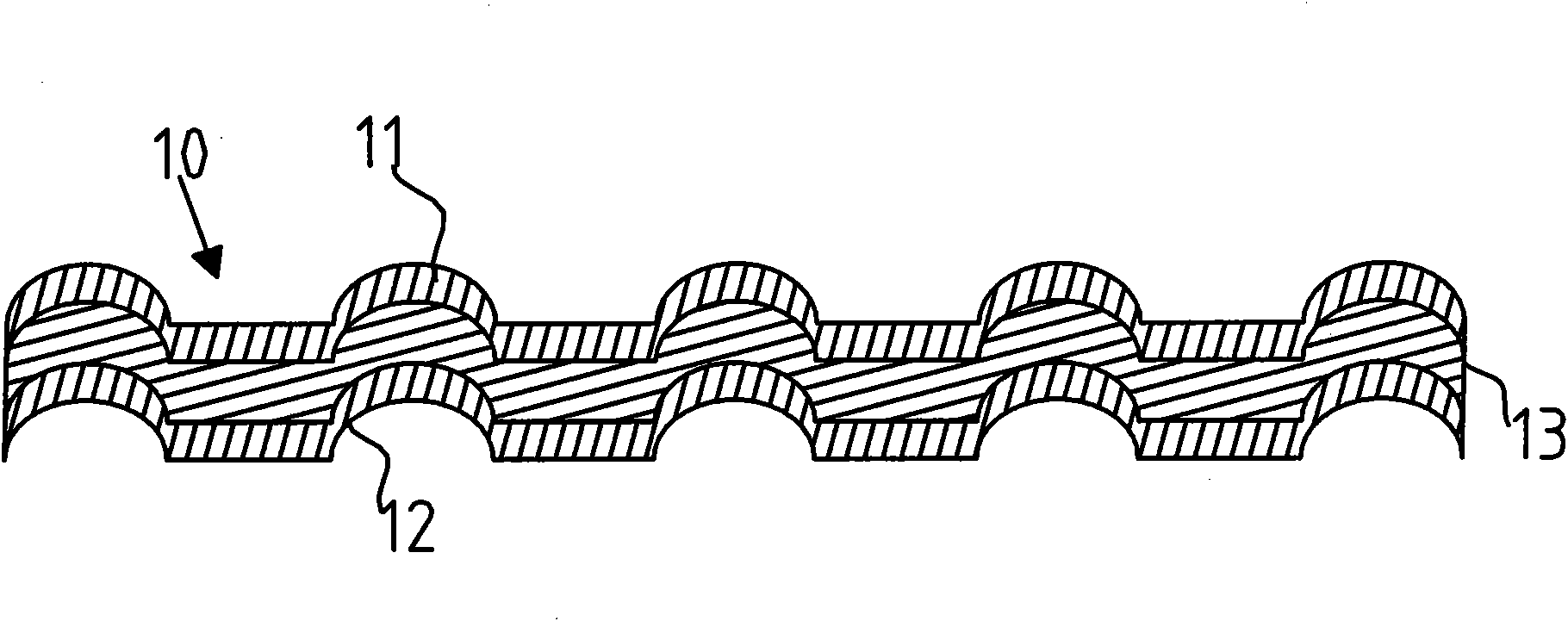

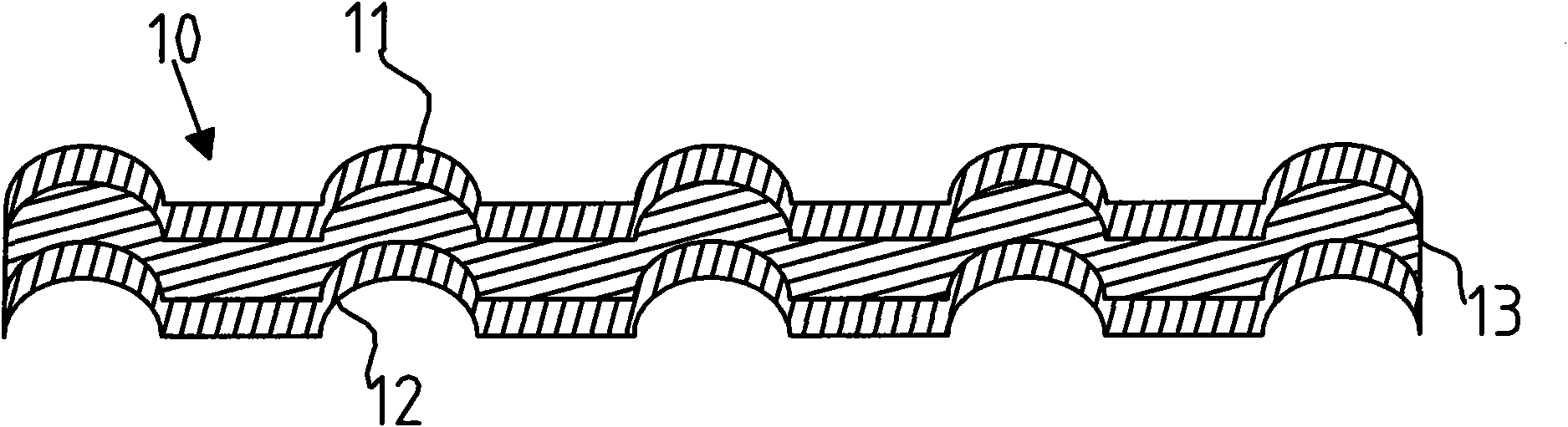

Three-layer resin glazed tile

A technology of glazed tiles and resins, which is applied to roof coverings, roofs, and roofs using flat/curved panels, etc., which can solve problems such as short service life, poor sound attenuation and heat insulation, and poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of three-layer resin glazed tile of the present invention comprises the following steps:

[0020] a. Mix the prepared intermediate layer raw materials and bottom layer raw materials in a high-speed mixer for 10-15 minutes, and then granulate them in an extruder at a temperature of 170-200°C; dry the surface layer raw materials at 60-90°C deal with;

[0021] b. Plasticize the above-mentioned intermediate layer pellets and bottom layer pellets at a temperature of 180-210°C;

[0022] c. Extrude the above-mentioned dry surface layer raw materials, plasticized middle layer raw materials and bottom layer raw materials through three co-extruders at 180-200 ° C, and overlap the extruded surface layer, middle layer and bottom layer, and simultaneously pass through the traction Device traction and molding machine pressing can be done.

Embodiment 1

[0025] a. After mixing 60% polyvinyl chloride resin, 15% impact modifier, 5% lubricant and 20% processing aid in the middle layer of raw materials in a high-speed mixer for 10 minutes, the temperature is 170 ° C. Granulating in the machine;

[0026] 70% polyvinyl chloride resin, 10% impact modifier, 5% lubricant, and 15% processing aids are mixed in a high-speed mixer for 10 minutes, and the temperature is 170 ° C in an extruder Carry out granulation; dry the surface material modified resin at 60°C;

[0027] The impact modifier is chlorinated polyethylene; the lubricant is oxidized polyethylene wax; the processing aid is a mixture of ACR, composite stabilizer and pigment;

[0028] The processing aid is ACR (Acrylic copolymer), which is an acrylic ester copolymer with a core-shell structure, and is a processing aid with excellent comprehensive performance.

[0029] b. Plasticize the above-mentioned intermediate layer pellets and bottom layer pellets at a temperature of 180°C;...

Embodiment 2

[0032] a. After mixing 70% polyvinyl chloride resin, 10% impact modifier, 3% lubricant and 17% processing aid in the middle layer of raw materials in a high-speed mixer for 12 minutes, the temperature is 190 ° C. Granulating in the machine;

[0033] 80% polyvinyl chloride resin, 8% impact modifier, 2% lubricant, and 10% processing aid are mixed in a high-speed mixer for 13 minutes, and the temperature is 180 ° C in an extruder Carry out granulation; dry the surface material modified resin at 70°C;

[0034] The impact modifier is chlorinated polyethylene; the lubricant is a mixture of oxidized polyethylene wax, stearic acid and paraffin; the processing aid is a mixture of ACR, calcium carbonate and pigments ;

[0035] b. Plasticize the above-mentioned intermediate layer pellets and bottom layer pellets at a temperature of 200°C;

[0036] c. Extrude the above-mentioned dry surface layer raw materials, plasticized middle layer raw materials and bottom layer raw materials throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com