Composite sound absorbing and insulating board

A technology of sound absorption and sound insulation, applied in the direction of sound insulation, sound-producing equipment, building components, etc., can solve the problems of restricting the amount of sound insulation, improvement, and insufficient sound wave isolation, so as to improve the overall sound insulation performance, high strength and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

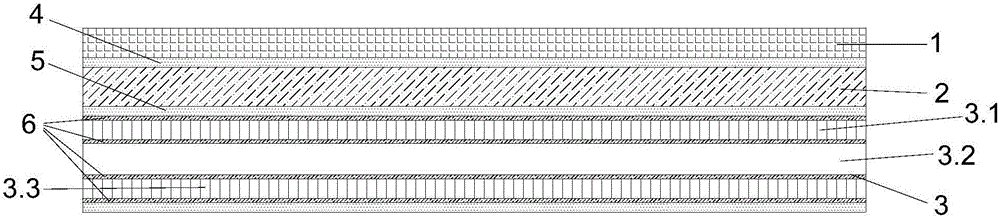

[0017] Such as figure 1 As shown, the composite sound-absorbing and insulating board of the present invention includes a fireproof layer 1, a sound-absorbing layer 2 and a sound-insulating layer 3. There are a first elastic damping layer 4 and a second elastic damping layer 5 . The first elastic damping layer 4 and the second elastic damping layer 5 are not only independent damping layers, but also a kind of adhesive layer connecting the fireproof layer 1 , the sound absorption layer 2 and the sound insulation layer 3 . Among them, the fireproof layer 1 is a plate made of glass magnesium and calcium silicate, and the sound-absorbing layer 2 is a plate made of glass wool, asbestos felt, or mineral wool. The first elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com