Patents

Literature

50results about How to "Good sound insulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

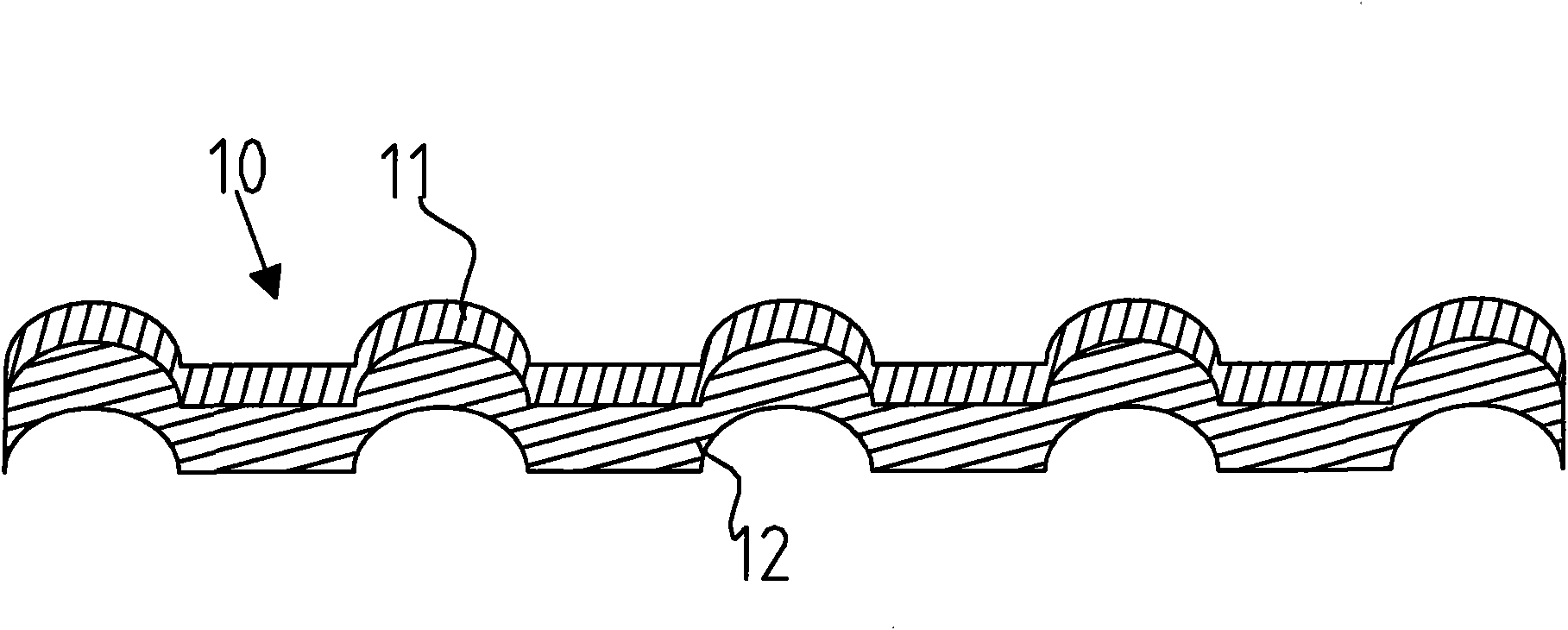

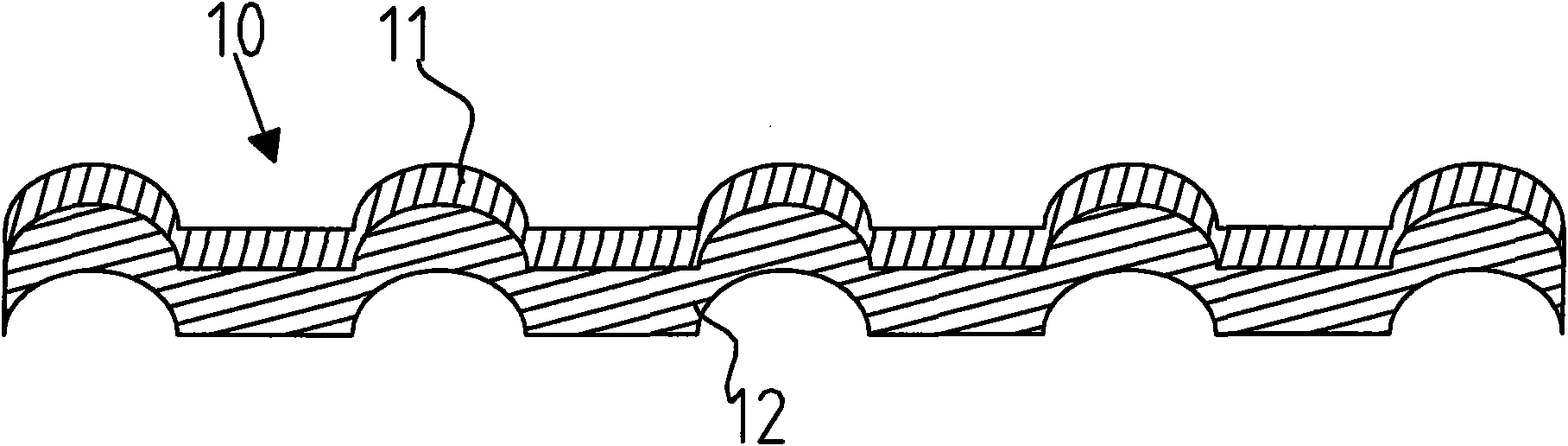

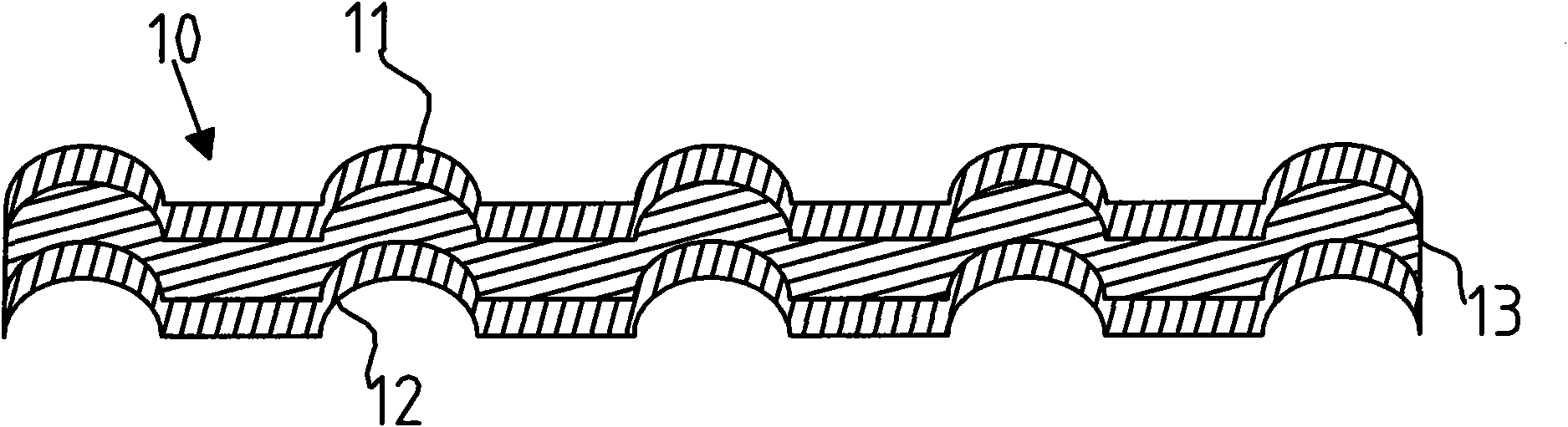

Double-layer resin glazed tile

InactiveCN101876193AImprove impact resistanceGood sound insulation effectRoof covering using slabs/sheetsParaffin waxSodium bicarbonate

The invention belongs to the technical field of building material, and more particularly relates to a double-layer resin glazed tile which takes on a sheet shape or a plate shape and is formed by a plurality of wave peaks and / or wave troughs which are sequentially connected. The glazed tile is formed by a surface layer and a bottom layer, wherein the surface layer is formed by modified resin ASA, and the bottom layer is formed by 60-80% of polyvinyl chloride resin, 1-3% of foaming agent, 8-15% of shock-resistant modifying agent, 2-5% of lubricating agent and 9-17% of processing auxiliary agent by weight percent, wherein the foaming agent is azo-compound or / and sodium hydrogen carbonate, the shock-resistant modifying agent is chlorinated polyethylene, the lubricating agent is one or mixture of more in oxidized polyethlene wax, stearic acids or paraffin, and the processing auxiliary agent is one or mixture of more in ACR, compound stabilizer, calcium carbonate or pigment. The glazed tile is light in weight and durable, and has good effects of noise reduction and heat insulation.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

Flame-retardant sound insulation composite material and sound insulation component

ActiveCN101735530AFlame retardant hasGood sound insulation effectSound producing devicesIron powderPlasticizer

The invention relates to a flame-retardant sound insulation composite material. The flame-retardant sound insulation composite material comprises the following components in percentage by weight: 5 to 30 percent of PVC, 5 to 30 percent of chlorinated polyethylene, 15 to 80 percent of iron powder of which the grain diameter is 10 to 100 microns, 0.5 to 2 percent of coupling agent and 9.5 to 23 percent of aid. The invention provides the flame-retardant sound insulation composite material, which is prepared from the PVC, the chlorinated polyethylene, the iron powder with the grain diameter of 10 to 100 microns, the coupling agent and the aid, has good flame-retardant sound insulation effect, and also has the characteristics of flame retardancy, innocuity, no lead, high strength, good construction property and low cost. Because the chlorinated polyethylene is particularly introduced into the material components of the flame-retardant sound insulation composite material, the using amount of a plasticizer of the material is reduced, and the composite material has better softness and can be widely applied to sound insulation treatment in the construction industry, decoration field and the like; and the sound insulation composite material can effectively reduce the noise, and the sound insulation index of the material can reach 25 to 32 decibels.

Owner:深圳洛赛声学技术有限公司

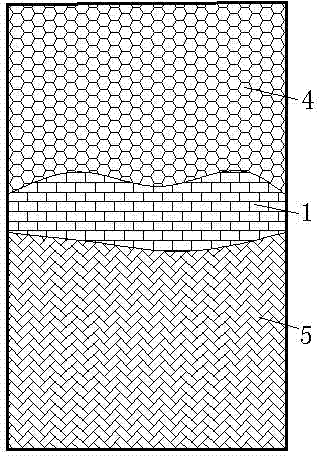

Air-purifying type wood floor

ActiveCN102926522ANo lossIncrease contact areaDispersed particle filtrationFlooringActivated carbon filtrationEnergy source

The invention belongs to an air-purifying type wood floor which mainly comprises a floor body, wherein vent grooves are formed on the upper end face of the floor body at intervals; filter chambers are arranged in the lower end face of the floor body; ventilating holes penetrate through the vent grooves and the filter chambers; the filter chambers are internally provided with active carbon filter blocks; a breathable layer seals the filter chambers and the lower end faces of the active carbon filter blocks in the filter chambers; and an air breathing structure is arranged at the lower end of the lower end face of the floor body. The air-purifying type wood floor has double functions of air purifying and sound insulation, can be popularized and used, and has the advantages that the wood floor is simple in structure and reasonable in design; no energy source is wasted; the contact area between active carbon and air is large; the manufacturing and use cost is low; and the wood floor is soft and elastic when in use.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

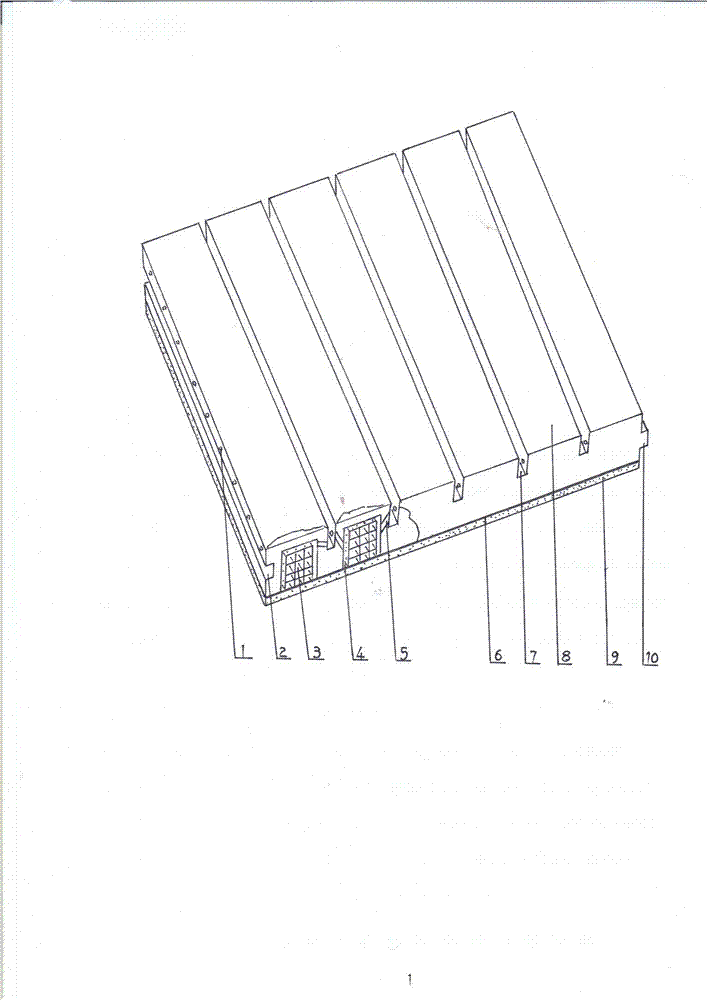

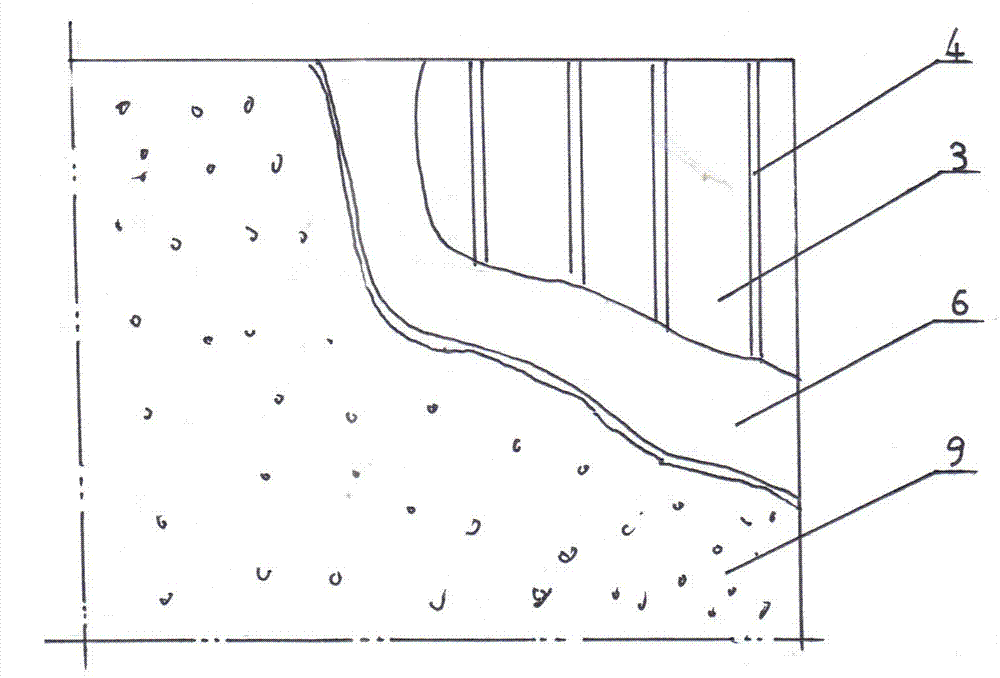

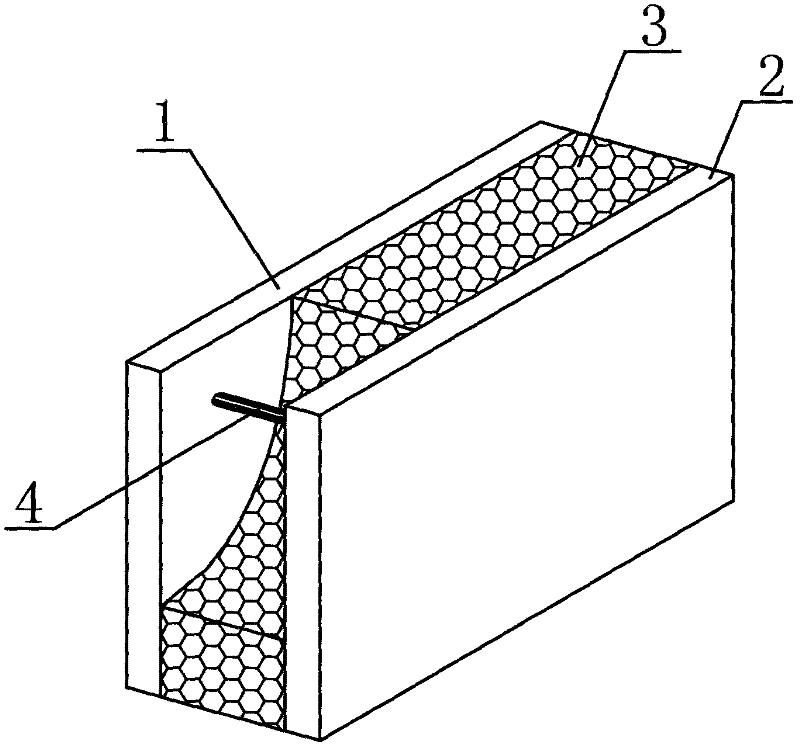

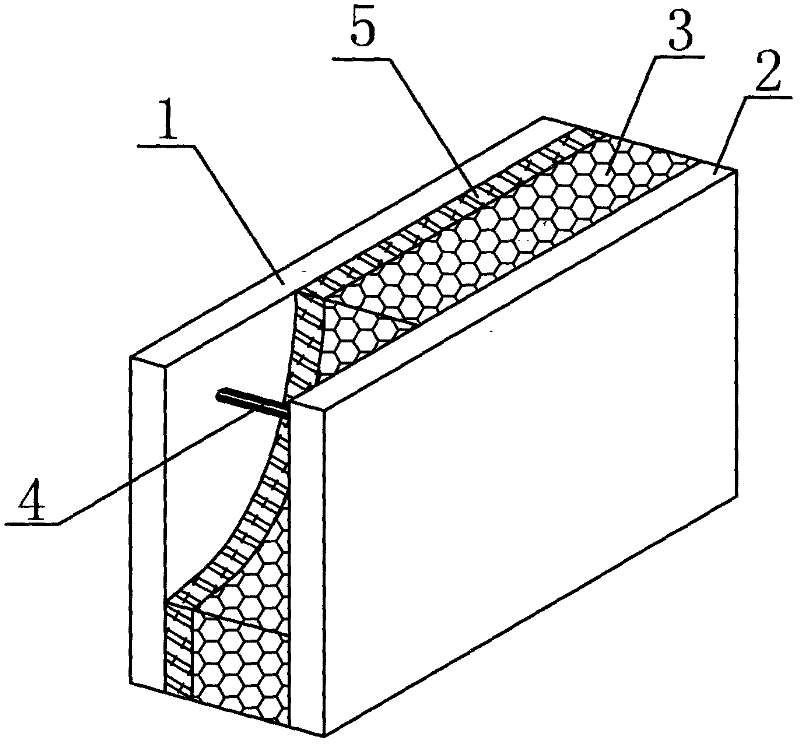

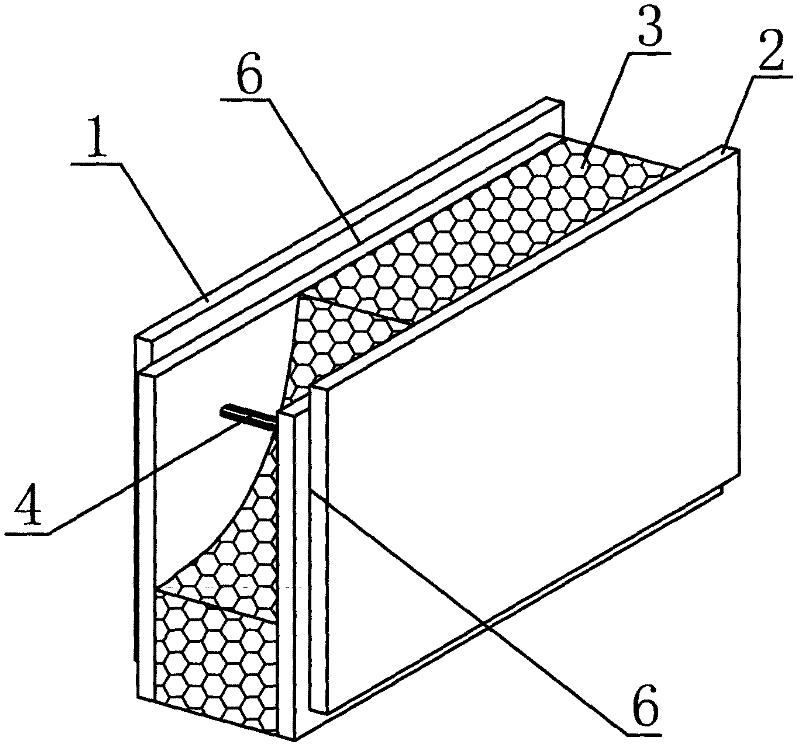

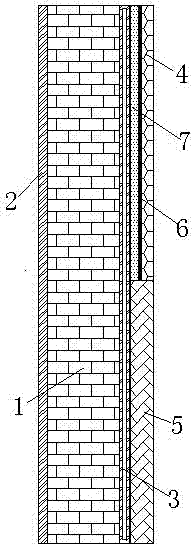

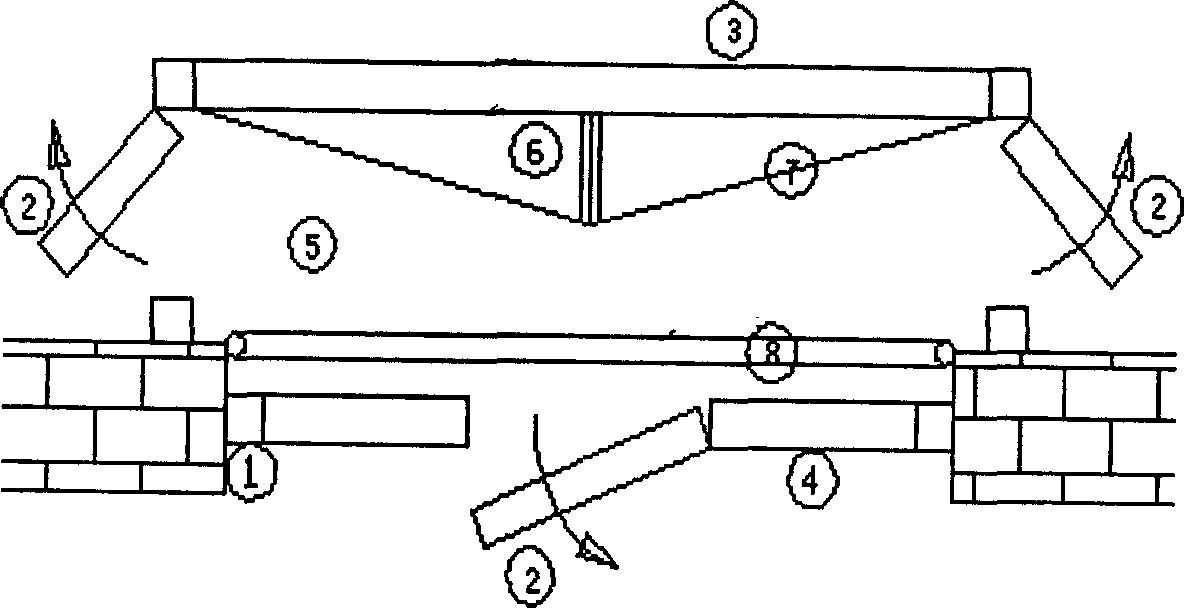

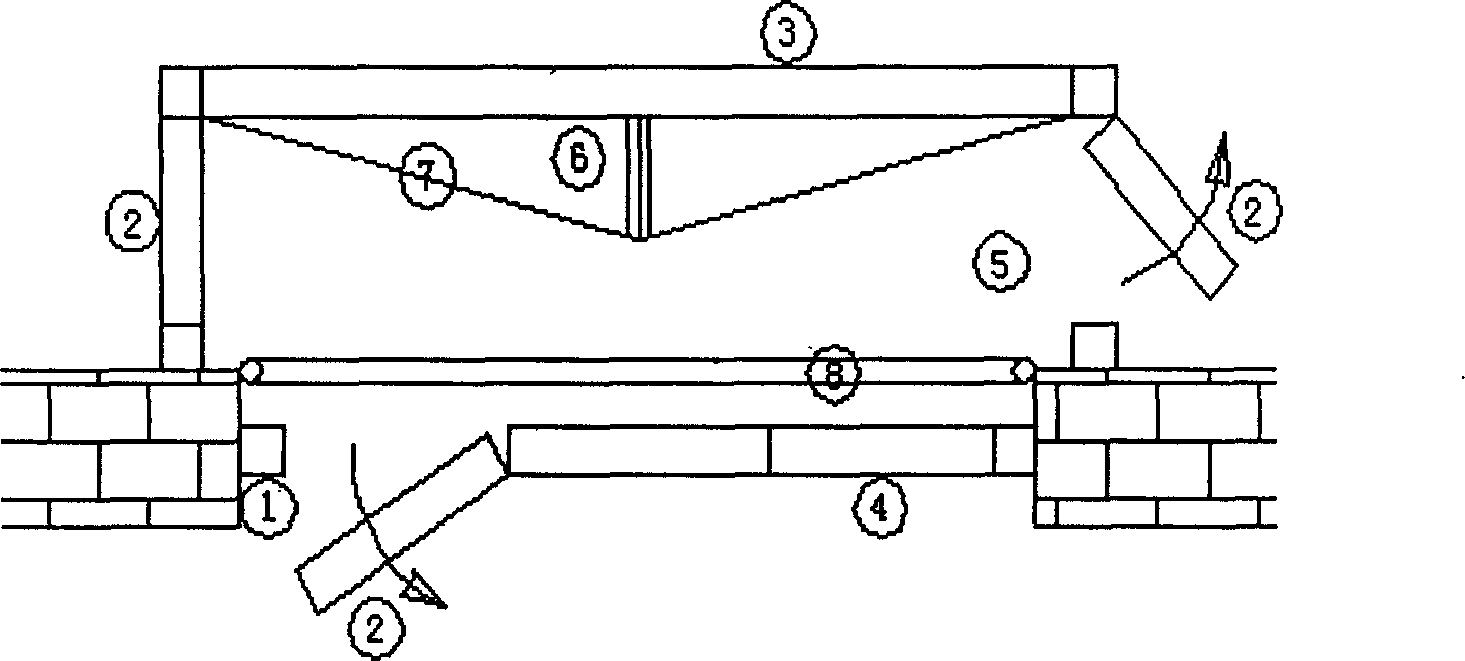

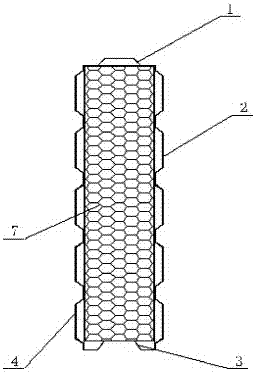

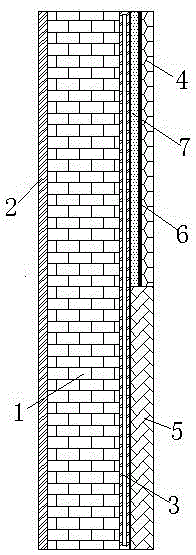

Composite mold clamp building block

InactiveCN102383521ALow costImprove thermal insulation performanceConstruction materialWallsBrickSlurry

A composite mold clamp building block is characterized by comprising an outer face plate (1) and an inner face plate (2). A heat preservation layer (3) is filled between the outer face plate (1) and the inner face plate (2). The outer face plate (1), the heat preservation layer (3) and the inner face plate (2) are connected to form a whole through connecting pieces (4). The composite mold clamp building block adopts an inner clamp heat preservation layer design, is lighter than a traditional clay brick, and meets the requirements of modern multiple floor buildings and high-rise buildings. A traditional process of on-site slurry wiping and wall building is changed, the building block can be directly installed and fixed, construction is fast, process flow and construction materials are reduced, and construction cost is lowered. After installation, the vertical face of a wall body is even and smooth, strength and rigidity of the vertical face are balanced. The composite mold clamp building block can effectively block heat bridge effect and obviously enhance heat preservation and insulation performance and fire-proof performance, and has good sound insulation effect and better comprehensive performance.

Owner:HUBEI SYNTHETIC SPACE TECH CO LTD

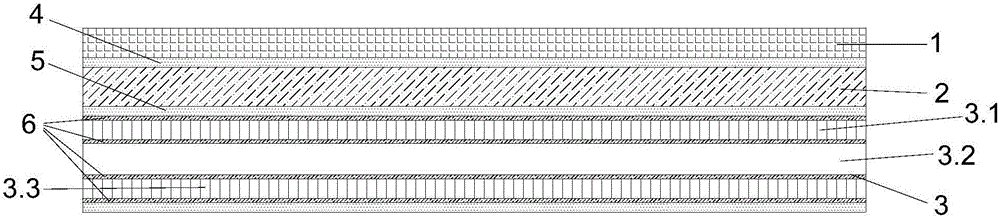

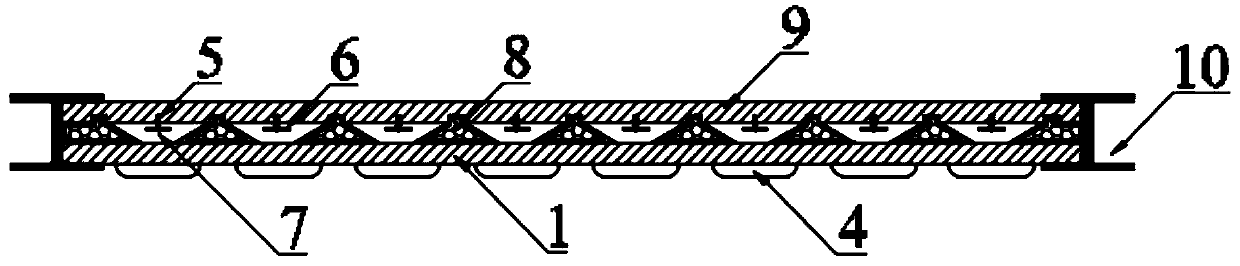

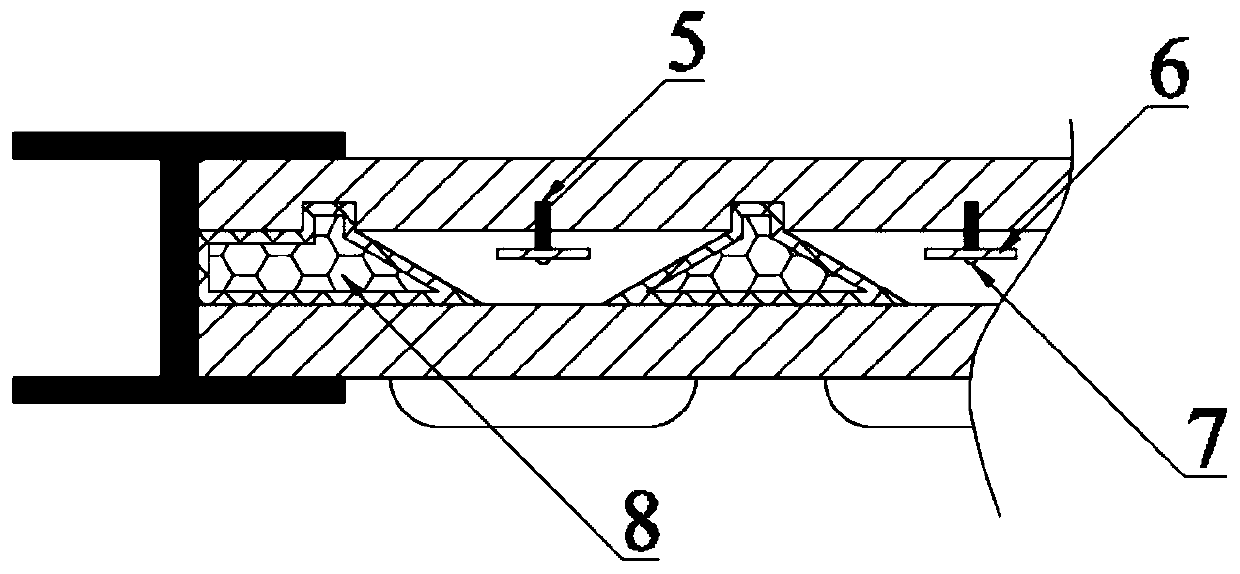

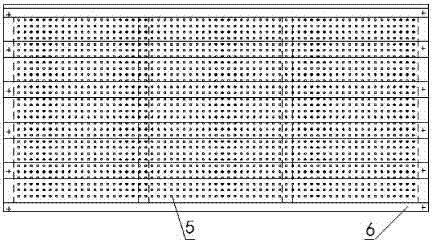

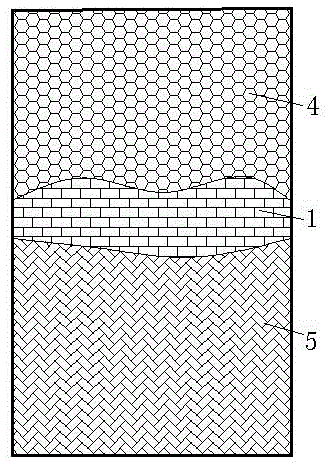

Composite sound absorbing and insulating board

InactiveCN106782482AImprove sound insulation performanceWide sound insulationSynthetic resin layered productsSound proofingWeather resistanceInsulation layer

The invention discloses a composite sound absorbing and insulating board. The composite sound absorbing and insulating board has a multi-layer structure, wherein an air layer is arranged between two panel honeycomb sandwich layers, so that the respective obstructing wave troughs can be avoided, the integral sound insulation property of the board can be effectively improved, meanwhile, elastic damping layers are arranged between a fireproof layer and a sound absorption layer and between the sound absorption layer and a sound insulation layer, so that the sound insulation amount and sound insulation frequency can be further improved, the propagation of noise can be effectively obstructed, and the composite sound absorbing and insulating board has the advantages of large sound insulation amount, wide sound insulation frequency and good sound absorbing and insulating properties. Due to the adoption of the structural form that the air layer is arranged between the two panel honeycomb sandwich layers, the composite sound absorbing and insulating board also has the features that the strength is high, the weight is small, meanwhile, the weather resistance, the fireproofing property and the like are also excellent, and the composite sound absorbing and insulating board is suitable for vibration and noise reduction in various fields including buildings, ships, automobiles and the like, and is wide in application range.

Owner:WUHAN UNIV OF TECH

Method for fabricating light sound absorption and insulation core board with waste slag powder modified micro-foam grains

InactiveCN103147520AGood sound absorption performanceLow costSolid waste managementNoise reduction constructionSlagAcoustic absorption

The invention relates to a method for fabricating a light sound absorption and insulation core board with waste slag powder modified micro-foam grains. With the adoption of density and acoustic impedance of the waste slag powder modified micro-foam grain added during micro-forming of polyurethane resin, the appropriate aperture and porosity of a micro-foaming material and the additive amount of waste slag powder are controlled to greatly improve sound insulation of the micro-foaming material with a sound absorption property, so that the light sound absorption and insulation core board with sound absorptivity and sound insulation ability is fabricated. The conventional concept that the traditional sound absorption material are poor in sound insulation effect generally is broken through, and the light sound absorption and insulation core board is suitable for composite sound insulation structures such as building walls in non-bearing structures, floors, interior decoration, and traffic sound barriers. The method has the advantages of waste recycling, high-rise building bearing reduction, increased indoor plot ratio, good sound absorption and insulation performances, low cost and the like, and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Environment-friendly partition for electric power station

ActiveCN103572862AImprove structural strengthReduce weightWallsSound proofingElectric power transmissionSteam-electric power station

The invention relates to an environment-friendly partition for an electric power station. The environment-friendly partition comprises a fence wall body, and is characterized in that a layer of non-punching metal plate covers the outer side wall of the fence wall body; a layer of vacuum glass is arranged on the inner side wall of the fence wall body. The structure is high in strength, light in weight, attractive in appearance, good in sound insulation capability and low in cost.

Owner:STATE GRID CORP OF CHINA +3

Novel sound barrier with resonance cantilever beam

ActiveCN111058391ASimple structurePracticalNoise reduction constructionCantilevered beamTraffic noise

A novel sound barrier with a resonance cantilever beam comprises an upper structure, a lower structure and a middle structure, wherein the upper structure and the lower structure are composed of combined sound absorption and insulation barrier plates, and the middle structure is composed of a fixed sound insulation frame and a transparent plate. The transparent plate and the up-down combined soundabsorption and insulation barrier plate are connected into a whole through the fixed sound insulation frame, and the transparent plate has a certain sound insulation effect besides providing a certain observation visual field for running traffic vehicles. The resonance sound absorption structure such as the resonance cantilever beam is applied to the sound barrier for the first time, the noise reduction effect of the sound barrier can be further enhanced, and the influence of traffic noise on life of people is reduced to the minimum.

Owner:EAST CHINA JIAOTONG UNIVERSITY

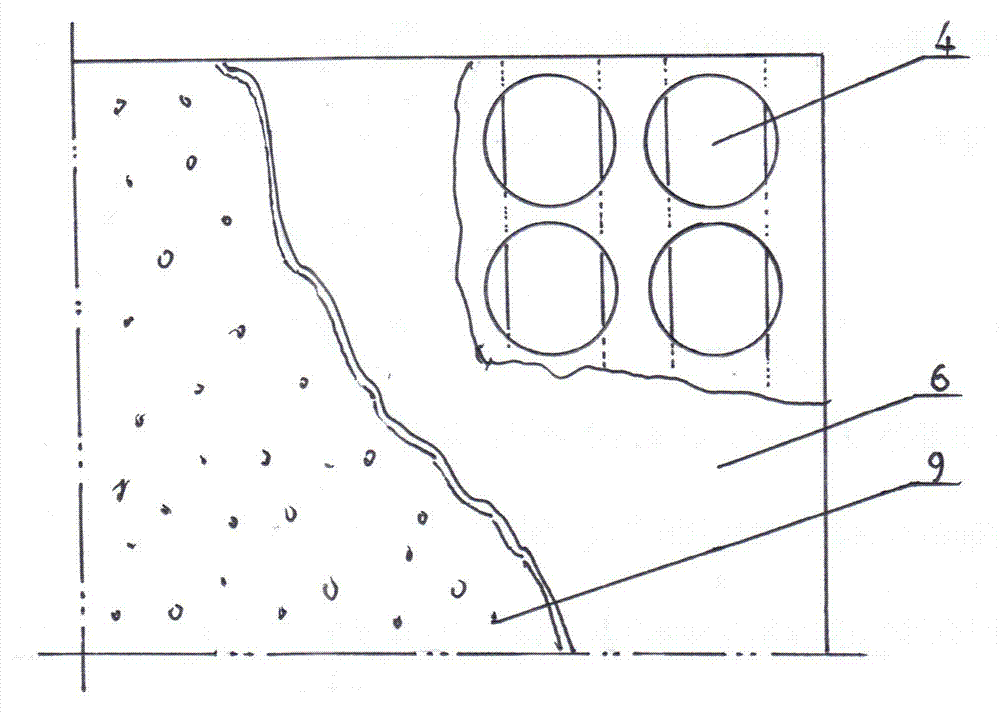

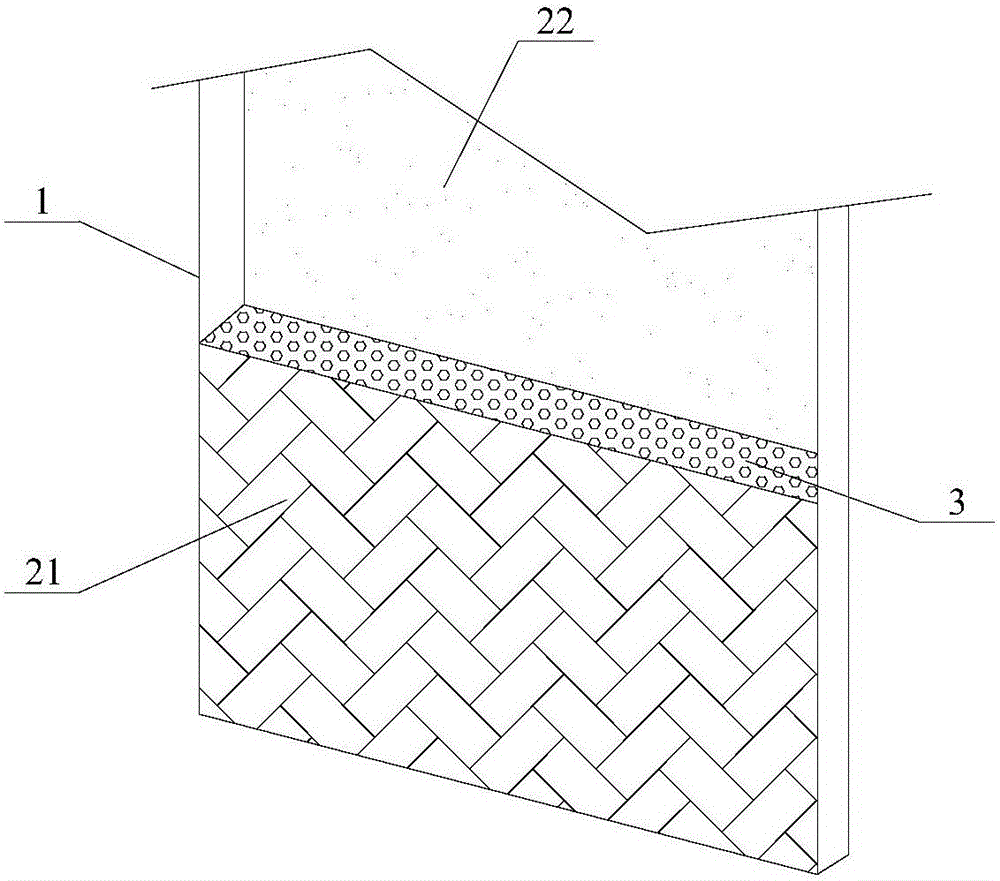

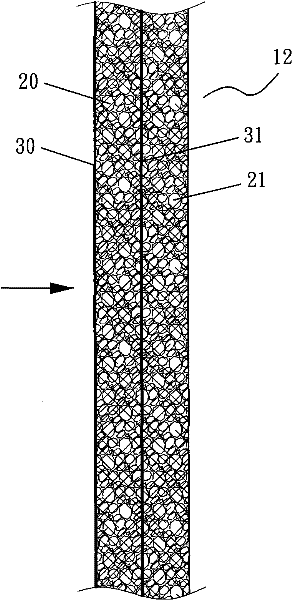

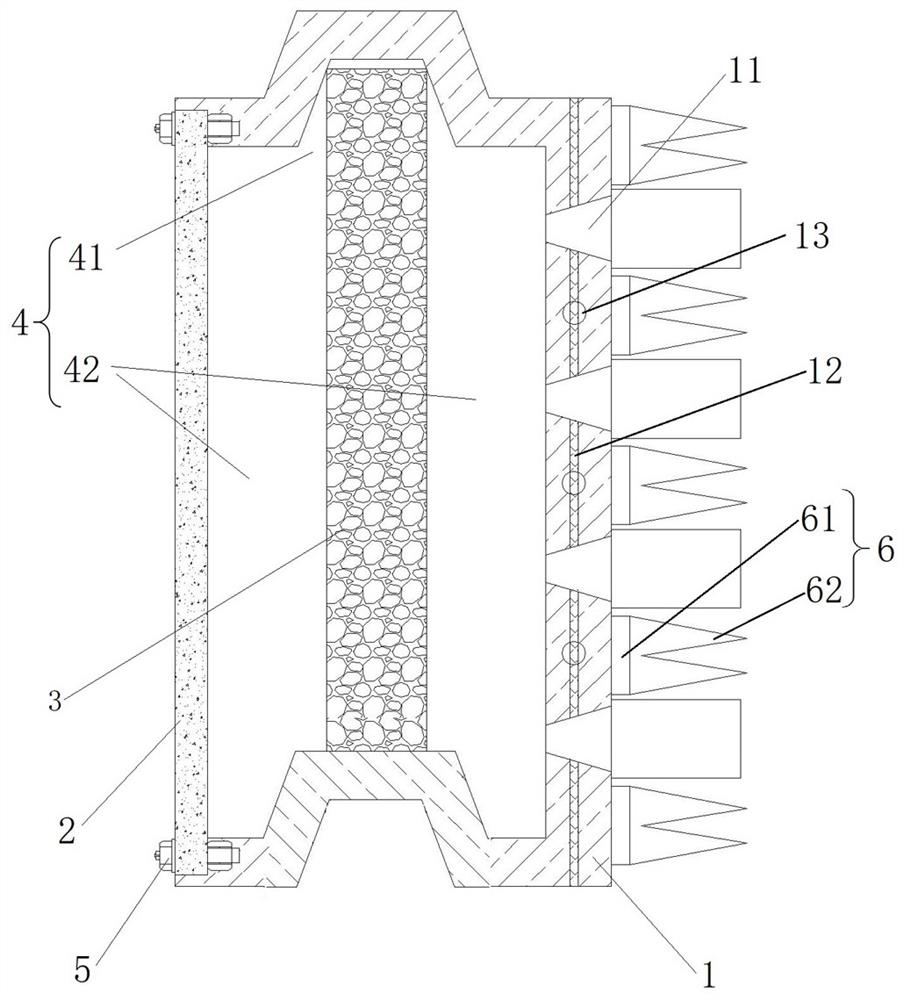

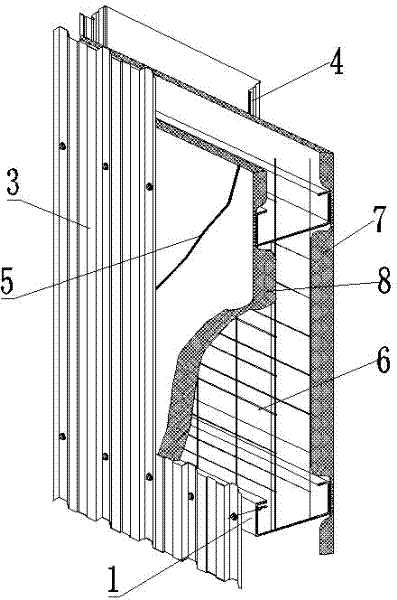

Light non-dismantling self-thermal-insulation cast-in-place wall and preparation method of filling material thereof

InactiveCN106284763AEliminate seam thermal bridgesReduce steel consumptionWallsHeat proofingMicron scaleKeel

The invention discloses a light non-dismantling self-thermal-insulation cast-in-place wall and a preparation method of filling material thereof. The preparation of the filling materials comprises the steps that micro-scale or micron-scale microcellular foam is prepared; the microcellular foam and inorganic compound gelatinization matrixes containing silicate are blended, microcellular slurry is formed through puffing foaming, and a light porous fire-resistant inorganic framework is prepared; the light porous fire-resistant inorganic framework is filled with organic lightweight aggregate, and mixed slurry is made; and the mixed slurry is solidified and formed. The light non-dismantling self-insulation cast-in-place wall comprises a keel frame, a non-dismantling wall plate fixed to the keel frame and the filling material. According to the light non-dismantling self-thermal-insulation cast-in-place wall and the preparation method of the filling materials thereof, no additional mould is supported, a pipeline can be embedded, construction is simplified greatly, cost is reduced greatly; in the casting process, plate expanding, template bursting and hollowing do not occur; the fireproof and self-insulation purposes are achieved, and thus no external thermal insulation needs to be conducted; seamless connection is achieved, and thus amount of steel used is reduced; weather resistance, the freezing and thawing resistance cycle and no crack are achieved, so that the service life of the wall is the same with that of a building; and no corrosion occurs, and thus a rust-proof role is played on a steel structure, and the service life of the steel structure is prolonged.

Owner:南京依科国特新材料科技有限公司

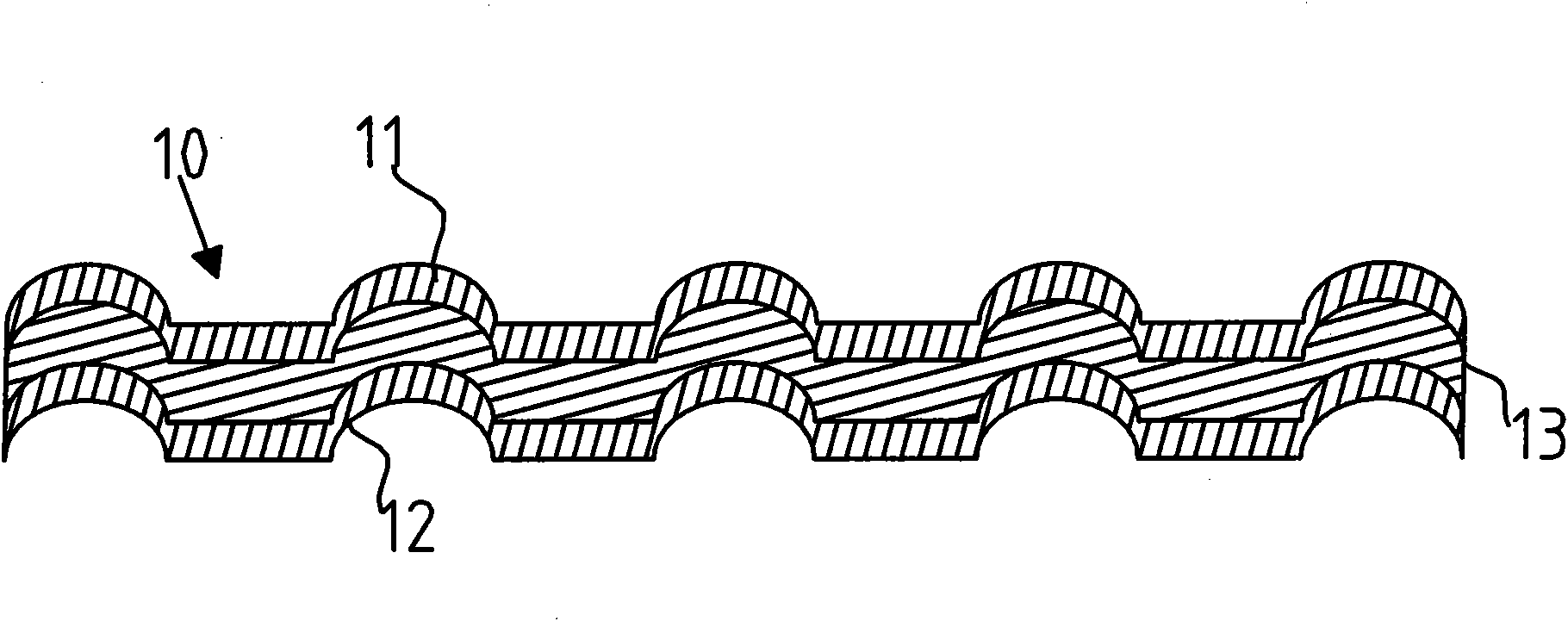

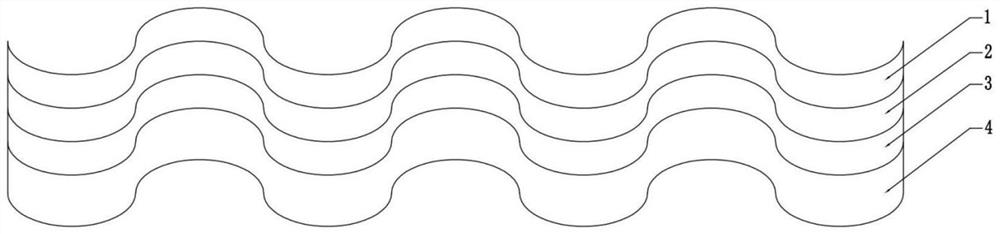

Three-layer resin glazed tile

InactiveCN101876194AImprove impact resistanceGood sound insulation effectRoof covering using slabs/sheetsParaffin waxProcedure Agents

The invention belongs to the technical field of building materials, in particular to a three-layer resin glazed tile, the glazed tile is in the shape of a sheet or a plate and constituted by a plurality of wave crests and / or wave troughs which are sequentially connected, and the glazed tile consists of a surface layer, a middle layer and a bottom layer, wherein the surface layer consists of modified resin ASA; the middle layer consists of 60-70% of polyvinyl chloride resin, 10-15% of anti-impact modifier, 3-5% of lubricant and 17-20% of processing aid; the bottom layer consists of 70-80% of polyvinyl chloride resin, 8-10% of anti-impact modifier, 2-5% of lubricant and 10-15% of processing aid; the anti-impact modifier is chlorinated polyethylene; the lubricant is one or mixture of more than one of oxidized polyethylene wax, stearic acid or paraffin; and the processing aid is one or the mixture of more than one of ACR, composite stabilizer, calcium carbonate or paint. The glazed tile has light weight, durability and good sound deadening and thermal insulation effects.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

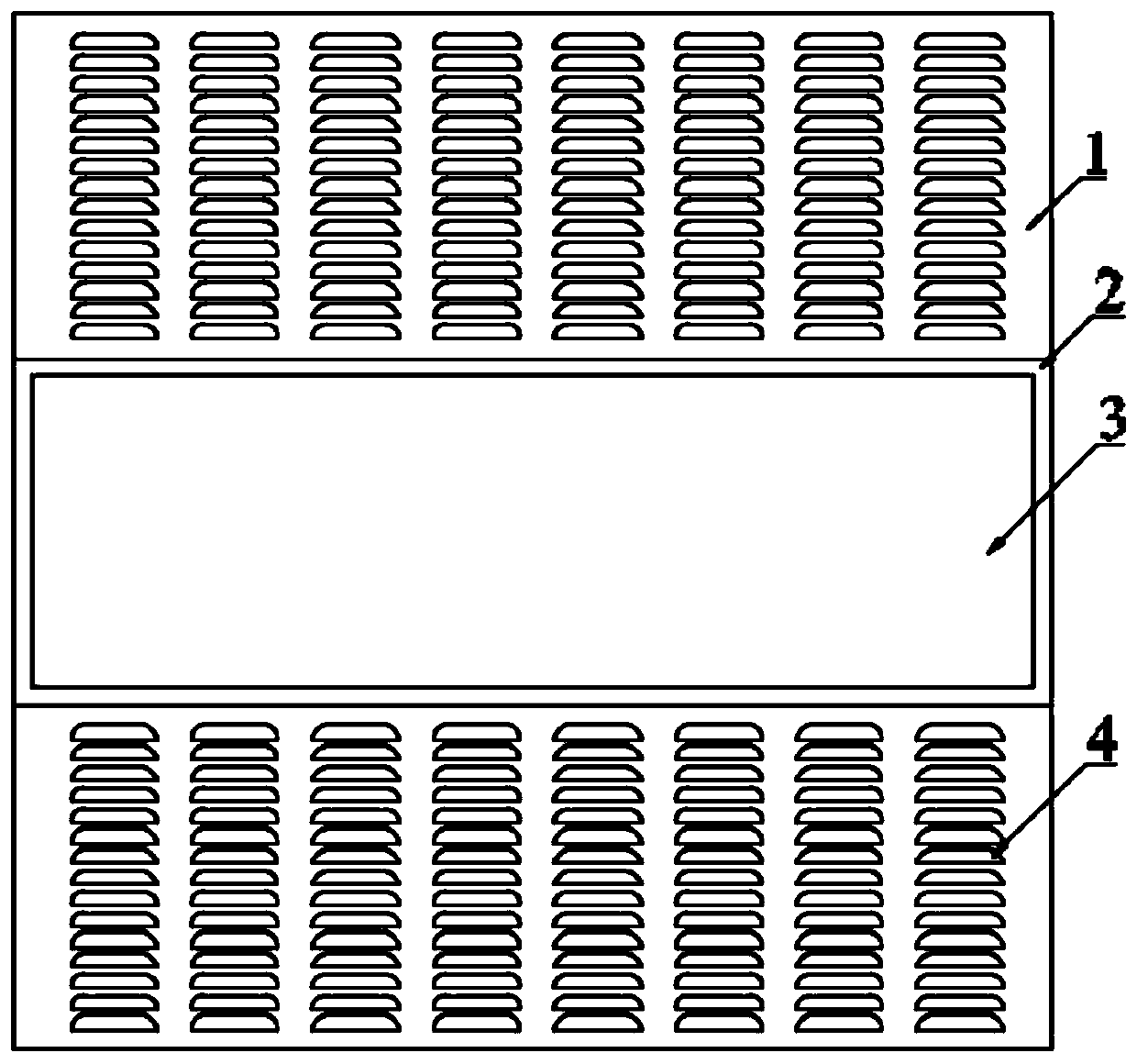

Sound absorbing and insulating ventilation window

InactiveCN1702286AMeet ventilation requirementsGood sound insulation effectVentilation arrangementNoise insulation doors/windowsAcoustic absorptionEngineering

This invention discloses a venting noise insulation widow, which comprises a window frame fixed in the wall and a group of glass widow set in the frame, wherein the window frame including a garment frame set outside the wall and a core frame set inside the wall, and both the garment and core frame are set glass widow can be opened; between the garment and core glass widow forms the acoustic cavity, and a transparent acoustic element is arranged in it; the invention can be the sound lock mode and the resonant mode according to the requirement. Between the garment and core frame it can be set shade and heatproof curtain.

Owner:NANJING CHANGRONG ACOUSTIC INC

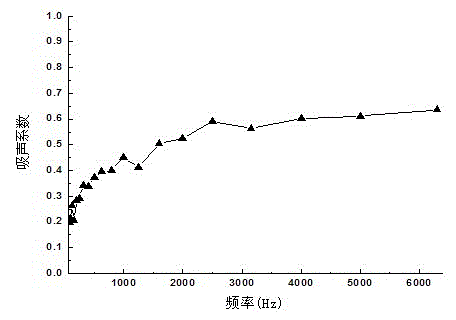

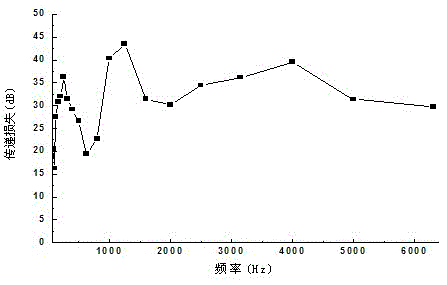

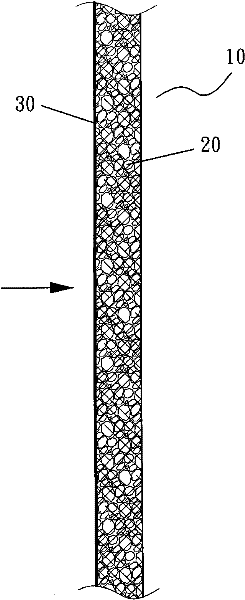

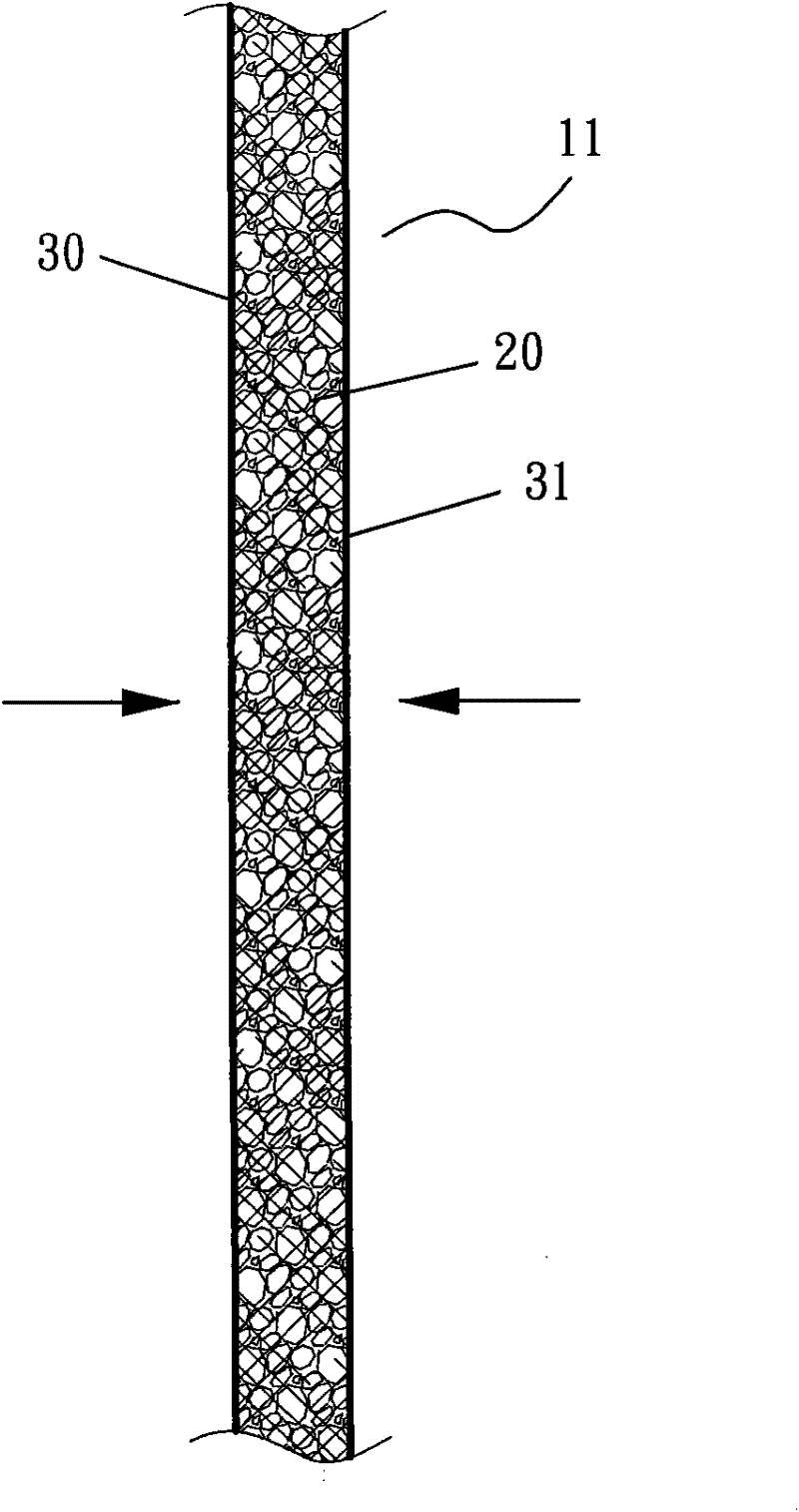

Sound absorption and insulation composite material structure

ActiveCN102689477AGood sound insulation effectGood sound absorption performanceSynthetic resin layered productsMaterial structurePolyethylene

The invention provides a sound absorption and insulation composite material structure composed by closely bonding at least one non woven fiber layer and at least one polyethylene film. Specifically, the non woven fiber layer is a fiber stack layer prepared from a recycled and environment friendly fiber material by a non woven technological process, and has thickness equal to or greater than 1mm. And the thickness of the polyethylene film is in the range of 0.009mm-0.1mm.

Owner:SAN SHIANG TECH

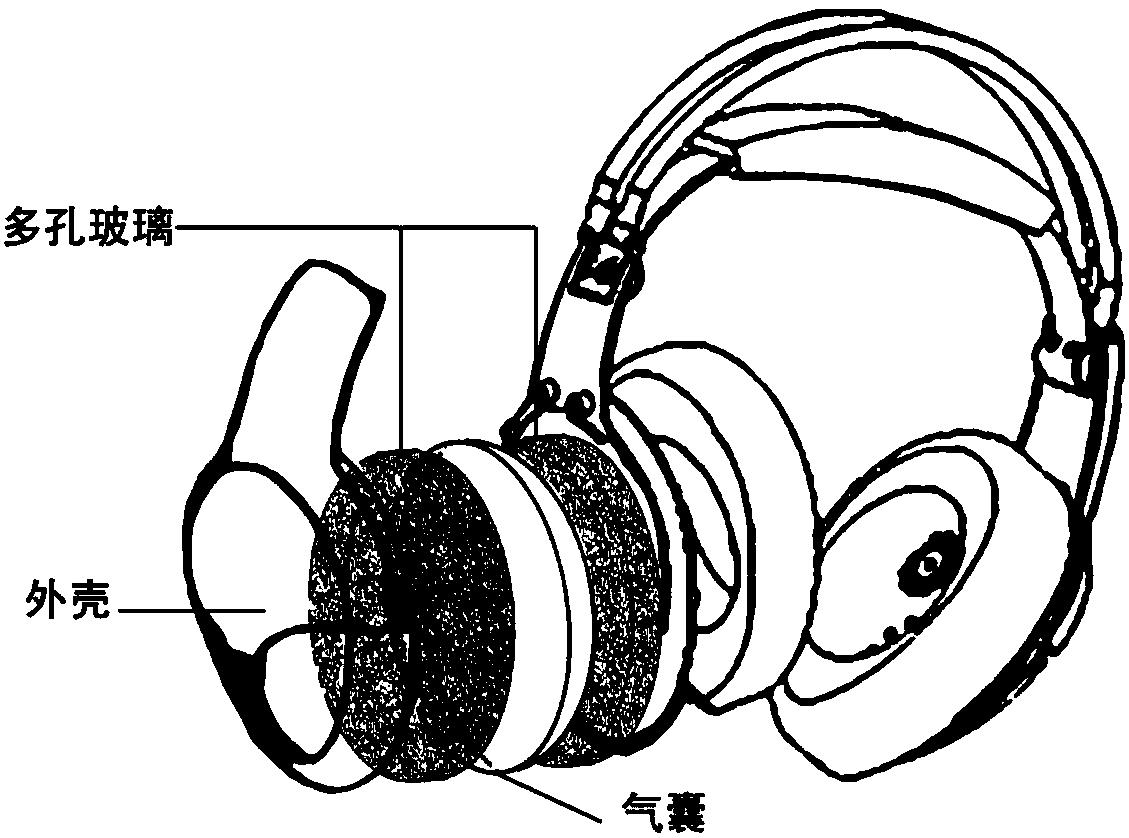

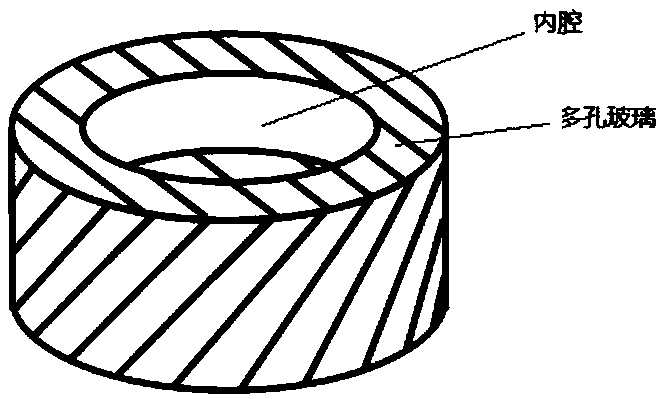

Sound insulation ear muff formed by tapping-type porous glass and air bag

PendingCN108269564ACommercializedEasy to processSound producing devicesEarpiece/earphone noise reductionFilling materialsEngineering

The present invention provides a sound insulation ear muff formed by tapping-type porous glass and an air bag. The sound insulation ear muff comprises an ear muff frame body, a housing, an external decoration layer and an internal filling layer; the internal filling layer is fixed in the ear muff frame body and the housing and is closed through the external decoration layer; the internal filling layer is formed by the tapping-type porous glass and a down-fill frameless air bag; the down-fill frameless air bag performs seaming by employing light flexible materials to form the air bag, and the air bag is filled with natural down feather. The tapping-type porous glass and the down-fill frameless air bag are taken as internal filling materials to prepare a light ear muff with a good sound insulation effect, and the light ear muff has good sound absorption and sound insulation effects in a human ear sensitive area range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flame-retardant sound insulation composite material and sound insulation component

ActiveCN101735530BFlame retardant hasGood sound insulation effectSound producing devicesIron powderPlasticizer

The invention relates to a flame-retardant sound insulation composite material. The flame-retardant sound insulation composite material comprises the following components in percentage by weight: 5 to 30 percent of PVC, 5 to 30 percent of chlorinated polyethylene, 15 to 80 percent of iron powder of which the grain diameter is 10 to 100 microns, 0.5 to 2 percent of coupling agent and 9.5 to 23 percent of aid. The invention provides the flame-retardant sound insulation composite material, which is prepared from the PVC, the chlorinated polyethylene, the iron powder with the grain diameter of 10to 100 microns, the coupling agent and the aid, has good flame-retardant sound insulation effect, and also has the characteristics of flame retardancy, innocuity, no lead, high strength, good construction property and low cost. Because the chlorinated polyethylene is particularly introduced into the material components of the flame-retardant sound insulation composite material, the using amount of a plasticizer of the material is reduced, and the composite material has better softness and can be widely applied to sound insulation treatment in the construction industry, decoration field and the like; and the sound insulation composite material can effectively reduce the noise, and the sound insulation index of the material can reach 25 to 32 decibels.

Owner:深圳洛赛声学技术有限公司

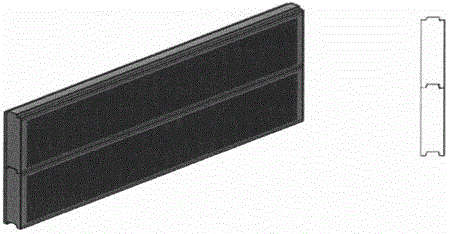

Sound absorbing and insulating barrier plate

InactiveCN107513948ASound absorption frequency bandwidthGood sound insulation effectNoise reduction constructionEngineeringLoad capacity

The invention provides a sound-absorbing and insulating barrier board with a wide sound-absorbing frequency band and good sound-absorbing and insulating effects, which includes a panel and a backboard. Installed on the frame, a cavity is formed between the panel and the back plate, and sound-absorbing material is arranged in the cavity. The surface and the back panel are respectively fixed to the skeleton so that the barrier panel has a strong resistance to external force loads, and the sound-absorbing material is arranged between the panel and the back panel to make the barrier panel have better sound absorption and sound insulation effects.

Owner:HUBEI XUFENG ENVIRONMENTAL TECH

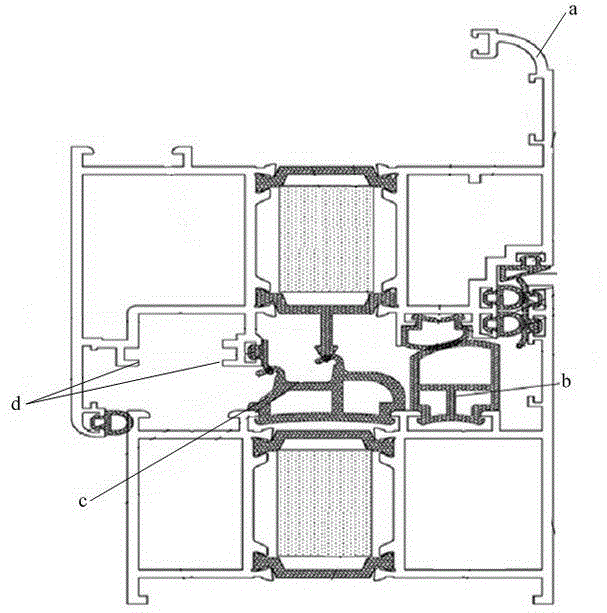

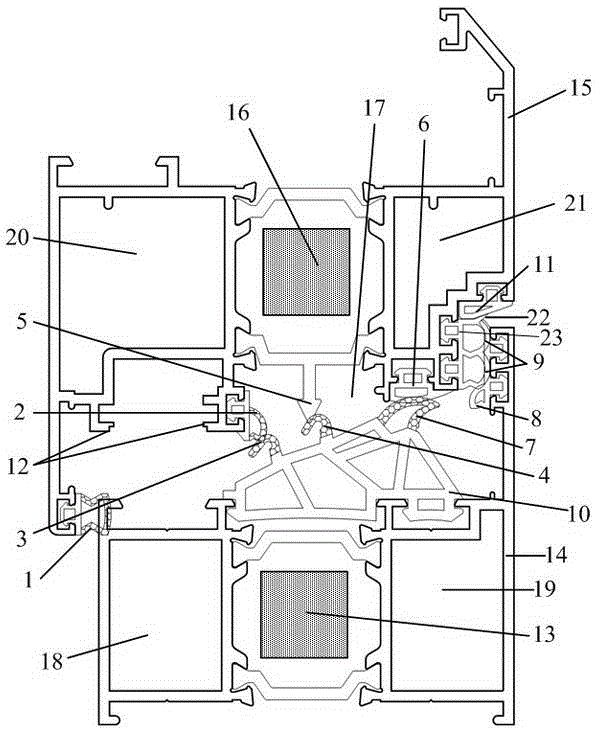

Heat-insulating aluminum alloy section comprising heat-insulating bars and multiple seals

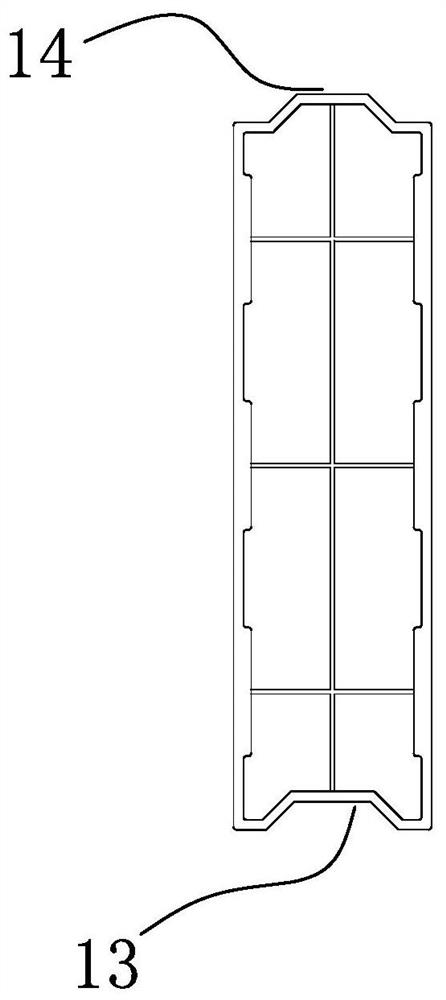

InactiveCN104594763AReduce resonance effectStop lossWindow/door framesSealing arrangementsSash windowEngineering

The invention discloses a heat-insulating aluminum alloy section comprising heat-insulating bars and multiple seals. The heat-insulating aluminum alloy section comprises a window frame (14) and a window sash (15), wherein the window frame (14) is compounded by an inner window frame (18) and an outer window frame (19); the window sash (15) is compounded by an inner window sash (20) and an outer window sash (21); the window frame (14) and the window sash (15) are provided with a plurality of sealing element notches; matched sealing elements and heat-insulating bars are arranged in the notches; the inner window frame (18) and the outer window frame (19) are connected through a deformed sealing channel (10); a plurality of sealing elements are arranged on the deformed sealing channel (10). The heat-insulating aluminum alloy section has a good sealing effect.

Owner:涂益红

Thermal-adapting and environment-friendly soundproof floor and manufacturing method thereof

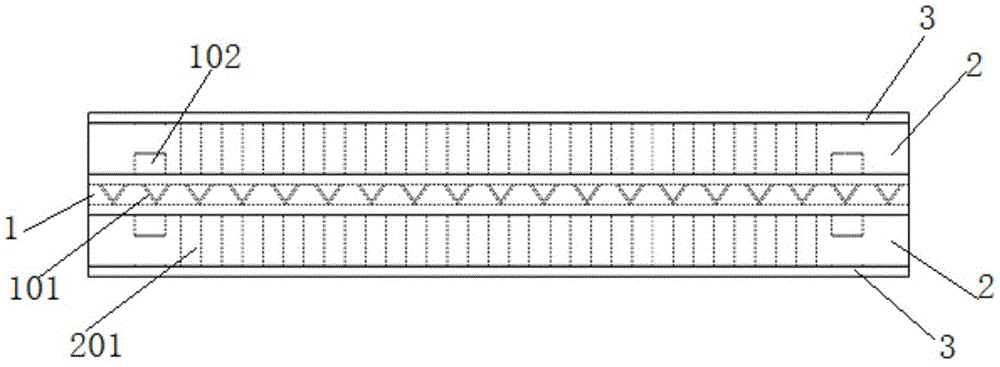

ActiveCN111251398AWith self-heating abilityImprove suitabilityReed/straw treatmentCellulose treatment using microorganisms/enzymesResin matrixFibrous composites

The invention discloses a thermal-adapting and environment-friendly soundproof floor and a manufacturing method thereof. Soundproof paint comprises an encapsulating material, functional filler and a surface wear-resisting layer, wherein the encapsulating material is a resin matrix prepared from 45-56 parts by weight of phenolic resin as a raw material, the functional filler is a bamboo fiber composite material prepared from 200-220 parts by weight of moso bamboo and 50-60 parts by weight of mirabilite as raw materials, and the surface wear-resisting layer is a wear-resisting composite materialprepared from 4-5 parts by weight of aluminum oxide powder and 1-1.2 parts by weight of phenolic resin as raw materials. The soundproof floor is thermal-adapting, endothermically liquefied, wholly softened, shake-proof and wear-resisting.

Owner:江苏昊星新材料有限公司

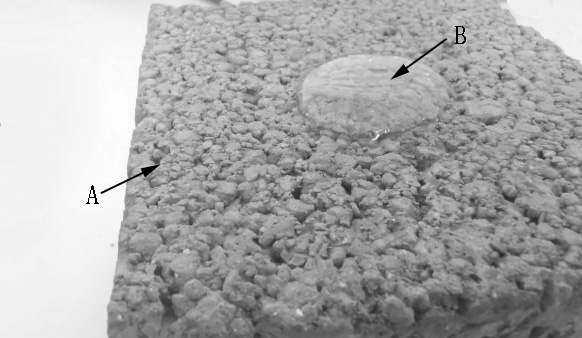

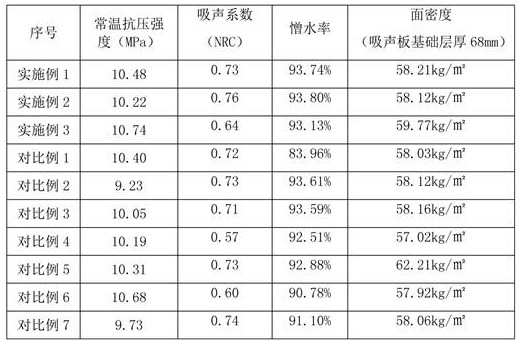

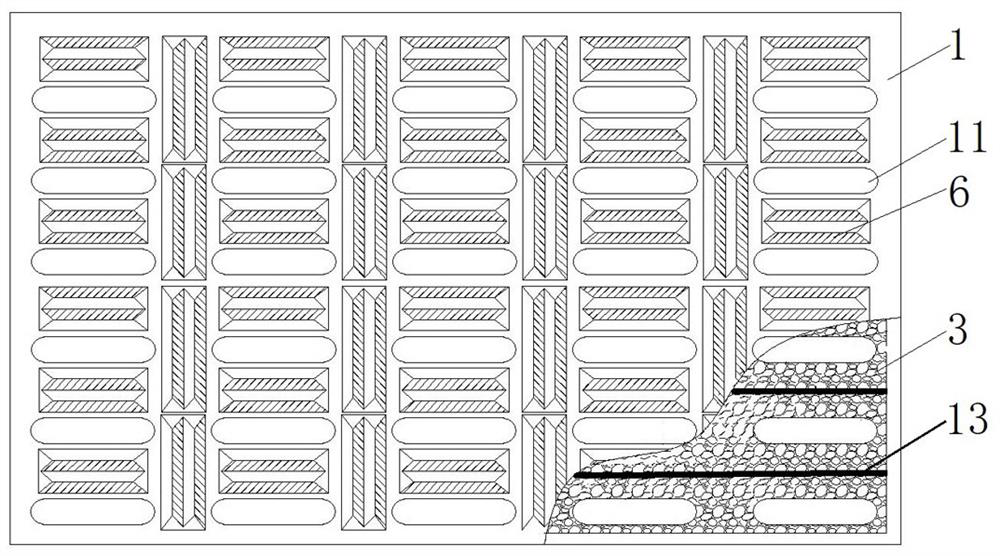

Ceramsite acoustic board and preparation method thereof

The invention relates to a ceramsite acoustic board and a preparation method thereof. The preparation method comprises the following steps: preparing a resin mixed bonding solution by adding a curingagent accounting for 75-85 wt% of the mass fraction of thermosetting resin, an accelerant accounting for 1-3 wt% of the mass fraction of the thermosetting resin and a thinner accounting for 60-70 wt%of the mass fraction of the thermosetting resin into the thermosetting resin and stirring, dispersing 0.3-3 wt% of graphene oxide powder equivalent to the mass fraction of the resin mixed bonding solution into 100 ml of solvent, performing ultrasonic treatment to obtain graphene oxide dispersion liquid, adding the graphene oxide dispersion liquid into the resin mixed bonding solution, and stirringto obtain a mixed molten liquid, adding the mixed molten liquid into a certain amount of mixed aggregate, stirring to obtain a mixture, pouring the mixture into a mold, paving the mold with the mixture, carrying out vibration compaction, carrying out a reaction for a period of time at a certain temperature to obtain a sound absorption plate base layer, and carrying out hydrophobic treatment on the outer side of the sound absorption plate base layer, so that the outer surface of the sound absorption plate base layer is coated with the hydrophobic layer, and the ceramsite sound absorption plateis obtained.

Owner:天工俐德科技发展有限公司

Integrated shell sound absorption unit for rail transit sound barrier

PendingCN111663462ABeautiful appearanceEasy to manufactureNoise reduction constructionSound barrierEngineering

The invention relates to an integrated shell sound absorption unit for a rail transit sound barrier. The unit comprises an integrated cylindrical shell, a sound absorption material and an end cover, the sound absorption material is arranged in an internal cavity formed by the integrated cylindrical shell, and the end cover is arranged on an end surface of the integrated cylindrical shell; and theintegrated cylindrical shell and / or the end cover are / is made of a fiber reinforced composite material. The unit is good in sound absorption and insulation performance, high in strength, simple in structure and the like by designing the structure. Because the selected fiber reinforced composite material can be pressed by a mold, the produced sound absorption unit is attractive in appearance, convenient to manufacture, high in production efficiency, suitable for batch production and particularly light, the sound absorption unit has a characteristic of light dead weight, a bearing load of an elevated light rail and an elevated road can be reduced, and structural cost can be decreased; and the fiber reinforced composite material has strong wind load resistance and is not easy to corrode.

Owner:CHINA RAILWAY ELECTRICAL IND CO LTD +3

Decoration plate

InactiveCN105421706AUniform internal and external structureGood dimensional stabilityCovering/liningsSound proofingQuality levelEngineering

The invention provides a decoration plate, and belongs to the field of high-performance materials; with the improvement of modern life quality level, people pay more and more attentions to the decoration of home life; and a traditional decoration plate has multiple problems, such as weak fireproof effect, low strength of a decoration layer and bad noise isolating effect, so that a decoration plate capable of making up the defects, convenient for production and lower in cost is needed. The decoration plate is level and smooth and uniform in inner and outer structures, has the characteristics of good size stability, high strength and good environmental protecting and noise isolating effect, and has excellent processability and surface decoration performance.

Owner:TIANJIN YINLONG HIGH TECH NEW MATERIAL RES INST

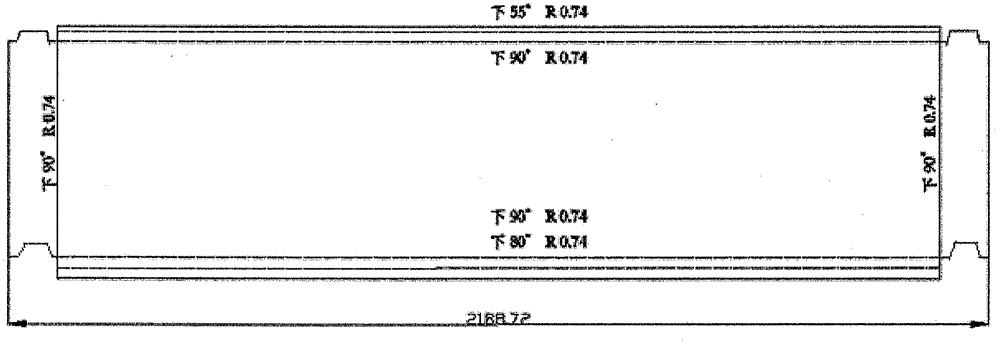

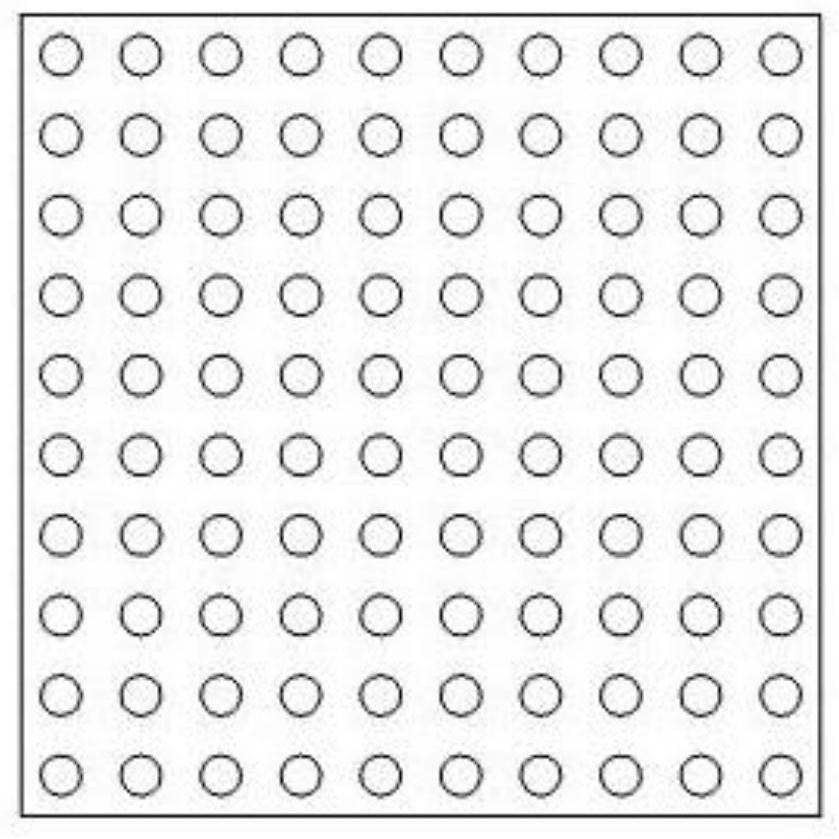

Combined non-metal sound barrier unit plate

PendingCN112359737ARegular appearance and sizeAvoid cloggingNoise reduction constructionSound barrierEngineering

The invention belongs to the technical field of non-metal sound barriers, and particularly relates to a combined non-metal sound barrier unit plate. Wherein the sound absorption plate comprises a panel, a back plate and a sound absorption material arranged between the panel and the back plate; wherein the panel is concaved inwards to form an outer shell with a box cavity, the sound absorption material is arranged in the box cavity, the panel and the back plate are connected through bolts, the panel is formed by pouring bubble concrete, and sound absorption holes are evenly distributed in the panel. The combined type nonmetal sound barrier unit plate has the advantages of being light in weight, high in durability, low in use cost and convenient to assemble and disassemble, and various soundabsorption structures achieve cooperative noise elimination.

Owner:衡水中裕铁信环保工程有限公司

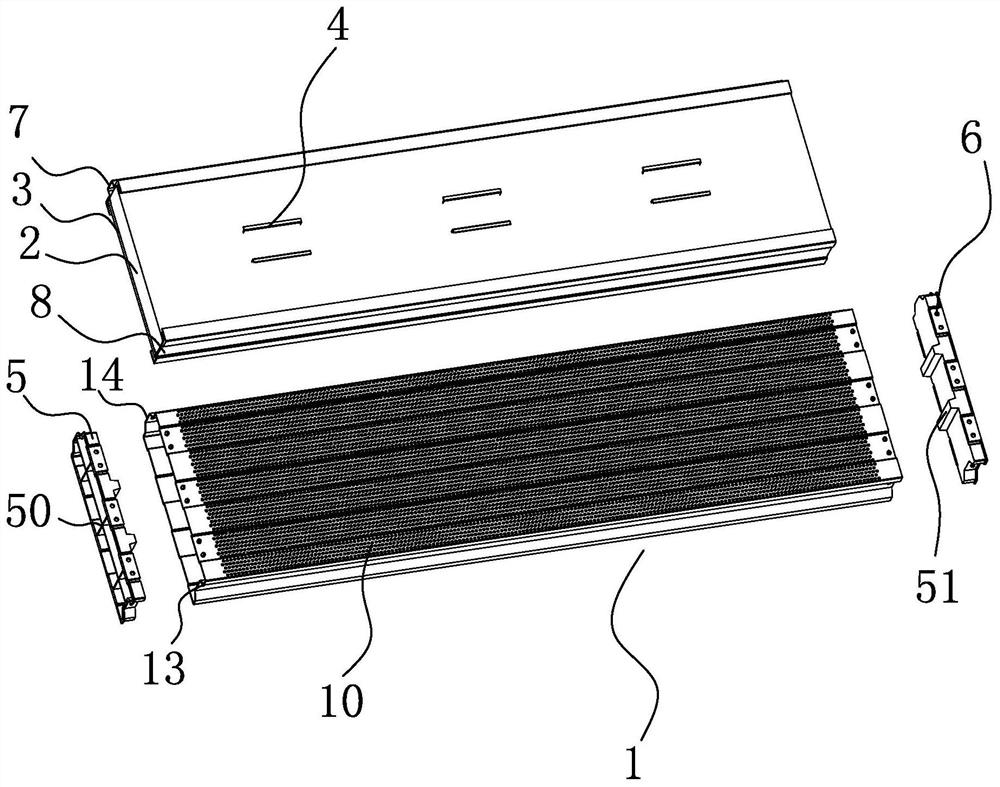

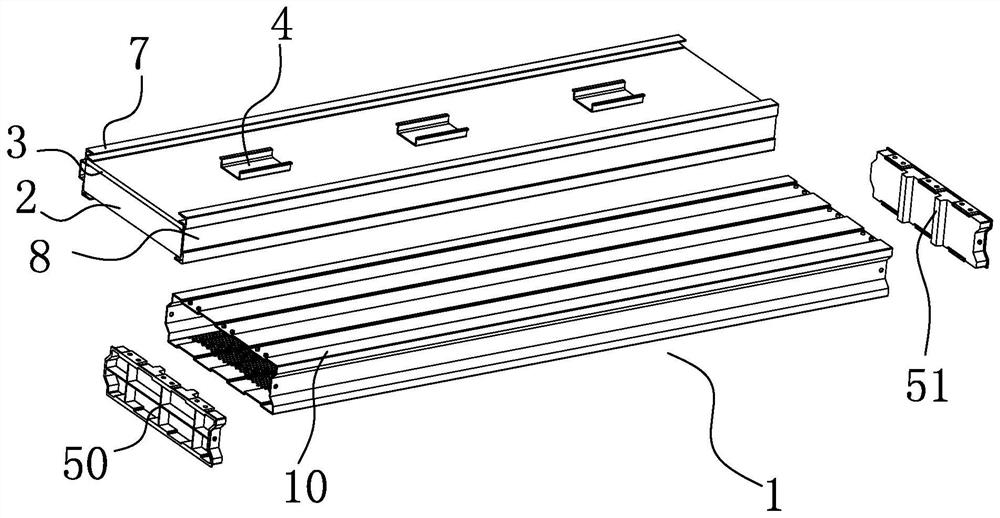

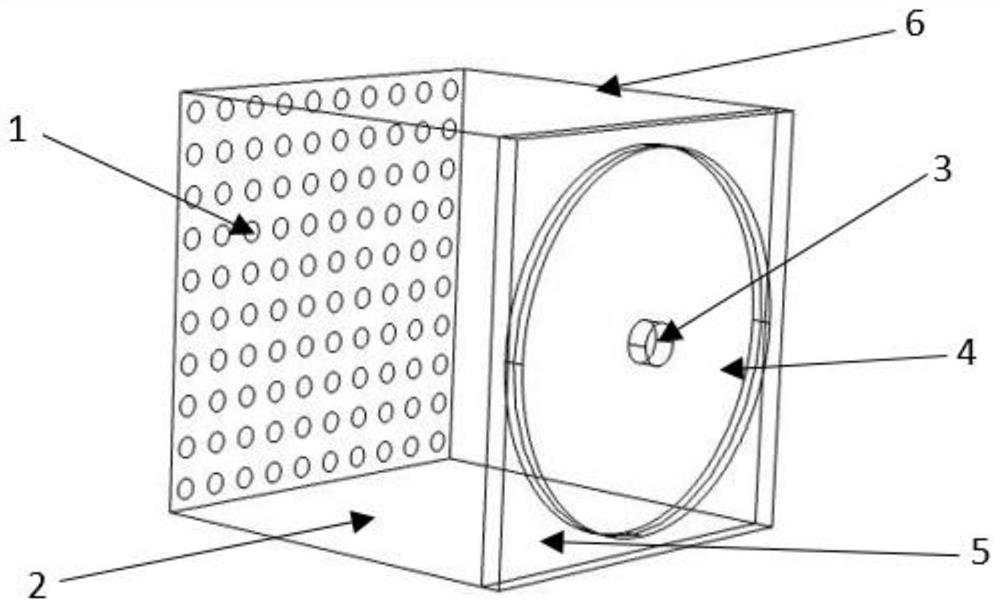

Non-cotton super-microporous metal noise barrier

The invention relates to a non-cotton super-microporous metal noise barrier. The non-cotton super-microporous metal noise barrier replaces harmful sound absorbing materials such as rock wool, glass cotton and so on and is shown in figure 1. The non-cotton super-microporous metal noise barrier comprises a microporous metal panel and a metal back plate; the microporous metal panel is an aluminum plate; a plurality of small holes with different shapes and apertures are formed in the surface of the microporous metal panel; the microporous metal panel is made of a galvanized steel sheet; the microporous metal panel and the metal back plate are assembled together in a buckling manner after being bent and formed; and three reinforcements having effects of supporting and enhancing the rigidity are additionally mounted in a chamber, close to the microporous metal panel, between the microporous metal panel and the metal back plate in a horizontal direction. The non-cotton super-microporous metal noise barrier has passed detection of national building materials test center and has obvious sound absorbing and insulating effects; in addition, the non-cotton super-microporous metal noise barrier has the advantages of simple structure, convenient production and mounting, rivetless connection, beautiful and elegant appearance, fire prevention and durability, can be widely applied to noise insulation for rail transit, expressways and various machineries and can be also used for ceilings, large-sized houses, classrooms and so on.

Owner:河北惠康恒达环保科技有限公司

Composite noise-proof barrier

InactiveCN108978504AExcellent noise barrier functionGood sound insulation effectNoise reduction constructionCeramicwareMoistureMaterials science

The invention belongs to the technical field of sound insulation barrier, in particular to a composite sound insulation barrier. 30 to 40 parts of magnesium oxide, 20 to 25 parts of magnesium chloride, 20 to 30 parts of water, 0.3 to 0.5 parts of modifier, 0.05 to 0.15 parts of foaming agent, 5 to 10 parts of fly ash, 5 to 10 parts of sawdust and 0.01-0.05parts of granulating agent. 0.05; The composite sound insulation barrier of the invention has excellent barrier noise function and good sound absorption and insulation effect, it also has high mechanical strength in construction application,Low density and light weight, the cutting adhesion construction performance is good, Water-proof, moisture-proof, corrosion-proof, mildew-proof, not easy to break, aging, long service life and other excellent material characteristics, and does not contain any heavy metals and other harmful substances, suitable for road sound barrier as sound-absorbing and insulation core material, but also used incity libraries, schools, hospitals, office buildings and other buildings as sound-absorbing and insulation materials for internal and external walls.

Owner:JINLING INST OF TECH

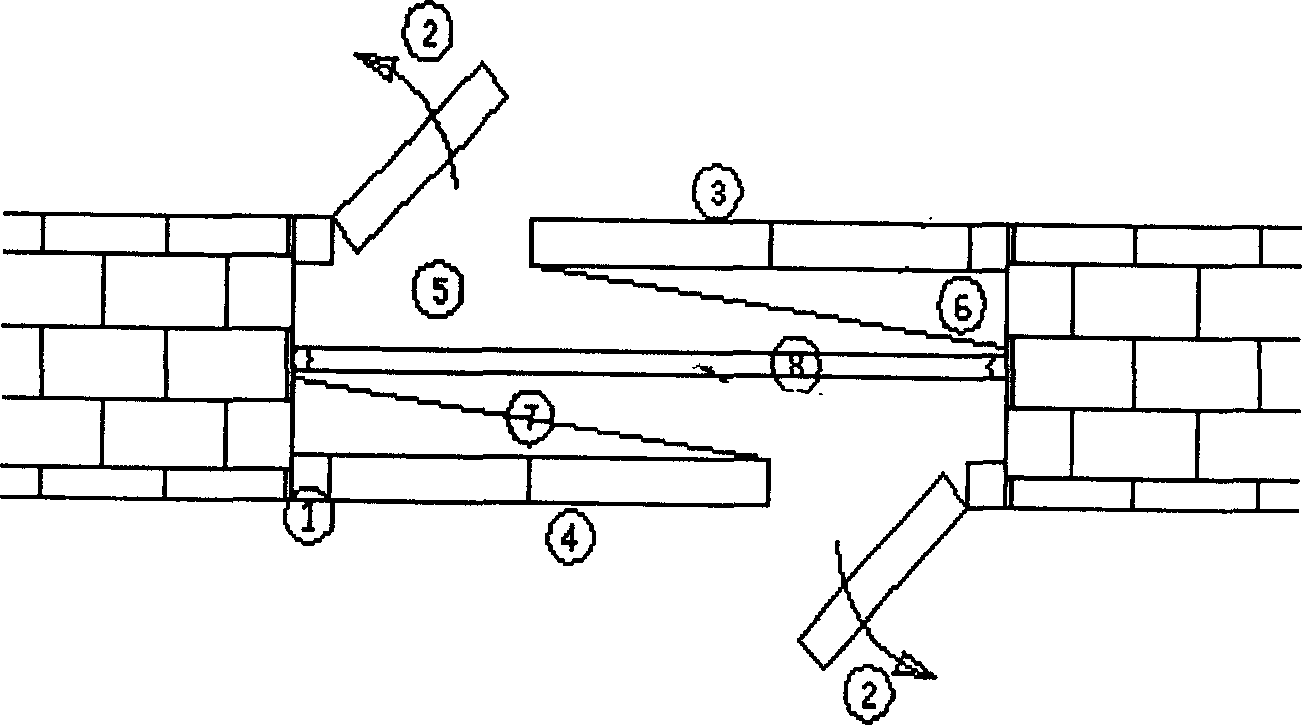

Disposable on-site compound explosion-venting sound-insulating wall

The invention relates to an explosion-venting sound-insulating wall and particularly relates to a disposable on-site compound explosion-venting sound-insulating wall which comprises a steel framework, wherein an outer wall body and an inner wall body are respectively arranged on the two sides of the steel framework. The explosion-venting sound-insulating wall is characterized in that a steel wire mesh is mounted on the steel framework; the outer wall body is composed of a plurality of hidden buckling plates which can be broken under the action of a certain pressure; and an explosion-proof non-woven fabric is paved on the inner side of an inner wall plate. The disposable on-site compound explosion-venting sound-insulating wall has the characteristics of simple structure, convenience in mounting, beautiful appearance, excellent explosion-venting sound-insulating effect and the like.

Owner:LINDE ENG HANGZHOU

Moisture-resisting self-disinfection environment-friendly sound insulation floor and manufacturing method thereof

InactiveCN111305508AGood hygroscopicityEfficient killingPressure wood treatmentWeft knittingAcetic acidMoisture absorption

The invention discloses a moisture-resisting self-disinfection environment-friendly sound insulation floor and a manufacturing method thereof. A sound insulation material is composed of a packaging material, function filler and a surface wear-resisting layer. The packaging material is an organic matter matrix prepared by adopting 45-56 parts of an ethylene-vinyl acetate polymer by weight as the raw material. The function filler is a bamboo fiber composite prepared by adopting 200-220 parts of sinocalamus affinis and 50-60 parts of glacial acetic acid by weight as raw materials. The surface wear-resisting layer is a wear-resisting composite prepared by adopting 4-5 parts of aluminum oxide powder and 1-1.2 parts of an ethylene-vinyl acetate polymer by weight as raw materials. The moisture-resisting self-disinfection environment-friendly sound insulation floor can achieve moisture absorption, self disinfection, long-time volatilization of disinfection components, softness and sound insulation.

Owner:WEISHAN HONGRUI POWER TECH CO LTD

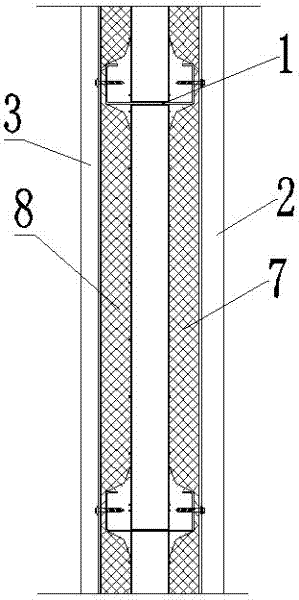

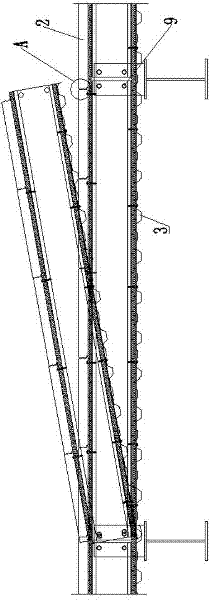

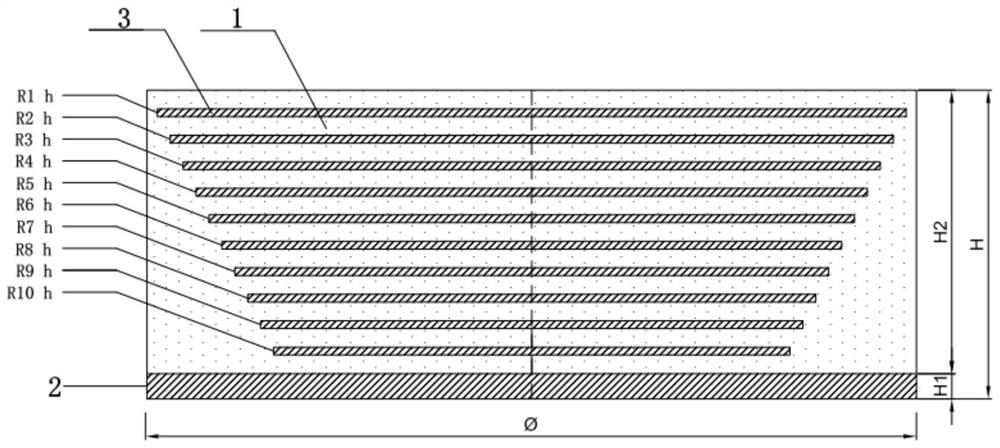

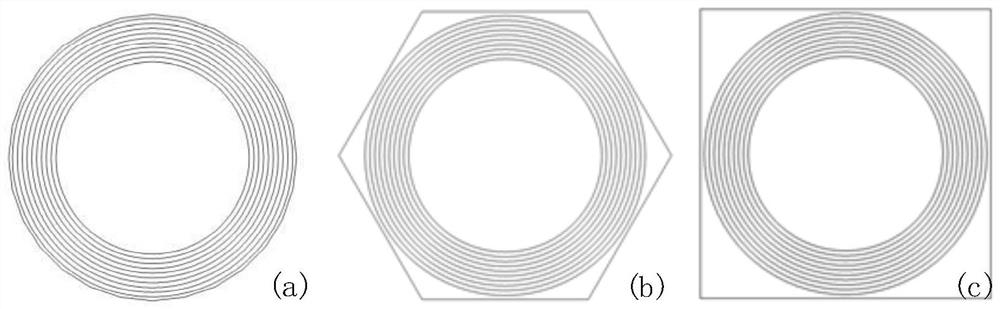

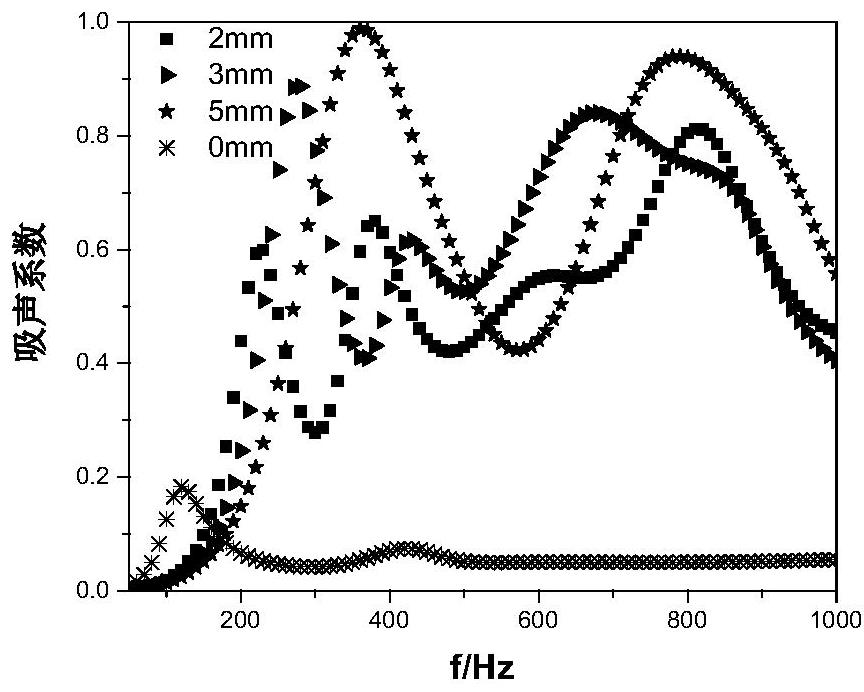

Local resonance type acoustic metamaterial low-frequency sound absorption and insulation structural member

PendingCN114023293AAchieve perfect sound absorption effectGood sound insulation effectSound producing devicesNoise controlResonance

The invention discloses a local resonance type acoustic metamaterial sound absorption and insulation structural member which comprises an elastic column, scatterers and a steel backing, the elastic column is connected to the steel backing, and a plurality of layers of circular scatterers with the same thickness and the diameters increasing in an equivalent mode are embedded into the elastic column at equal intervals from bottom to top; the elastic column is made of rubber, and the steel backing and the scatterer are made of steel. On the basis of the local resonance principle, the scattering bodies are evenly embedded into the elastic columns, sound waves are subjected to resonance coupling of the elastic columns and the scattering bodies and blocking of the steel backing, the sound absorption broadband is widened to be as low as 200 Hz, even the perfect sound absorption effect can be achieved at a certain specific frequency, meanwhile, the sound insulation index is increased to 97 dB, and excellent sound absorption and insulation performance is shown in a low broadband range. The structure is simple to prepare and low in cost, and engineering application value is provided for noise control in a low-frequency range.

Owner:JIANGSU UNIV OF SCI & TECH

Multilayer resin tile and manufacturing process thereof

PendingCN112389059AHigh strengthImprove waterproof performanceLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolyolefin

The invention discloses a multilayer resin tile which is of a corrugated plate structure and comprises a surface layer, a corrosion-resistant layer, a bonding layer and a heat insulation base materiallayer, and the surface layer, the corrosion-resistant layer, the bonding layer and the heat insulation base material layer are sequentially arranged from top to bottom. The surface layer is composedof modified resin ASA; the corrosion-resistant layer is prepared from the following components in parts by weight: 20-35 parts of PVC, 7-12 parts of high-impact polystyrene, 1-7 parts of talcum powder, 2-5 parts of urea resin, 5-12 parts of polyethylene glycol, 7-10 parts of glass beads, 0.2-1 part of an antioxidant, 2-7 parts of glass fibers and 15-20 parts of PE wax; and the bonding layer comprises the following components in parts by weight: 20-25 parts of modified PMMA resin and 1-5 parts of polyolefin hot melt adhesive. The invention belongs to the field of building materials, and particularly relates to a multi-layer resin tile and a manufacturing process thereof. The multi-layer resin tile is light in weight, durable, good in noise reduction and heat insulation effect, flame-retardant, fireproof, long in service life and good in performance.

Owner:湖南省建新建材有限公司

Ultraviolet-proof, noise-reduction, heat-insulation and energy-saving glass film and preparation method thereof

InactiveCN106541657AReasonable collocationHigh strengthSynthetic resin layered productsInsulation layerUltraviolet

The invention discloses an ultraviolet-proof, noise-reduction, heat-insulation and energy-saving glass film and a preparation method thereof. The glass film is formed through compounding an ultraviolet ray absorption layer, a sound absorption layer, a heat insulation layer and a nano-grade metal layer. The glass film has an efficient ultraviolet-proof effect and high strength, and has three effects of resisting ultraviolet rays, reducing noises and insulating heat; components of each coating are reasonably matched, and a production method is simple and easy to operate; the glass film has the advantages of low coefficient of thermal conductivity, good sound-insulation and attraction effects, low economic cost, long service life, wide application range, energy saving and environment protection, is applicable to industrial production and can be used for houses, offices and car windows; and the glass film has relatively good ultraviolet-ray-shielding, heat-insulation and sound-insulation effects so as to maintain a comfortable indoor environment.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

Power station environmental protection partition wall

The invention relates to an environment-friendly partition for an electric power station. The environment-friendly partition comprises a fence wall body, and is characterized in that a layer of non-punching metal plate covers the outer side wall of the fence wall body; a layer of vacuum glass is arranged on the inner side wall of the fence wall body. The structure is high in strength, light in weight, attractive in appearance, good in sound insulation capability and low in cost.

Owner:STATE GRID CORP OF CHINA +3

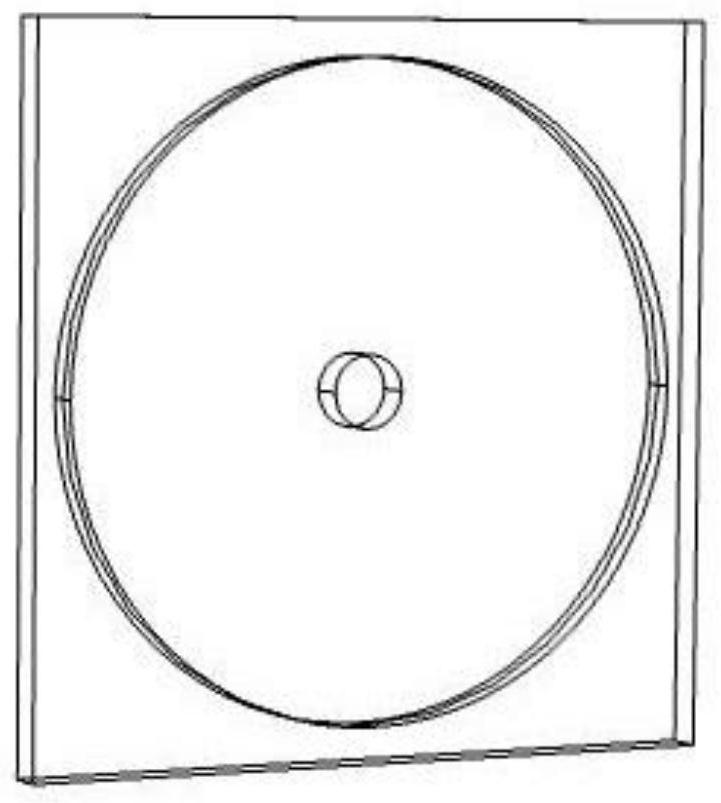

A membrane-type acoustic metamaterial sound-absorbing and insulating device with perforated plates

ActiveCN111916040BImproved sound insulationBroaden the sound absorption bandwidthSound producing devicesThin membraneSound wave

The invention provides a membrane-type acoustic metamaterial sound absorption and insulation device with perforated plates. The four cavity walls of the sound insulation device are enclosed into a frame wall with a square cross-section. The rear of the frame wall is installed with a perforated plate and the front is installed with The opening frame has a cavity formed in the middle, a film is fixed in the opening frame, a mass block is pasted in the center of the film, the film is circular, and the mass block is a solid cylindrical structure. To solve the problem that the existing thin-film acoustic metamaterials have limited effect on the sound wave in the mid-frequency range, a perforated plate with a perforated plate or a single-membrane acoustic metamaterial with a narrow sound absorption frequency band that is suitable for use in a wide frequency range is proposed. The membrane-type acoustic metamaterial sound absorption and insulation device is used in the design of sound absorption and insulation in ships and other fields to improve people's living environment, and has good engineering application prospects.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com