A K1 type electrical connector assembly for mineral insulated cables for nuclear power

A technology for mineral insulated cables and electrical connectors, which is applied to insulated cables, fixed/insulated contact members, electrical components, etc., and can solve the problems of mechanical strength and dielectric performance decline, easy to absorb moisture, insulation performance, easy to short circuit, etc. Improve sealing reliability and shock resistance, improve aging life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further illustrate the technical means and technical effects adopted by the present invention, a K1-type electrical connector assembly for nuclear power mineral insulated cables of the present invention will be described in detail below in conjunction with embodiments.

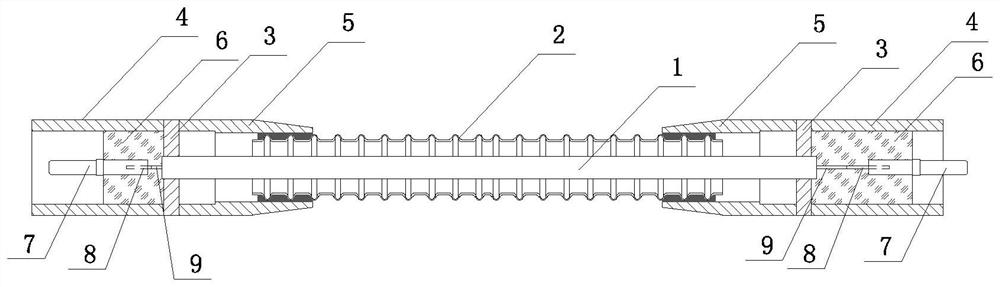

[0050] The present invention includes a cable assembly and plugs and sockets connected to both ends of the cable assembly. The cable assembly includes a mineral cable 1, a stainless steel bellows 2 wrapped outside the mineral cable, a positioning plate 3 for fixing the two ends of the mineral cable, and a positioning plate Stainless steel pipe 4 welded by laser welding. The two ends of the stainless steel bellows are connected with a terminal sleeve 5, and the positioning plate and the terminal sleeve are welded by laser welding, and the stainless steel pipe and the terminal sleeve are respectively located on both sides of the positioning plate. There is at least one mineral cable wrapped in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com