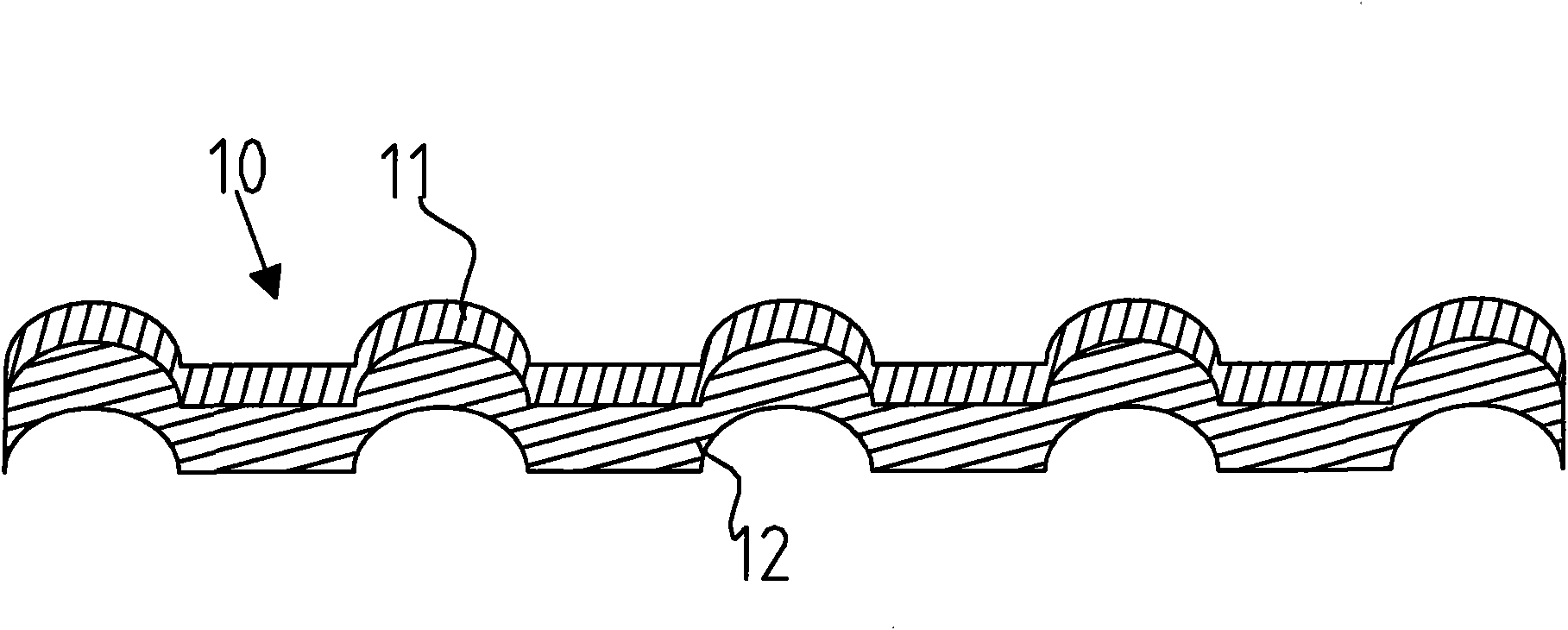

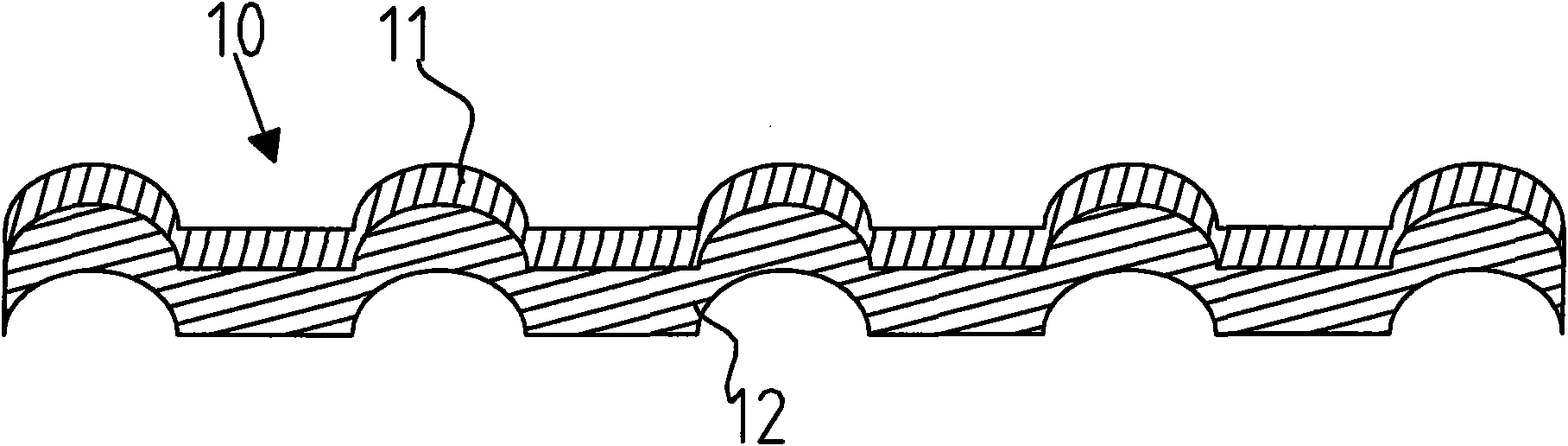

Double-layer resin glazed tile

A glazed tile and resin technology, applied in the direction of roof covering, roof, roof using flat/curved panels, etc., can solve the problems of short service life, poor impact resistance, poor sound insulation and heat insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of double-layer resin glazed tile of the present invention comprises the following steps:

[0020] a. Mix the prepared bottom layer raw materials in a high-speed mixer for 10-15 minutes, then granulate in an extruder at a temperature of 170-200°C; dry the surface layer raw materials at 60-90°C;

[0021] b. Plasticize the above-mentioned pellets at a temperature of 180-210°C;

[0022] c. Extrude the above-mentioned plasticized bottom layer material and dry surface layer material through two co-extrusion machines at 180-200°C, overlap the extruded surface layer and bottom layer, and simultaneously pull it through the traction device and press it with the molding machine type.

Embodiment 1

[0025] a. After mixing 60% polyvinyl chloride resin, 3% foaming agent, 15% impact modifier, 5% lubricant, and 17% processing aid in a high-speed mixer for 10 minutes, the temperature is 170 ° C Granulate in the extruder; dry the surface material modified resin at 60°C; the foaming agent is an azo compound, the impact modifier is chlorinated polyethylene, and the lubricating agent is The agent is oxidized polyethylene wax, and the processing aid is ACR, and ACR (Acrylic copolymer) is an acrylic ester copolymer with a core-shell structure, and is a processing aid with excellent comprehensive performance;

[0026] b. Plasticizing the above-mentioned pellets at a temperature of 180°C;

[0027] c. Extrude and overlap the above-mentioned plasticized bottom layer material and dry surface layer material through two co-extrusion machines at 180°C, and then pull them through a traction device and press them into a molding machine.

Embodiment 2

[0029] a. After mixing 80% polyvinyl chloride resin, 1% foaming agent, 8% impact modifier, 2% lubricant, and 9% processing aid in a high-speed mixer for 12 minutes, the temperature is 180 ° C Granulate in the extruder; dry the surface material modified resin at 80°C; the foaming agent is sodium bicarbonate, the impact modifier is chlorinated polyethylene, and the lubricating The agent is a mixture of oxidized polyethylene wax and paraffin; the processing aid is a mixture of ACR and pigment;

[0030] b. Plasticizing the above-mentioned pellets at a temperature of 200°C;

[0031] c. Extrude and overlap the above-mentioned plasticized bottom layer material and dry surface layer material through two co-extruders at 200°C, and then pull them through a traction device and press them into a molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com