Sound insulation ear muff formed by tapping-type porous glass and air bag

A porous glass and perforated technology, which is applied to sound-generating devices, earpiece/earphone accessories, and earphones to reduce environmental noise. It can solve problems such as unsatisfactory sound insulation, poor low-frequency sound absorption, and uncomfortable wearing. Low cost, environmental protection, sound absorption and insulation performance, and excellent sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

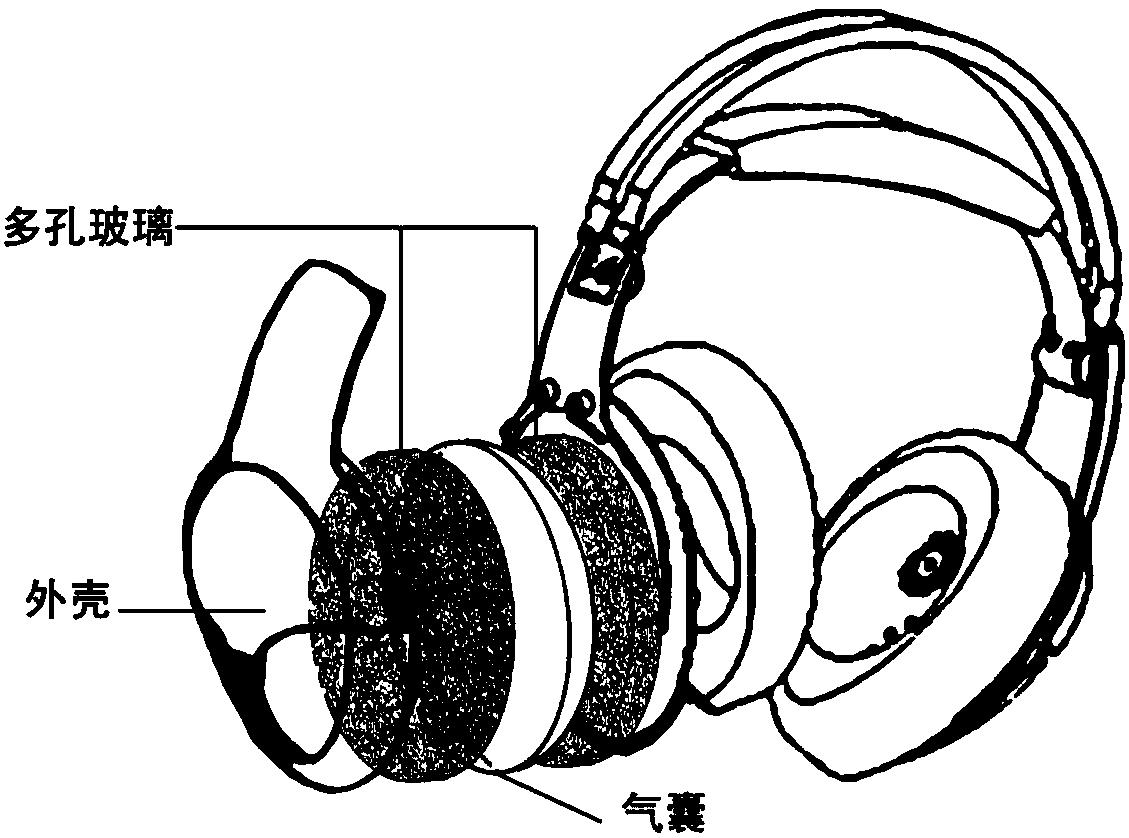

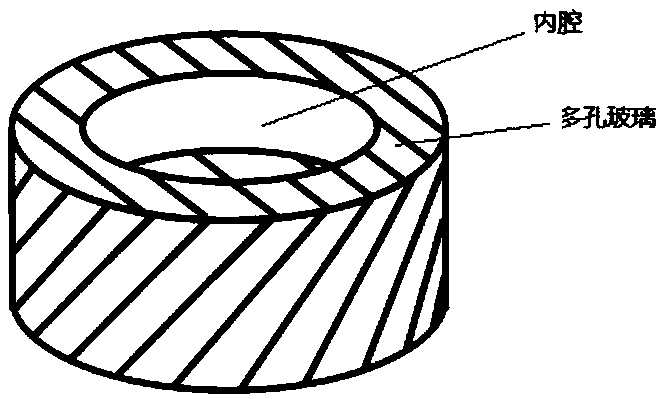

[0041] The sound-insulating earmuffs made of perforated porous glass and an air bag in this embodiment include an earmuff frame, a shell, an outer decorative layer and an internal filling layer; the internal filling layer is fixed in the earmuff frame and the shell, and It is closed by the outer decoration layer; the inner filling layer is composed of perforated porous glass and velvet-filled frameless airbag; the velvet-filled frameless airbag is sewn into an airbag made of light and flexible material, and the airbag is filled with natural down.

[0042] Among them, the open-hole porous glass in the inner filling layer and the down-filled skeletonless airbag adopt a three-layer structure of glass + airbag + glass. The inner and outer layers are open-hole porous glass, and the middle is a down-filled skeletonless airbag. The outer layer of the airbag is made of non-woven fabric, and the inside is filled with natural down. Due to the support of the natural down, the airbag can b...

Embodiment 2

[0046] In this embodiment, the open-celled porous glass in the inner filling layer and the down-filled skeletonless airbag adopt a glass+airbag two-layer structure, the airbag is 20mm thick, the diameter is 100mm, and the filling down density is 0.0255g / cm 3 , the glass layer is porous glass with a thickness of 10mm, a diameter of 99mm and a porosity of 0.75, the overall thickness is 30mm, and the total mass is 53g. The average sound insulation is 14.26dB (800Hz—1600Hz), and the sound insulation curve is as follows Figure 7 shown. It can be seen that with the increase of frequency, the sound insulation is linearly correlated, and the sound insulation can be estimated to be about 17.67dB in the frequency range of 800Hz-2500Hz, which is sensitive to the human ear, so it has a good sound insulation effect in the middle and high frequencies.

Embodiment 3

[0048] In this embodiment, the open-celled porous glass in the inner filling layer and the down-filled frameless airbag adopt a three-layer structure of airbag + glass + airbag, the inner and outer layers are 10mm in thickness, 100mm in diameter and filled with down and down with a density of 0.0509g / cm 3 The airbag, the middle layer is porous glass with a thickness of 10mm, a diameter of 99mm and a porosity of 0.75, and the total mass is 57g. The average sound insulation is 12.83dB (800Hz-1600Hz). Sound insulation curve such as Figure 8 shown. It can be seen that with the increase of frequency, the sound insulation is linearly correlated, and the sound insulation can be estimated to be about 16.75dB in the frequency range of 800Hz-2500Hz, which is sensitive to the human ear, so it has a good sound insulation effect in the middle and high frequencies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com