Patents

Literature

53results about How to "Long aging life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as production method thereof

The invention discloses a compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as a production method thereof. Chemigum is adopted as a main raw material, and forms synthetic rubber with high-tenacity reclaimed rubber and coumarone resin, and the synthetic rubber has extremely good oil resistance, abrasion resistance and thermal resistance; the synthetic rubber is matched with carbon black, ceramic micro powder, silicon powder, manganese powder, teflon, zinc oxide, argil, vulcanizing activators and hot-oxygen aging resistant agents, so that the performance of tearing resistance, self-lubricating effect, compression deformation resistance, thermal resistance, corrosion resistance, abrasion resistance and the like of the seal ring can be improved effectively, and the service life of the seal ring is prolonged. The favorable seal effect can be protected in severe cold and hot climate environments, and the service life of the seal ring is more than twice that of a traditional seal ring.

Owner:STATE GRID CORP OF CHINA +1

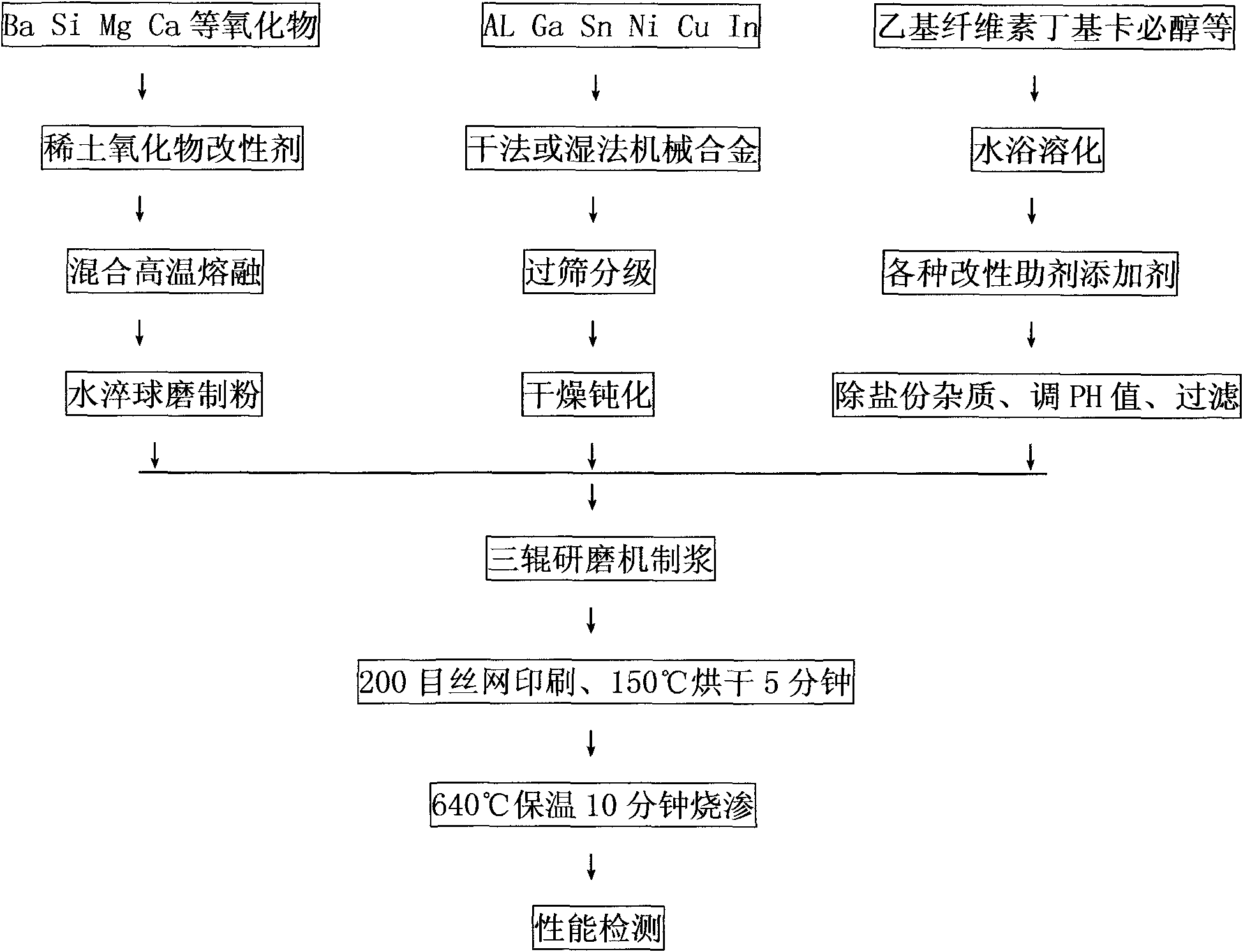

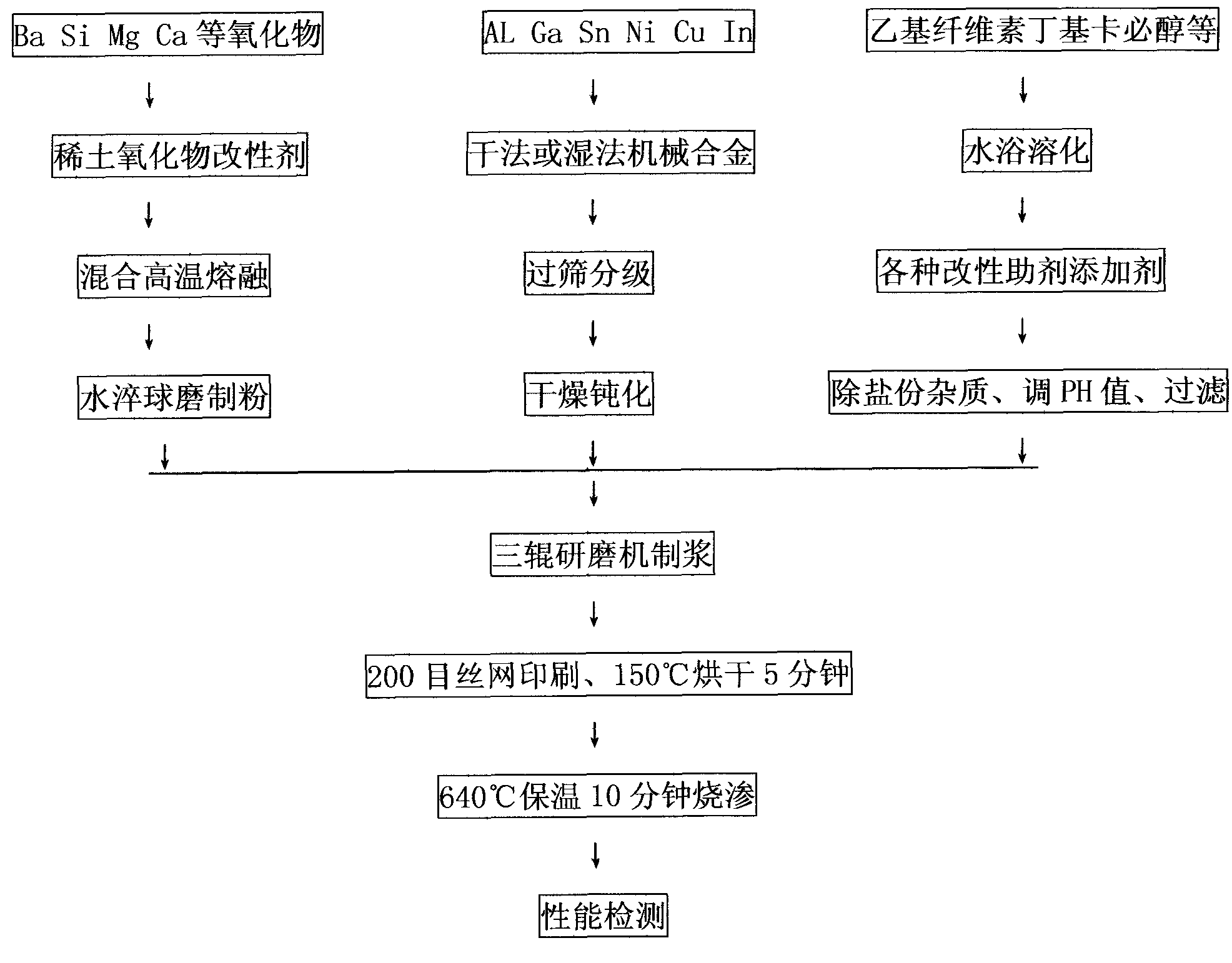

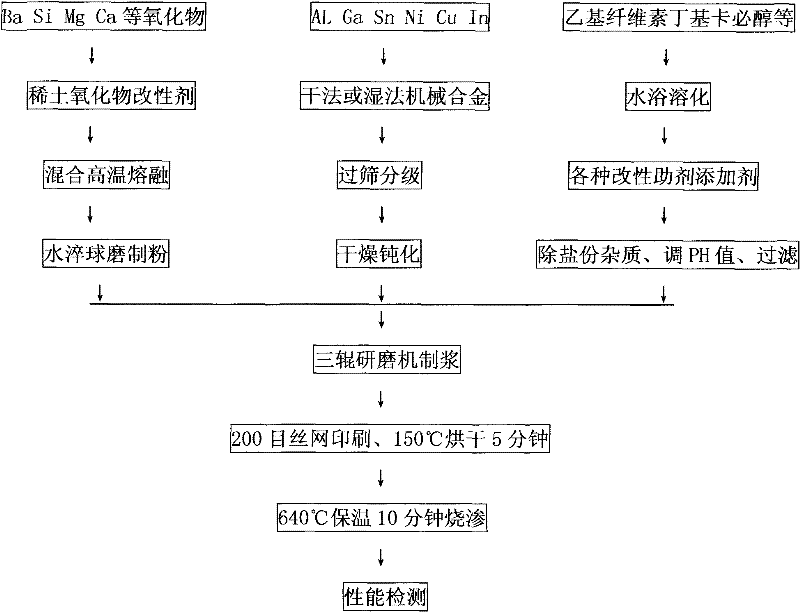

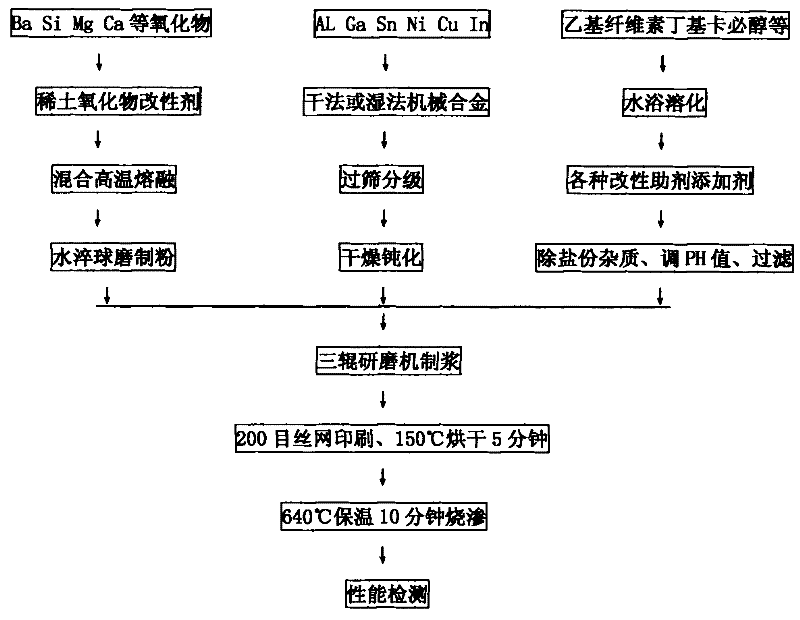

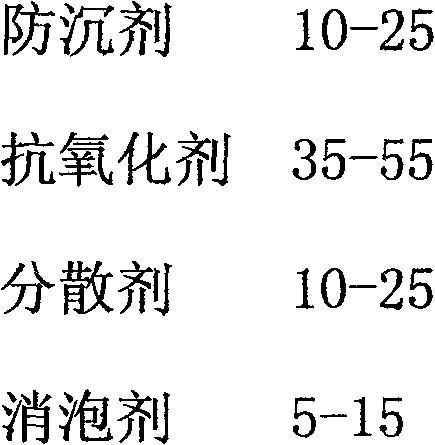

Environmental friendly lead-free aluminum slurry and preparation method thereof

InactiveCN101840744AAchieve stabilityAchieving printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureHazardous substanceFerrosilicon

The invention relates to an environmental friendly lead-free aluminum slurry and a preparation method thereof. The environmental friendly lead-free aluminum slurry comprises the following components: antioxidant ultrafine aluminum alloy micropowder, barium ferrosilicon borate composite frit and a composite organic carrier. The invention has the advantages that the prepared lead-free aluminum slurry is an environmental friendly electronic slurry without harmful substances including lead, cadmium, mercury and hexavalent chromium, is used as a function material, completely replaces lead containing aluminum slurry, is stable and reliable, and has excellent performance, favorable ohmic contact quality, wide sintering temperature range, low sheet resistance, water boiling resistance, long ageing life and favorable replaceability to noble metals.

Owner:WUHAN YILAI RUIER HIGH TECH

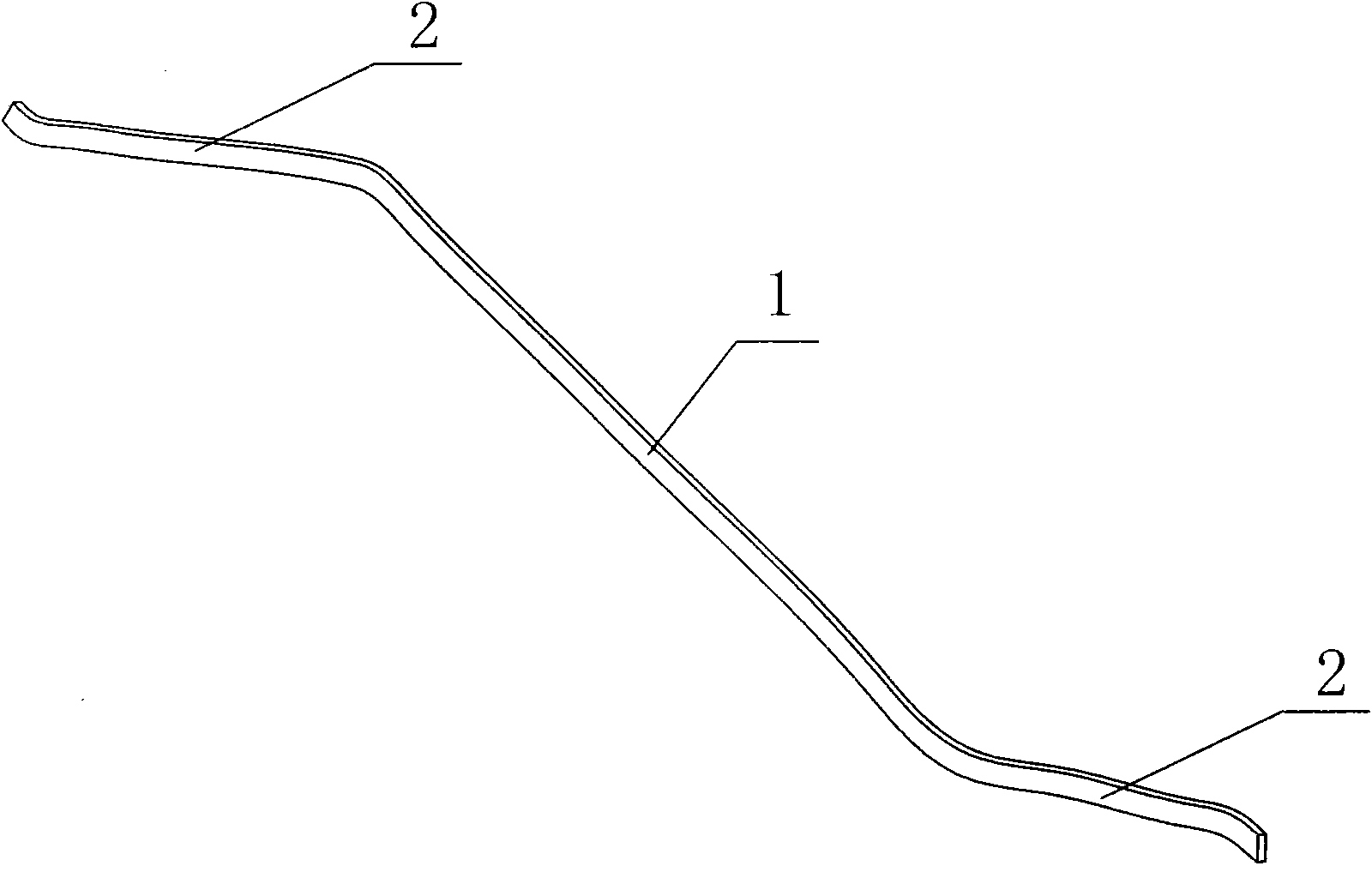

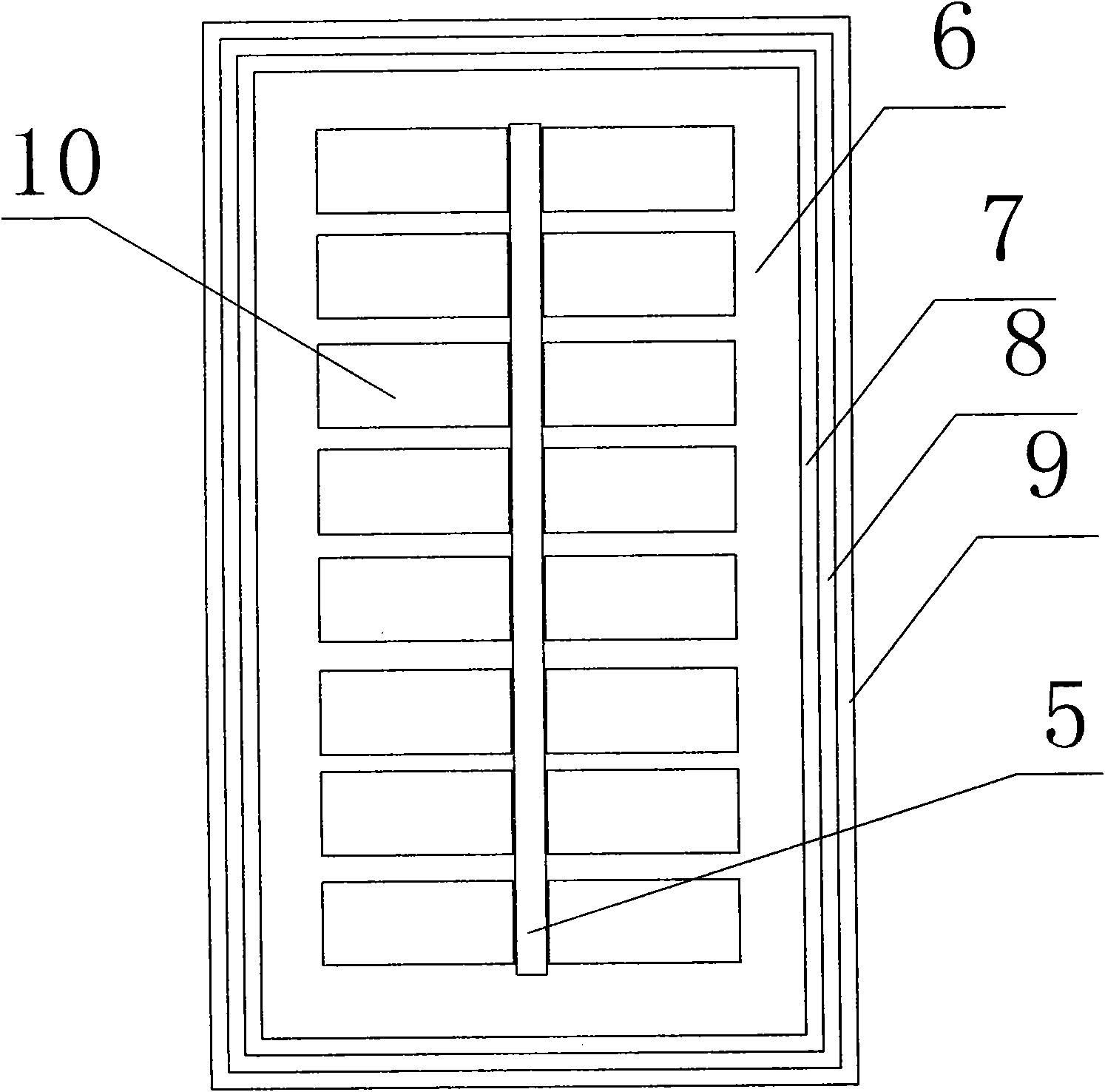

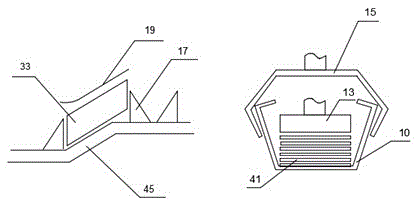

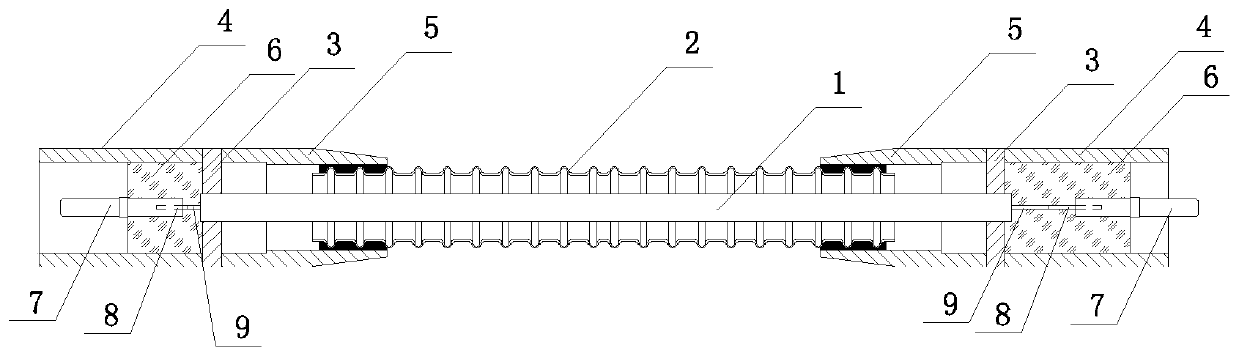

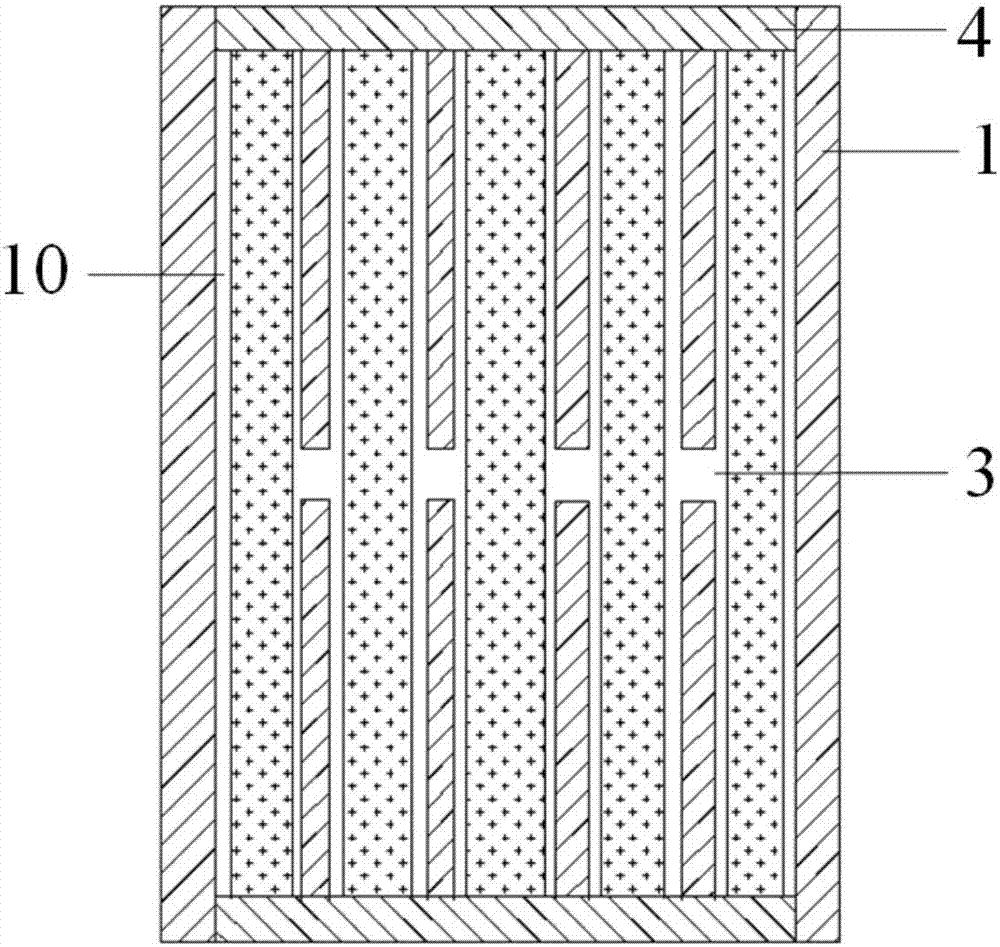

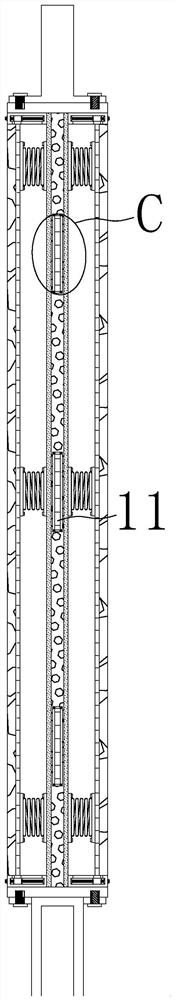

VPI stator wire bar

ActiveCN101917078AReduce labor productivityLong aging lifeWindings insulation materialWindings insulation shape/form/constructionInternal pressureWhole body

The invention relates to a VPI stator wire bar. The VPI stator wire bar consists of a straight line part and two end parts. The straight line part comprises a lead wire board, displacement gaskets, displacement fillers, an inter-row insulator, an internal pressure equalizing layer, an insulator to ground, an anti-corona processor, an additional insulator and an electromagnetic wire, wherein the inter-row insulator wraps the lead wire board; the displacement gaskets are arranged at the two side ends of the inter-row insulator; the electromagnetic wire wraps the inter-row insulator and the displacement gasket; the displacement fillers are fixed at the two side ends; and the internal pressure equalizing layer, the insulator to ground, the anti-corona processor and the additional insulator sequentially wrap the structure. Each end part comprises a conducting board, an inter-row isolator, an internal pressure equalizing layer, an insulator to ground, an anti-corona processor, an additionalinsulator and an electromagnetic wire, wherein the inter-row insulator wraps the conducting board; the electromagnetic wire is fixed on the two wide end faces of the inter-row insulator; and the internal pressure equalizing layer, the insulator to ground, the anti-corona processor and the additional insulator sequentially wrap the structure. The VPI stator wire bar of the invention has the advantages of fewer layers, thin layers and thin whole body.

Owner:浙江富春江水电设备有限公司

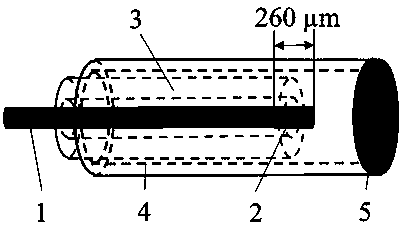

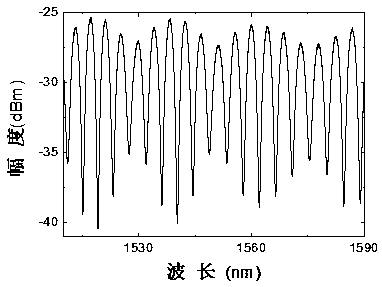

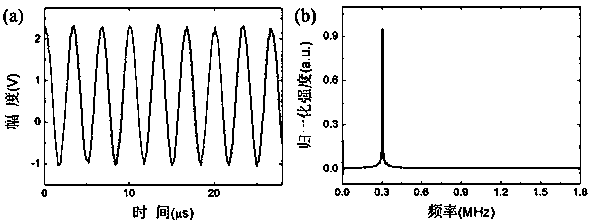

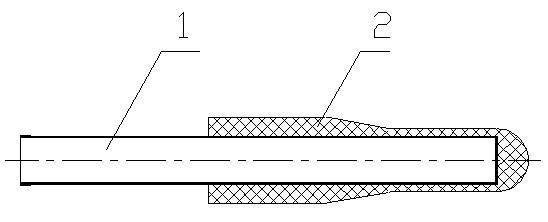

Optical fiber ultrasonic sensor with high signal to noise ratio based on polytetrafluoroethylene (PTFE) film

ActiveCN107561160AIncrease the slope of the sidebandLarge ultrasonic responseAnalysing solids using sonic/ultrasonic/infrasonic wavesSubsonic/sonic/ultrasonic wave measurementFiberUltrasonic sensor

The invention discloses an optical fiber ultrasonic sensor with a high signal to noise ratio based on a polytetrafluoroethylene (PTFE) film. The optical fiber ultrasonic sensor comprises a standard single-mode fiber, wherein one section of multimode fiber with gradient index is in fusion welding with one end of the standard single-mode fiber to form an optical fiber collimator; the end face of theoptical fiber collimator and the PTFE film form two reflecting surfaces of an F-P interferometer; the PTFE film is used as a response media of ultrasonic waves and is stuck at one end of an aluminumtube; an organic glass tube is arranged inside the aluminum tube; and a moving part is fixed with AB glue. The optical fiber ultrasonic sensor disclosed by the invention has the advantages of small size, low cost, simplicity and convenience in production, excellent ultrasonic response and high signal to noise ratio. The optical fiber ultrasonic sensor disclosed by the invention is applied to scanning imaging of a seismic physical model, a multilayer model structure can be distinctly differentiated and a model ultrasonic image is reconstructed, which shows that the optical fiber ultrasonic sensor has potentials in the fields of structural health monitoring, biomedicine and the like. With higher temperature resistance and corrosion resistance, the optical fiber ultrasonic sensor also can beapplied to severe environments such as high-temperature ultrasonic flaw detection.

Owner:NORTHWEST UNIV(CN)

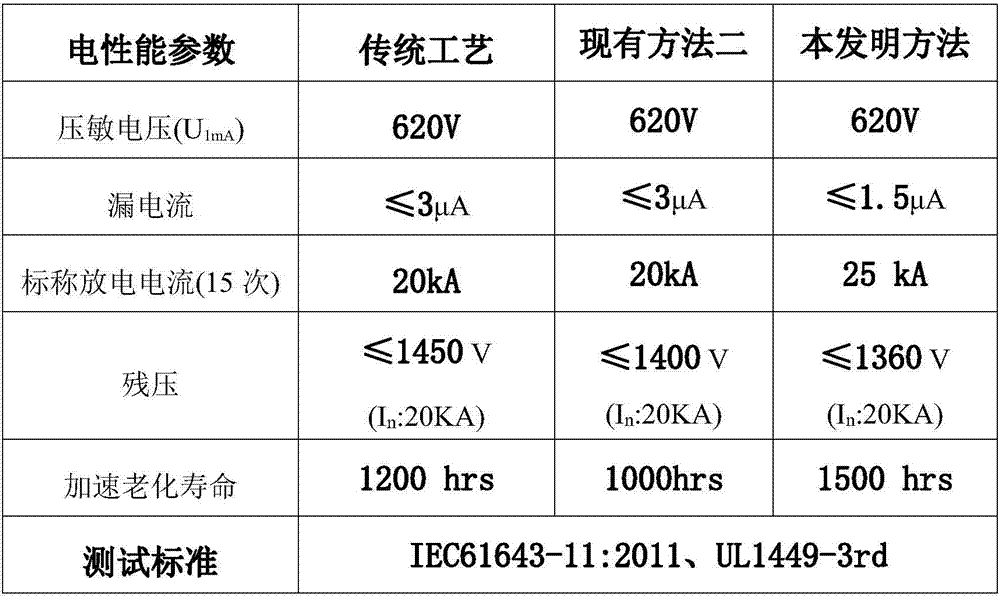

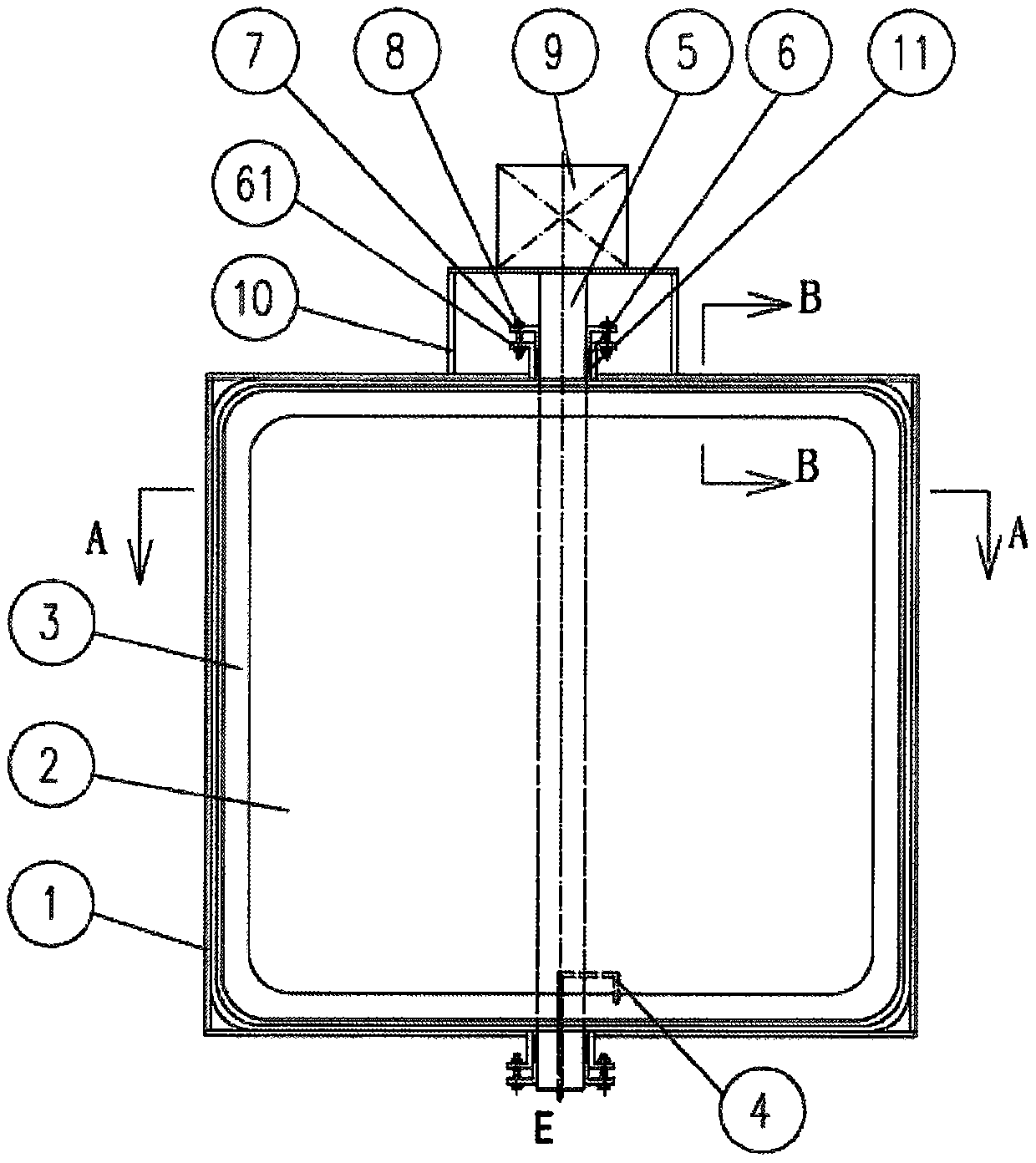

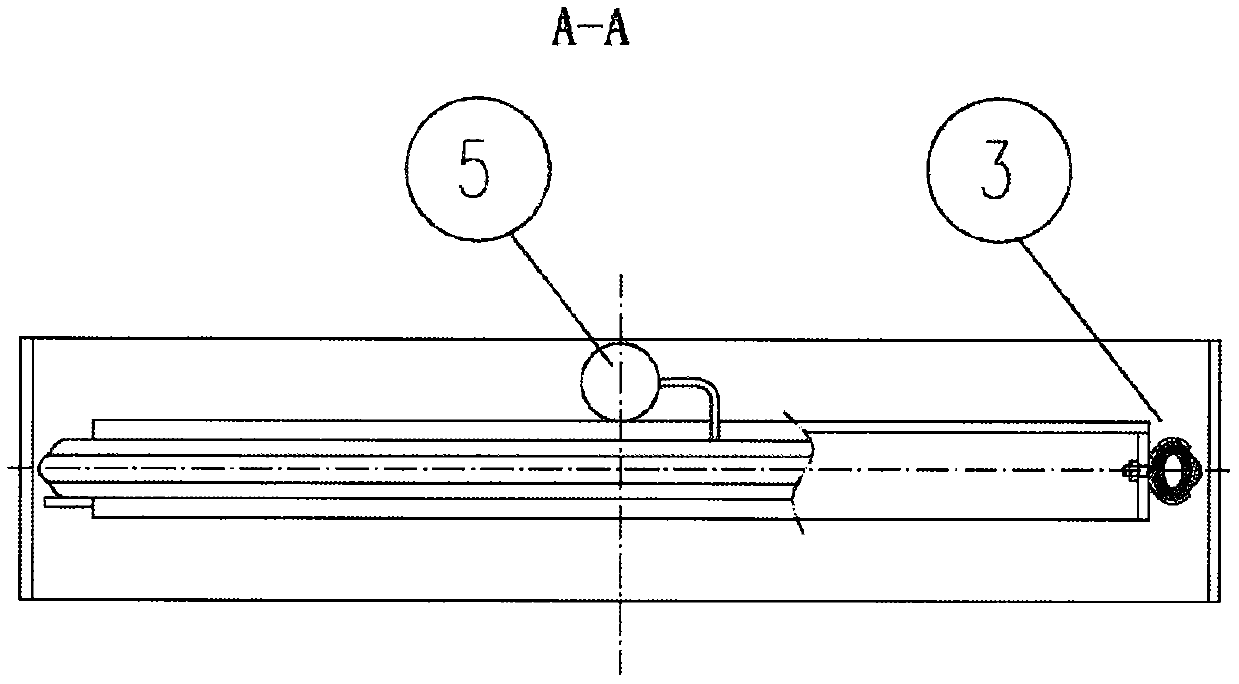

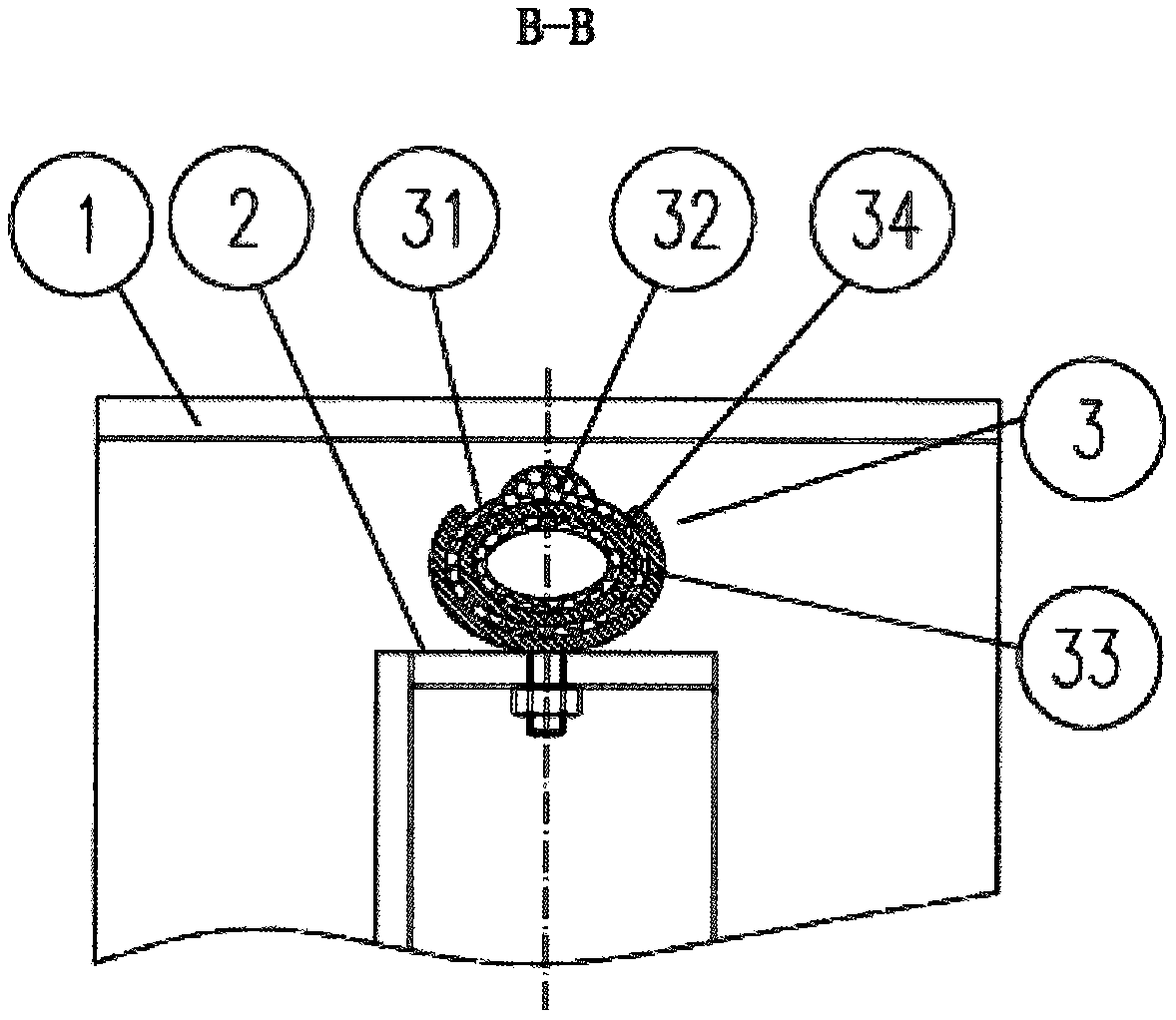

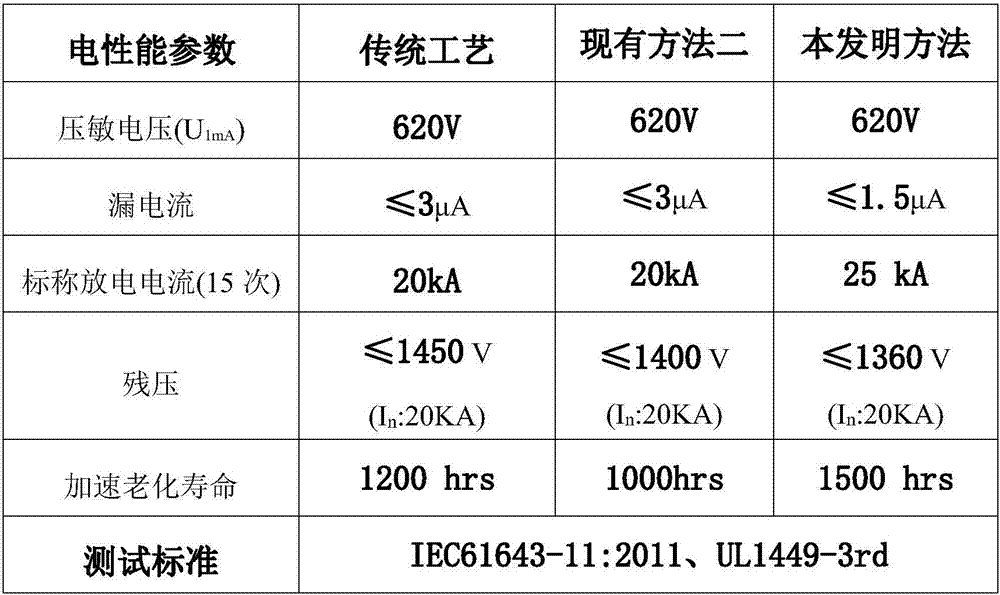

High-performance direct-current zinc oxide varistor and preparation process thereof

ActiveCN105427977ARaise the potential gradientReduce leakage currentResistor manufactureVaristor coresVaristorBismuth preparation

The invention provides a high-performance direct-current zinc oxide varistor and a preparation process thereof. The varistor is prepared from the following components in parts by mol: 90 to 98 parts of ZnO, 0.5 to 7 parts of Bi2O3, 0.1 to 10 parts of Sb2O3, 0.1 to 2 parts of Co2O3, 0.1 to 5 parts of SiO2, 0.1 to 5 parts of MnO2, 0.1 to 5 parts of Cr2O3, 0.1 to 4 parts of NiO, 0.1 to 1 part of B2O3, 0.01 to 0.6 part of Al(NO3) 3.9HO, 0.01 to 0.5 part of V2O5, 0.01 to 0.5 part of CeO2 and 0.05 to 0.5 part of silver glass powder. According to the varistor and the preparation method thereof, by adding B2O3, V2O5, CeO2 and silver glass powder in a traditional varistor, and by coating a varistor blank surface with bismuth-containing oxide during high-temperature firing and by carrying out direct-current coating and diffusion treatment on the varistor obtained by high-temperature firing according to the preparation process, various performances, such as aging resistance, rectangular wave current impact tolerance stability and large current impact tolerance stability of the varistor can be greatly improved, and the preparation process has the advantages of low cost, high efficiency and the like.

Owner:STATE GRID CORP OF CHINA +2

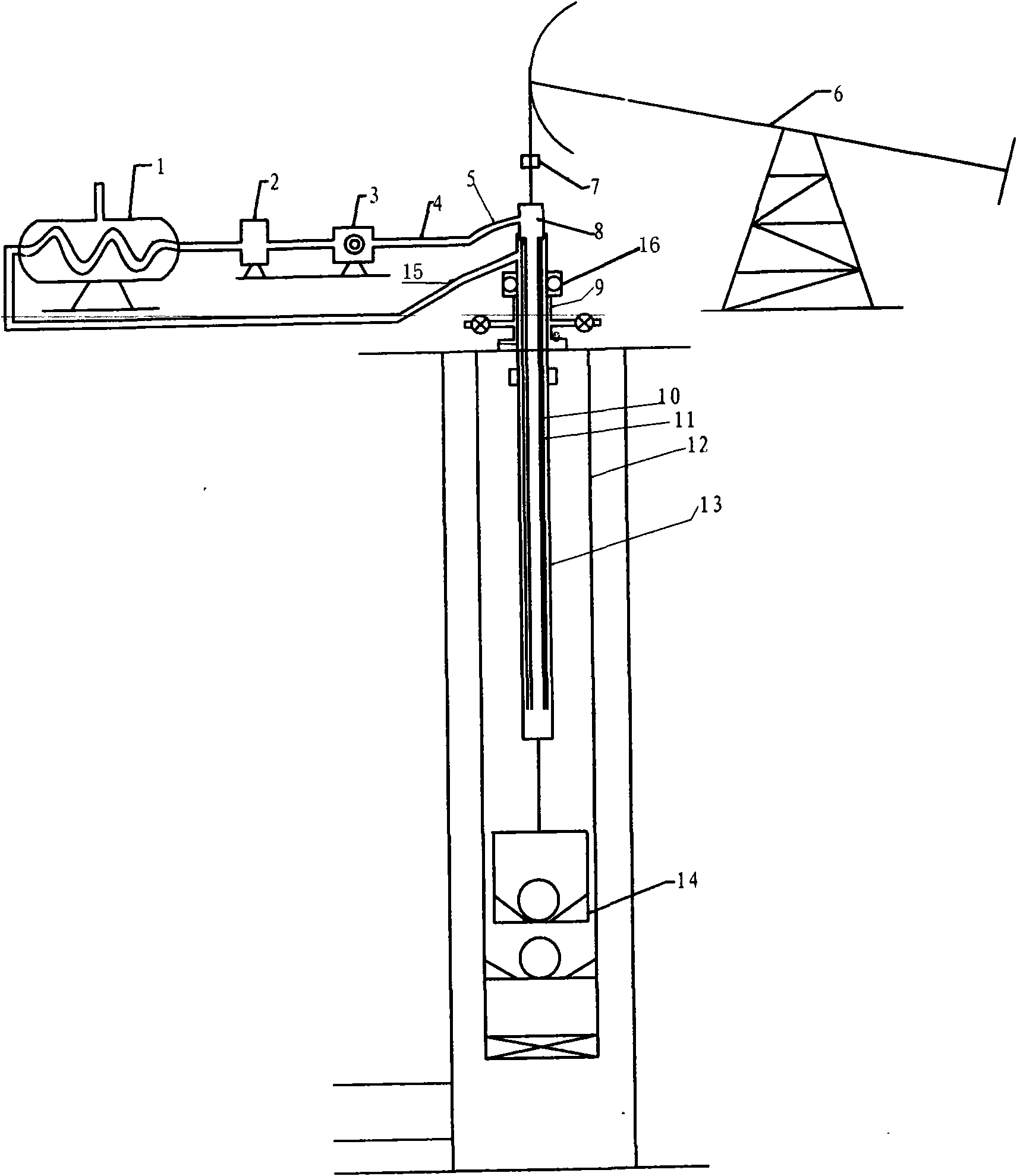

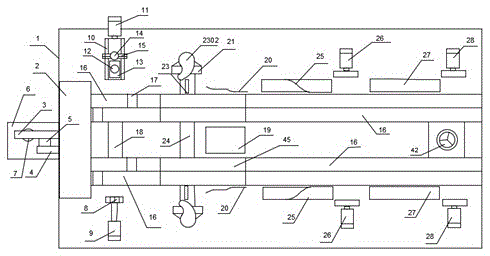

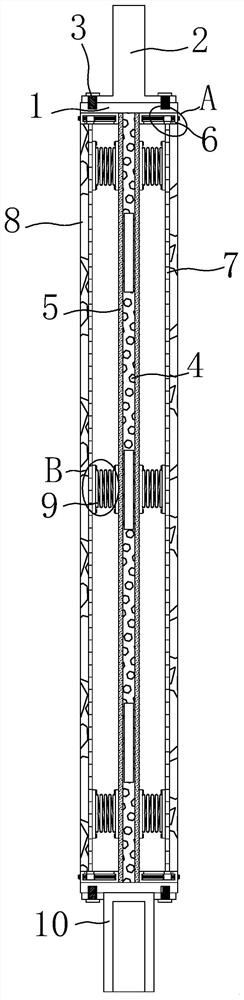

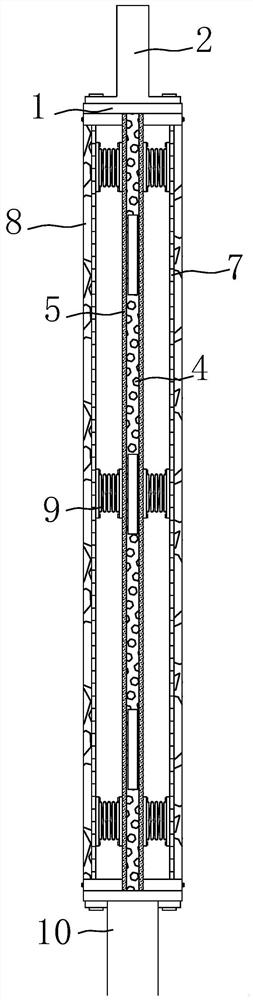

Oil recovery method of closed circulation and viscosity breakback of hot oil in viscous oil well and device

The invention relates to an oil recovery method of closed circulation and viscosity breakback of hot oil in a viscous oil well and a device; the method comprises the following steps of: putting the crude oil into a heating system of a special device, adopting two sets of systems with burning of coal or gas or a single system with burning of coal or gas, being capable of adopting one well with one system or a plurality of wells with one system, and heating and injecting the crude oil into the well for closed circulation. The device comprises a heating system, a buffering tank, an injecting circulating system and an oil pumping system; the circulating system comprises a telescoped central pipe and a telescoped outer sleeve; the telescoped central pipe is sleeved into the telescoped outer pipe, an opening of the lower end thereof is a free end and the upper end thereof is connected with a circulating valve, an injecting pipe, a surface flow pipe, a boosting pump, the buffering tank and the outlet of the heating system in sequence; the lower end of the telescoped outer pipe is connected with the oil-well pump and the upper end thereof is connected with a polished rod, a drain pipe and the inlet of a heating system in sequence by a polished rod sealer; and the upper end of the circulating valve is connected with a polished rod eye of an oil pumping unit. The invention has the characteristics of good heat exchange performance, good viscosity breakback, high pump efficiency, and the like and is widely applied in viscous oil recovery technology.

Owner:王顺华

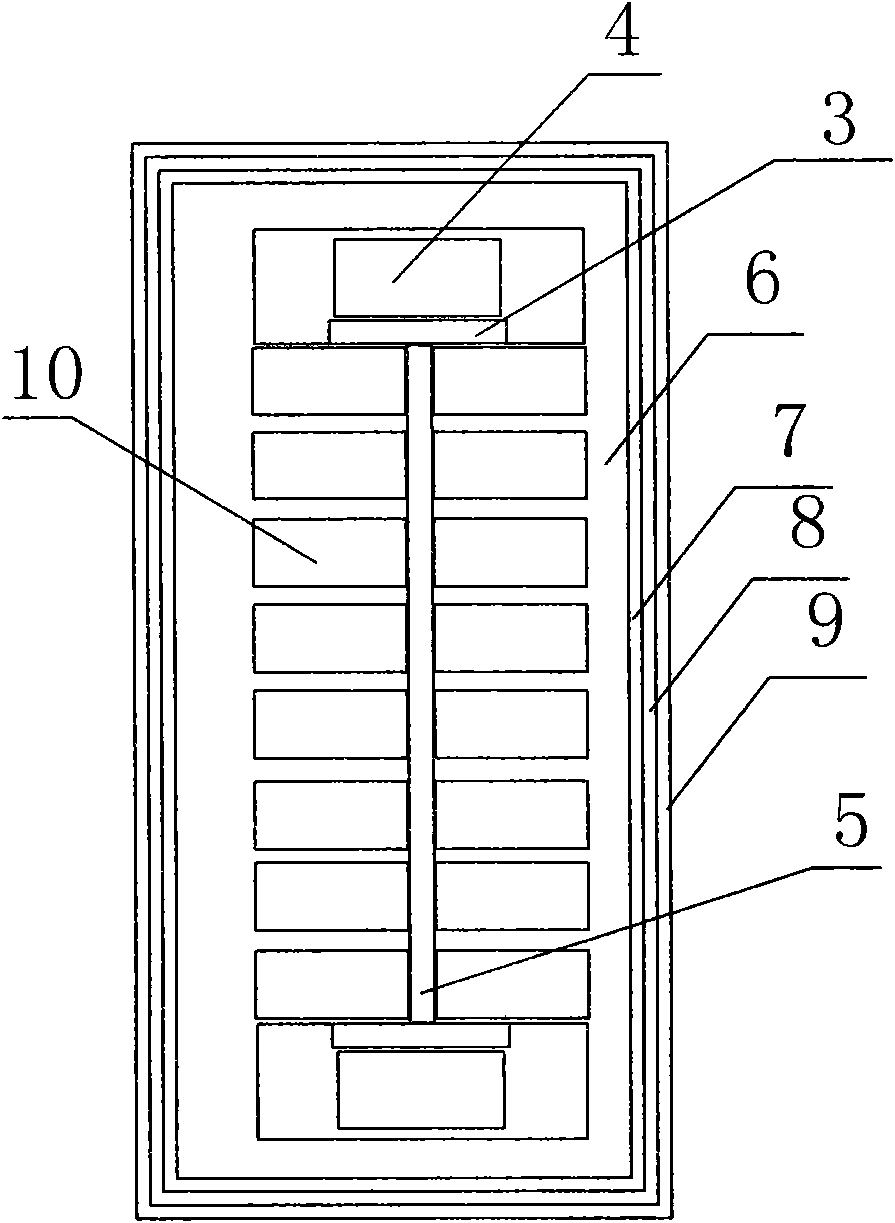

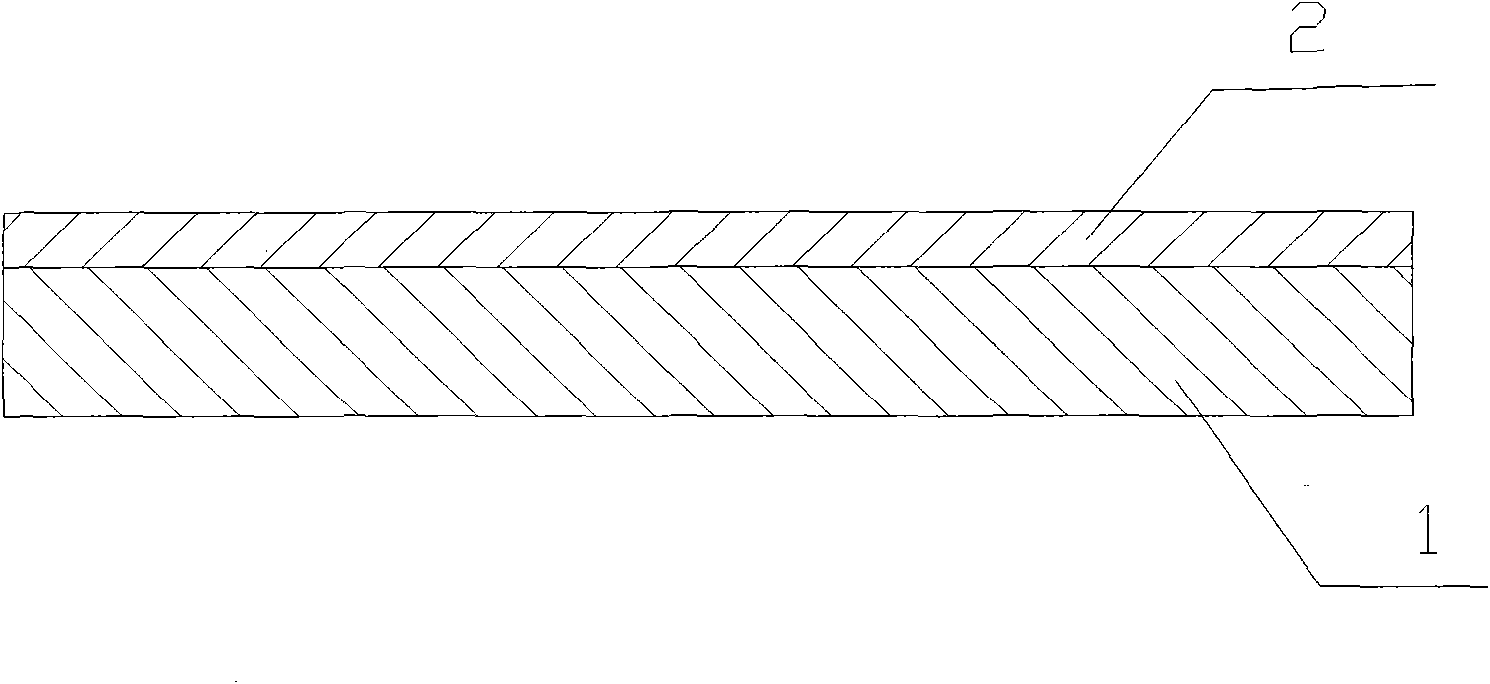

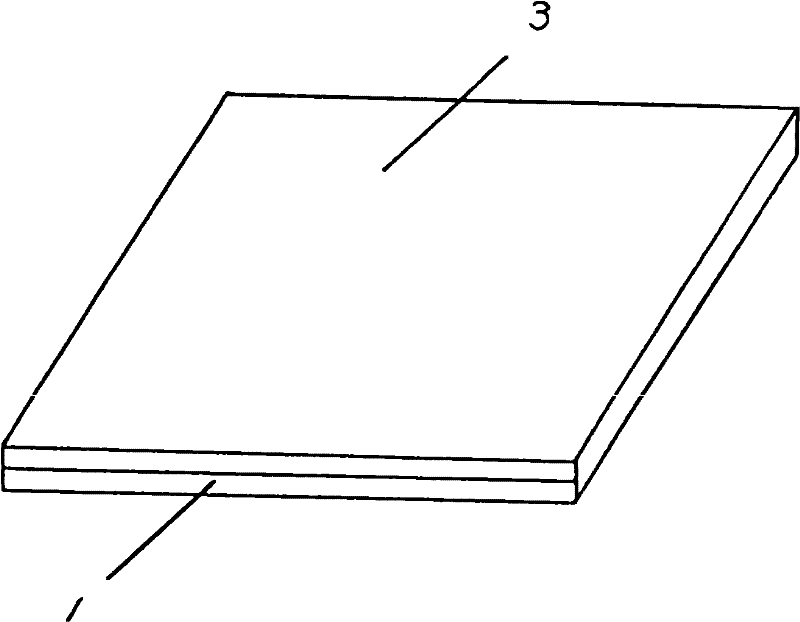

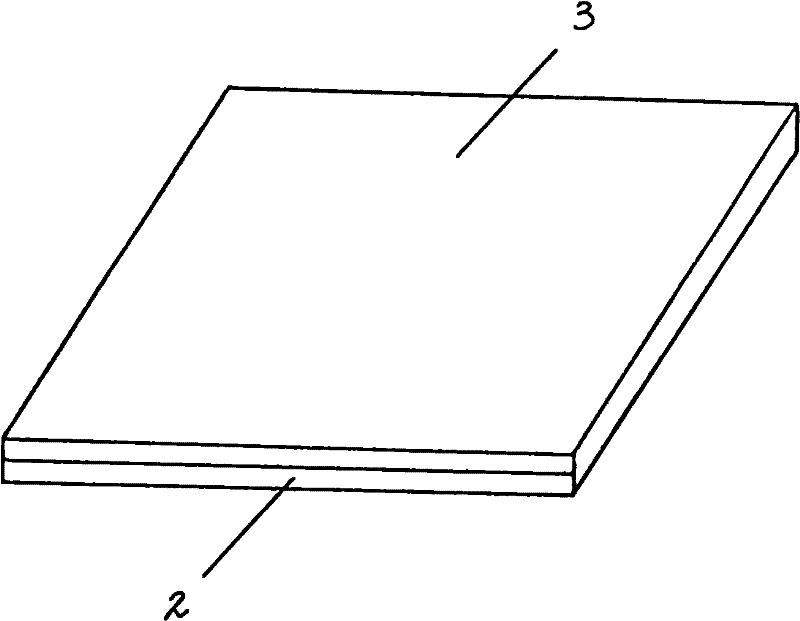

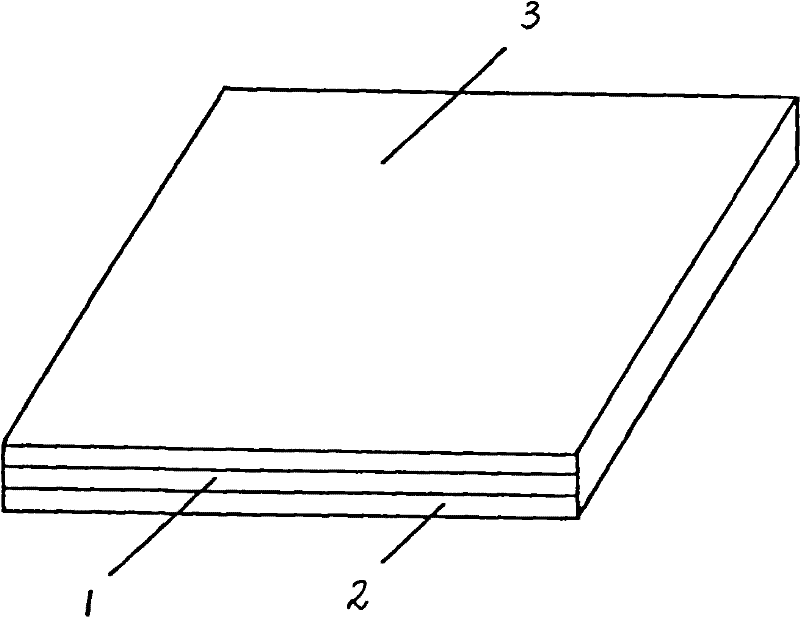

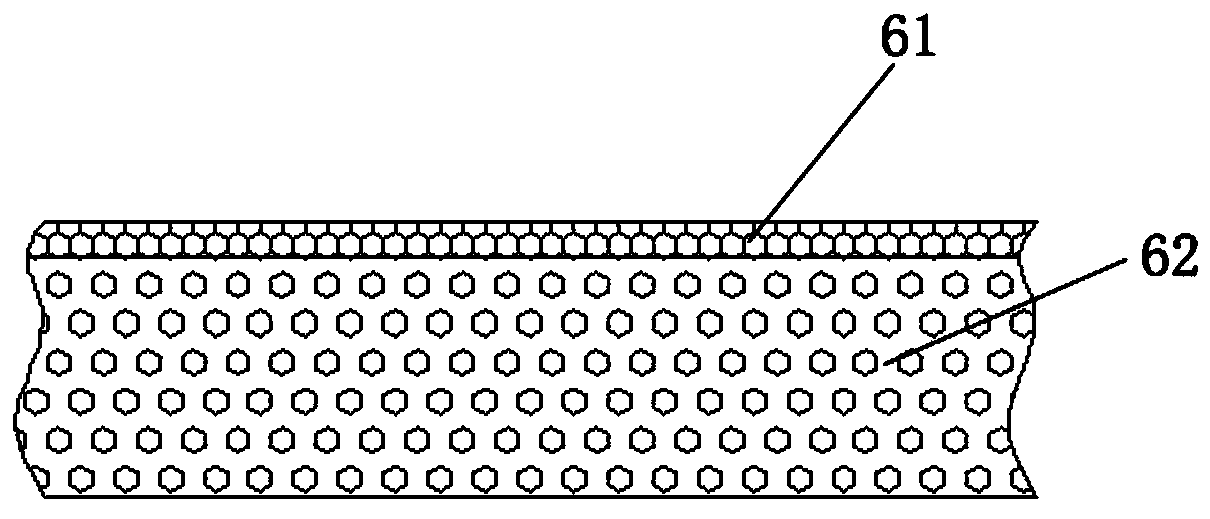

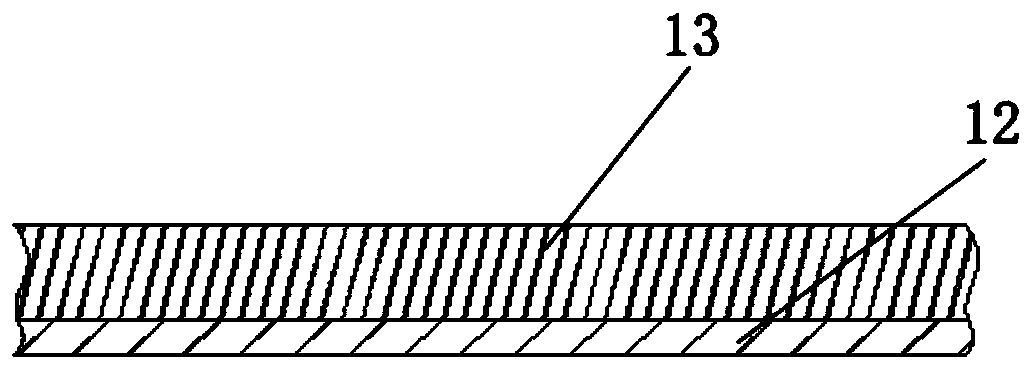

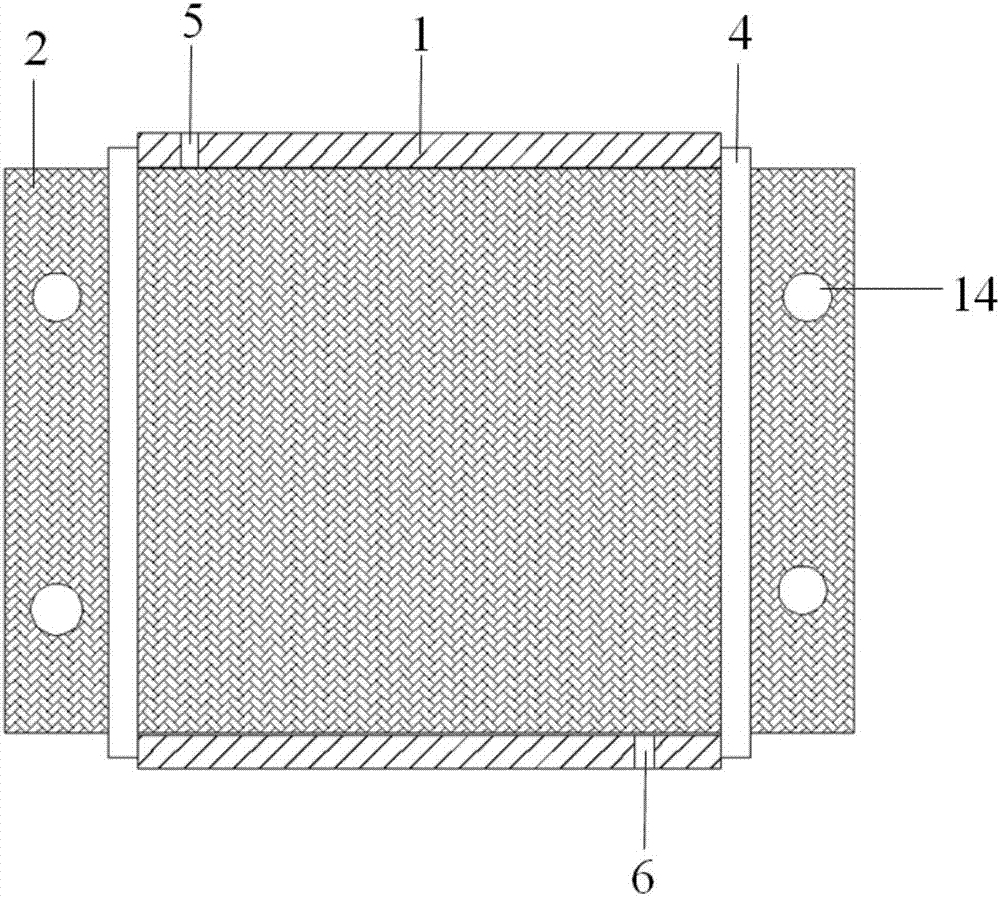

Semiconductor thermal expansion glass mat and production method thereof

ActiveCN101662178AHigh mechanical strengthLong aging lifeWindings insulation shape/form/constructionApplying solid insulationThermal expansionSemiconductor

The invention discloses a semiconductor thermal expansion glass mat and a production method thereof. The semiconductor thermal expansion glass mat is a multi-layer structure, which is characterized bycomprising a thermal expansion glass mat and semiconductor low resistance fabric; and at least one surface of the thermal expansion glass mat is compounded with the semiconductor low resistance fabric. The production method is characterized by comprising the procedures as follows: a. mixing glue; b. fully injecting glue liquid into a glue groove of a horizontal gluing machine; c. mounting the glass mat on the horizontal gluing machine and connecting the glass mat with guiding fabric; d. starting sizing; e. cutting; f. preheating an oil press for standby; g. tidily placing the glass mat according to required thickness to form a glass mat blank, and arranging interval spacers between each glass mat blank; h. pressing to obtain heat expansion glass mat; i. selecting proper semiconductor lowresistance fabric, and arranging the semiconductor low resistance fabric on the single surface or double surfaces of the thermal expansion glass mat; and j. thermally pressing the composite products of the thermal expansion glass mat and the semiconductor low resistance fabric to form the semiconductor thermal expansion glass mat. The semiconductor thermal expansion glass mat and the production method thereof can prolong the service life of a motor as well as save labor and time.

Owner:浙江博菲电气股份有限公司

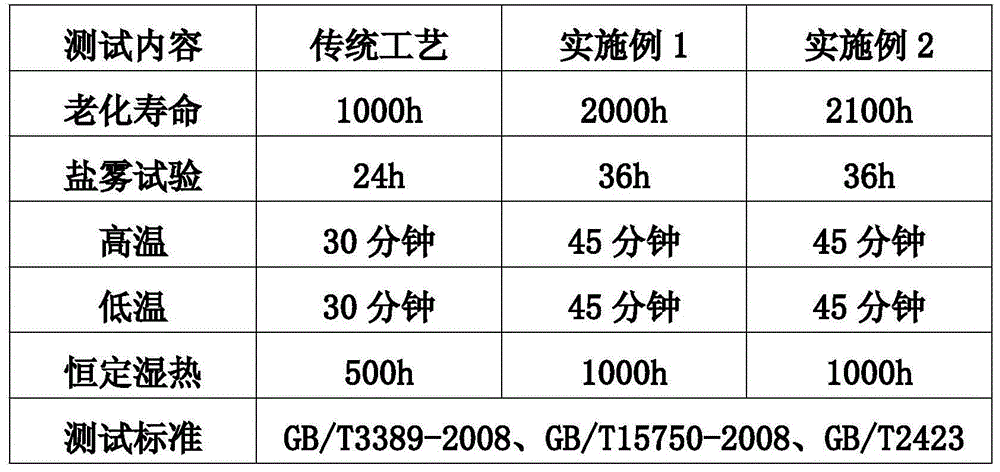

A pressure-resistant, wear-resistant and corrosion-resistant transformer sealing ring and its production method

The invention discloses a compression-resistant, abrasion-resistant and corrosion-resistant transformer seal ring as well as a production method thereof. Chemigum is adopted as a main raw material, and forms synthetic rubber with high-tenacity reclaimed rubber and coumarone resin, and the synthetic rubber has extremely good oil resistance, abrasion resistance and thermal resistance; the synthetic rubber is matched with carbon black, ceramic micro powder, silicon powder, manganese powder, teflon, zinc oxide, argil, vulcanizing activators and hot-oxygen aging resistant agents, so that the performance of tearing resistance, self-lubricating effect, compression deformation resistance, thermal resistance, corrosion resistance, abrasion resistance and the like of the seal ring can be improved effectively, and the service life of the seal ring is prolonged. The favorable seal effect can be protected in severe cold and hot climate environments, and the service life of the seal ring is more than twice that of a traditional seal ring.

Owner:STATE GRID CORP OF CHINA +1

Die for producing water-base polyurethane condom

InactiveCN102107473AIncreased mechanical toughnessLong aging lifeProduced waterPTFE - Polytetrafluoroethylene

The invention relates to a die for producing a water-base polyurethane condom. The die is made of a polytetrafluoroethylene material, namely the die can be made of a pure polytetrafluoroethylene material and also can be made of the polytetrafluoroethylene material added with glass fibers or the polytetrafluoroethylene material added with iron powder. The die can bear the change of high and low temperature repeatedly, realize a membrane-carrying drying process in a straight dipping method of the condom and reduce adhesion degree between the die and a glue membrane, and has the advantages that the glue membrane is easy to crimp and is non-stick.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

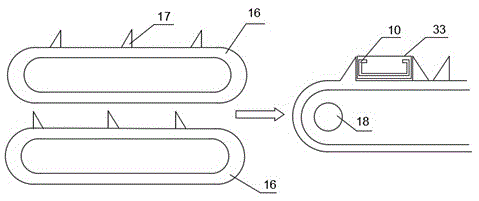

Automatic packing machine for soft gloves

InactiveCN105539937ASimple structureImprove operational efficiencyPackagingCable carrierPackaging Case

The invention relates to a mechanically-and-electrically-integrated packing machine for gloves, in particular to an automatic packing machine for soft gloves. The automatic packing machine for soft gloves aims at achieving the technical purpose of overcoming defects of the prior art. Air cylinders of the packing machine are reduced in the boxing procedure and the box sealing procedure, the packing procedure is optimized, and a new technical scheme is provided. The packing machine is simple in structure, low in cost and reliable in operation. Packing of side lugs of packing boxes is completed through slope sections of two tow chains. The packing machine further comprises a bicircular box unfolding mechanism and a tow chain movement boxing mechanism, wherein two rows of parallel double-gear-form chains are adopted in the tow chain movement boxing mechanism. Due to the fact that boxing is conducted through movement of the double-gear-form chains, an erecting air cylinder, a positioning air cylinder and other links in a packing machine in the prior art are eliminated. The automatic packing machine is simple in structure, convenient to operate and safe and reliable to use.

Owner:刘曙光

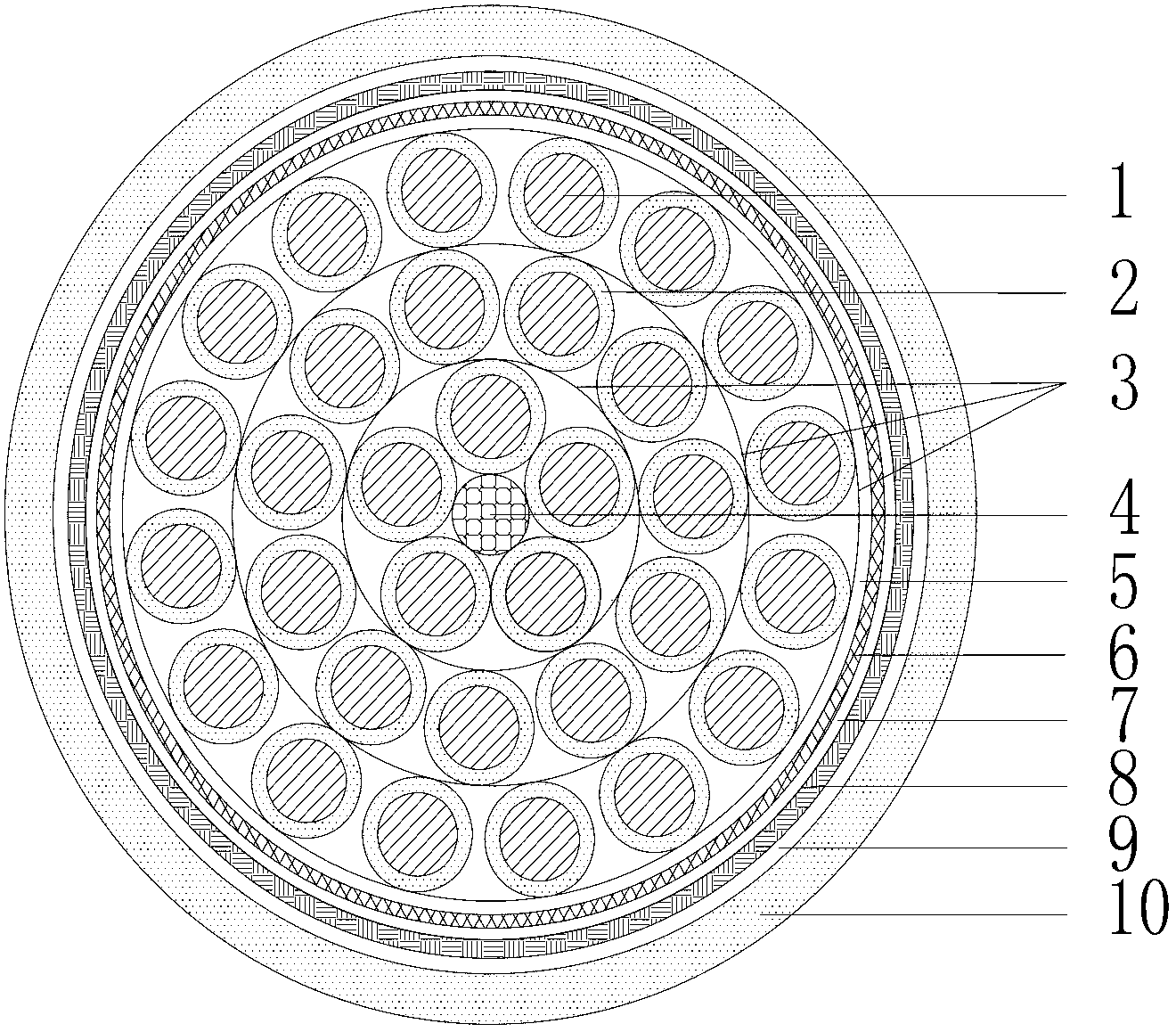

Light and cold-proof screening control cable

InactiveCN102708954AImprove low temperature resistanceGood chemical stabilityClimate change adaptationInsulated cablesCopper conductorYarn

The invention belongs to the field of a cable, and particularly relates to a light and cold-proof screening control cable. An insulating cable core is formed by a stranded copper conductor of the screening control cable and a polyethylene insulating layer outside the stranded copper conductor; the insulating cable core is divided into an inner layer of the insulating cable core, a middle layer of the insulating cable core, and an outer layer of the insulating cable core; the middle layer of the insulating cable core is separated from the outer layer of the insulating cable core through a polyamide yarn loose lapping and tight bundling layer; a polytetrafluoroethylene thin film or a polytetrafluoroethylene lapping cushion layer is arranged outside the outer layer of the insulating cable core; a composite aluminum-plastic tape is arranged outside the polytetrafluoroethylene thin film or the polytetrafluoroethylene lapping cushion layer; a non-absorbent material isolation belt is arranged outside the composite aluminum-plastic tape; a high-permeability alloy belt is arranged outside the non-absorbent material isolation belt; the non-absorbent material isolation belt is arranged outside the high-permeability alloy belt; and a polyurethane jacket is arranged outside the non-absorbent material isolation belt. With the adoption of the light and cold-proof screening control cable provided by the invention, the problems that the conventional cable can not meet the requirement of cold resistance in special industries can be solved; and the light and cold-proof screening control cable is applicable to a condition with a temperature in a range from minus 70 DEG C to minus 100 DEG C in a metallurgy industry, an electric industry, a petrochemical industry and the like.

Owner:LIAONING JINHUAN CABLE

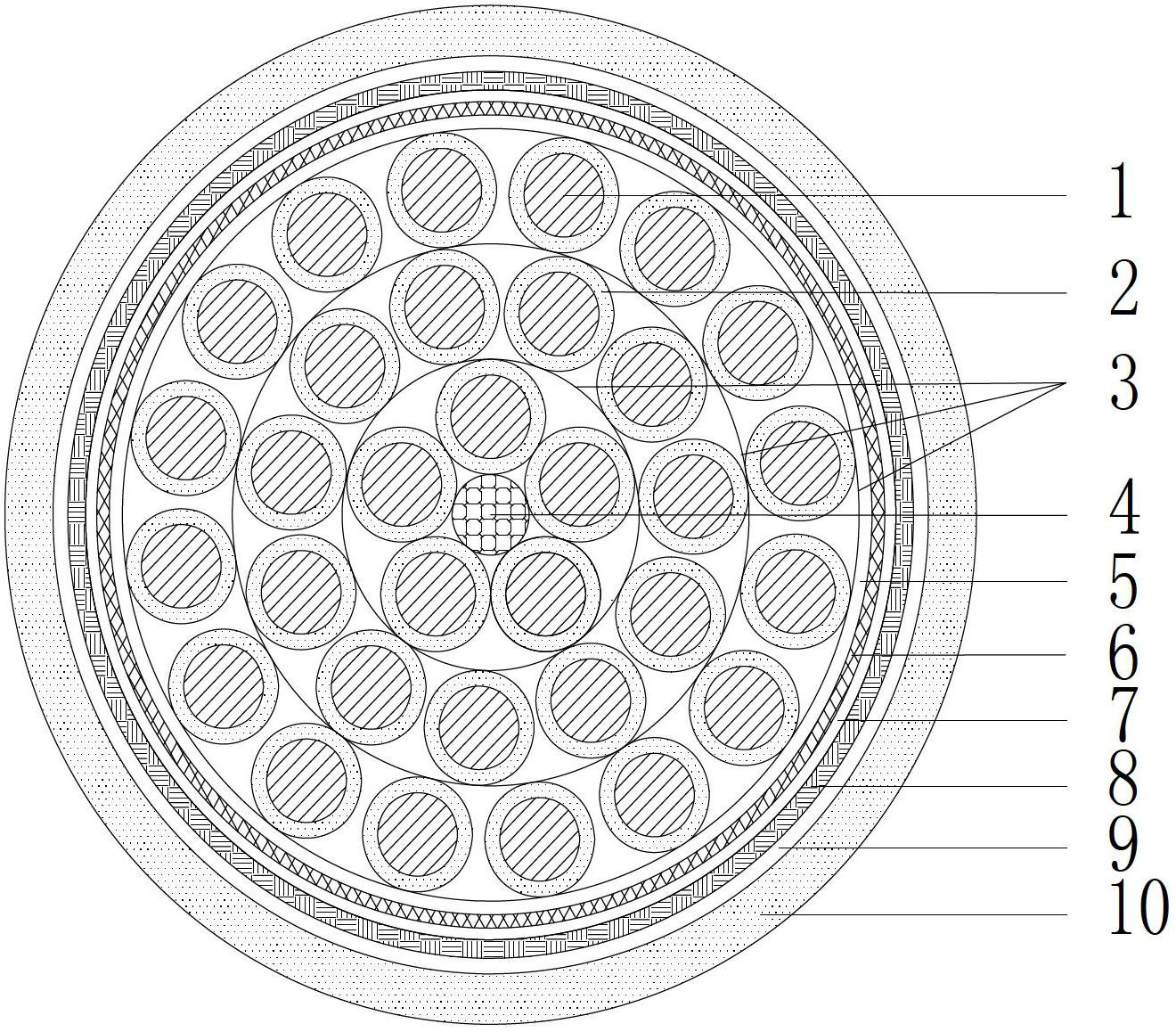

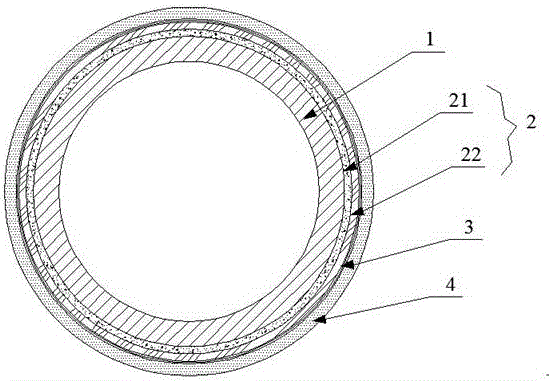

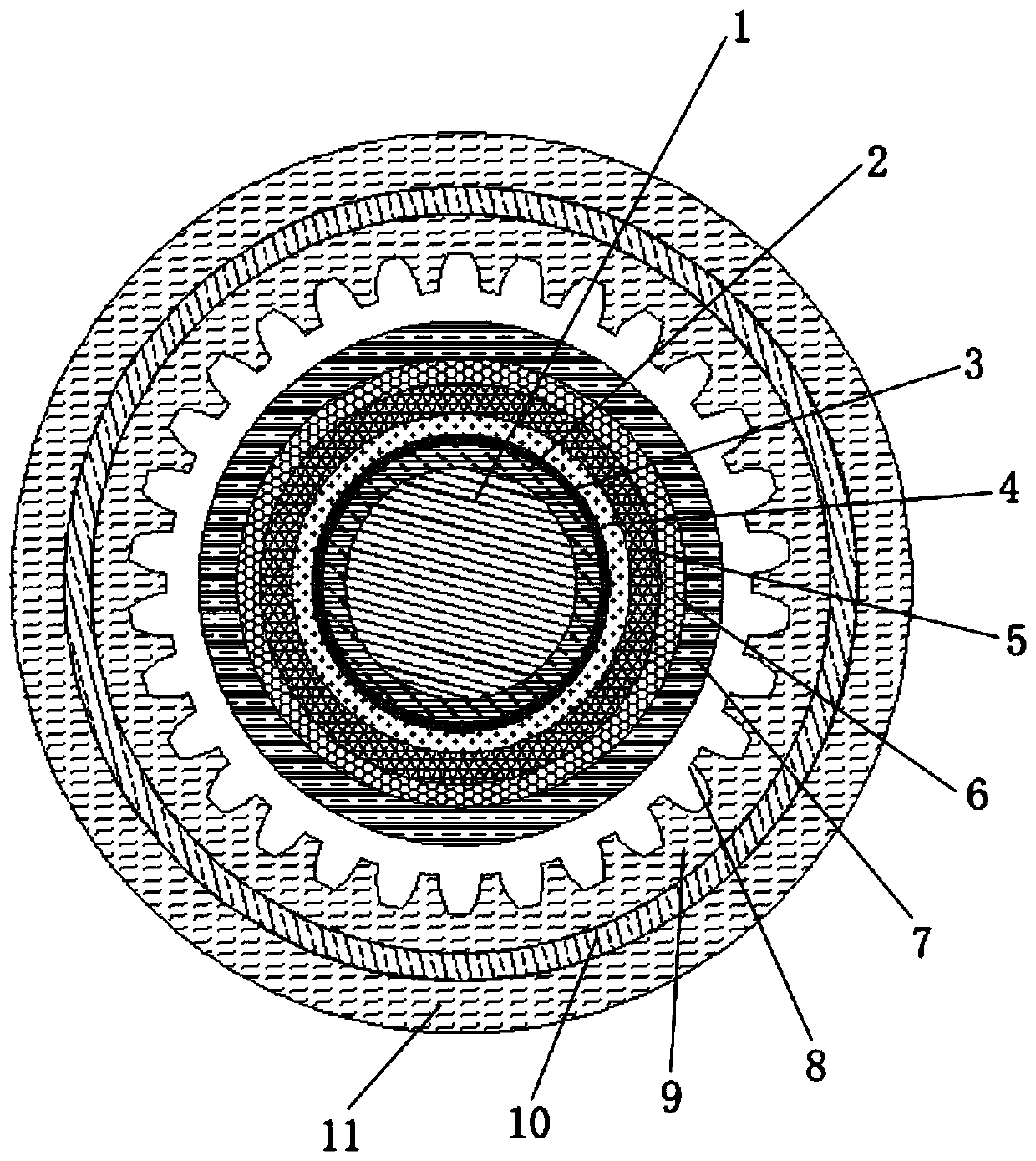

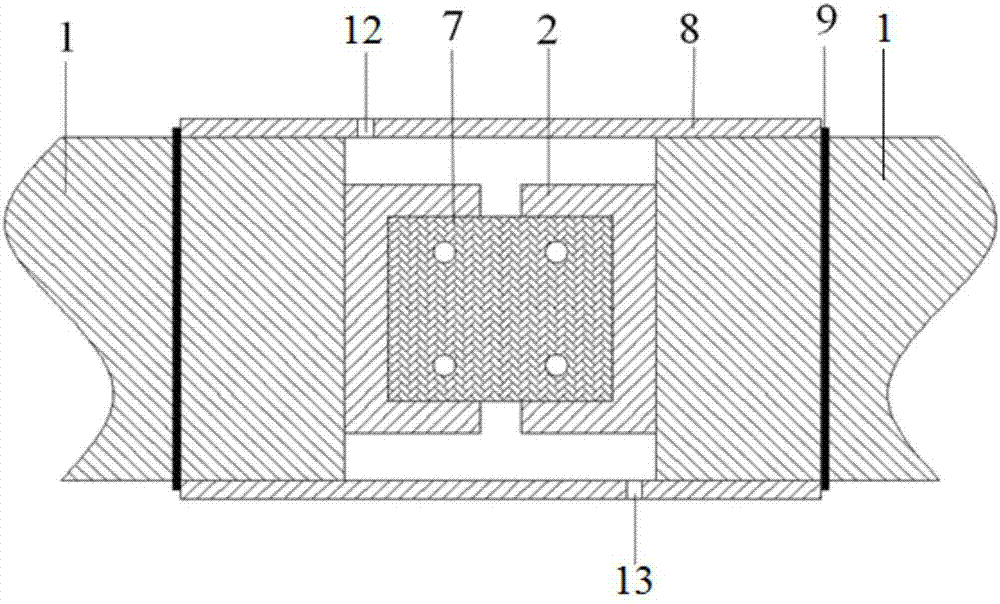

Insulated tubular busbar having composite insulation layer and in voltage class of 1kV and below and preparation method thereof

InactiveCN105931700AAvoid enteringLong aging lifeSingle tube conductorsPower cables with screens/conductive layersPolyolefinElectrical conductor

The invention discloses an insulated tubular busbar having a cold-hot shrinkage composite insulation layer and in a voltage class of 1kV and below and a preparation method thereof. The cross section structure of a tubular busbar is a four-layer structure, which is formed by a metal tube conductor layer, a cold-hot shrinkage composite insulation layer (the inner layer is an ethylene propylene diene monomer cold shrinkage layer, and the outer layer is a polyolefin hot shrinkage layer), a metal grounding shielding layer and an outer protection cover layer from the inside out in sequence. The provided insulated tubular busbar product suitable for the voltage class of 1kV and below is characterized in that a shrinkage tube co-extruded by the cold-hot shrinkage composite insulation layer can be fit to a metal conductor pipe very well without leaving a gap inbetween after heating shrinkage, and the phenomenon of heat expansion and cold contraction does not appear due to the influence of hot and cold environment. The preparation method is simple and feasible; works and labor intensity are reduced; product quality is not influenced by human factors; production efficiency and finished product ratio are improved greatly; cost is reduced; and comprehensive competitiveness of an enterprise is improved.

Owner:深圳市智豪特材科技有限公司

Environmental friendly lead-free aluminum slurry and preparation method thereof

InactiveCN101840744BGood substitutionImprove performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureHazardous substanceFerrosilicon

The invention relates to an environmental friendly lead-free aluminum slurry and a preparation method thereof. The environmental friendly lead-free aluminum slurry comprises the following components: antioxidant ultrafine aluminum alloy micropowder, barium ferrosilicon borate composite frit and a composite organic carrier. The invention has the advantages that the prepared lead-free aluminum slurry is an environmental friendly electronic slurry without harmful substances including lead, cadmium, mercury and hexavalent chromium, is used as a function material, completely replaces lead containing aluminum slurry, is stable and reliable, and has excellent performance, favorable ohmic contact quality, wide sintering temperature range, low sheet resistance, water boiling resistance, long ageing life and favorable replaceability to noble metals.

Owner:WUHAN YILAI RUIER HIGH TECH

Manufacturing method of polyvinyl chloride plain film

The invention discloses a method for producing a polyvinyl chloride plain film. The method is characterized by comprising the following steps: using 100 parts of PVC resin, 40-60 parts of a tackifier, 20-40 parts of a heat stabilizer, 50-200 parts of a strengthening agent, 10-20 parts of reinforced resin, 0.5-1.5 parts of a lubricant and 4-6 parts of an accelerant as raw materials to form a formula, and performing high-speed hot mixing, low-speed hot mixing, extrusion, open milling, calendering, cooling, molding, cutting and packaging to produce the polyvinyl chloride plain film. According to the method, the technology is simple, and the manufactured polyvinyl chloride plain film has good quality; the method disclosed by the invention uses a special formula; the film material is uniform to plasticize, flawless, good in toughness, resistant to impact, flame-retardant, good in low temperature performance, resistant to ageing and long in service life.

Owner:WUXI LONGSHUN IND

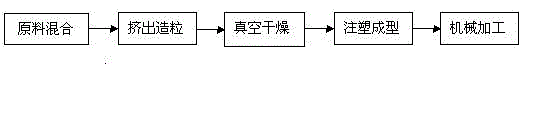

Modified polytetrafluoroethylene, preparation method of modified polytetrafluoroethylene and application of modified polytetrafluoroethylene to high frequency connector

The invention provides a modified polytetrafluoroethylene, a preparation method of the modified polytetrafluoroethylene and application of the modified polytetrafluoroethylene to a high frequency connector. The modified polytetrafluoroethylene is obtained through polymerization reaction of tetrafluoroethylene and perfluoropropoxyethylene; a side group is introduced into a molecular chain of the polytetrafluoroethylene; crystallinity and melt viscosity of the polytetrafluoroethylene are reduced; and when original excellent performance of the polytetrafluoroethylene is basically kept, processing performance of the polytetrafluoroethylene is improved to enable the modified polytetrafluoroethylene to be formed by injection molding, so that the production process is simplified and the production efficiency is improved. When the high frequency connector is produced, the injection molding can be carried out in one step and the post processing step is omitted.

Owner:NANJING COMPTECH COMPOSITES CORP +1

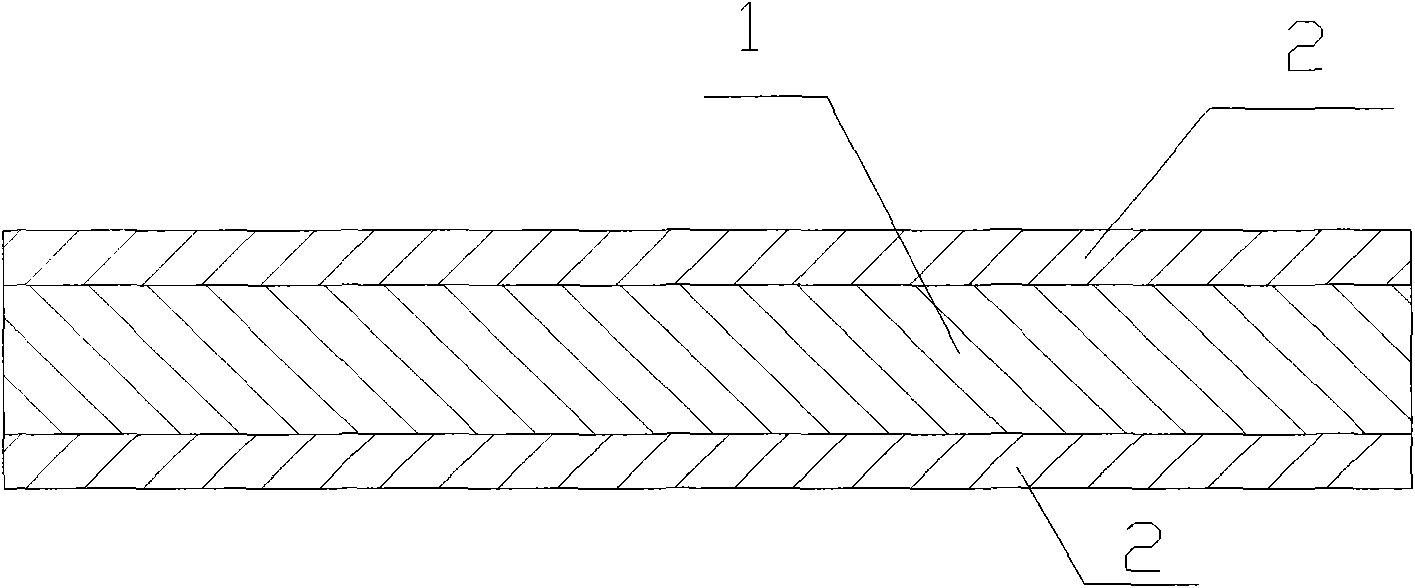

Polytetrafluoroethylene composite isolation membrane for lithium battery

InactiveCN102163703AImprove performanceLong aging lifeSynthetic resin layered productsCell component detailsIsolation membranePolypropylene

The invention discloses a polytetrafluoroethylene composite isolation membrane for a lithium battery. The polytetrafluoroethylene composite isolation membrane comprises an isolation membrane which is a polyethylene microporous membrane or a polypropylene microporous membrane or a composite membrane of the polyethylene microporous membrane and the polypropylene microporous membrane; and the polytetrafluoroethylene composite isolation membrane is characterized in that: a polytetrafluoroethylene microporous membrane is coated on an end face and two sides of the polyethylene microporous membrane, or a polytetrafluoroethylene microporous membrane is coated on an end face and two sides of the polypropylene microporous membrane, or a polytetrafluoroethylene microporous membrane is coated on an end face of the polyethylene microporous membrane of the composite membrane of the polyethylene microporous membrane and the polypropylene microporous membrane and on two sides of the composite membrane. The polytetrafluoroethylene composite isolation membrane for the lithium battery can effectively isolate positive and negative plates of the lithium battery and completely eradicate a short circuit; moreover, the lithium battery is safe and reliable and has no accident in the charging and discharging processes. The polytetrafluoroethylene composite isolation membrane for the lithium battery can be used for isolating the positive and negative plates of the lithium battery.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

Corrosion-resistant and water-blocking aluminum-sheathed single-conductor heating cable and method for preparing same

PendingCN110691437ALong aging lifeImprove heating efficiencyOhmic-resistance heating detailsHeating element shapesElectrical conductorEngineering

The invention discloses a corrosion-resistant and water-blocking aluminum-sheathed single-conductor heating cable and a method for preparing the same. The heating cable comprises a heat-generating conductor and a group consisting of an XLPE insulating layter, an corrosion-resistant functional coating layer, a PET semiconductor wrapping tape layer, a metal shielding layer, a water blocking layer, an insulation fireproof wrapping tape layer, an aluminum alloy sheath, a neoprene inner sheath, a CPE heat-resistant layer and a neoprene outer sheath which successively coat the heat-generating conductor. The water blocking layer is formed co-extruding an MDPE water-blocking inner layer at the inner side and a LDPE water blocking outer layer at the outer side. The cross-sectional profile of the aluminum alloy sheath is in a gear shape. The heating cable, by structurally optimized design, is greatly improved in thermal efficiency, has good corrosion resistance and water resistance, reduces energy consumption, and has a long service life.

Owner:ZHEJIANG ZETASTONE SPECIAL CABLE CO LTD

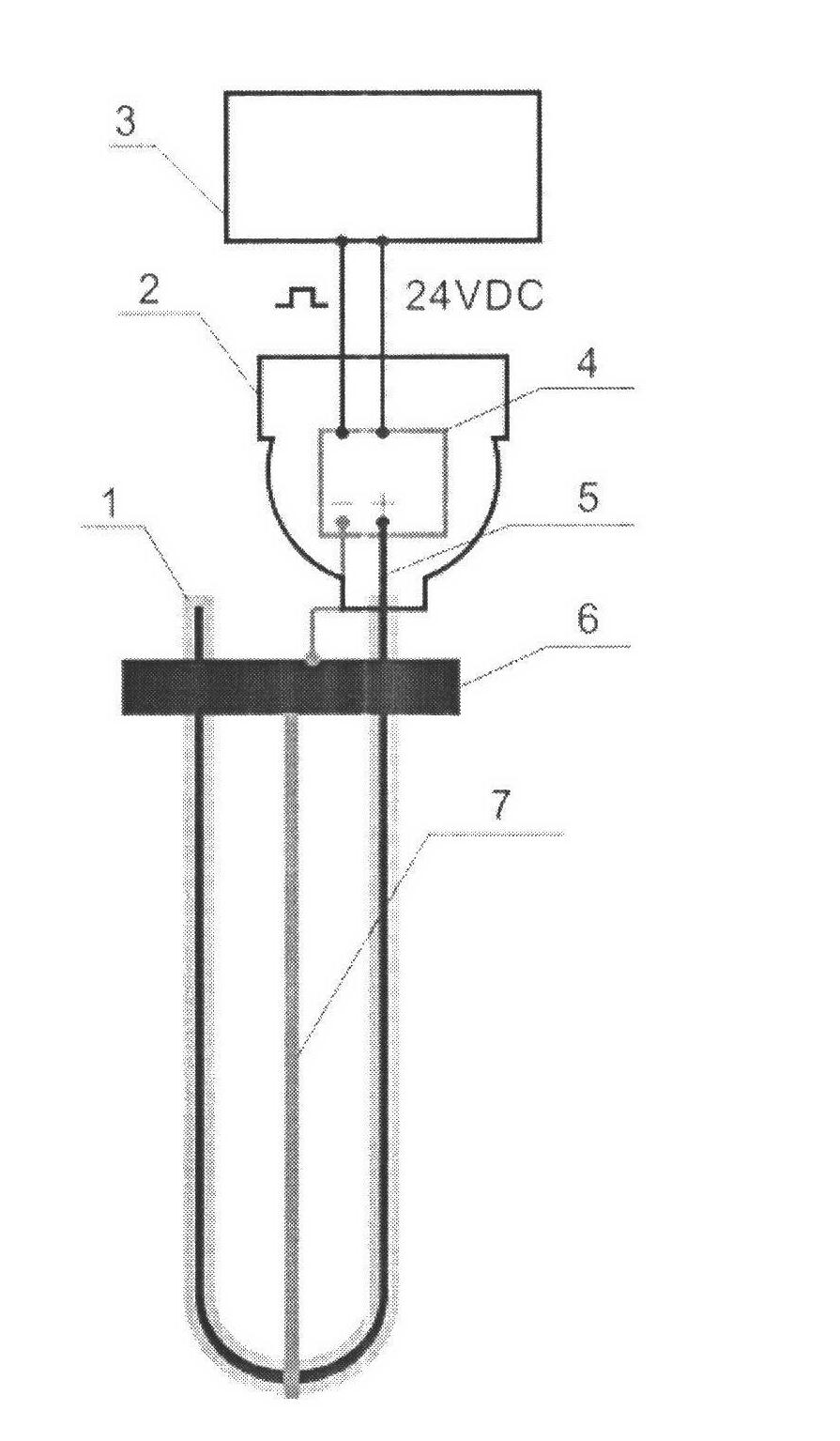

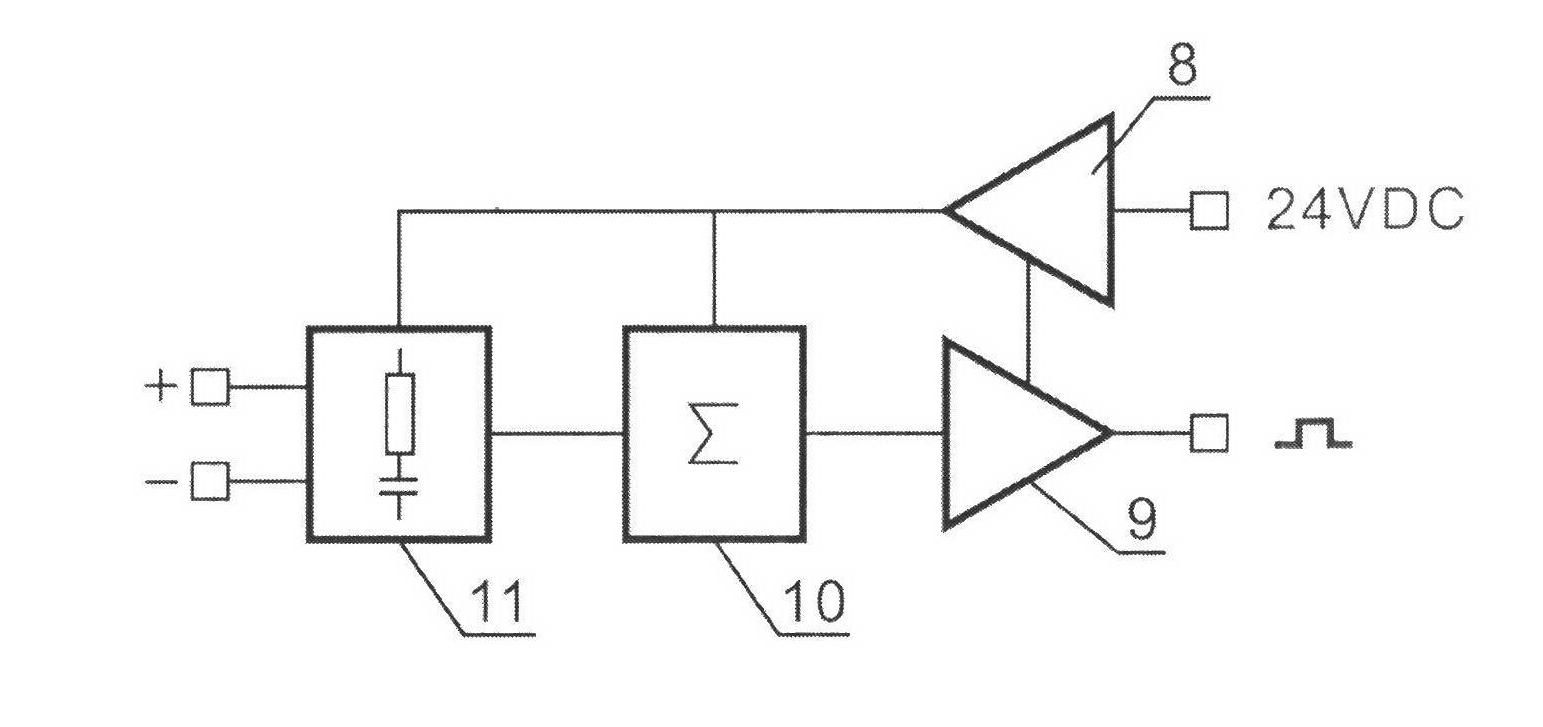

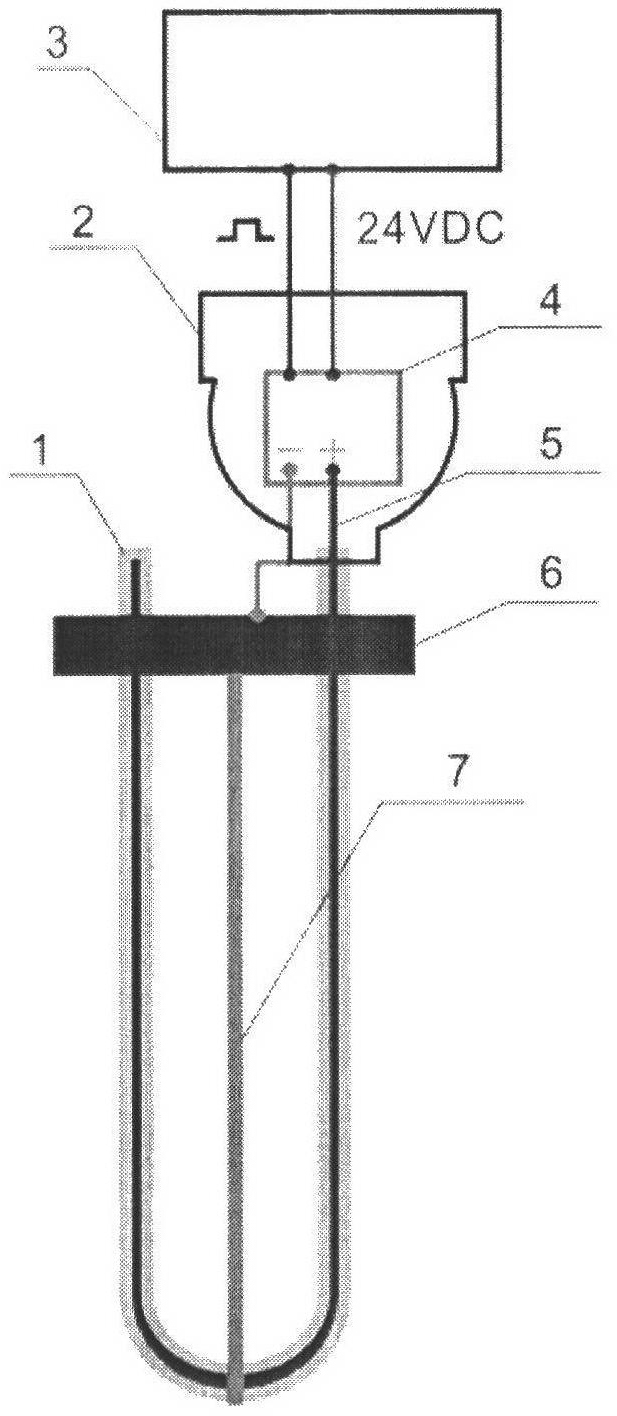

U-shaped capacitive liquid level meter

InactiveCN102589646AThere will be no leakageIncrease the areaLevel indicators by physical variable measurementNon toxicityTemperature resistance

The invention discloses a U-shaped capacitive liquid level meter, which is composed of an electrode insulation outer sleeve, a transmitter casing, a displayer, a transmitter circuit, an inner electrode, a flange and an outer electrode. The transmitter circuit is composed of a power supply circuit, a pulse output circuit, a phase step time integrating circuit and an RC phase step circuit. The U-shaped capacitive liquid level meter has the advantage that 1 the electrode sleeve adopts the U-shaped structure in design, the changing area is twice that of pole type sleeve, and measurement is led tobe stable and accurate; and 2 the liquid level meter adopts a Teflon pipe with good performance as a material, the material has the advantages of high temperature resistance, abrasion resistance, weather resistance, high lubrication, non-adhesiveness, non-toxicity and excellent electric performance, and the liquid level meter can perfectly and completely measure liquid level under the effects of temperature, pressure fusion, molasses adhesion, molasses adhesion and scale deposition even the dielectric parameter is affected by temperature.

Owner:南宁测控自动化科技有限公司

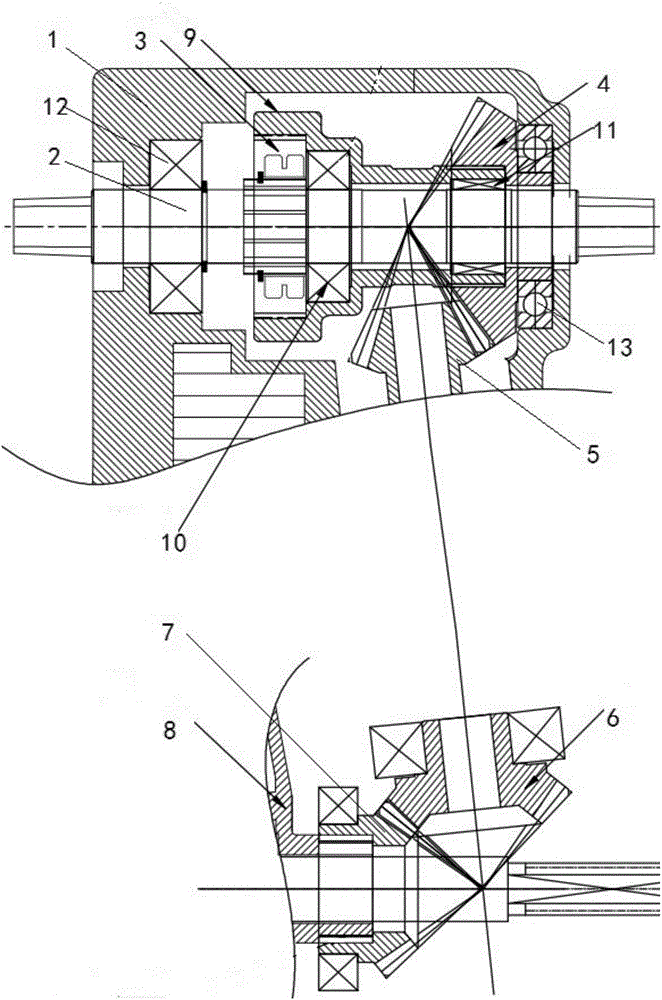

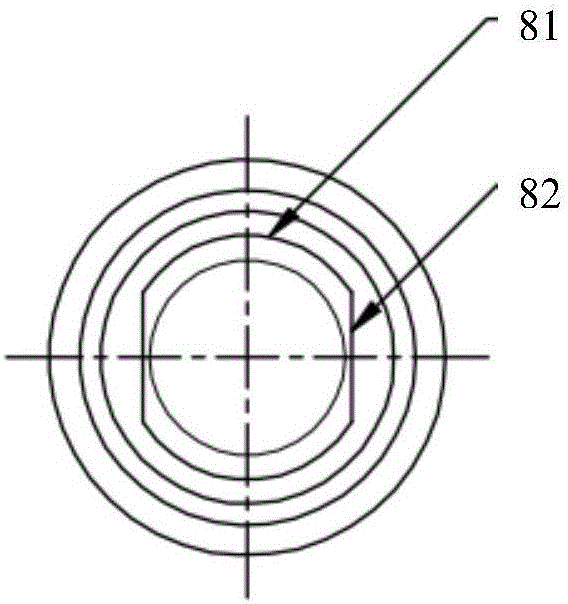

Novel connecting structure for five-way joint center shaft bevel gear and bicycle rim

InactiveCN106542042ACompact structureDoes not affect aestheticsWheel based transmissionFreewheel clutchesEngineeringBevel gear

The invention discloses a novel connecting structure for a five-way joint center shaft bevel gear and a bicycle rim. The novel connecting structure for the five-way joint center shaft bevel gear and the bicycle rim comprises a bicycle five-way joint, a five-way joint center shaft, a clutch, the five-way joint center shaft bevel gear, a first transmission bevel gear, a second transmission bevel gear, an output bevel gear and the bicycle rim. The five-way joint center shaft is rotationally connected with the bicycle five-way joint. The five-way joint center shaft bevel gear can rotate relative to the five-way joint center shaft. The clutch is arranged between the five-way joint center shaft and the five-way joint center shaft bevel gear. The five-way joint center shaft bevel gear is meshed with the first transmission bevel gear. The second transmission bevel gear is meshed with the output bevel gear. The first transmission bevel gear and the second transmission bevel gear synchronously rotate. The output bevel gear is fixedly connected with the bicycle rim. The novel connecting structure for the five-way joint center shaft bevel gear and the bicycle rim is compact in structure, does not change the existing structure of a rear wheel of a bicycle and does not influence the attractiveness of an original product, and meanwhile because the clutch of a bicycle bevel gear structure is arranged on the five-way joint center shaft, the transmission space of the back wheel is greatly reduced.

Owner:慈溪浩然驱动科技有限公司

Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic and preparation method thereof

The invention discloses Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic and a preparation method thereof. The voltage-sensitive ceramic comprises base materials and doping materials. The base materials contain, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.2-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping materials. The seed crystal doped materials include ZnO, Nb2O5 and Y2O3, wherein mass ratio of ZnO: Nb2O5: Y2O3 is 90-95:0.1-5: 0.1-5. The Y<3+> and Nb<5+> composite donor doped ZnO voltage-sensitive ceramic has characteristics of reducing ZnO grain resistivity and controlling ZnO lattice distortion to finally achieve low residual voltage of ZnO varistor, long aging life and strong pulse current withstand capacity.

Owner:贵阳高新益舸电子有限公司

Butterfly valve without valve seat and soft sealing method thereof

The invention relates to a butterfly valve without a valve seat and a soft sealing method of the butterfly valve without the valve seat. The butterfly valve comprises a valve body and a valve plate, the outer diameter of the valve plate is smaller than the inner diameter of the valve body, and a soft sealing structure is sleeved and fixed along the radial outer surface of the valve plate; the softsealing structure comprises a soft sealing ring, and the soft sealing ring is internally provided with an internal annular communicating cavity; the butterfly valve is provided with a medium inlet and outlet pipeline to communicate with the cavity of the soft sealing ring; and in the closed state of the butterfly valve, the soft sealing ring is close to the inner wall of the valve body. After thebutterfly valve is closed, the cavity of the soft sealing ring is filled with a medium through the medium inlet and outlet pipeline, and the soft sealing ring is attached to the inner wall of the valve body after being deformed or displaced, so that the butterfly valve is sealed; before the butterfly valve is to be opened, the medium in the cavity of the soft sealing ring is discharged through the medium inlet and outlet pipeline, the soft sealing ring automatically restores to the original shape, and then the butterfly valve is opened. The sealing problem of the butterfly valve is effectively solved, the structure is reasonable, the sealing effect is good, and the service life is long.

Owner:DALIAN CONSERVATION SCI & TECH CO LTD

Anti-pressure wear-resistant corrosion-resistant transformer sealing ring

The invention discloses an anti-pressure wear-resistant corrosion-resistant transformer sealing ring. Nitrile rubber is adopted to serve as the main raw material and combined with high-tenacity reclaimed rubber and coumarone resin to form synthetic rubber, and excellent oil resistance, wear resistance and heat resistance are achieved; carbon black, ultrafine ceramic powder, silica powder, manganese powder, polytef, zinc oxide, argil, vulcanizing activators and anti-aging agents capable of being resistant to thermo-oxidative aging serve as auxiliary materials, the properties such as tear resistance, the self-lubricating effect, compressive deformation resistance, heat resistance, corrosion resistance and friction resistance of the sealing ring can be effectively improved, and the service life of the sealing ring can be prolonged. Good sealing effect can be protected under severe cold and hot summer climatic environment, and compared with a traditional sealing ring, the service life is effectively prolonged by over one time.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Combined In3+ and Sn4+ donor doped ZnO varistor ceramic and preparation method thereof

ActiveCN106892657ASuppresses the increase in leakage currentSuppresses the decrease of the nonlinear coefficientOvervoltage protection resistorsCeramicSeed crystal

The invention discloses combined In3+ and Sn4+ donor doped ZnO varistor ceramic and a preparation method thereof; the combined In3+ and Sn4+ donor doped ZnO varistor ceramic comprises a base material and a doping material, wherein the base material comprises, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.1-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping material; the seed crystal doping material comprises ZnO, SnO2 and In2O3 having a mass ratio of (90-95):(0.1-5):(0.1-5). The combined In3+ and Sn4+ donor doped ZnO varistor ceramic has the advantages that ZnO grain resistivity can be decreased and ZnO lattice distortion can also be controlled, and also has the advantages of low final ZnO varistor residue, long ageing life and high pulse current tolerance.

Owner:贵阳高新益舸电子有限公司

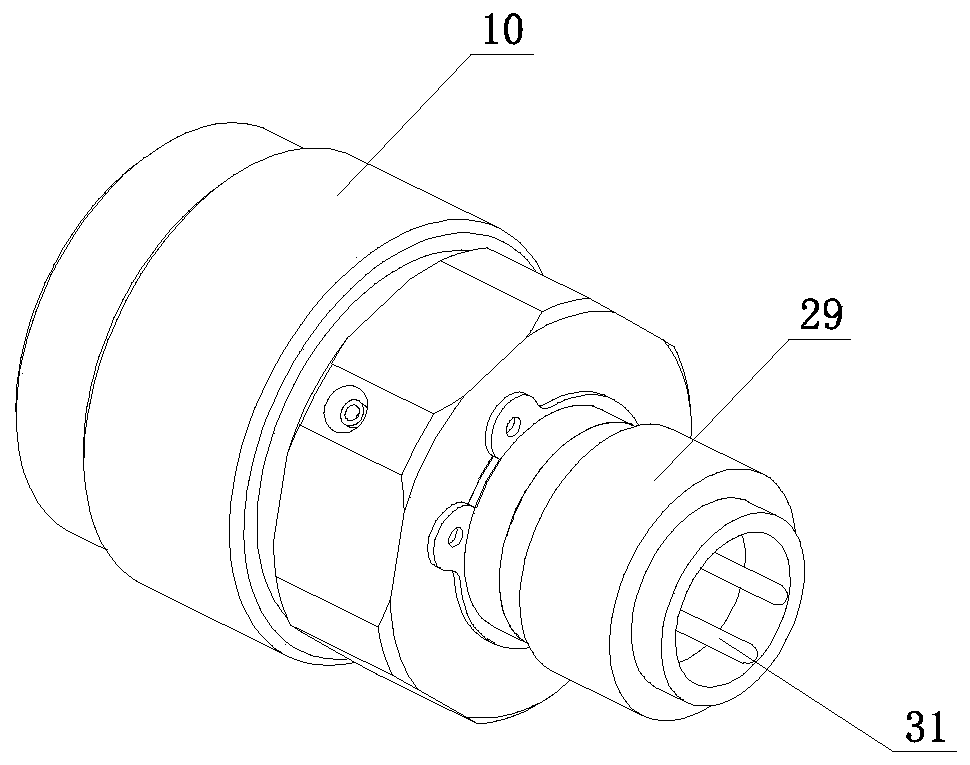

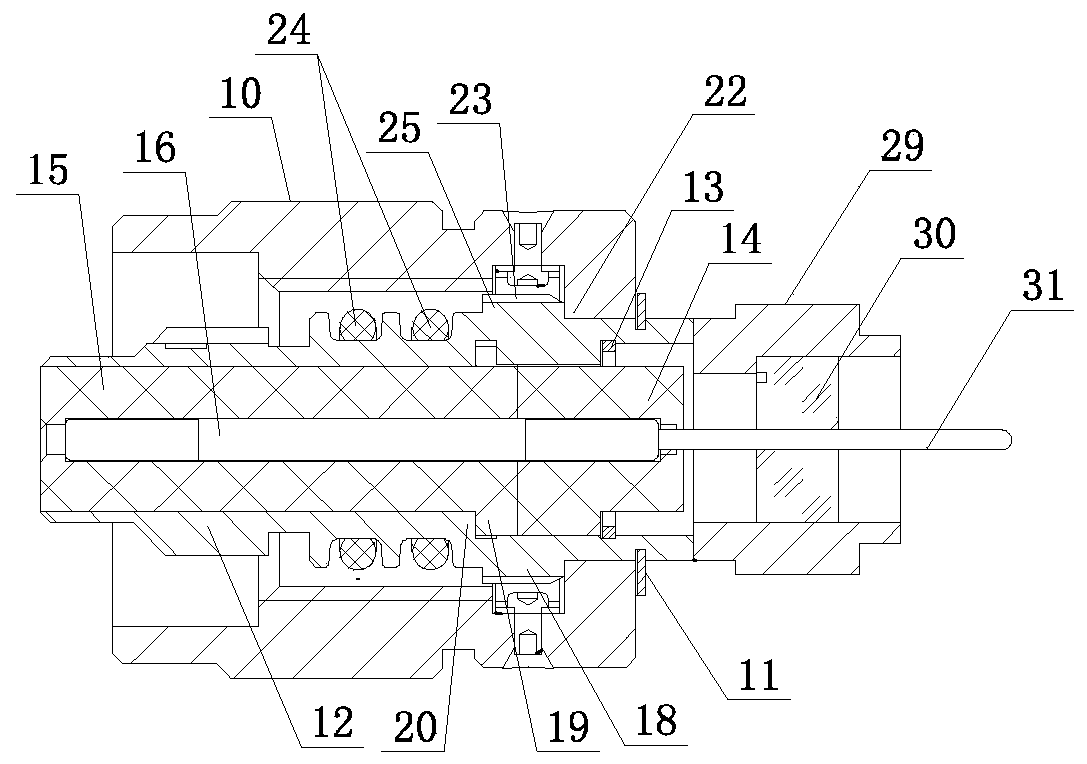

K1-type electrical connector assembly of mineral insulated cable for nuclear power

ActiveCN110380252AImprove corrosion resistanceNo maintenanceSoldered/welded conductive connectionsSecuring/insulating coupling contact membersNuclear powerButt joint

The invention relates to a K1-type electrical connector assembly of a mineral insulated cable for nuclear power, and the assembly comprises a cable assembly, and a plug and a socket which are respectively spliced with two ends of the cable assembly. The cable assembly is characterized in that the cable assembly comprises a mineral cable, a corrugated pipe wrapped outside the mineral cable, a positioning plate for fixing the mineral cable, and a stainless steel pipe welded with the positioning plate; the stainless steel pipe is internally provided with a glue pouring area and a switching jack contact piece; the switching jack contact piece is of a double-end jack structure, one end of the switching jack contact piece is electrically connected with the mineral cable core wire through a barewire, and the other end is plugged with the plug or the socket; the plug comprises a connecting nut, a spline housing, an insulator part, and a glass sintering part which is in butt joint with the double-end jack contact part; the socket is of an integrated structure formed by sintering a socket shell, a glass cake II and a double-end contact pin contact piece II through glass. The assembly provided by the invention is resistant to irradiation and aging and long in service life, and it is guaranteed that the product can still be used after being subjected to severe accident working conditionswhile the using requirements of a nuclear-grade K1-type electrical connector are met.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Pure silicon BETA molecular sieve with ultraviolet resistance and preparation method thereof

InactiveCN112110455AImprove anti-aging propertiesLong aging lifeCrystalline aluminosilicate zeolitesMolecular sieveUltraviolet

The invention discloses a preparation method of a pure silicon BETA molecular sieve with ultraviolet resistance, wherein the preparation method comprises the steps: step 1, mixing raw materials according to a molar ratio of SiO2:(0.3-0.6)B2O3:(0.75-1.5)template agent:(10-20)water to obtain a gel reactant; step 2, carrying out hydrothermal dynamic crystallization at the temperature of 120-180 DEG Cfor 4-8 days, filtering, washing and drying the crystallized product, and roasting at the temperature of 500-700 DEG C for 4-6 hours to obtain a silicon-boron molecular sieve B-MWW; step 3, mixing the prepared silicon-boron molecular sieve B-MWW matrix with ammonium nitrate or ammonium chloride with the concentration of 4-10 mol / L according to the mass ratio of 1:(30-50), carrying out acid pickling treatment for 2-6 hours at the temperature of 60-90 DEG C, repeating the acid pickling operation twice, and then filtering; and washing, drying and roasting at the temperature of 500-700 DEG C for6-10 hours to obtain the pure silicon BETA molecular sieve raw powder. The pure silicon BETA molecular sieve prepared by the method is used as an anti-aging auxiliary agent of plastic, and the anti-ultraviolet aging life of the plastic added with the molecular sieve can be prolonged by 3 times or more compared with that of a plastic added with a common anti-aging auxiliary agent.

Owner:南京博酝化工科技有限公司

Combined In3+ and Ga3+ donor doped ZnO varistor ceramic and preparation method thereof

The invention discloses combined In3+ and Ga3+ donor doped ZnO varistor ceramic and a preparation method thereof; the combined In3+ and Ga3+ donor doped ZnO varistor ceramic comprises a base material and a doping material, wherein the base material comprises, by weight, 87-95 parts of ZnO, 2.0-4.0 parts of Bi2O3, 0.4-0.7 part of MnO2, 1.5-3.5 parts of Sb2O3, 0.5-1.5 parts of Co2O3, 0.2-1.0 part of Cr2O3, and 1-5 parts of seed crystal doping material; the seed crystal doping material comprises ZnO, Ga2O3 and In2O3 having a mass ratio of (90-95):(0.1-5):(0.1-5). The combined In3+ and Ga3+ donor doped ZnO varistor ceramic has the advantages that ZnO grain resistivity can be decreased and ZnO lattice distortion can be controlled, and also has the advantages of low finish ZnO varistor residue long ageing life and high pulse current tolerance.

Owner:GUIZHOU UNIV

Transformer sealing ring and production method thereof

InactiveCN105254950AGood oil resistanceImprove wear resistanceOther chemical processesTransformerManganese

The invention discloses a transformer sealing ring and a production method thereof. Nitrile rubber is adopted as a main material, the nitrile rubber, high-tenacity reclaimed rubber and coumarone resin form synthetic rubber. The sealing ring has extremely good oil resistance, abrasion resistance and heat resistance, by means of carbon black, ceramic micro powder, silicon powder, manganese powder, polytetrafluoroethylene, zinc oxide, pottery clay, a vulcanizing activator and an anti-thermo-oxidative-aging agent, the tear resistance, the self-lubricating effect, compression deformation resistance, heat resistance, corrosion resistance, friction resistance and other performance of the sealing ring can be effectively improved, and the service life of the sealing ring is prolonged. A good sealing effect can be protected in the cold environment and in hot summer. Compared with a traditional sealing ring, the service life is effectively prolonged by over one time.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Composite frame type low-voltage bus slot and preparation method thereof

ActiveCN107394721ANo swelling defectExpansion defects do not appearContact member assembly/disassemblyPartially enclosed bus-bar installationsElectricityElectrical conductor

The invention discloses a composite frame type low-voltage bus slot. The composite frame type low-voltage bus slot comprises a plurality of bus straight-line segment brackets, a joint segment is connected between every two bus straight-line segment brackets; the invention further discloses a manufacturing method of the composite frame type low-voltage bus slot, and mainly comprises the following steps: selecting material, pre-manufacturing the straight-line segment bracket, filling potting material, manufacturing the joint segment, and filling the potting material; the application performance of the low-voltage bus slot is improved, the conductor and the insulating sleeve are fixed through the tenacity material; the expansion defect between the conductor and the insulating material is avoided when the temperature of the conductor is changed; the low-voltage bus slot is low in internal bubble content, small in bubble size, low in dielectric loss of insulating material, high in voltage resistance, and low in ageing life; the insulating material is high in density, good in tensile resistance, bending resistance and torsion resistance; the insulating material can adopt the heating curing process, the curing period is shortened to tens of minutes or several hours, and the insulating material can be extensively applied to the industrial and mining power distribution industry.

Owner:XIAN UNIV OF TECH

Water filtering wall body of fabricated all-aluminum building

InactiveCN113006318ALight in massEasy to moveWallsBuilding insulationsWater filterArchitectural engineering

The invention discloses a water filtering wall body of a fabricated all-aluminum building, and relates to the technical field of all-aluminum buildings. The water filtering wall body of the fabricated all-aluminum building comprises two sets of base plates which are symmetrically arranged, wherein connecting plates are arranged on the base plates, threaded nails are arranged on the connecting plates, an aluminum support is fixedly connected to the bottoms of the base plates, a composite plate mechanism and an adjusting mechanism are arranged on the aluminum support, an aluminum frame is arranged on the adjusting mechanism, one side of the aluminum frame is fixedly connected with a damp-proof gypsum board, and the composite plate mechanism is provided with a cushioning mechanism. The water filtering wall body is made of an aluminum material, the overall mass of the wall body is light, the wall body is more convenient to move, meanwhile, the water filtering wall body can be spliced and assembled in a simple clamping mode, a large amount of time does not need to be consumed in the assembling process, installation operation can be conducted by common workers, the installation cost is greatly reduced, the installation efficiency is remarkably improved, and the construction period is greatly shortened.

Owner:重庆中昆新材料科技有限公司

Surface treatment method for improving performance of piezoelectric ceramic

ActiveCN104876642AImprove salt spray corrosion resistanceGood high and low temperature resistanceElectricityMonocalcium phosphate

The invention discloses a surface treatment method for improving the performance of piezoelectric ceramic. The method comprises the following steps: (1) providing a piezoelectric ceramic body; (2) configuring a Ca(OH)2 solution and a mixed solution of boric acid and monocalcium phosphate for later use; (3) soaking the piezoelectric ceramic body into the Ca(OH)2 solution to obtain a product A; (4) taking the product A out, and heating and drying the product A to obtain a product B; (5) soaking the product B into the mixed solution of boric acid and monocalcium phosphate to obtain a product C; and (6) taking the product C out, drying the product C at first, and then performing heat treatment to generate a boron phosphate calcium glass film on the surface of the piezoelectric ceramic to obtain a finished product. By adopting the technical scheme, the surface treatment method provided by the invention has the advantages that the salt-spray corrosion resistance, high-low temperature resistance and moisture resistant performance of the surface of the piezoelectric ceramic are improved, and the aging service life of the piezoelectric ceramic is obviously prolonged.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com