Die for producing water-base polyurethane condom

A technology for water-based polyurethane and condoms, which is applied in the field of molds for the production of polyurethane impregnated products and molds for the production of water-based polyurethane condoms. The effect of weather aging resistance life and good mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

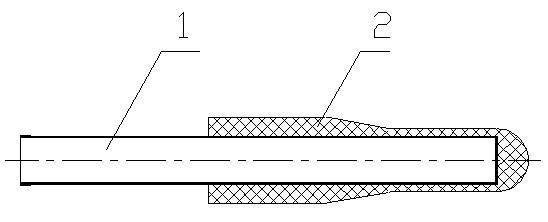

[0037] A kind of water-based polyurethane condom production mold, such as Figure 1-3 As shown, it is made of a pure polytetrafluoroethylene layer 2 wrapped on the outer wall of the stainless steel tube 1 used for female condom production, and made into a hollow one with a bell mouth diameter of 50 mm and a bell mouth diameter of 70 mm. A mold for the production of female condoms. One end of the stainless steel pipe 1 for the production of female condoms is placed outside the pure polytetrafluoroethylene layer 2. This mold is used to produce a horn with a diameter of 50 mm and a diameter of the bell mouth of 70 mm. The female condom with the mouth adopts the direct immersion drying process with film. The mold has repeatedly withstood the high and low temperature changes from 0 to 150 degrees during the film drying process. It has good stability and is easy to curl when the condom is processed. sticky mold.

Embodiment 2

[0039] A kind of water-based polyurethane condom production mold, such as Figure 4-6 As shown, it is a polytetrafluoroethylene layer 4 filled with glass fiber that is fully wrapped on the outer wall of the stainless steel tube 3 for male condom production to make a hollow mold with a diameter of 35 mm for male condom production. Glass fiber weight percentage is 5% in the polytetrafluoroethylene material layer 4 of glass fiber, adopts this mold production diameter to be the water-based polyurethane male condom of 35 millimeters, adopts direct immersion method band film drying process, and this mold is dried in band film During the process, it has repeatedly withstood high and low temperature changes from 0 to 150 degrees. The water-based polyurethane condom is easy to curl when processing, does not stick to the mold, and the bending strength and hardness of the mold are significantly improved.

Embodiment 3

[0041] A kind of water-based polyurethane condom production mold, such as Figure 7As shown, it is a polytetrafluoroethylene layer 5 filled with iron powder that is fully wrapped on the outer wall of the stainless steel tube 3 for male condom production to make a hollow mold with a diameter of 33 mm for male condom production. The percentage by weight of iron powder in the polytetrafluoroethylene material layer 5 of iron powder is 2%, adopting this mold to produce diameter is the water-based polyurethane male condom of 33 millimeters, adopts direct immersion method band film drying process, this mold is dried in band film During the process, it has repeatedly withstood high and low temperature changes from 0 to 150 degrees. The water-based polyurethane condom is easy to curl when processing, and does not stick to the mold. By adding iron powder to the PTFE material, the bending strength and hardness of the mold can be improved. Significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com