Butterfly valve without valve seat and soft sealing method thereof

A soft-seal, butterfly valve technology, applied in lift valves, valve devices, mechanical equipment, etc., can solve problems affecting valve reliability, dust accumulation, water accumulation, etc., to ensure smooth and sealing performance, increase service life, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

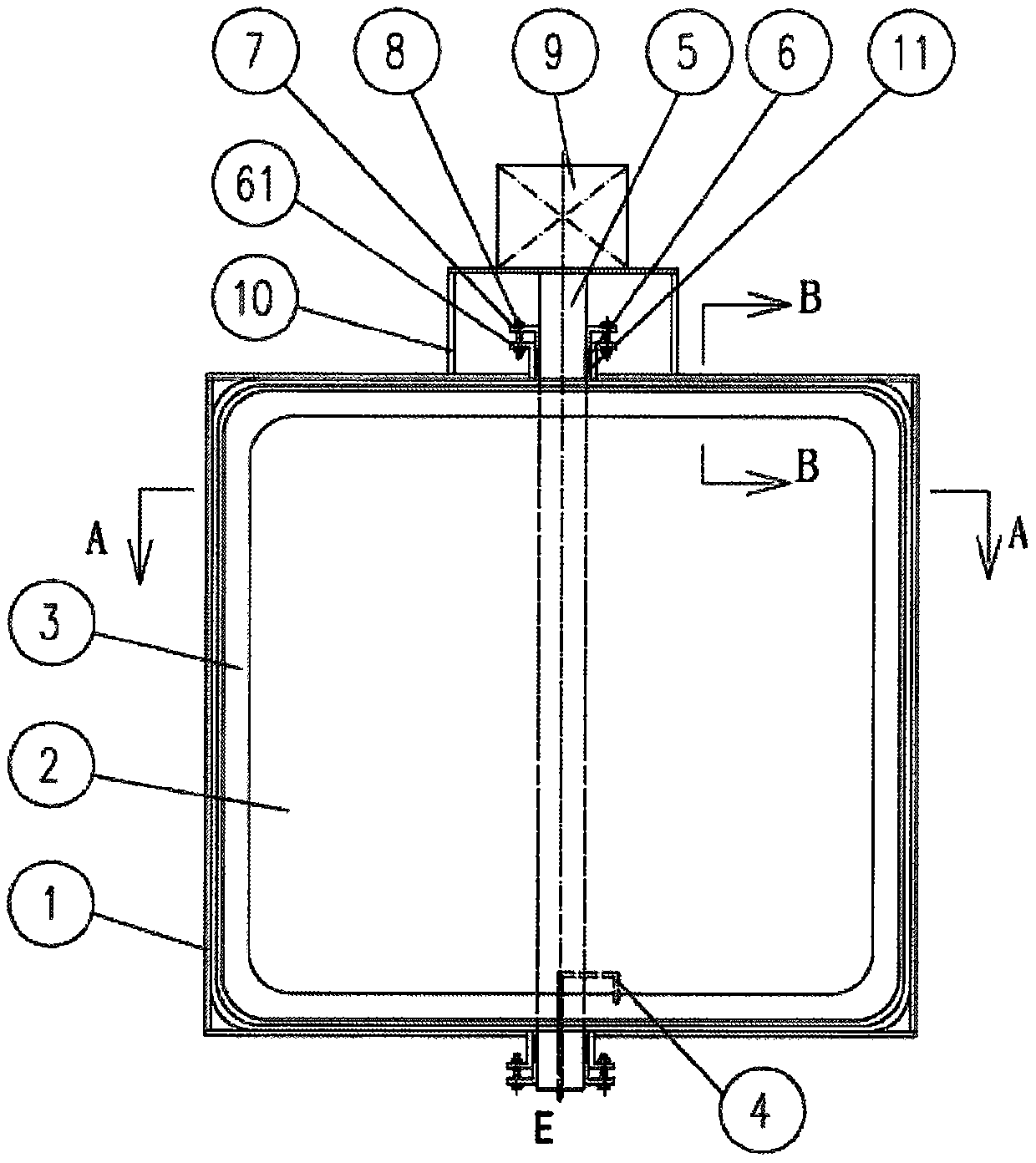

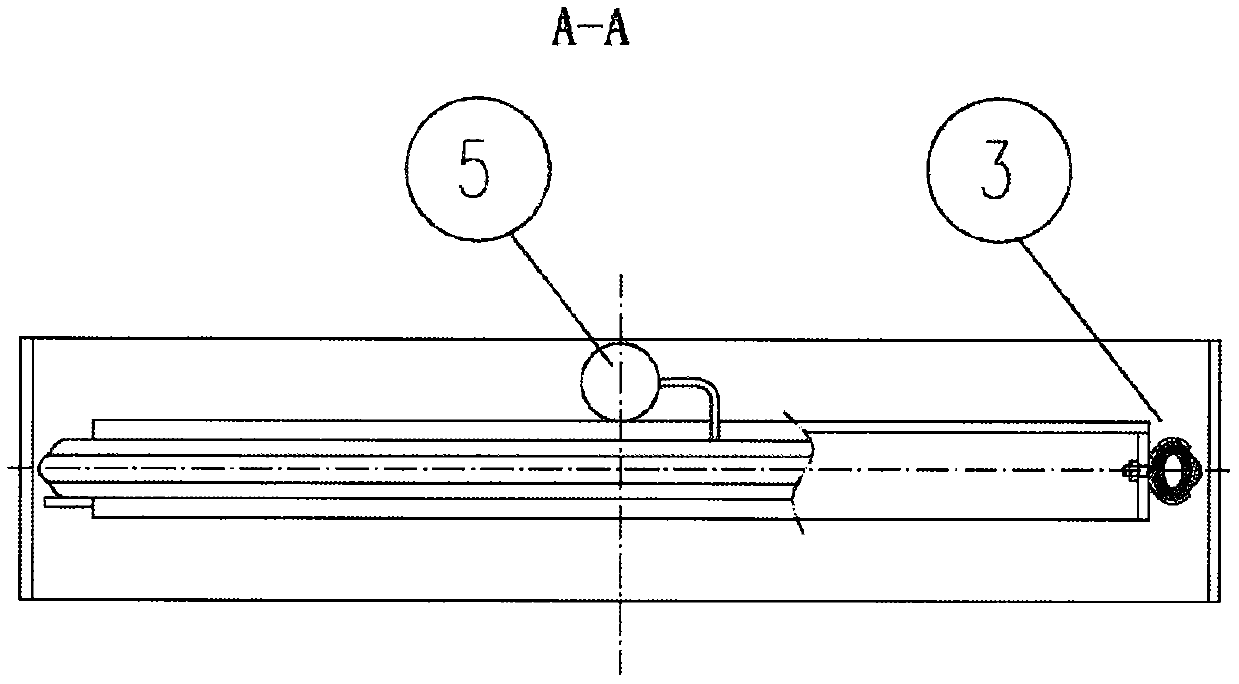

[0078] A butterfly valve, such as figure 1 and 2 As shown, it includes a valve body 1, a valve plate 2, a valve stem 5, two valve stem sleeves 6 with flanges 61, a flange gland 7 corresponding to the flanges 61, an actuator 9, and a support 10, The support 10 is located on the valve body 1 and is integrated with the valve body 1 to fix the actuator 9 . The valve body 1 is provided with two through holes symmetrical to the central axis of the valve body 1 along its radial direction, and the two valve stem sleeves 6 are respectively fixed on the two through holes of the valve body 1, and the valve stem 5 passes through Into two valve stem sleeves 6, the inner diameter of the valve stem sleeve 6 is larger than the inner diameter of the valve stem 5, and the inner diameter near the end of the valve body is relatively small, slightly larger than the shaft diameter of the valve stem 5, and forms with the valve stem 5 Sliding fit, the inner diameter of the other end of the valve st...

Embodiment 2

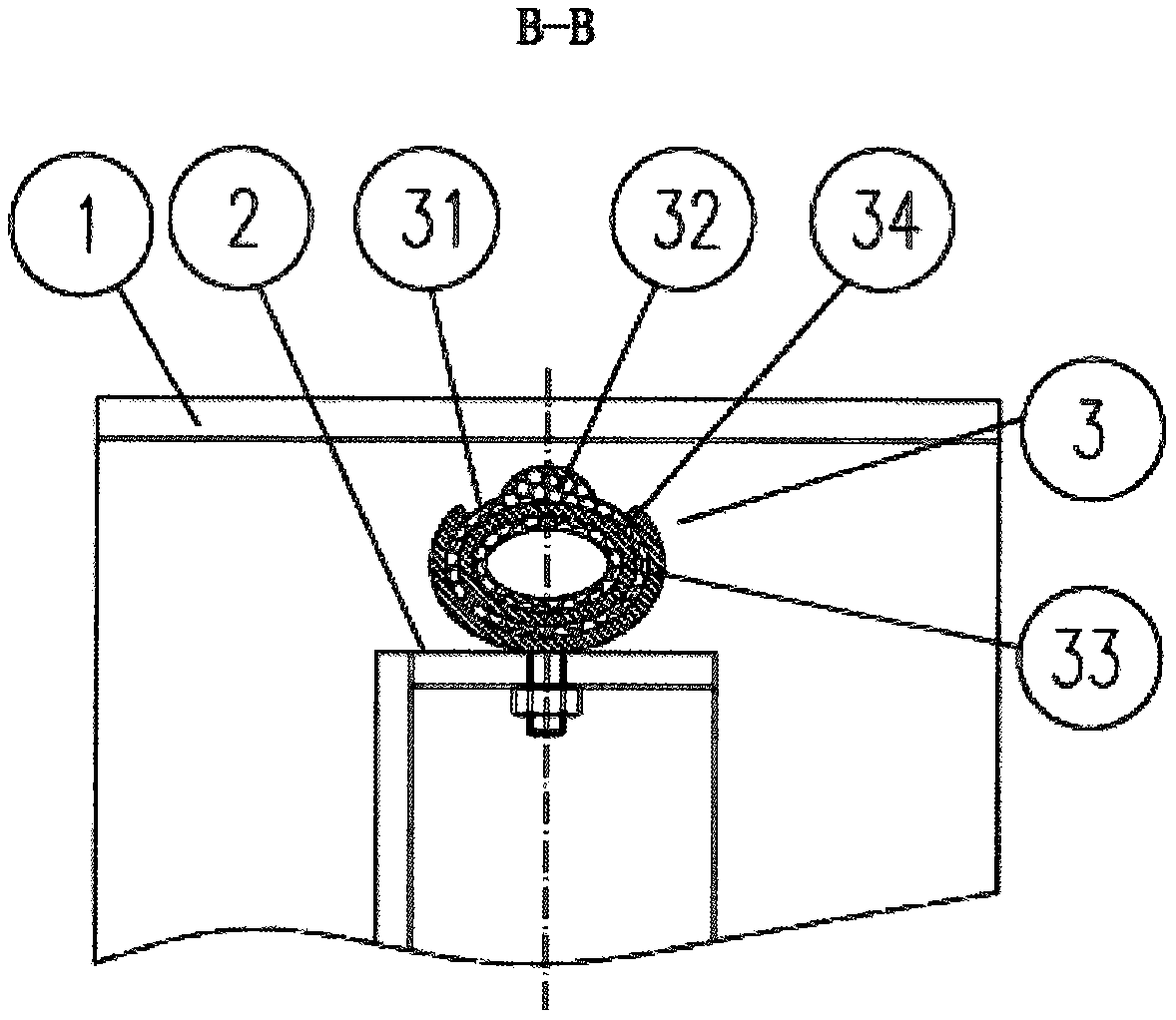

[0085] A kind of butterfly valve, on the basis of embodiment 1, its soft sealing ring 31 is a flexible pipe, and the cross section cut perpendicular to its axis is oval, as image 3 As shown, the minor axis of the elliptical cross-section intersects the radially outer surface of the valve plate at its position and is perpendicular to the tangent of the radially outer surface of the valve plate at the intersection point, that is, the elliptical cross-section The major axis of the valve body is basically parallel to the corresponding radial outer surface or inner surface of the valve plate or valve body where it is located. Compared with Embodiment 1, the soft sealing ring of this shape is filled with medium into its medium inlet and outlet E, so that the soft sealing ring is deformed and attached to the inner wall of the valve body 1, and the soft sealing ring is not even needed. Elastic expansion occurs, which effectively realizes the sealing of the valve. The smaller the exp...

Embodiment 3

[0087] A square butterfly valve, the soft sealing structure 3 on each radial side of the valve plate 2 also includes an elastic clip or buckle 33; the elastic clip or buckle 33 is a slotted metal tube sleeved on the soft sealing ring 31 is externally fixed on the radial surface of the valve plate 2, coaxial with the soft sealing ring 31, and its cross-sectional shape is consistent with the cross-sectional shape of the corresponding soft sealing ring 31; as image 3 shown.

[0088] The notch of the slotted metal pipe runs through from the beginning to the end along its axial direction, and when the valve is closed, the notch faces the radially inner surface or inner wall of the valve body 1 opposite to the valve plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com