Novel connecting structure for five-way joint center shaft bevel gear and bicycle rim

A connection structure, bicycle technology, applied to vehicle components, vehicle gearboxes, wheel transmissions, etc., can solve the problems of no clutch performance, increase the limited space of the original model, increase the size of the rear wheel opening, etc., to increase the aging life , Easy to operate and use in batches, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

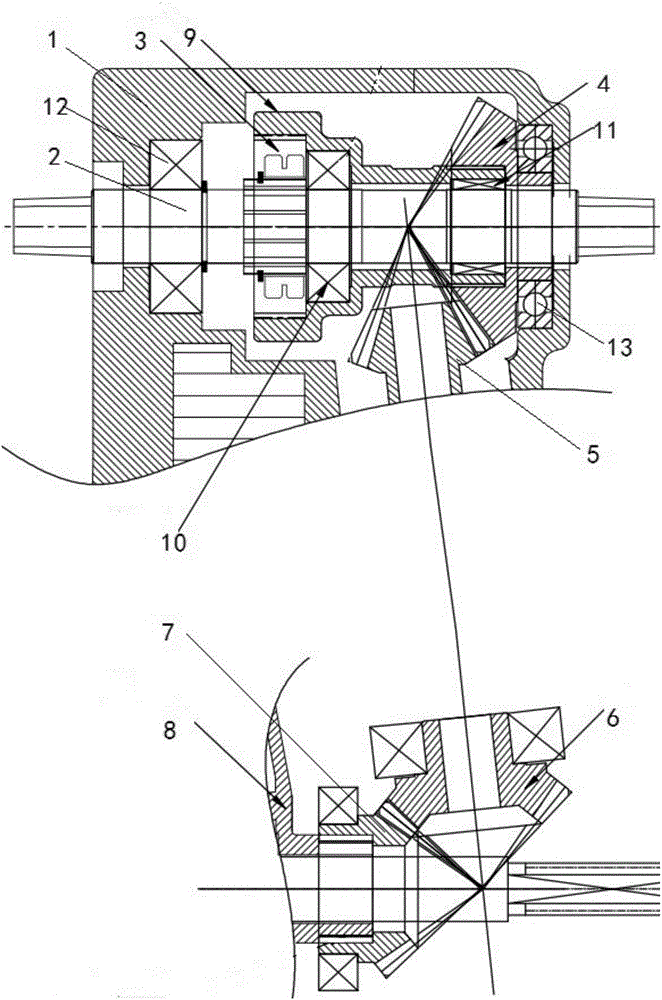

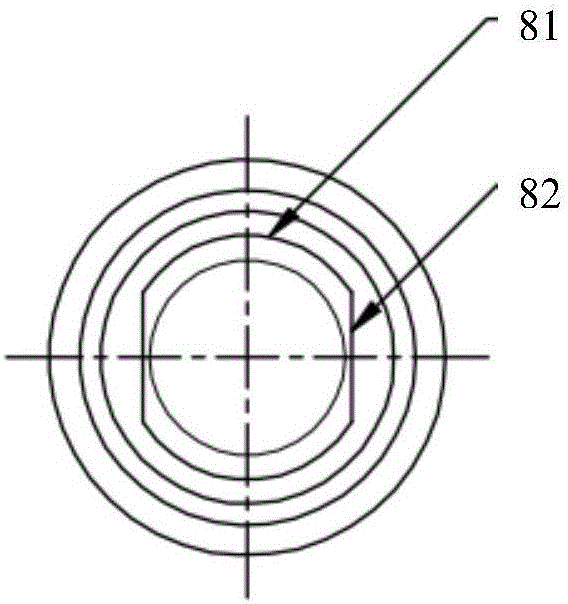

[0017] as attached figure 1 The connection structure of the new bottom bracket bevel gear and the bicycle rim shown includes the bicycle bottom bracket 1, the bottom bracket 2, the clutch 3, the bottom bracket bevel gear 4, the first transmission bevel gear 5, the second Transmission bevel gear 6, output bevel gear 7, bicycle rim 8 and connector 9, the bottom bracket axis 2 is rotationally connected to the bicycle bottom bracket 1, and the connector 9 and the bottom bracket axis 2 are Rotationally connected, the bottom bracket bevel gear 4 is fixed on the connector 9, the clutch 3 is arranged between the bottom bracket 2 and the connector 9; the bottom bracket bevel gear 4 is connected to the first A transmission bevel tooth 5 meshes, a second transmission bevel tooth 6 meshes with the output bevel tooth 7, the first transmission bevel tooth 5 and the second transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com