Environment-friendly sound insulating high speed train floor structure

A technology for high-speed trains and floors, which is applied to railway car bodies, parts of railway car bodies, transportation and packaging, etc. It can solve the problems of insignificant sound insulation effect of surface wood boards, inability to make full use of space resources, and inability to achieve vibration reduction effects, etc. , to improve the effect of sound insulation, reduce the transmission coefficient and improve the ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

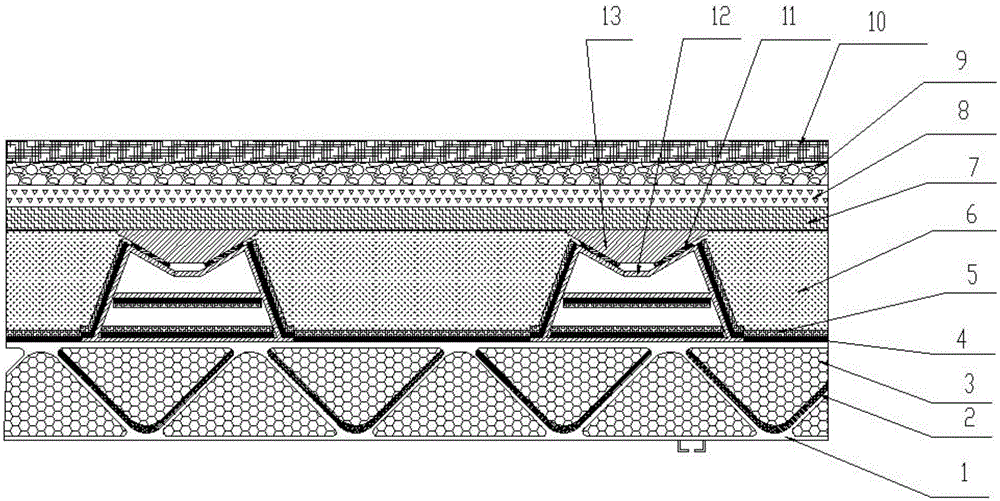

[0021] Such as figure 1 As shown, the novel environment-friendly sound insulation and vibration reduction high-speed train floor structure of the present invention, its floor aluminum profile 1 web upper surface sprays free viscoelastic damping material 2 (for example: Changzhou Lanjin ZN03); Each cavity is filled with polyurethane sound-absorbing material 3; floor aluminum profile 1 top plate and lower support 12 are bonded with viscoelastic damping material 4 (for example: Changzhou Lanjin ZN03); viscoelastic damping material 4 is bonded with constraining layer aluminum plate 5 ; The lower support 12 is bonded to the top of the floor aluminum profile 1; the lower support 12 and the upper support 13 are connected with a rubber pad or a damping pad 11, which reduces the connection stiffness and plays the role of buffering and vibration reduction, and also red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com