Low-cost, high-thermal-shock-resistance, low-thermal-conductivity and light-weight heat-insulating brick and preparation method thereof

A light-weight heat insulation and low-cost technology, applied to ceramic products, clay products, and other household appliances, can solve the problems of frequent maintenance, easy cracking, and brick falling, and achieve low thermal conductivity, good thermal shock resistance, and small volume The effect of low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

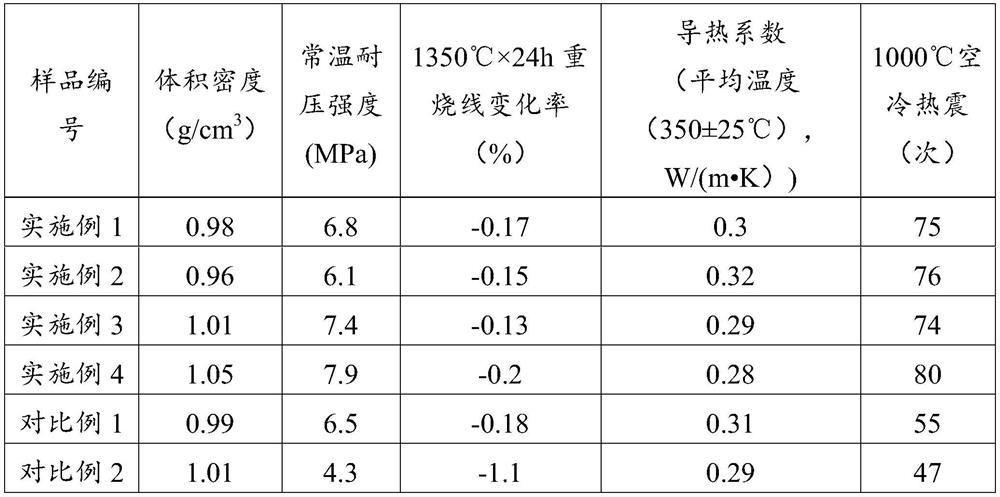

Examples

preparation example Construction

[0057] Correspondingly, the present invention also provides a method for preparing the above-mentioned lightweight heat-insulating brick with low cost, high thermal shock resistance and low thermal conductivity, comprising the following steps:

[0058] (1) Pour ceramic roller rod waste material roller rod waste material, alumina powder, magnesia clay, kaolin into the grinding equipment, and obtain the mixture after grinding;

[0059] (2) adding sawdust and water to the mixture, and mixing uniformly to obtain mud;

[0060] (3) Pour the mud material into a mould, and form it to obtain a green body;

[0061] (4) drying and firing the green body to obtain a finished product.

[0062] Preferably, the mud material is poured into a mold, and formed by vibration and pressure to obtain a plurality of green bodies. Vibration pressure molding is a process in which materials collide with each other under the action of high-frequency vibration, and gradually pile up to fill the green bod...

Embodiment 1

[0084] A low-cost, high thermal shock resistance, low thermal conductivity lightweight heat insulation brick and its preparation method

[0085] Low cost, high thermal shock resistance and low thermal conductivity lightweight insulation brick formula, including the following raw materials by volume:

[0086] 50 parts of low thermal expansion ceramic roller waste, 20 parts of α-alumina powder, 15 parts of magnesia clay, 25 parts of kaolin, 40 parts of wood chips.

[0087] Wherein, the Al of the low thermal expansion rate ceramic roller waste 2 o 3 Content is 50wt%, SiO 2 The content is 30wt%, the MgO content is 6wt%, the mullite crystal phase content is 50%, the cordierite crystal phase content is 50%, and the maximum particle size is 44 μm;

[0088] Al of the α-alumina powder 2 o 3 The content is 99.5%, the particle size is 40μm;

[0089] Al of the magnesia clay 2 o 3 The content is 23wt%, the content of MgO is 23wt%, and its particle size is ≤80μm;

[0090] Al of the...

Embodiment 2

[0105] A preparation method of low-cost, high thermal shock resistance and low thermal conductivity lightweight heat insulation brick

[0106] The thermal shock-resistant lightweight heat insulation brick formula includes the following raw materials in parts by volume:

[0107] 60 parts of low thermal expansion ceramic roller waste, 10 parts of α-alumina powder, 15 parts of magnesia clay, 20 parts of kaolin, 50 parts of sawdust;

[0108] Wherein, the Al of the low thermal expansion rate ceramic roller waste 2 o 3 Content is 50wt%, SiO 2 The content is 30wt%, the MgO content is 6wt%, the mullite crystal phase content is 40%, the cordierite crystal phase content is 60%, and the maximum particle size is 40 μm;

[0109] Al of the α-alumina powder 2 o 3 The content is 99.5%, the particle size is 40μm;

[0110] Al of the magnesia clay 2 o 3 The content is 23wt%, the content of MgO is 23wt%, and its particle size is ≤75μm;

[0111] Al of the kaolin 2 o 3 Content is 36wt%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com