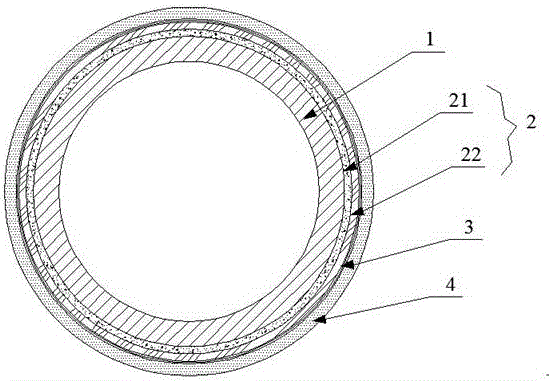

Insulated tubular busbar having composite insulation layer and in voltage class of 1kV and below and preparation method thereof

A technology of composite insulation and insulating tubes, applied in the direction of insulating cables, insulating conductors, conductors/cables, etc., can solve the problem of thermal expansion and cold contraction of insulating materials and conductor materials, cracks in the insulating layer, and the inability to realize direct extrusion of the bent pipe structure , bending pipe insulation layer stress concentration and other problems, to achieve the effect of reducing labor and labor intensity, excellent electrical performance and chemical stability, and small dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of cold-shrinkable-heat-shrinkable composite insulation tube

[0028] Composition of raw materials: cold-shrinkable inner insulating layer: 100 parts by weight of EPDM (Jihua brand: 4045); 0.3 parts by weight of Ciba's IRGANOX B215 antioxidant; 2 parts by weight of commercially available anti-aging agent RD. Heat-shrinkable outer insulating layer: polyethylene LDPE (1i2A of Yanshan Petrochemical) 80 parts by weight; thermoplastic elastomer EVA (French Atofina brand 2803) 20 parts by weight; Ciba IRGANOX B215 antioxidant 0.3 parts by weight.

[0029] Preparation of cold-shrinkable composite insulation tube:

[0030] 1) Masterbatch preparation of the cold-shrinkable inner insulation layer: cut the EPDM rubber sheet into long strips on a rubber cutting machine, break it into granules on a crusher, and then put the granulated rubber, anti-aging agent, and antioxidant in the Stir in the mixer at high speed for 3 minutes, and stop stirring when the temperatur...

Embodiment 2

[0044] (1) Preparation of cold-shrinkable-heat-shrinkable composite insulation tube

[0045] Composition of raw materials: cold-shrinkable inner insulating layer: 100 parts by weight of EPDM (Jihua brand: 4045); 0.3 parts by weight of IRGANOX B215 antioxidant from Ciba; 2 parts by weight of commercially available anti-aging agent RD. Heat-shrinkable outer insulating layer: polyethylene LDPE (1i2A of Yanshan Petrochemical) 80 parts by weight; thermoplastic elastomer EVA (French Atofina brand 2803) 20 parts by weight; Ciba IRGANOX B215 antioxidant 0.3 parts by weight.

[0046] Preparation of cold-shrinkable composite insulation tube:

[0047] 1) Masterbatch preparation of the cold-shrinkable inner insulation layer: cut the EPDM rubber sheet into long strips on a rubber cutting machine, break it into granules on a crusher, and then put the granulated rubber, anti-aging agent, and antioxidant in the Stir in the mixer at high speed for 3 minutes, and stop stirring when the tempera...

Embodiment 3

[0061] (1) Preparation of cold-shrinkable-heat-shrinkable composite insulation tube

[0062] Composition of raw materials: cold-shrinkable inner insulating layer: 100 parts by weight of EPDM (Jihua brand: 4045); 0.3 parts by weight of IRGANOX B215 antioxidant from Ciba; 2 parts by weight of commercially available anti-aging agent RD. Heat-shrinkable outer insulating layer: polyethylene LDPE (1i2A of Yanshan Petrochemical) 80 parts by weight; thermoplastic elastomer EVA (French Atofina brand 2803) 20 parts by weight; Ciba IRGANOX B215 antioxidant 0.3 parts by weight.

[0063] Preparation of cold-shrinkable composite insulation tube:

[0064] 1) Masterbatch preparation of the cold-shrinkable inner insulation layer: cut the EPDM rubber sheet into long strips on a rubber cutting machine, break it into granules on a crusher, and then put the granulated rubber, anti-aging agent, and antioxidant in the Stir in the mixer at high speed for 3 minutes, and stop stirring when the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com