Ceramsite acoustic board and preparation method thereof

A technology of sound-absorbing panels and ceramsite, which is applied in the field of ceramsite-absorbing panels and its preparation, can solve problems such as poor sound-absorbing performance, poor hydrophobicity, and sinking of sound-absorbing materials, and achieve good sound-absorbing performance and good hydrophobicity. Water-based, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

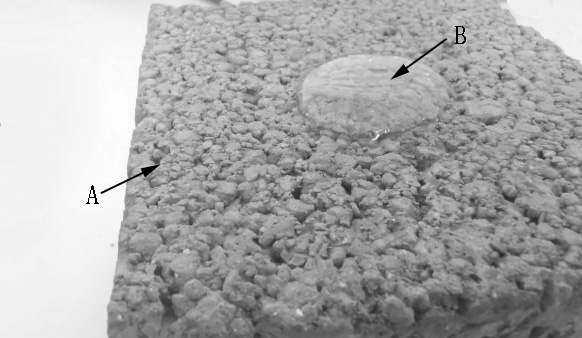

Image

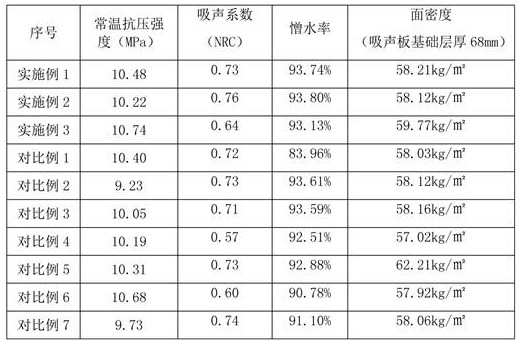

Examples

Embodiment 1

[0031] (1) Prepare resin mixed bonding solution: weigh 200g thermosetting resin (50g epoxy resin, 50g polyurethane resin, 100g phenolic resin), and 150g curing agent (20g aromatic polyamine, 30g acid anhydride, 100g resole phenolic resin) , 6g of DMP-30, 140g of epoxy diluent 692 were added to the thermosetting resin, and stirred at 225r / min at a temperature of 90°C for 1.5min to obtain 496g of resin mixed adhesive solution with good fluidity;

[0032] (2) Preparation of graphene oxide dispersion: disperse 5.0 g of graphene oxide powder in a mixed solution of 100 ml of ethanol and isopropanol (60 ml of ethanol, 40 ml of isopropanol) to obtain a graphene oxide dispersion;

[0033] (3) Preparation of mixed melt: add the graphene oxide dispersion obtained in step (2) to the resin mixed bonding solution obtained in step (1), and stir at 90°C for 45s at a speed of 225r / min to obtain mixed melt;

[0034] (4) Prepare the base layer of the sound-absorbing board: lay a layer of high-t...

Embodiment 2

[0038] (1) Prepare resin mixed bonding solution: weigh 125g polyester resin, add 97.5g curing agent (47.5g amino resin, 50g dicyandiamide), 2.5g DMP-30, 75g epoxy diluent 692 to polyester In the resin, stir at 200r / min at a temperature of 80°C for 1min to obtain 300g of resin mixed adhesive solution with good fluidity;

[0039] (2) Preparation of graphene oxide dispersion: disperse 9g of graphene oxide powder in 100ml of N-methylpyrrolidone and ultrasonically obtain graphene oxide dispersion;

[0040] (3) Preparation of mixed melt: add the graphene oxide dispersion obtained in step (2) to the resin mixed bonding solution obtained in step (1), and stir at 80°C for 30s at a speed of 200r / min to obtain mixed melt;

[0041](4) Prepare the base layer of the sound-absorbing board: lay a layer of high-temperature-resistant tarpaulin on the bottom of the mold; add the mixed melt obtained in step (3) to 9.4kg of mixed aggregate (3.76kg of fine aggregate with a particle size of 2-5mm, ...

Embodiment 3

[0045] (1) Preparation of resin mixed bonding solution: Weigh 200g of furan resin, add 170g of hydrazide, 2g of DMP-30, and 128g of epoxy diluent 692 into the polyester resin, and rotate at 250r / min at a temperature of 100°C Stir for 2 minutes to obtain 500 g of resin mixed adhesive solution with good fluidity;

[0046] (2) Preparation of graphene oxide dispersion: disperse 1.5 g of graphene oxide powder in a mixed solution of 100 ml of isopropanol and water (20 ml of isopropanol, 80 ml of water) and obtain a graphene oxide dispersion by ultrasonication;

[0047] (3) Preparation of mixed melt: add the graphene oxide dispersion obtained in step (2) to the resin mixed bonding solution obtained in step (1), and stir at a temperature of 100°C at a speed of 250r / min for 60s to obtain mixed melt;

[0048] (4) Prepare the base layer of the sound-absorbing board: lay a layer of high-temperature-resistant tarpaulin on the bottom of the mold; add the mixed melt obtained in step (3) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com