Electrochemical sensor of hydrogen in extreme environment

A hydrogen sensor and extreme environment technology, applied in the field of sensors, can solve the problem that it can only work under lower temperature and pressure, and achieve the effect of easy promotion, small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

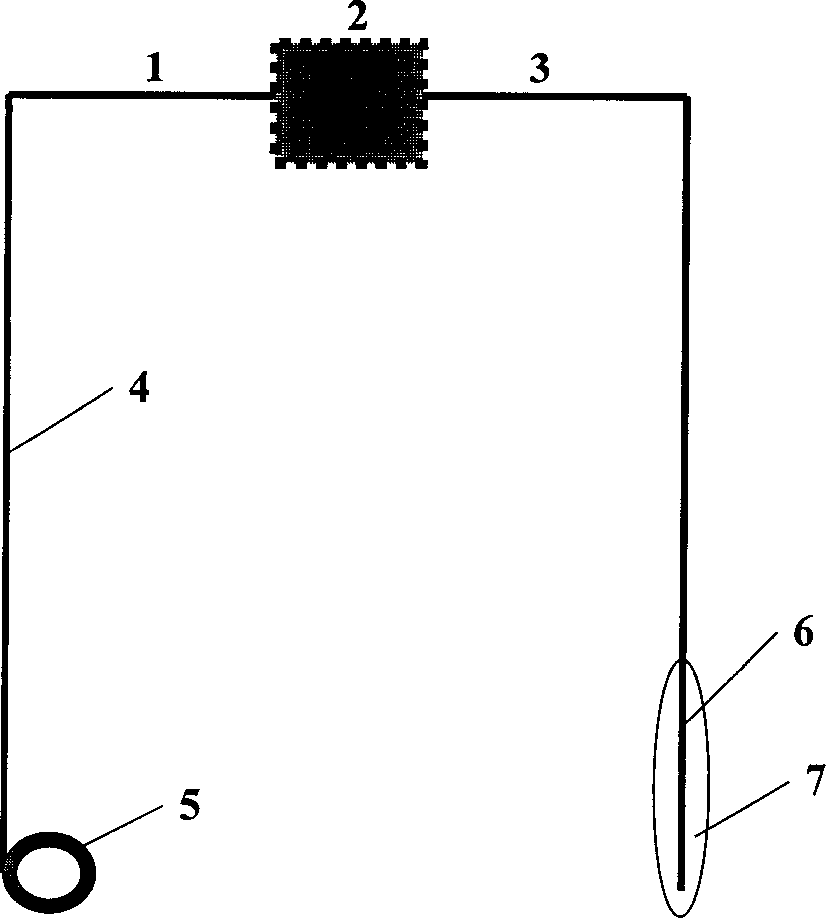

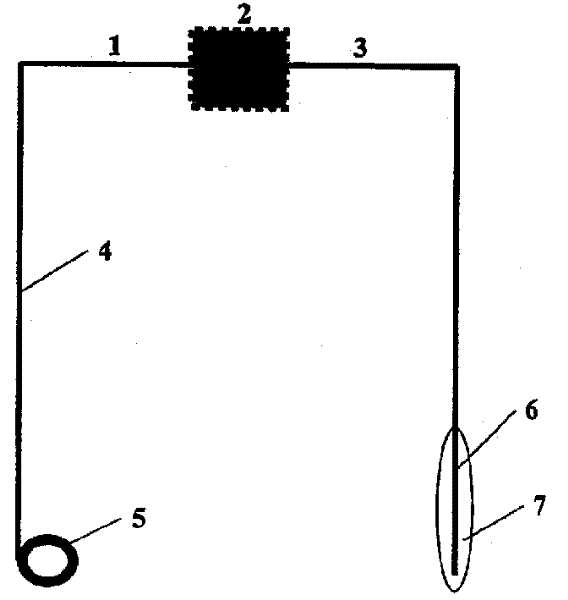

Image

Examples

preparation example Construction

[0009] The preparation method steps of said metal hydrogen electrode are as follows:

[0010] 1) Take a metal sheet with a thickness of 0.1-0.4 mm, cut it into strips with a length of 5-12 mm and a width of 3-8 mm, and bend it into a metal sheet with the long side as the perimeter. ring, on one side of which a metal wire is welded;

[0011] 2) Immerse the metal ring and the welding part in acetone or trichlorethylene and boil to remove organic impurities, then immerse in a hydrochloric acid solution with a concentration of 3-6M, ultrasonically clean for more than 1 minute, take it out, wash it with distilled water, and air dry;

[0012] 3) Dissolving the soluble polyimide in an organic solvent to form a solution with a concentration of 5-50%, coating the solution on the metal wire, and air-drying.

[0013] The material of the metal ring is one of platinum, palladium, ruthenium, iridium and gold; the material of the metal wire is one of platinum, gold, silver and copper;

[0...

example 1

[0034] Example 1: Making a hydrogen electrode with platinum

[0035]1) Take a platinum metal sheet with a thickness of 0.2 mm, cut it into strips with a length of 8.5 mm and a width of 4.5 mm, take the long side of the platinum sheet as the perimeter, bend it into a ring, and weld it on one side Put the gold wire; then boil it in acetone to remove organic impurities, then immerse it in a hydrochloric acid solution with a concentration of 6M, ultrasonically clean it for more than 1 minute, take it out, wash it with distilled water, and air dry;

[0036] 2) Immerse the platinum ring and the welding part in acetone and boil to remove organic impurities, then immerse in a hydrochloric acid solution with a concentration of 6M, ultrasonically clean for more than 1 minute, take it out, wash it with distilled water, and air dry;

[0037] 3) Dissolving the soluble polyimide in an organic solvent to prepare a solution with a concentration of 30%, coating the solution on the gold wire, a...

example 2

[0038] Example 2: Making a hydrogen electrode with palladium

[0039] 1) Take a palladium metal sheet with a thickness of 0.2 mm, cut it into a strip with a length of 8.5 mm and a width of 4.5 mm, take the long side of the palladium sheet as the perimeter, bend it into a ring, and weld it on one side Platinum wire;

[0040] 2) Immerse the palladium ring and the welding part in trichlorethylene and boil to remove organic impurities, then immerse in a 3M hydrochloric acid solution, ultrasonically clean for more than 1 minute, take it out, wash it with distilled water, and air dry;

[0041] 3) Dissolving the soluble polyimide in an organic solvent to prepare a solution with a concentration of 30%, coating the solution on a platinum wire, and air-drying. It can be repeated several times until an insulating protective layer of sufficient thickness is formed, and the electrode is thus completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com