Combined non-metal sound barrier unit plate

A non-metal, sound barrier technology, used in construction, noise absorption devices, etc., can solve the problems of easy aging of sound absorbing materials, poor resonance and noise reduction effect, and inability to adjust, and achieve good ramming effect, sound absorption and sound insulation. Excellent performance and easy installation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

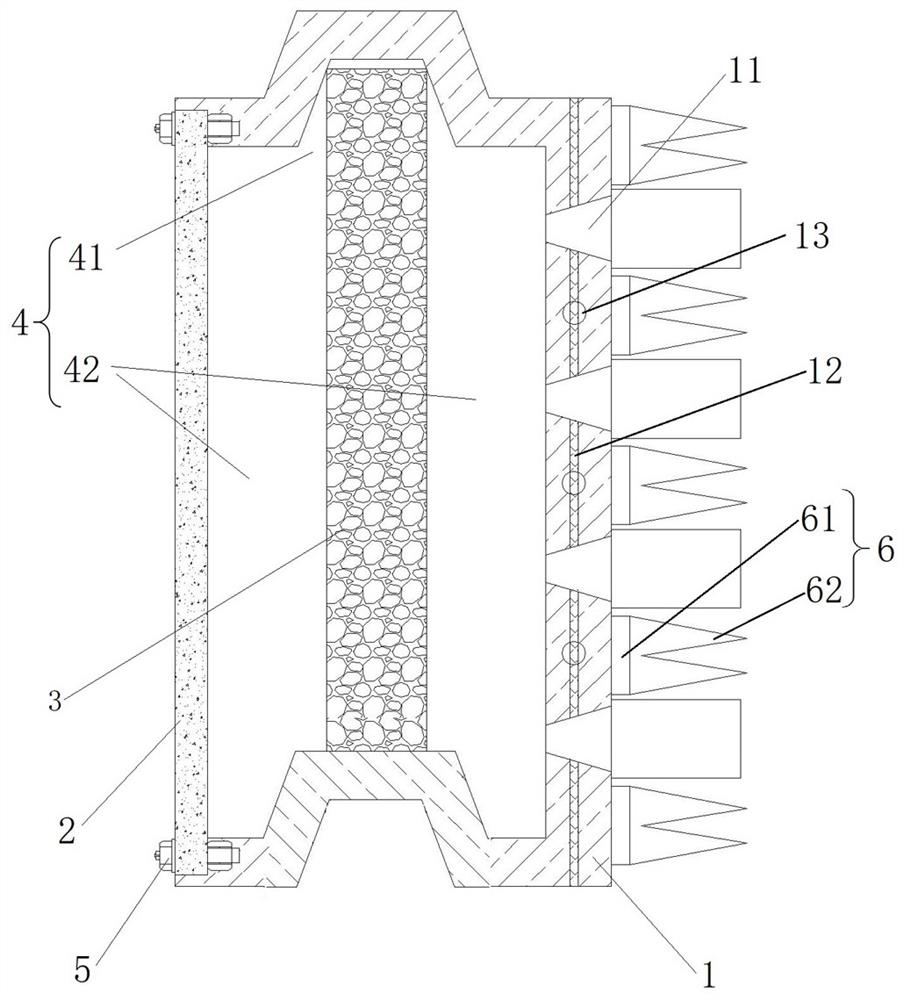

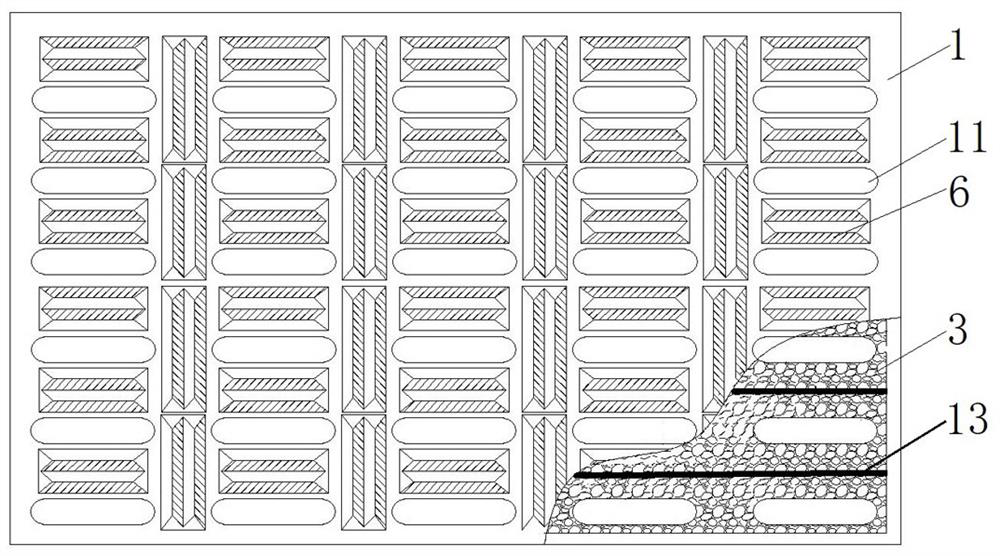

[0022] The structure and working principle of a combined non-metallic sound barrier unit panel provided by the present invention will be further described in detail below with reference to the accompanying drawings.

[0023] see figure 1 , is a schematic cross-sectional view of a combined non-metallic sound barrier unit panel provided by the present invention. The structure constituting the combined non-metallic sound barrier unit panel includes a panel 1, a back panel 2 and a sound-absorbing material 3 placed between them; wherein, the panel 1 is recessed to form a shell with a cavity 4, and the sound-absorbing material 3 Placed in the box cavity 4, the panel 1 and the back panel 2 are connected 5 by bolts, the panel 1 is poured from air-filled concrete, and the panel 1 is provided with evenly distributed sound-absorbing holes 11 .

[0024] Its working principle is: the panel 1 of the combined non-metallic sound barrier unit panel is formed by pouring air bubble concrete, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com