Non-cotton super-microporous metal noise barrier

An ultra-micro-hole, sound barrier technology, applied in the field of sound absorption, sound insulation and noise reduction, can solve the problems of high production, installation and maintenance costs, health hazards, weakening of transmitted sound energy, etc., and achieves easy cutting and installation, no rivet connection. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The best implementation mode of the present invention will be described in further detail below in conjunction with the accompanying drawings.

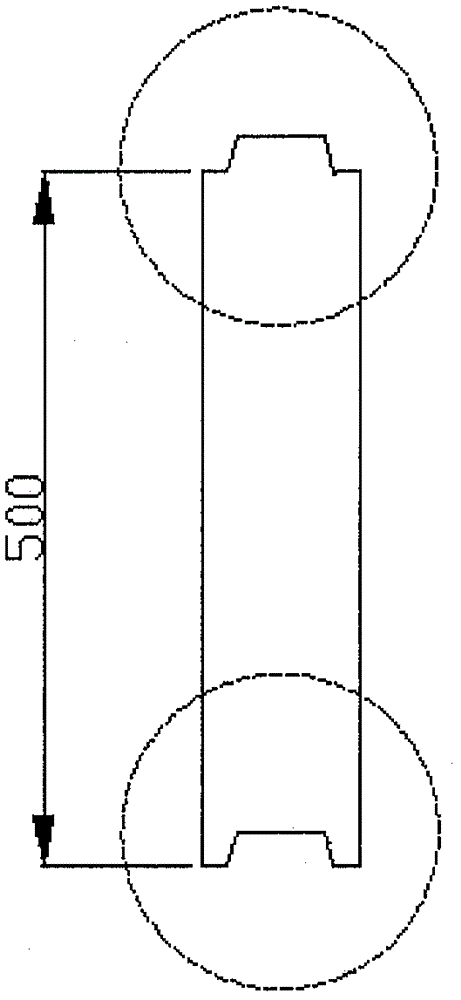

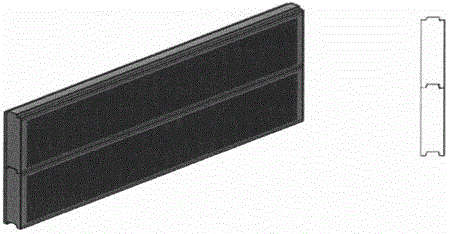

[0020] The invention relates to a non-cotton ultra-microporous metal sound barrier, such as figure 1 As shown, it includes a microporous metal panel 1, a metal back plate 5, left and right heads 2, ribs 3, upper and lower heads 4, and a metal back plate 5. It is characterized in that,

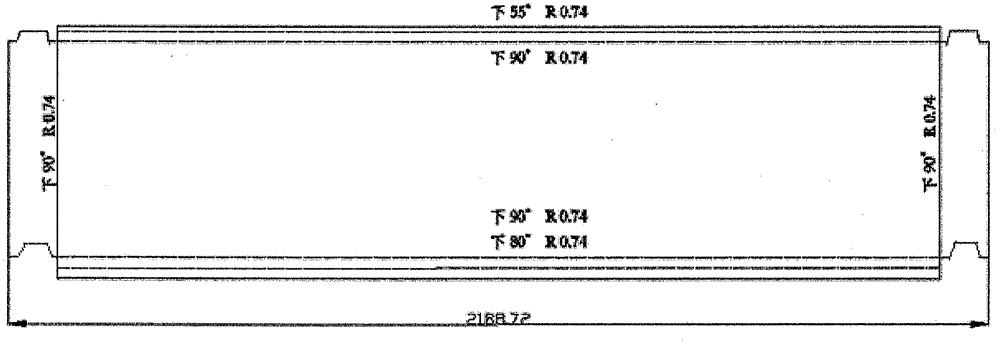

[0021] The material of the microporous metal panel 1 is an aluminum plate, and there are 400,000 micropores per square meter on the surface of the plate, with a diameter of less than 0.1mm. The shapes and diameters of the small holes are different, and the left and right sides are respectively bent and cut. Convex and concave, folded into a trapezoidal shape, forming left and right heads 2, see detailed structure image 3 ; The microporous metal panel 1 can be selected to include fluorocarbon baking varnish, anodic treatment or powder baking va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com