A plug-in sound barrier sound-absorbing and insulating unit board

A technology of sound absorption and sound insulation, which is applied in the direction of noise absorption devices and buildings, can solve problems such as inconvenience of engineering construction, and achieve the effects of excellent sound absorption and sound insulation performance, excellent sound absorption and sound insulation performance, and accurate cross-sectional size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

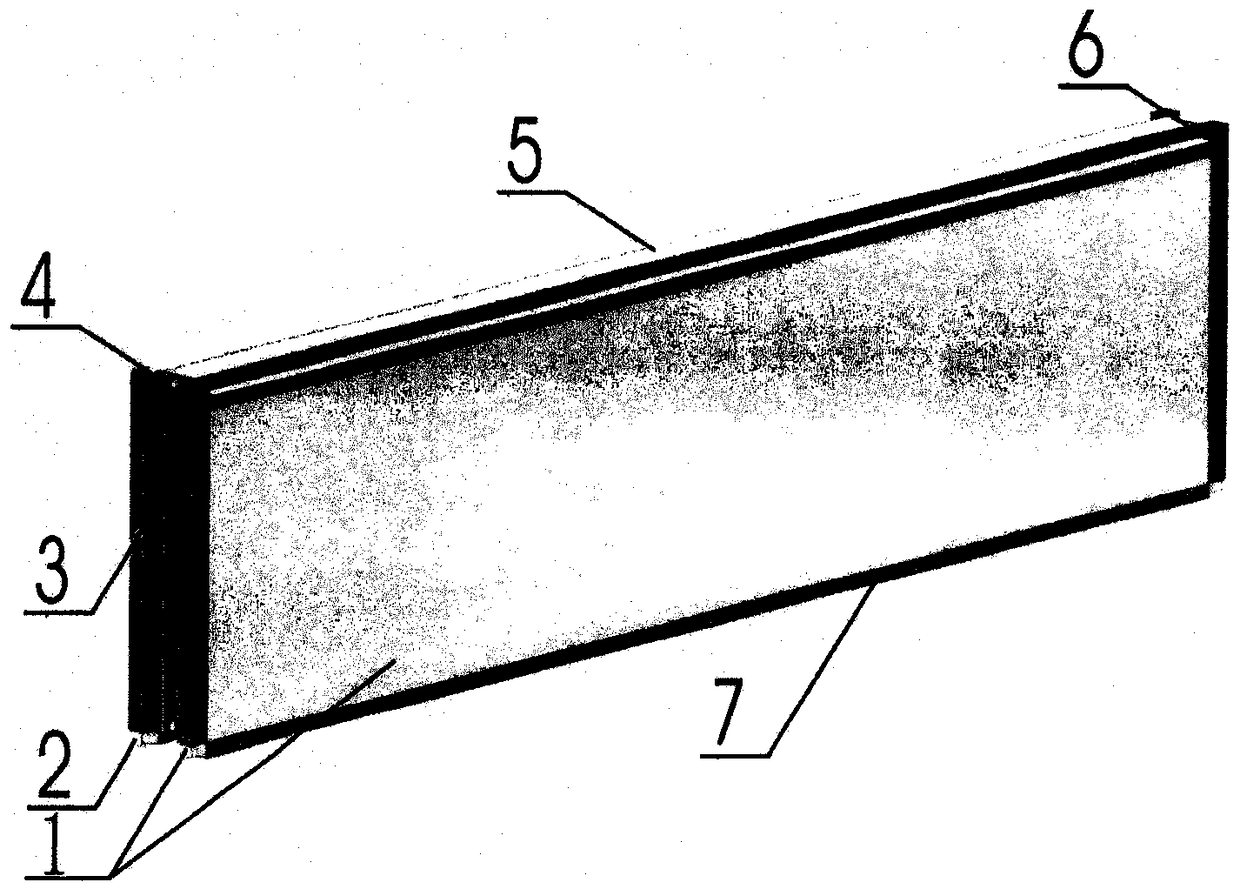

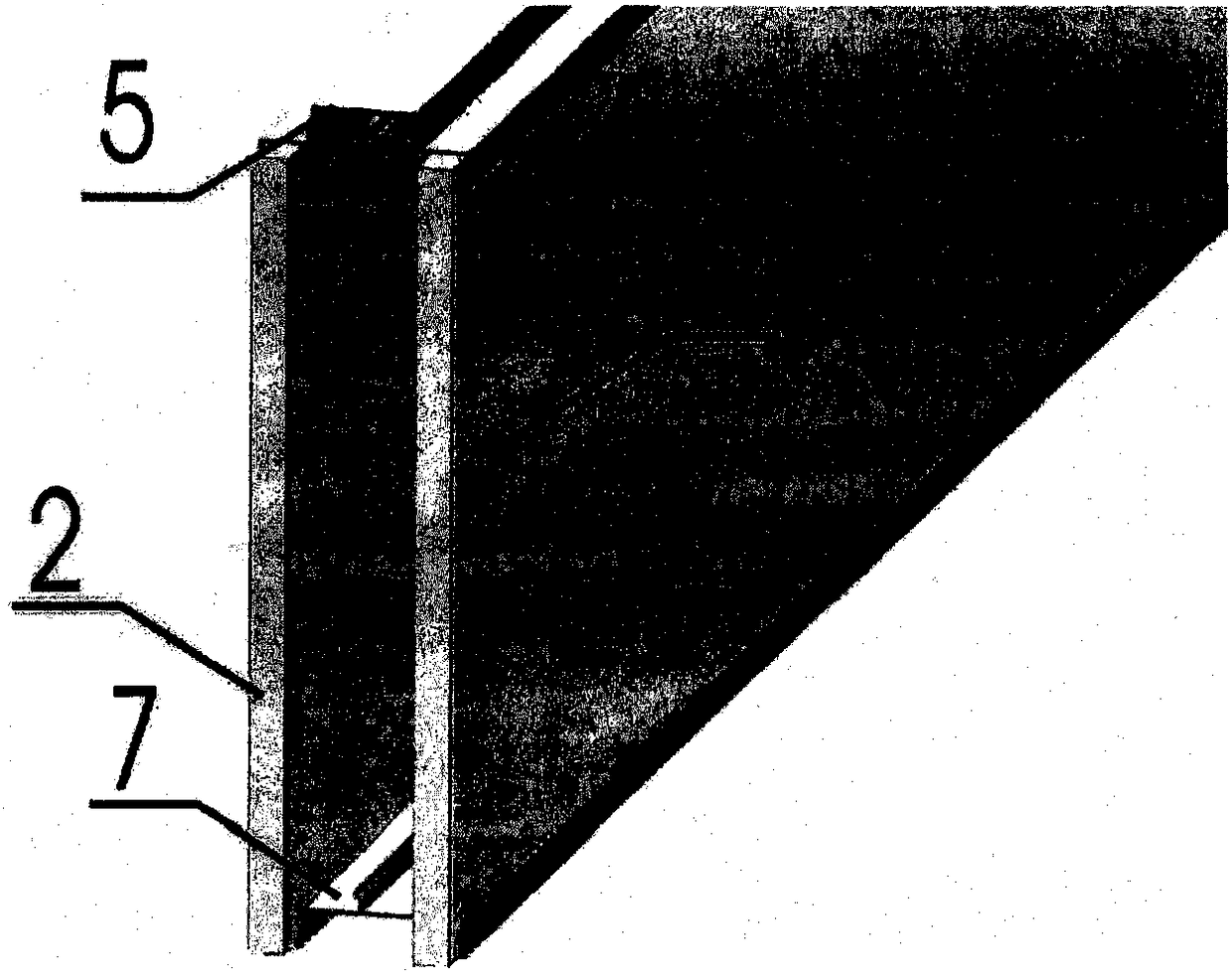

[0019] Such as figure 1 As shown, the plug-in sound barrier sound-absorbing and insulating unit board includes a hard sound-absorbing and insulating panel 1, a hard sound-absorbing and insulating back panel 2, a left metal frame 3, a right metal frame 6, and an upper metal frame 5 , lower metal frame 7, dovetail nails 4, wherein the hard sound-absorbing and sound-insulating panel 1 and the hard sound-absorbing and sound-insulating bottom plate 2 all adopt microporous rock sound-absorbing and sound-insulating panels with a thickness of 20mm.

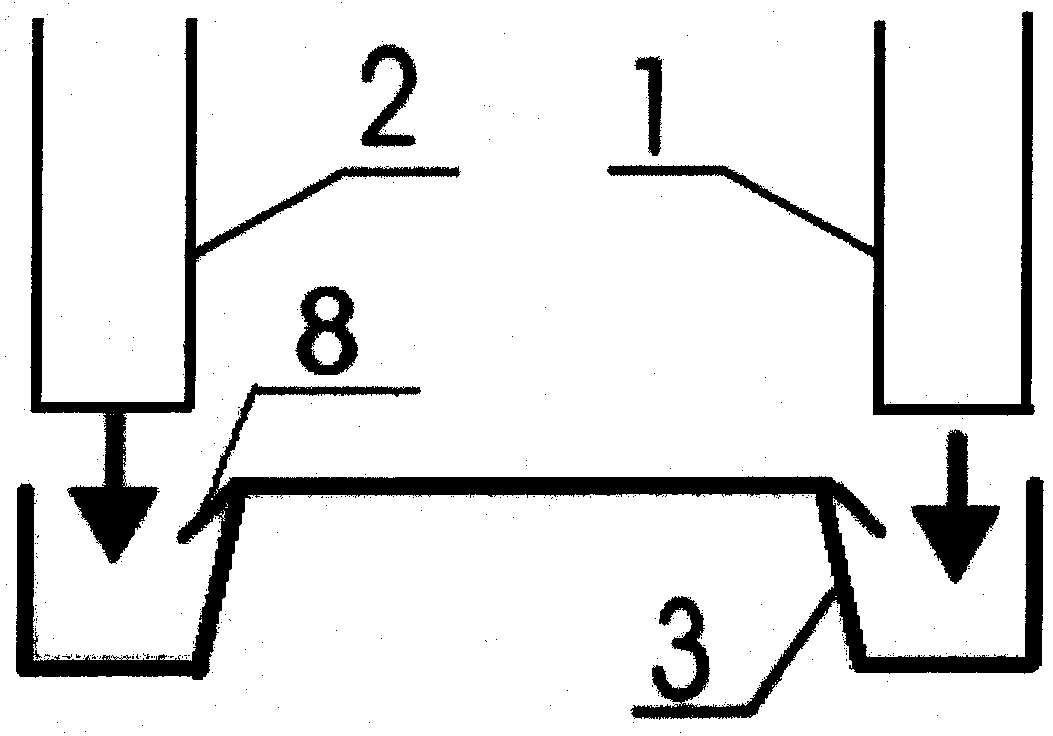

[0020] Such as figure 2 As shown, the left metal frame 3, the right metal frame 6, the upper metal frame 5, and the lower metal frame 7 are all bow-shaped structures, and are extruded by aluminum alloy hollow thin walls; The glyph structure forms a 20mm wide cavity on both sides of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com