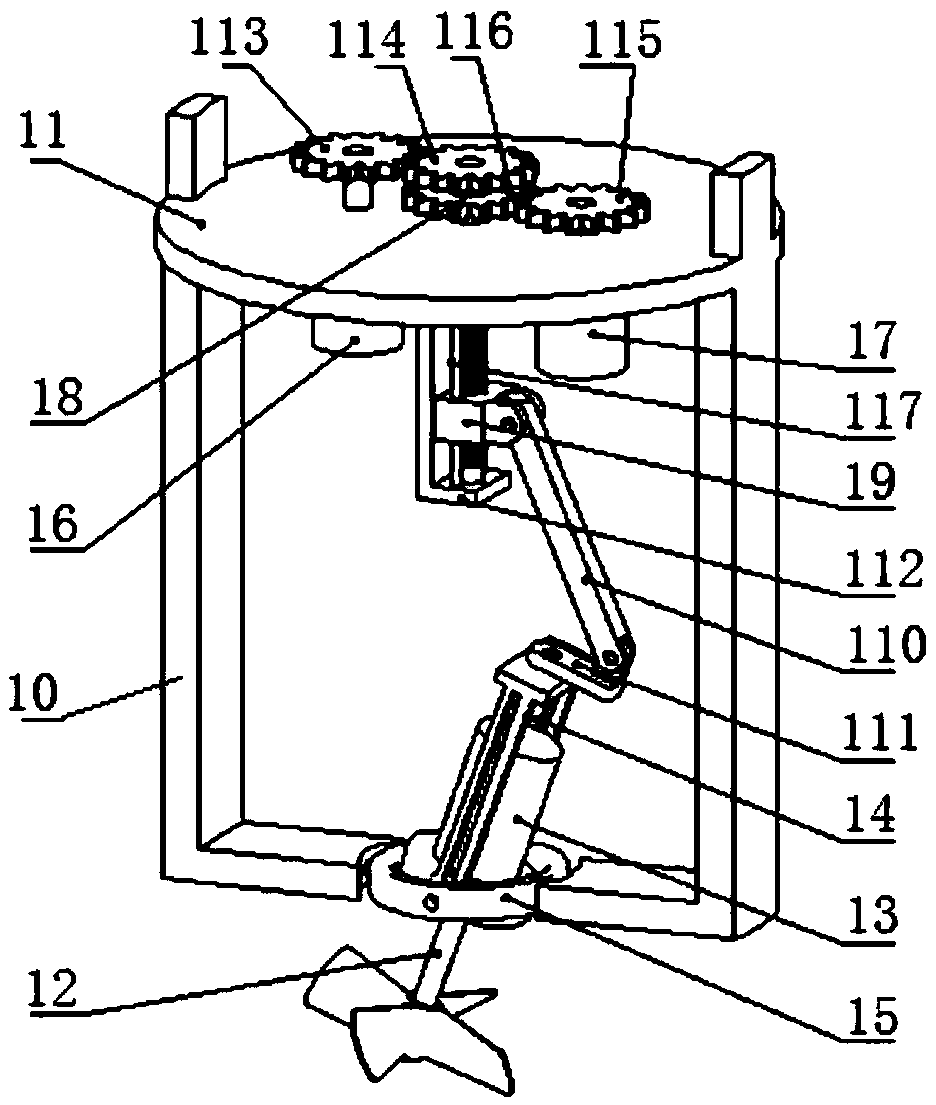

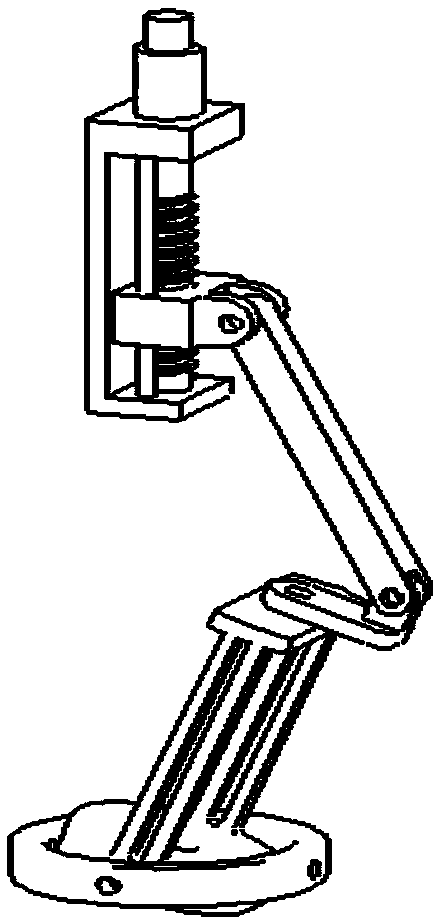

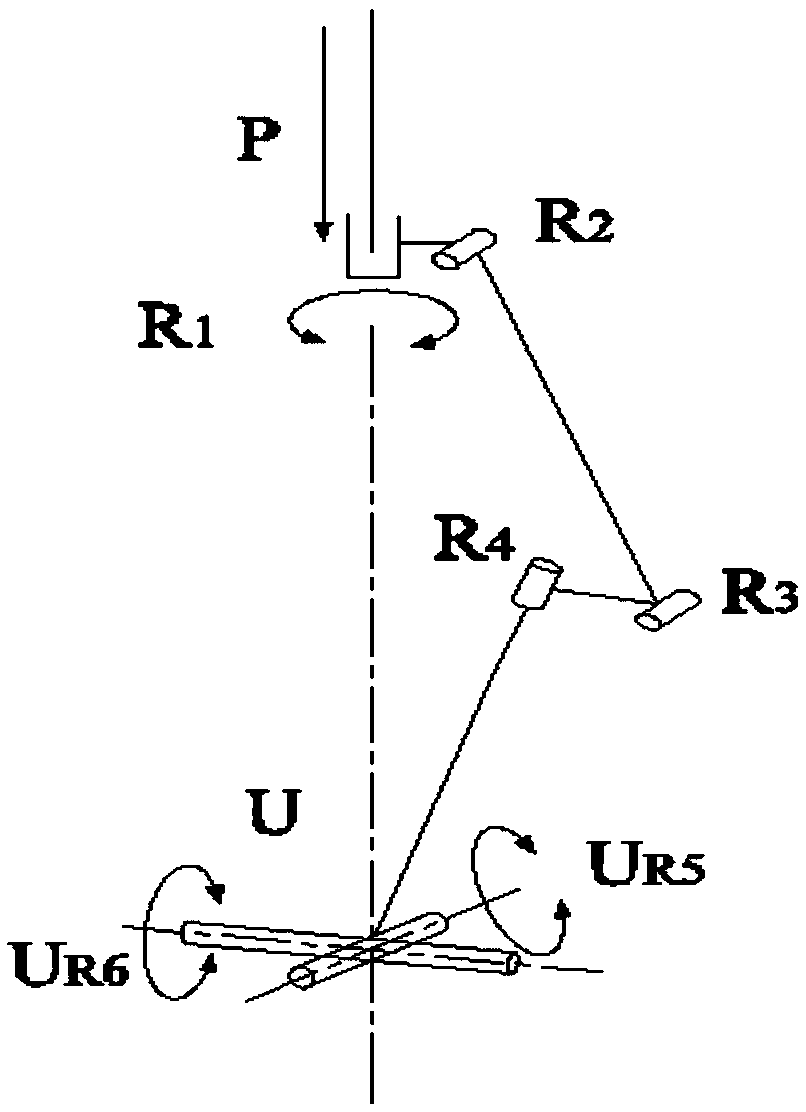

[0034] Such as Figure 1-3 As shown, in this embodiment, the universal joint includes a universal joint a14 and a universal joint b15 hinged with the universal joint a14, the propulsion motor 13 is arranged on the universal joint a14, and the universal joint b15 is hinged under the bracket 10 Middle; In this way, the propeller rotation motion transmission mechanism includes the propulsion motor 13, the propeller 12 and so on. The propeller 12 is connected with the propulsion motor 13 to form a tail thruster, which is fixedly connected to the external universal joint a14. The propulsion motor 13 directly transmits the rotational motion to the propeller 12 to make it generate rotational motion to provide propulsion for the underwater robot. The tail thruster uses the universal joint a14 as a platform, and realizes all-round rotation in space through the yaw mechanism and slewing mechanism described below.

[0035] A yaw motor 16 and a rotary motor 17 are arranged on the static...

Embodiment 2

[0044] Such as Figure 4-7 As shown, the second embodiment has many similarities with the first embodiment. Wherein, the universal joint includes universal joint a14' and universal joint b15' hinged with the universal joint a14', the propulsion motor 13' is arranged on the universal joint a14', and the universal joint b15' is hinged on the support 10' The lower middle part; in this way, the propeller rotation motion transmission mechanism includes the propulsion motor 14, the propeller 17, the universal joint a14' and so on. The propulsion motor 13' is placed on the universal joint a14' and can transmit motion to the propeller through a pair of meshing gears.

[0045] The static platform is provided with a yaw motor 16' and a rotary motor 17', and the middle part of the static platform is provided with a first annular connecting piece 210' driven by the yaw motor 16' (specifically, a pair of meshing gears 113' and a gear 114 'to drive) and the second ring-shaped connecting p...

Embodiment 3

[0055] Such as Figure 8-10 As shown, in this embodiment, the tail thruster also includes a motor box 310 ", and the propulsion motor is located in the motor box 310 ";

[0056] A C-shaped intermediate plate 32 "is arranged between the disc 11" and the lower part of the support 10 ", and the lower end surface of the intermediate plate 32 " is provided with a cylindrical protrusion, and the cylindrical protrusion is inserted in a suitable shape of the lower part of the support 10 " In the circular through hole, the two form a rotating pair; the inner lower part of the middle plate 32" is provided with a rotating shaft 311", and the lower end of the motor box 310" is hinged on the rotating shaft 311"; the cooperation between the cylindrical protrusion and the circular through hole 1. The hinge between the motor box 310" and the middle plate 32" jointly forms a universal joint used as a moving platform;

[0057] The lower end of the motor box 310" and the lower end of the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com