Composite mold clamp building block

A composite mold and block technology, applied in building materials, building components, walls, etc., can solve the problems of inability to completely cut off thermal bridges, limited thickness of thermal insulation layers, and difficult to guarantee quality, and achieve good sound insulation and fast construction. , reduce the effect of construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

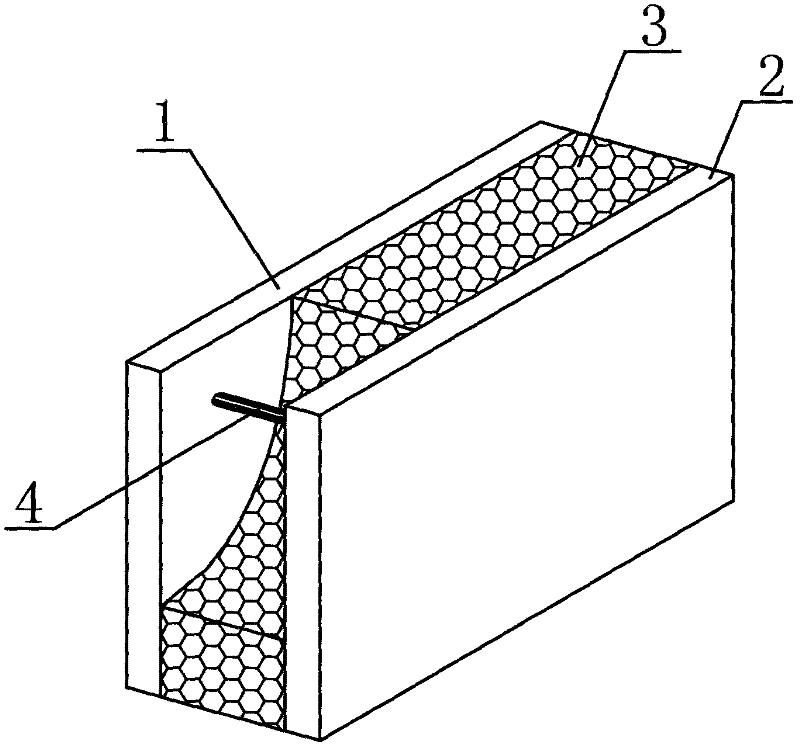

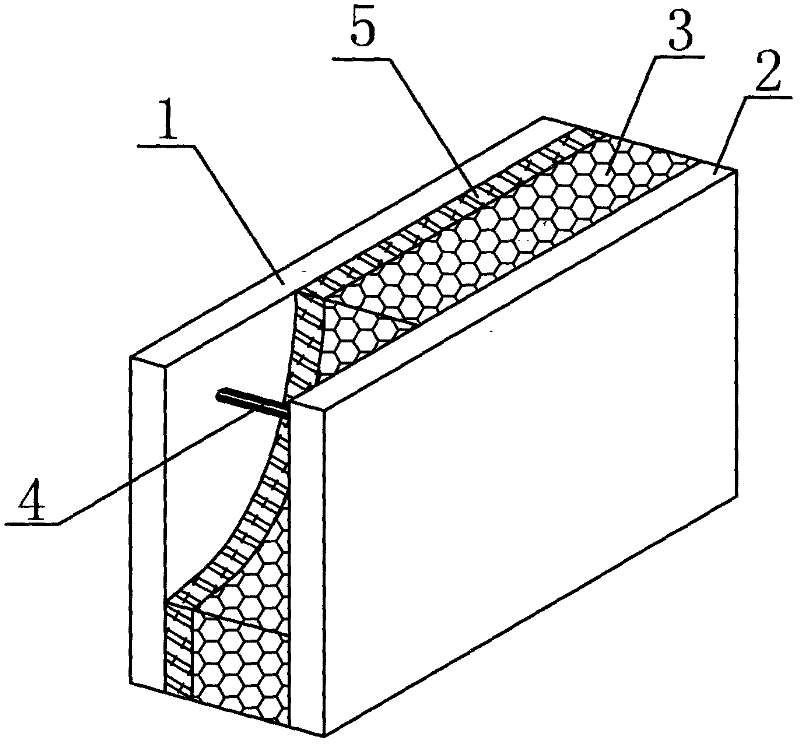

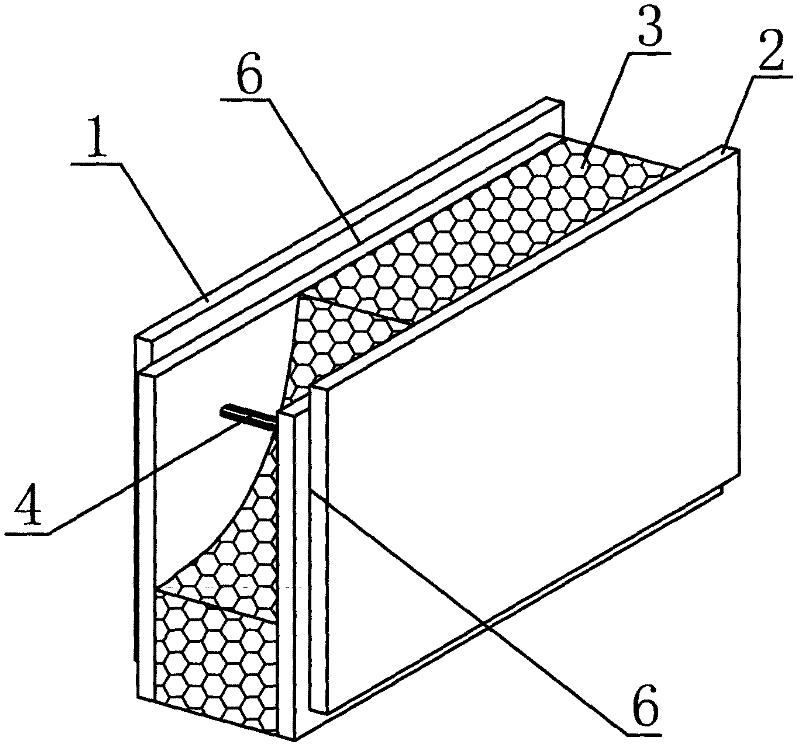

[0058] Below in conjunction with accompanying drawing, the present invention is further described: in each accompanying drawing, numbering is identical, and its description is identical. In the figure, 1 is the outer panel, 2 is the inner panel, 3 is the insulation layer, 4 is the connector, 5 is the heat insulation layer, 6 is the gap, 7 is the stiffener, 8 is the fixed support, 9 is the bump, and 10 is the Convex line, 11 is a concave hole, 12 is a pit, 13 is an embedded part, 14 is a hole, 15 is a groove, 16 is a connecting rod, 17 is a connecting piece, 18 is an injection hole, 19 is a movable hole cover, 20 for the insulation layer.

[0059] Such as figure 1 The composite molded block shown is characterized in that the composite molded block includes an outer panel 1 and an inner panel 2, and an insulating layer 3 is filled between the outer panel 1 and the inner panel 2, and the outer panel 1 and the inner panel 2 pass through The connecting piece 4 connects the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com