Multilayer resin tile and manufacturing process thereof

A manufacturing process and technology for resin tiles, applied in the field of multi-layer resin tiles and their manufacturing processes, can solve the problems of lack of weather resistance, troubled developers, damage to waterproofing of tiles, etc., to achieve safe and non-toxic raw materials, broad market application prospects, Good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

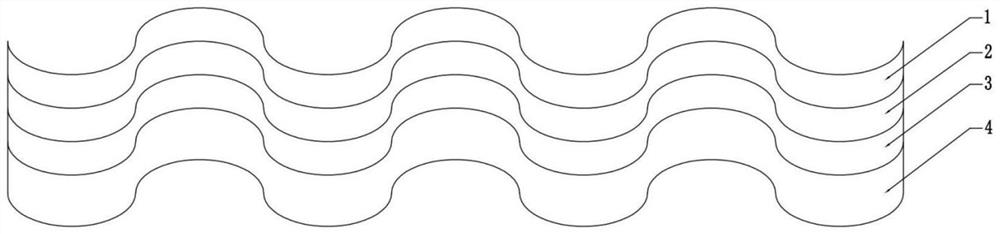

[0014] Example 1, a multi-layer resin tile has a corrugated board structure. The multi-layer resin tile includes a surface layer 1, a corrosion-resistant layer 2, an adhesive layer 3 and a heat-insulating substrate layer 4. The surface layer 1, the corrosion-resistant Corrosion layer 2, adhesive layer 3, heat insulation substrate layer 4 are arranged sequentially from top to bottom, the surface layer 1 is composed of modified resin ASA; the corrosion-resistant layer 2 includes: 25 parts of PVC, high-resistant 7 parts of polystyrene, 4 parts of talcum powder, 2 parts of urea-formaldehyde resin, 6 parts of polyethylene glycol, 8 parts of vitrified microspheres, 0.4 part of antioxidant, 3 parts of glass fiber, and 17 parts of PE wax; The junction layer 3 includes in parts by weight: 22 parts of modified PMMA resin and 3 parts of polyolefin hot melt adhesive; 1 part of cobalt octanoate, 1 part of methyl ethyl ketone peroxide MEKP, 1 part of trichloroethyl phosphate TCEP, 3 parts o...

Embodiment 2

[0019] Example 2, a multi-layer resin tile has a corrugated board structure. The multi-layer resin tile includes a surface layer 1, a corrosion-resistant layer 2, an adhesive layer 3 and a heat-insulating substrate layer 4. The surface layer 1, the corrosion-resistant Corrosion layer 2, adhesive layer 3, heat insulation substrate layer 4 are arranged sequentially from top to bottom, the surface layer 1 is composed of modified resin ASA; the corrosion-resistant layer 2 includes: 25 parts of PVC, high-resistant 13 parts of polystyrene, 6 parts of talcum powder, 4 parts of urea-formaldehyde resin, 10 parts of polyethylene glycol, 8 parts of vitrified microspheres, 1 part of antioxidant, 7 parts of glass fiber, and 20 parts of PE wax; The junction layer 3 includes in parts by weight: 24 parts of modified PMMA resin and 3 parts of polyolefin hot melt adhesive; 3 parts of cobalt octanoate, 2.5 parts of methyl ethyl ketone peroxide MEKP, 7 parts of trichloroethyl phosphate TCEP, 14 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com