Sound barrier panels made from solid waste

A technology of solid waste and barrier panels, applied in the direction of noise absorption devices, buildings, etc., to achieve excellent sound absorption and insulation performance, improve weather resistance and service life, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

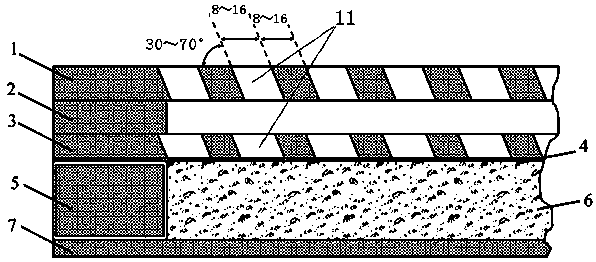

[0021] Example figure 1 As shown, the sound barrier board prepared by solid waste in the present invention includes a perforated panel 1, a first partition 2, a perforated bottom plate 3, a fixed net 4, a second partition 5 and a sound insulation board 7 connected in sequence. The perforated panel 1, the first dividing plate 2, the perforated bottom plate 3, the second dividing plate 5 and the sound insulation plate 7 are made of the following raw materials in parts by weight: polyvinyl chloride resin 50-80%, solid waste 10- 40%, processing aid 1-8%, stabilizer 2-6%, foaming agent 0-3%, lubricant 1-10%, and it is made by one-shot molding process of crust micro-foaming melt extrusion. This molding process makes the core layer of the product present a dense and uniform cell structure on the microscopic level, which not only achieves a certain sound-absorbing effect, but also meets its service strength, aging resistance, and corrosion resistance, and is easy to process and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com