Disposable on-site compound explosion-venting sound-insulating wall

A one-time, wall technology, applied in the direction of walls, sound insulation, building components, etc., can solve the problems of being unsuitable for on-site installation, inability to install on-site, and high cost, and achieve good sound insulation effect, light texture and beautiful appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

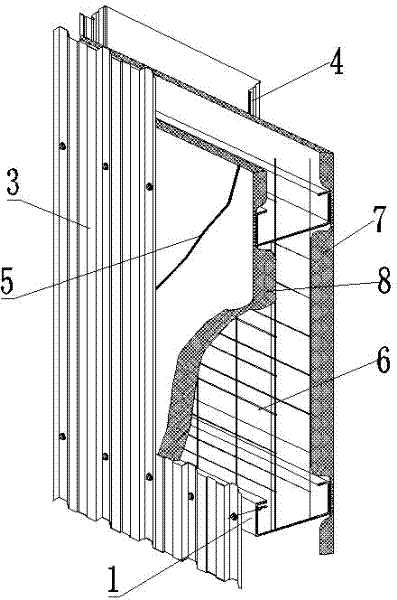

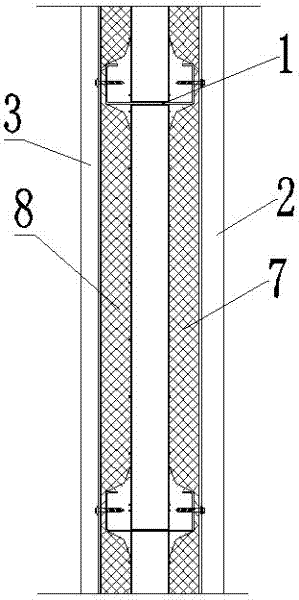

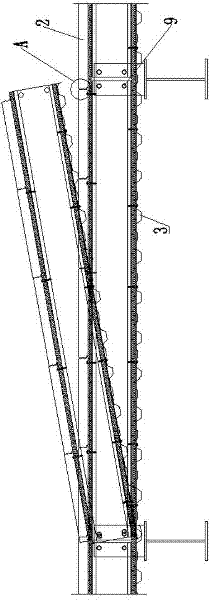

[0021] As attached to the manual figure 1 , 2 , 3, and 4, a one-time on-site composite explosion-reducing and sound-insulating wall includes a "C"-shaped steel frame 1, an outer wall 2 and an inner wall 3 are respectively arranged on both sides of the steel frame, and on the steel frame Steel wire mesh 6 is installed, and the outer wall body is made of several concealed gussets 4 that need a certain pressure to be broken open, and the inner wall board inner side is laid with explosion-proof non-woven fabric 5. The insulation cotton I7 with aluminum foil is arranged between the steel mesh and the outer wall, and the aluminum foil faces inward. Body of outer wall, insulating cotton 1 are fixed with steel wire mesh by self-tapping screw. Between the steel wire mesh and the inner wall, thermal insulation cotton II 8 with aluminum foil is arranged, and the aluminum foil faces inward. The inner wall and thermal insulation cotton II are fixed by self-tapping screws and steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com