Patents

Literature

44results about How to "Improve salt spray corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel chemical nickel-plating method for magnesium alloy

InactiveCN102586763AImprove salt spray corrosion resistanceReduce electrode potential differenceLiquid/solution decomposition chemical coatingSalt spray testAcid washing

The invention relates to a novel chemical nickel-plating method for magnesium alloy, which comprises alkaline washing, acid washing, activation, conversion, nickel plating and other processes, solves the technical problems of easy blistering, poor bonding force and poor corrosion resistance in the chemical nickel-plating process of the magnesium alloy and has the advantages of being simple in process, low in cost and the like. A nickel-phosphorus alloy coating prepared by means of the method is smooth, flat, even, compact and strong in bonding force with basic materials, and meets the technical requirements of a military standard GJB150A-2009 thermal shock test (220 DEG C) and a salt spray test (96 hours).

Owner:CHENGDU QINGYUAN MAGNESIUM SCI & TECH

Preparation method for aluminum alloy surface chromium-free corrosion-resistant chemical conversion membrane formation solution and membrane layer

PendingCN109402620ALow costIncrease costMetallic material coating processesAlloy substrateBond Force

The invention relates to an aluminum alloy surface corrosion resistance treatment and in particular discloses a preparation method for an aluminum alloy surface chromium-free corrosion-resistant chemical conversion membrane formation solution and a membrane layer. The membrane formation solution is a mixed solution with a main salt, a buffer agent, a membrane formation promoter, a pH value adjuster and water, and the pH value of the membrane formation solution is 2-5. The chemical conversion membrane formation preparation method comprises four steps of oil removal, alkali washing, acid washingactivation and membrane formation, the whole treatment process is free of components such as chromium or chromate which can do harm to the environment, the membrane formation process is simple, the membrane formation solution is low in constitution component cost, the obtained chemical conversion membrane is uniform and dense and excellent in corrosion resistance, and the bonding force of an organic coating and an aluminum alloy substrate can be remarkably improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

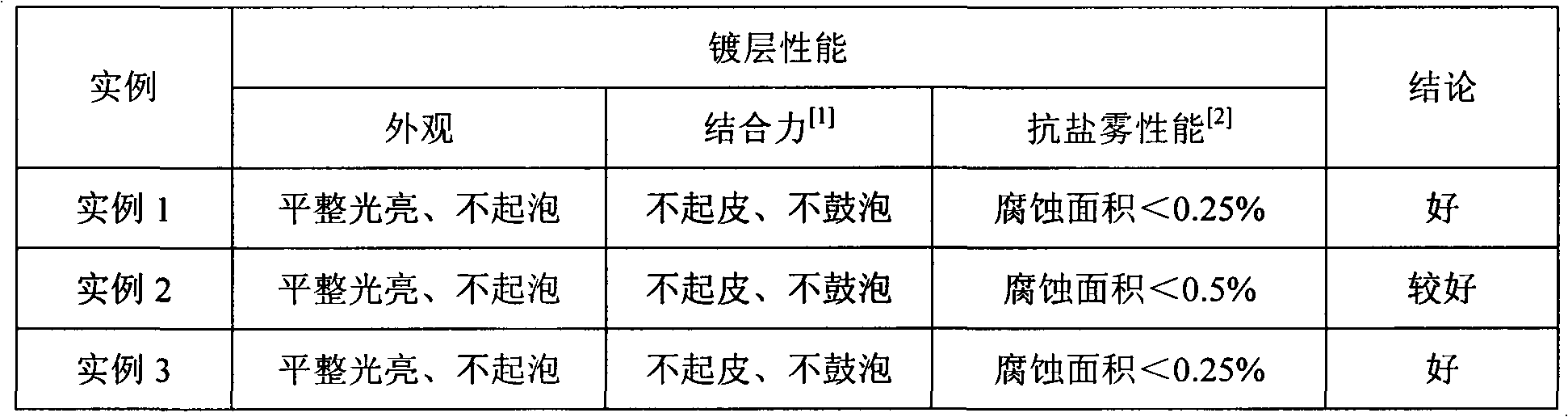

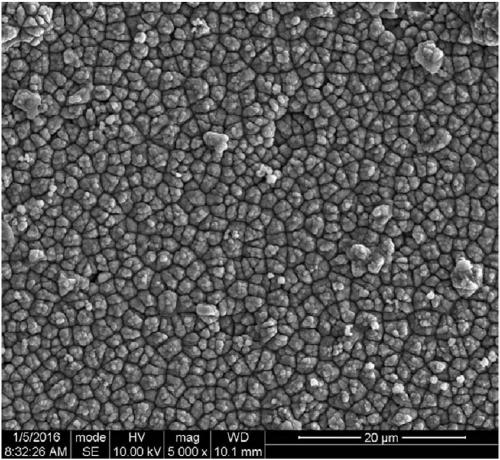

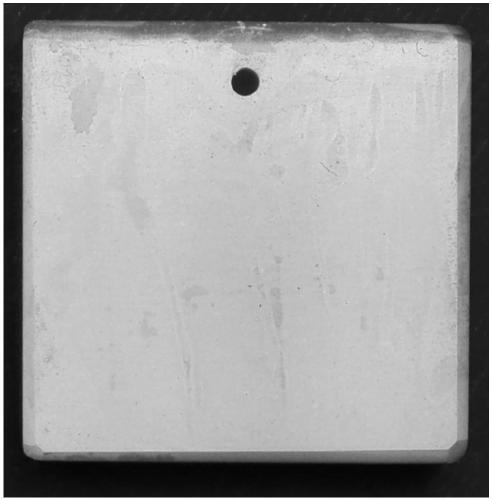

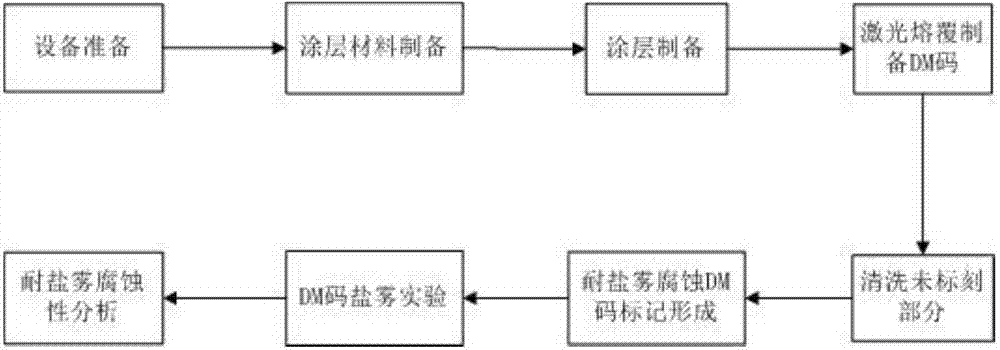

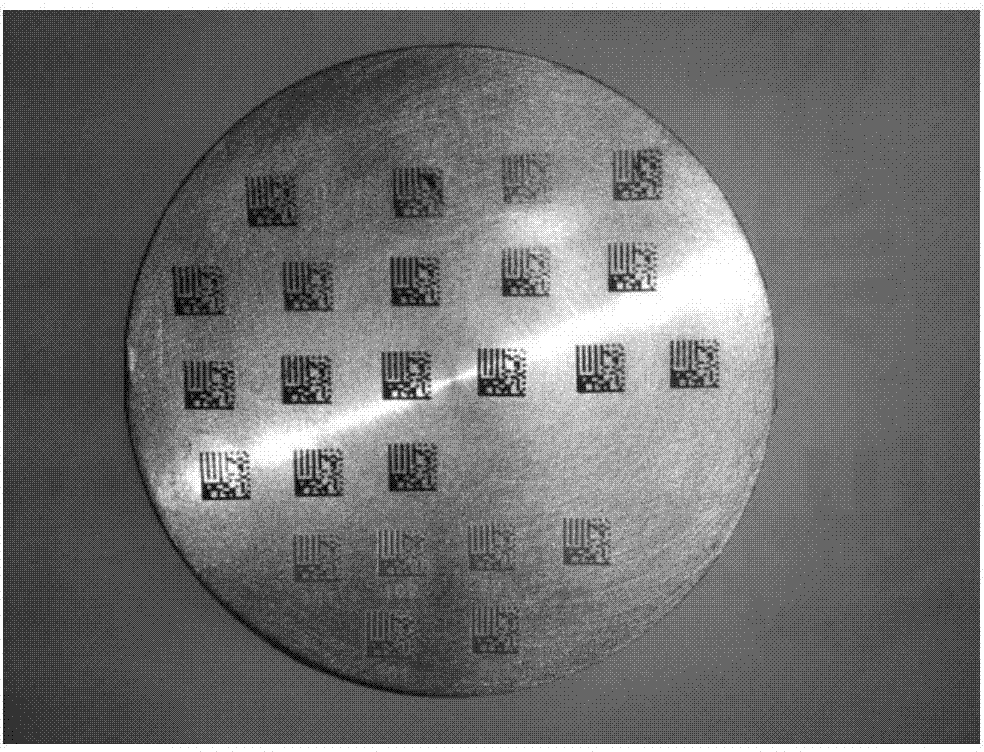

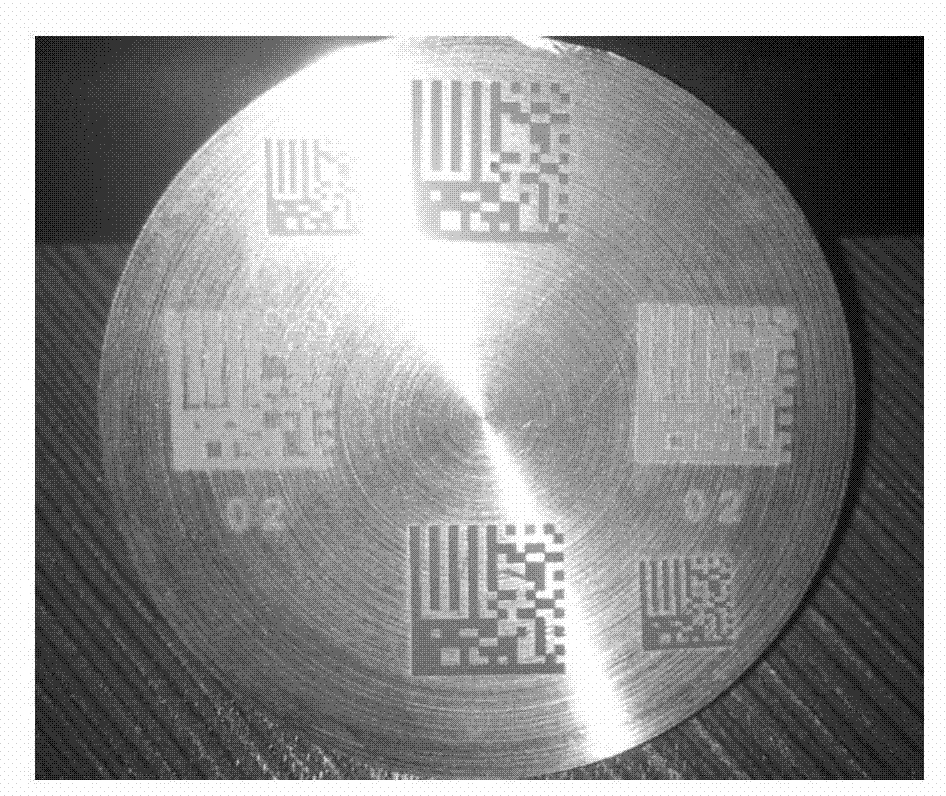

Aluminum alloy corrosion resistance two-dimensional code marking method based on laser cladding

ActiveCN104846368AImproved salt spray corrosion resistanceImprove salt spray corrosion resistanceMetallic material coating processesLacquerAlloy substrate

The invention provides an aluminum alloy corrosion resistance two-dimensional code marking method based on laser cladding. According to the method, a preset powder method is adopted for uniformly coating a layer of coating material on an aluminum alloy substrate; the coating material is formed by mixing nickel-based alloy powder, graphite powder, absolute ethyl alcohol and lacquer varnish; DM (digital matrix) codes are marked on the surface of the coating layer through laser so that the coating layer and a thin layer of the surface of the substrate are simultaneously melted, and a surface coating which has ultra-low dilution degree and forms metallurgical bonding with the substrate is formed after fast solidification; then, an ultrasonic cleaner is used for cleaning away unmarked parts, so that a DM code mark realizing salt spray corrosion resistance is formed. The salt spray corrosion resistance performance of the generated DM code mark is greatly improved, and in addition, the influence on part substrates outside the DM code mark region is smaller. Compared with other methods for improving the corrosion resistance of the DM code, the aluminum alloy corrosion resistance two-dimensional code marking method has the advantage that the efficiency is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

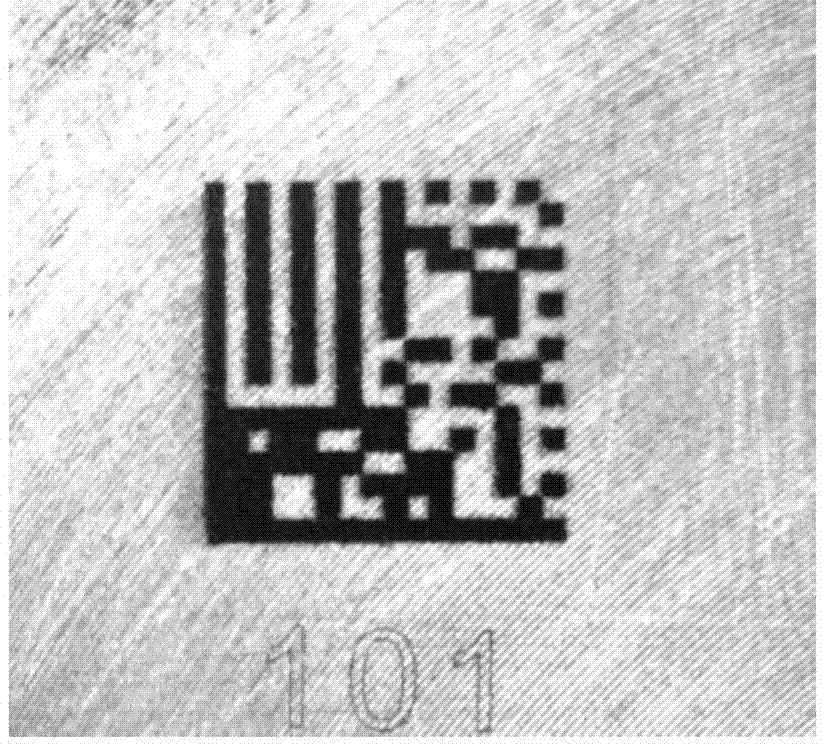

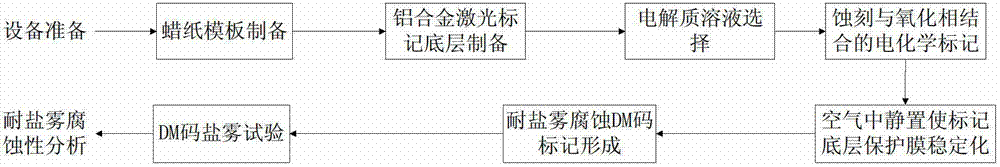

Laser marking method for increasing salt spray corrosion resistance of two-dimension codes on surface of aluminum alloy

InactiveCN102776541AStrong resistance to salt spray corrosionStable structureAnodisationWaxElectrochemistry

The invention provides a laser marking method for increasing salt spray corrosion resistance of two-dimension codes on a surface of an aluminum alloy. A DM code bottom layer is formed by directly marking with laser on an aluminum plate substrate; a square pattern is made on wax paper by using a thermo-sensitive method; the square pattern is larger than specification of existing DM codes on the surface of an aluminum plate; electrochemical etching is carried out in a DM code area of the aluminum plate by using an electrochemical etching method with the wax paper as a template to form a layer of oxidation film having protection function, so that a DM code mark with salt spray corrosion resistance is formed. Compared with the DM code mark directly marked on the surface of the aluminum alloy with laser, salt spray corrosion resistance of the DM code mark generated by the method can be increased greatly, and the oxidation film in a marking area is controllable; the influence of the mark for part matrix out of the marking area is poor; the operation is simple; and the efficiency is higher.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

InactiveCN109762446AIncrease the conductive pathIncrease profitAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne epoxy graphene zinc anticorrosive coating. The waterborne epoxy graphene zinc anticorrosive coating comprises a first component and a second component, wherein thefirst component is prepared from the following components in parts by weight: 5-10 parts of a waterborne epoxy resin curing agent, 0.5-1 part of a dispersant, 1-3 parts of an anti-settling agent, 1-3parts of a coalescing agent, 10-15 parts of body pigment, 42-65 parts of zinc powder and 4.5-5 parts of graphene dispersion slurry. The second component is prepared from the following components in parts by weight: 30-40 parts of aqueous epoxy emulsion, 1-2 parts of an anti-flash rust agent, 5-15 parts of water and 0.2-0.8 part of a defoaming agent. The waterborne epoxy graphene zinc anticorrosive coating has high utilization rate of zinc powder and is easy to prepare, and the formed coating has excellent comprehensive properties, such as good compactness, excellent cathodic protection performance and shielding performance, anticorrosive performance is remarkably improved, and the waterborne epoxy graphene zinc anticorrosive coating has wide application prospects in the field of marine equipment anticorrosion.

Owner:宁波中科银亿新材料有限公司 +1

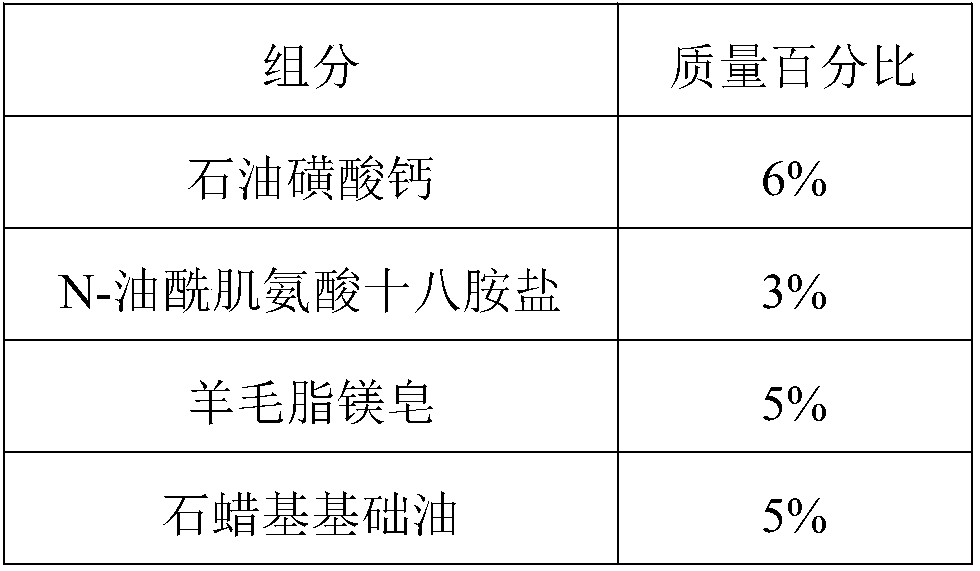

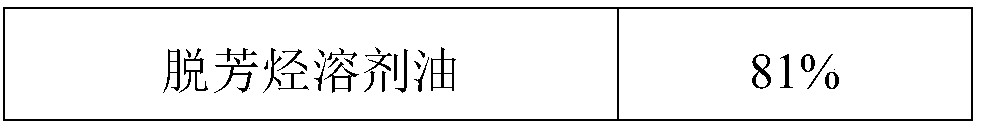

Environmentally-friendly antirust oil with synergistic effects

ActiveCN108517246AImprove salt spray corrosion resistanceShorten drying timeLubricant compositionSulfonateLanolin

The invention relates to an environmentally-friendly antirust oil with synergistic effects. The antirust oil comprises, by weight, 0.5-30% of barium-free sulfonate, 0.05-15% of an amine salt, 0.5-20%of a lanolin soap and 30-95% of base oil. The environmentally-friendly antirust oil has the following advantages: an oil-soluble antirust agent free from bismuth, lead and other heavy metals, so the antirust oil is environmentally friendly; and the antirust agent is a composition of the barium-free sulfonate, the amine salt and the lanolin soap, so the salt spray corrosion resistance of the antirust oil is effectively improved.

Owner:NTIC (SHANGHAI) CO LTD

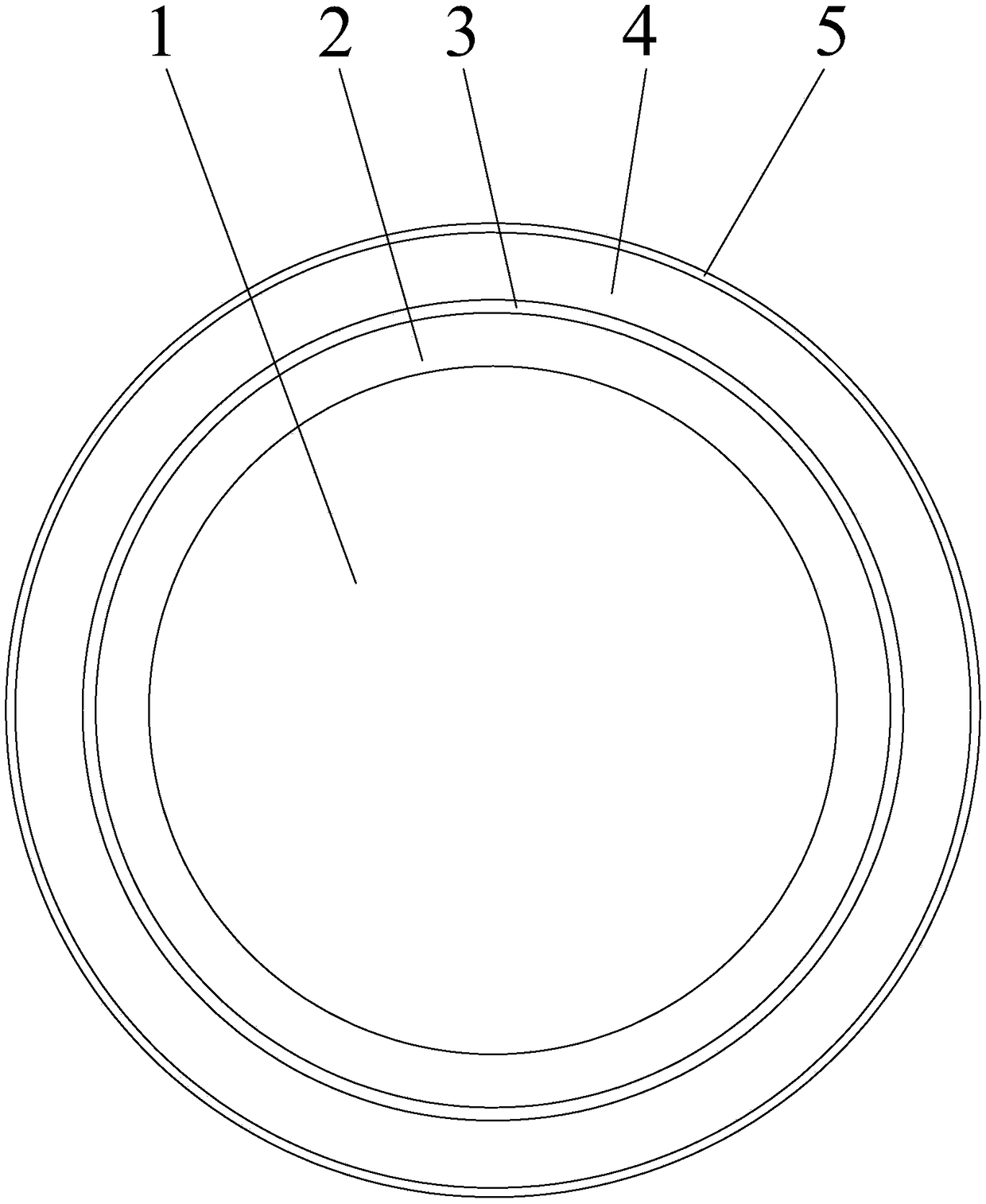

Salt mist-resisting alloy wire and manufacturing process thereof

InactiveCN108707939AReduce thicknessImprove salt spray corrosion resistanceTinningElectrical conductor

The invention discloses a salt mist-resisting alloy wire and a manufacturing process thereof. The salt mist-resisting alloy wire comprises a steel wire conductor, the outer side of the steel wire conductor is wrapped by a copper plated layer, the outer side of the copper plated layer is wrapped by a nickel plated layer, the outer side of the nickel plated layer is wrapped by a tin plated layer, the thickness size of the tin plated layer is larger than that of the nickel-plated layer, and the outer side of the tin plated layer is wrapped by a polishing film. The manufacturing process specifically comprises the first step of material selecting, the second step of quenching and tempering, the third step of electroplating of the copper plated layer, the fourth step of electroplating of nickelplated layer, the fifth step of electroplating of tin plated layer, and the sixth step of polishing and passivation. By optimizing the production process, clad layers are more uniform and smooth; polishing passivation is adopted, and a polishing film is formed; and under the situation of improving the salt mist corrosion resisting performance, the thickness of the tin plating layer can be appropriately reduced, and therefore the production cost is reduced.

Owner:JIANGYIN SIX CIRQUE ALLOY WIRE CO LTD

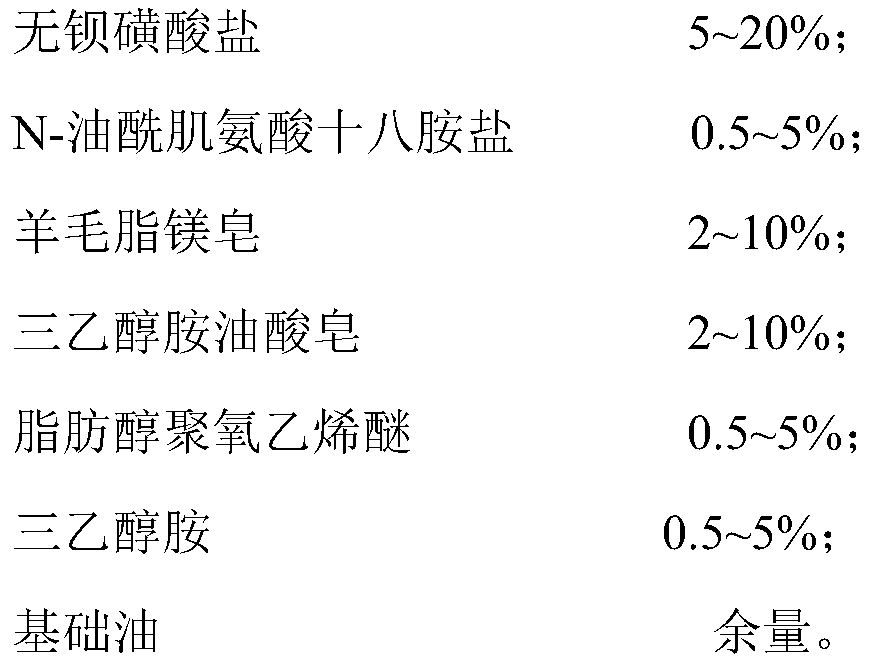

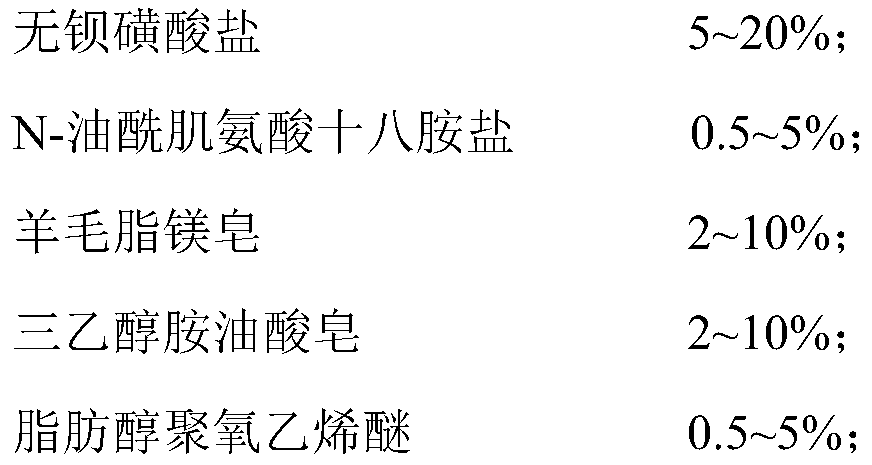

Environment-friendly emulsified anti-rust oil

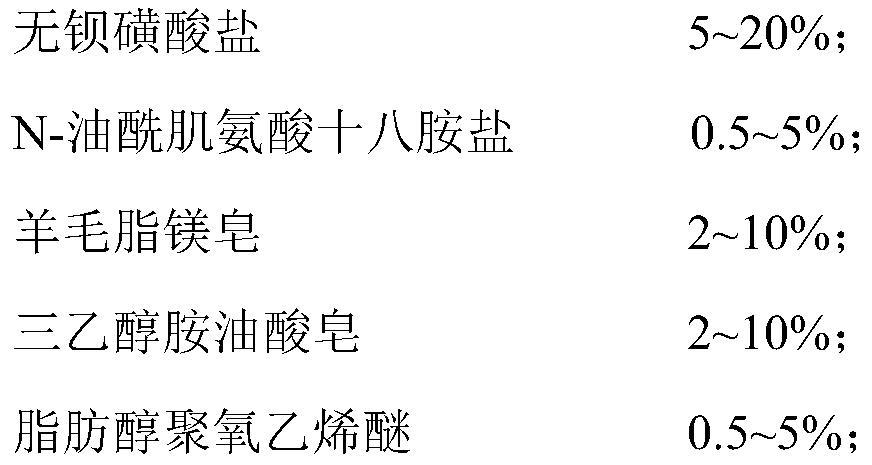

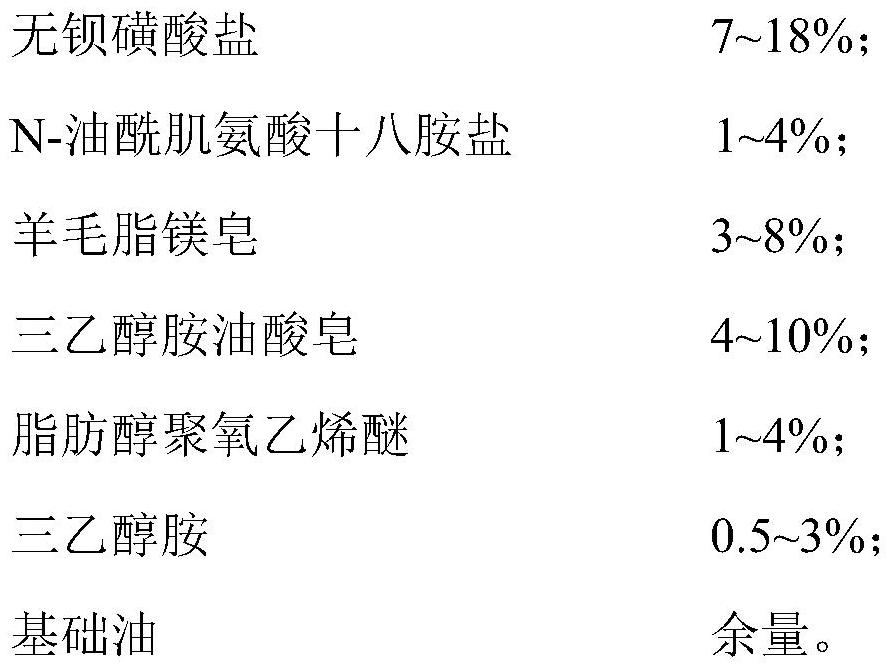

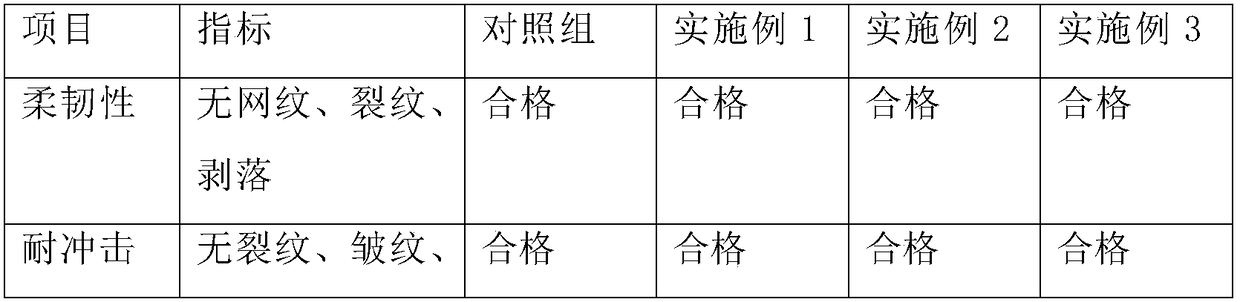

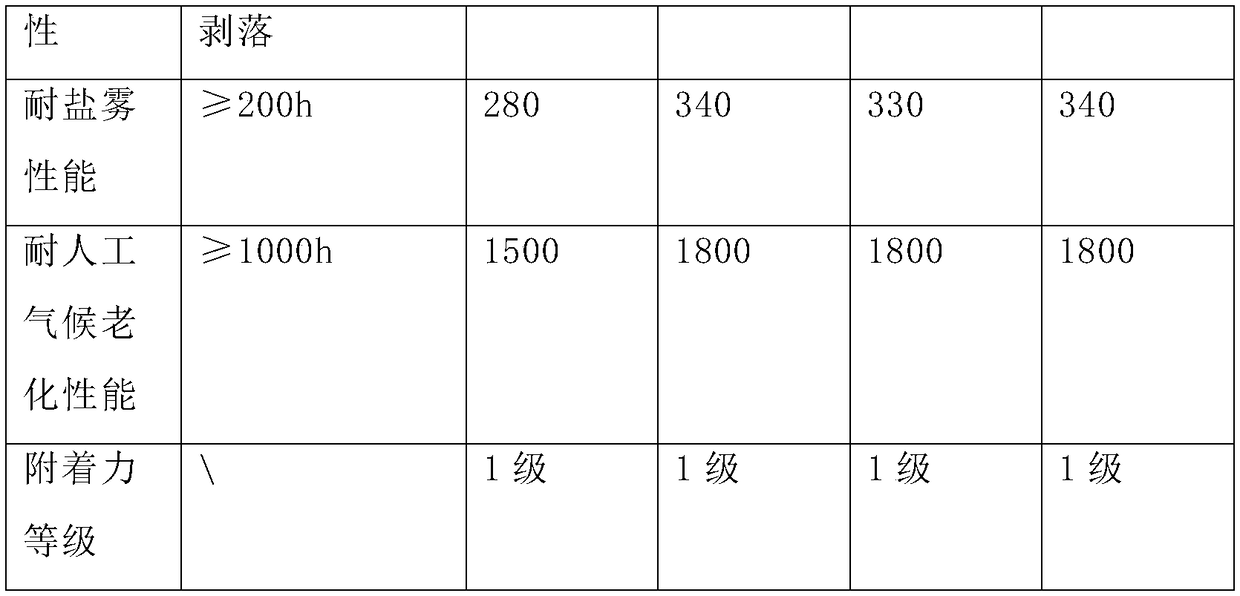

ActiveCN110591796AImprove rust resistanceImprove salt spray corrosion resistanceLubricant compositionLanolinFatty alcohol

The invention discloses environment-friendly emulsified anti-rust oil. The environment-friendly emulsified anti-rust oil is prepared from the following components in percentage by mass: 5-20% of barium-free sulfonate, 0.5-5% of N-octadecylamine oleoylsarcosinate, 2-10% of magnesium lanolin soap, 2-10% of triethanolamine oleate soap, 0.5-5% of fatty alcohol polyoxyethylene ether, 0.5-5% of triethanolamine, and the balance of base oil. According to the provided environment-friendly emulsified anti-rust oil, oil soluble anti-rust agents without heavy metals such as barium and lead are adopted, and are environment-friendly; the oil soluble anti-rust agents such as the barium-free sulfonate, the N-octadecylamine oleoylsarcosinate and the magnesium lanolin soap are compounded with the triethanolamine oleate soap, the fatty alcohol polyoxyethylene ether, the triethanolamine and the base oil, the anti-rust performance, especially the salt-spray corrosion resistance of the emuldified anti-rustoil can be effectively improved.

Owner:NTIC (SHANGHAI) CO LTD

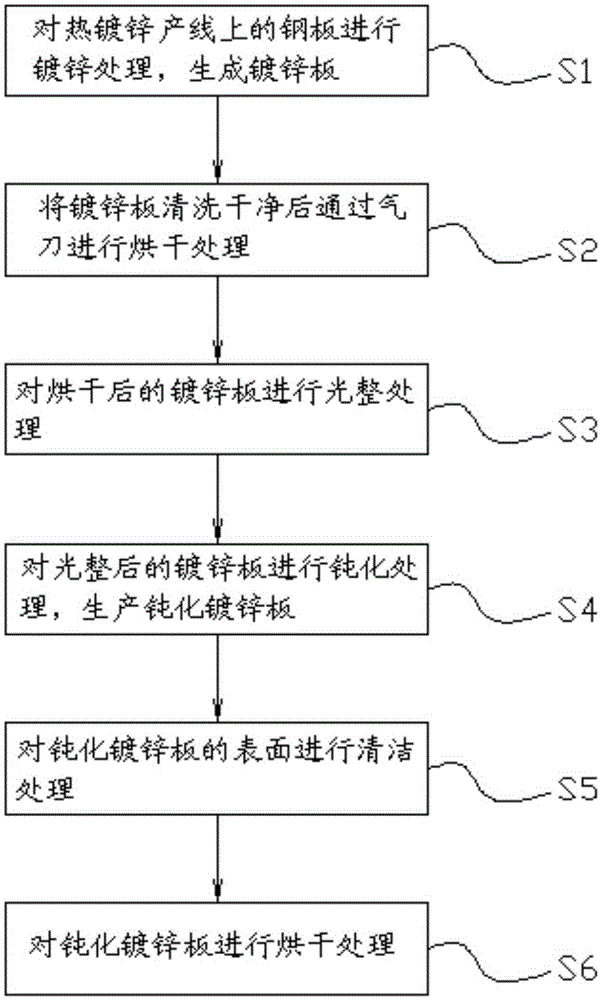

Control method of surface cracks of passivated membrane of chromium-free passivated galvanized plate

InactiveCN105296998AImprove performancePrevent oxidationHot-dipping/immersion processesChromium freeProduction line

The invention relates to a control method of surface cracks of a passivated membrane of a chromium-free passivated galvanized plate. The method includes the steps that a steel plate on a hot galvanizing production line is subjected to galvanizing treatment, and the galvanized plate is generated; after being washed clean, the galvanized plate is dried through an air knife; the dried galvanized plate is subjected to finishing; the finished galvanized plate is passivated, and the passivated galvanized plate is generated; the surface of the passivated galvanized plate is cleaned; the passivated galvanized plate is dried. The control method effectively avoids the surface cracks of the chromium-free passivated galvanized plate, and the salt-spray corrosion resistance of the chromium-free passivated galvanized plate is improved.

Owner:SHOUGANG CORPORATION

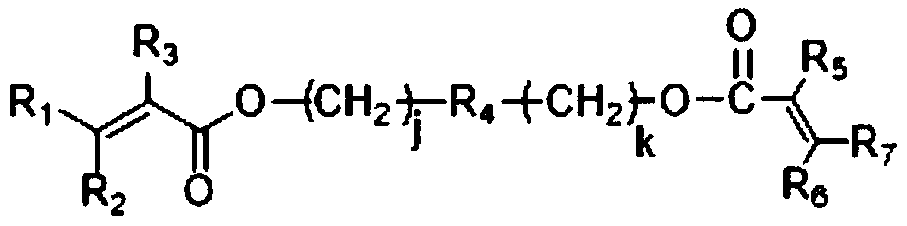

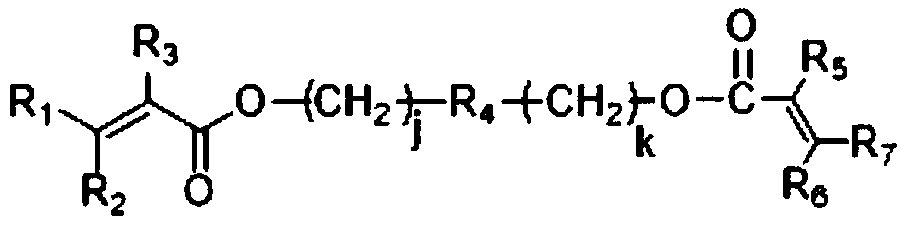

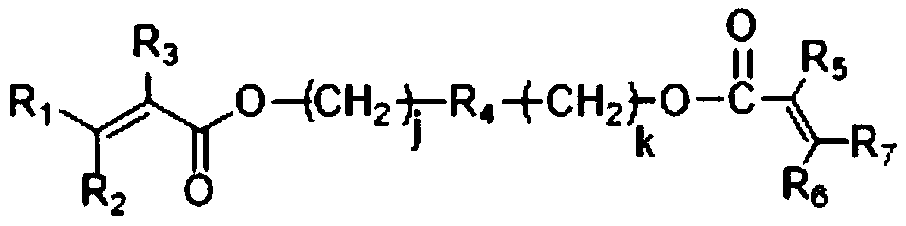

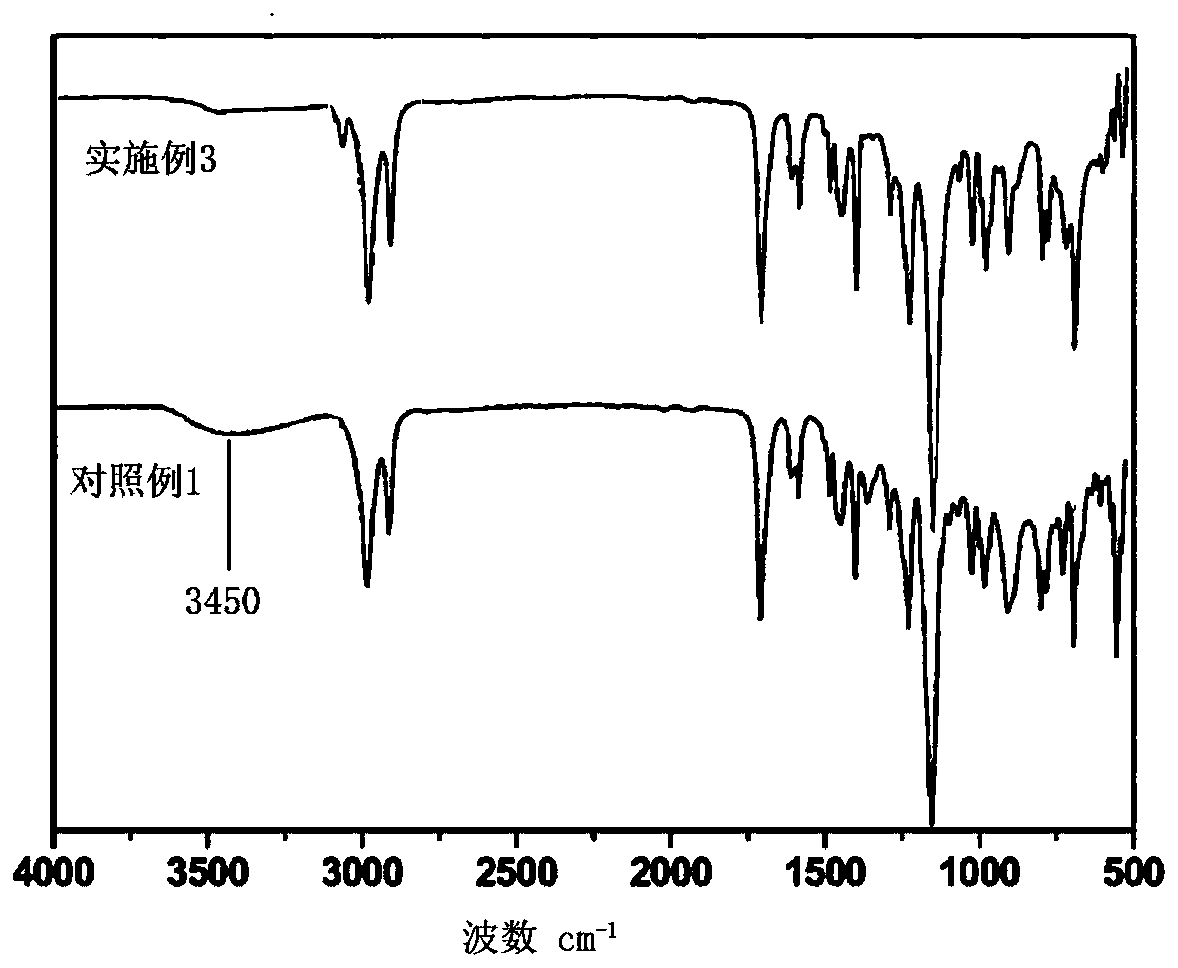

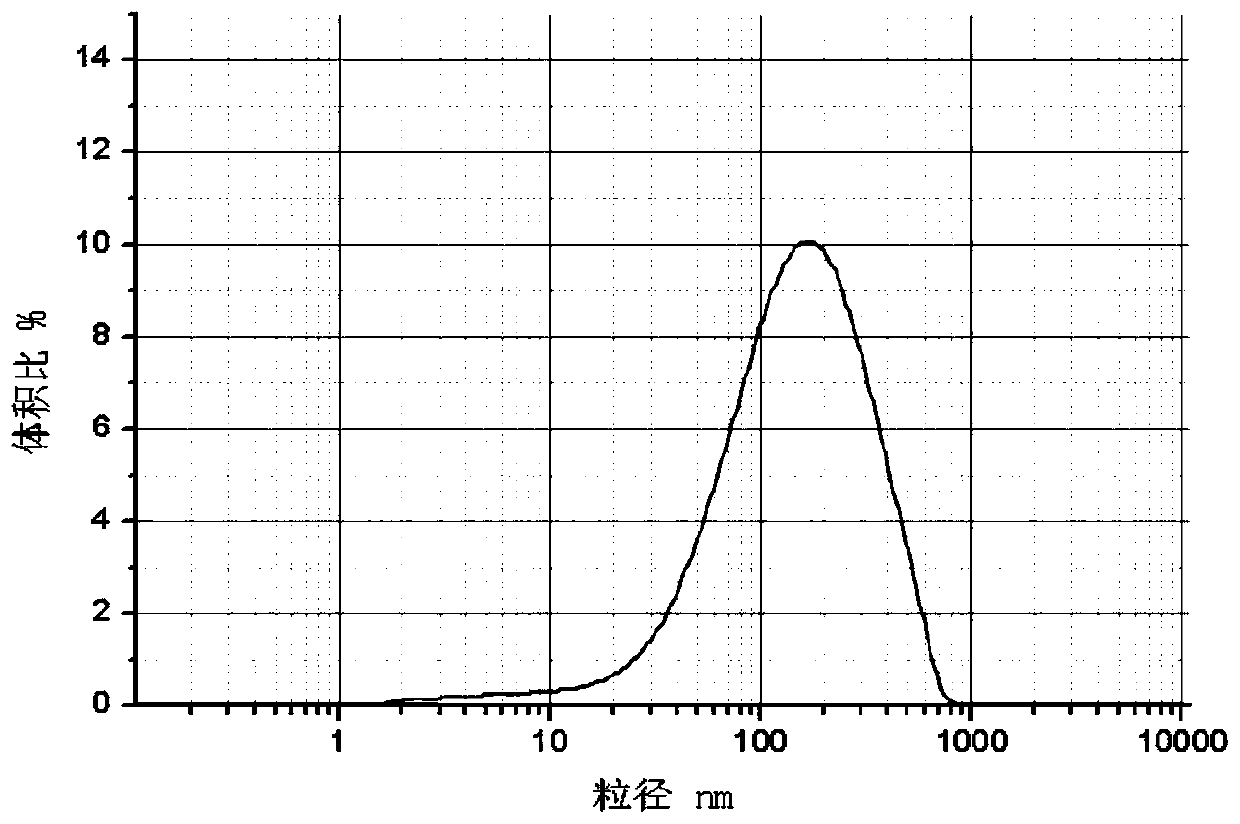

Novel high-corrosion-resistance waterborne epoxy curing agent and preparation method thereof

PendingCN107090077AImprove lipophilicityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyQuinoline

The invention provides a novel high-corrosion-resistance waterborne epoxy curing agent and a preparation method thereof. The molecular structure of the epoxy curing agent is as shown in the formula I or II: the formulas I and II are as shown in the specification. The novel high-corrosion-resistance waterborne epoxy curing agent has the following beneficial effects that an EO chain segment and a little of neutralized ion amine and hydroxyl in the curing agent structure provide corresponding hydrophilcity for emulsification of the curing agent, and rigid structures on aromatic diamine and epoxy resin provide high lipophilicity and corrosion resistance for the curing agent; 2, a quinoline structure in the curing agent structure achieves an amphiphilic balance effect under a phase action system, so that the salt fog corrosion resisting property of a paint film matched with epoxy resin is greatly improved; by the introduction of the aromatic diamine, an effective primary amine group can be provided for the curing agent through a steric effect, and an aromatic group is introduced, so that the corrosion resisting effect of the paint film is effectively enhanced; by introducing an epoxy resin structure into the curing agent structure, the curing agent has the water-oil content close to that of the epoxy resin, and the shortcomings of the paint film can be effectively reduced.

Owner:HAOLISEN CHEM TECH (JIANGSU) CO LTD

Hydrophobic surface coating and preparation method thereof

ActiveCN111303673AImprove compactnessImprove mechanical propertiesPhysical treatmentVacuum evaporation coatingAlcoholWeather resistance

The invention provides a hydrophobic surface coating and a preparation method thereof, and the hydrophobic surface coating is formed on the surface of a substrate through a plasma enhanced chemical vapor deposition method by taking one or more fluorinated alcohol compounds as reaction gas raw materials, so as to improve the hydrophobicity, chemical corrosion resistance and weather resistance of the surface of the substrate.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Method for improving salt spray corrosion resistance of german silver

InactiveCN103361583AImprove salt spray corrosion resistanceMeet the requirements of salt spray corrosion resistanceAbrasion apparatusRollsCupronickelZinc

The invention discloses a method for improving salt spray corrosion resistance of german silver, wherein the salt spray corrosion resistance of german silver is improved by increasing the manganese content of the material, reducing the surface roughness of the material, removing erodible substance on the surface and blocking or slowing down the galvanic reaction of the german silver material in a NaCl mist environment with concentration of 5%.

Owner:ANHUI XINKE NEW MATERIALS

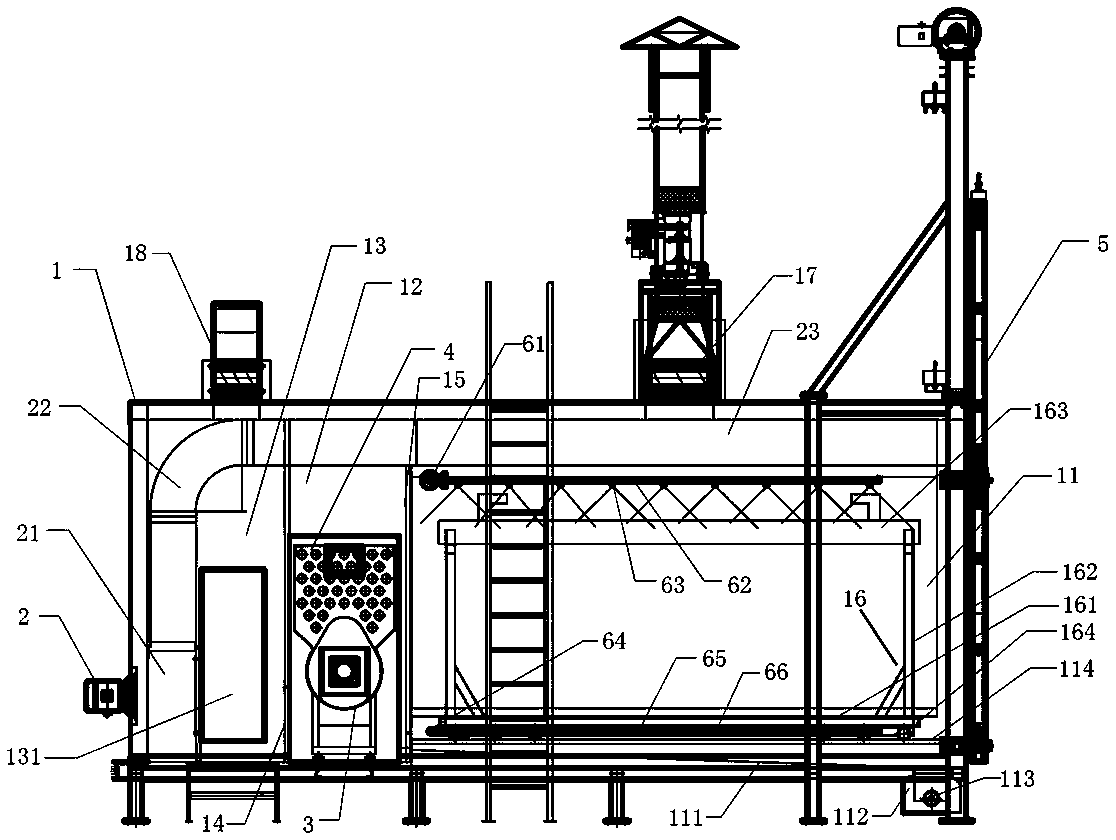

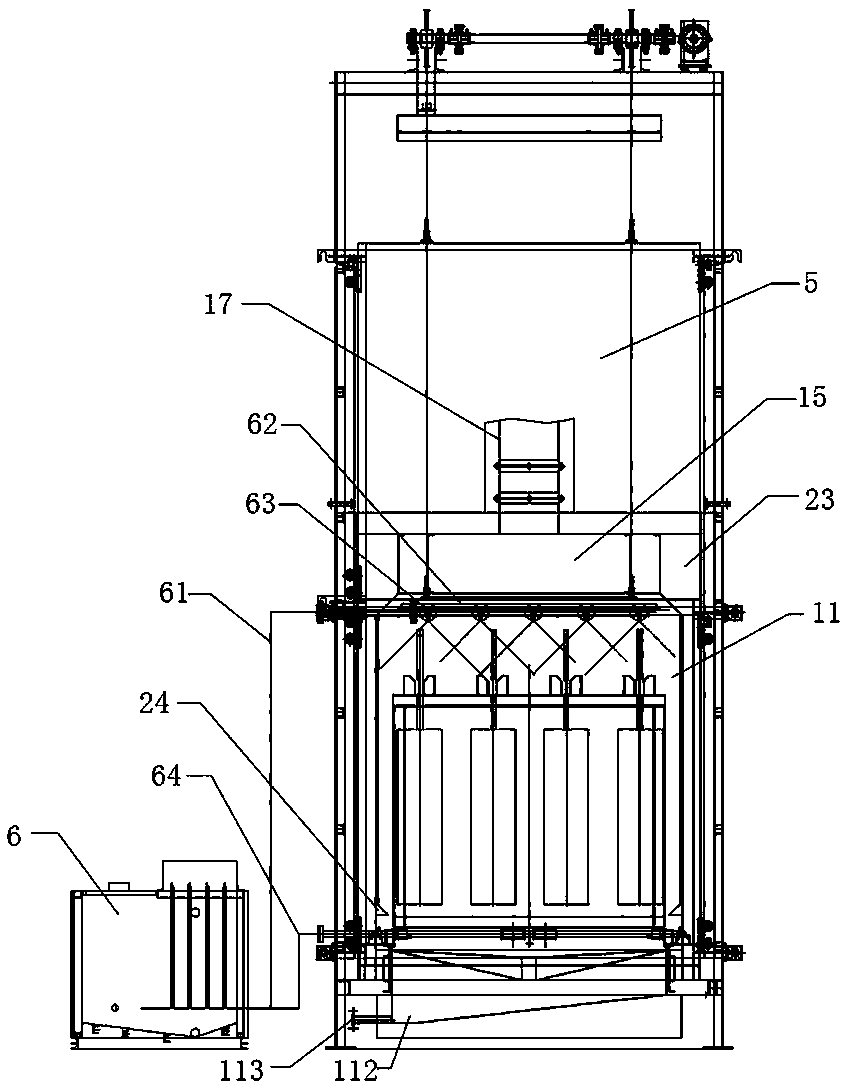

Device for salt mist tolerance test of aluminum alloy workpiece and test method using device

PendingCN107589066ALong-term anti-salt spray test timeSafe and efficient handlingWeather/light/corrosion resistanceSalt spray testHeat exchanger

The invention discloses a device for a salt mist tolerance test of an aluminum alloy workpiece. The device comprises a steam box, a fan, a burner, a heat exchanger, a vertical lifting door and a heatable water tank, wherein the steam box comprises a workpiece steaming chamber, an air return chamber and an air supply chamber; a test method of salt mist tolerance of an aluminum alloy workpiece usingthe device comprises the following steps: (1) preheating of the steam chamber; (2) entering of the workpiece into the steam chamber; (3) primary flushing; (4) heating treatment; (5) moisturizing treatment; (6) secondary flushing; (7) discharging of the workpiece out of the steam chamber. According to the test method of salt mist tolerance of the aluminum alloy workpiece, an aluminum alloy workpiece test enhanced than before can be effectively realized, so that the workpiece can endure long-time salt mist resisting test without being damaged, and the quality of the final product is remarkablyimproved; the device for the salt mist tolerance test of the aluminum alloy workpiece is perfect in structure and convenient to use and is completely suitable for the test method; a safe and effectivetreatment environment is provided, the product quality is effectively improved, and the method and device are worthy of popularization and application.

Owner:ZHEJIANG HUALI INTELLIGENT EQUIP CO LTD

Epoxy resin emulsion and application thereof in water-based paint

InactiveCN111548461AHigh hardnessGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to an epoxy resin emulsion and application thereof in a water-based paint, and belongs to the technical field of paints. The emulsion is prepared by the following steps: performing crosslinking and hydrolytic polymerization on polyether and siloxane to obtain a prepolymer with unsaturated bonds, and performing grafting reactions on the prepolymer, an acrylic monomer, and epoxy resin at the same time to obtain modified epoxy resin emulsion. The emulsion has better weather resistance and ultraviolet resistance than conventional acrylic acid modified water-based epoxy resinemulsion when being applied to water-based epoxy coatings.

Owner:南京霄祥工程技术有限公司

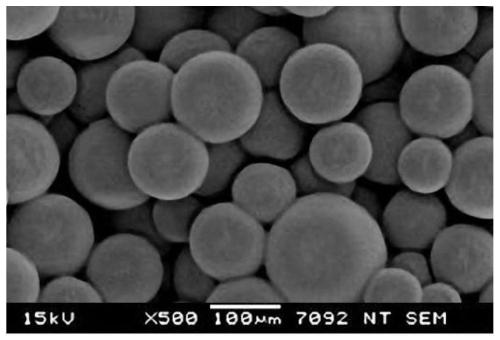

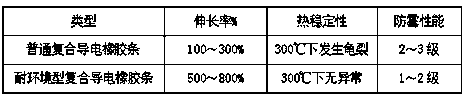

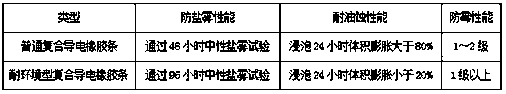

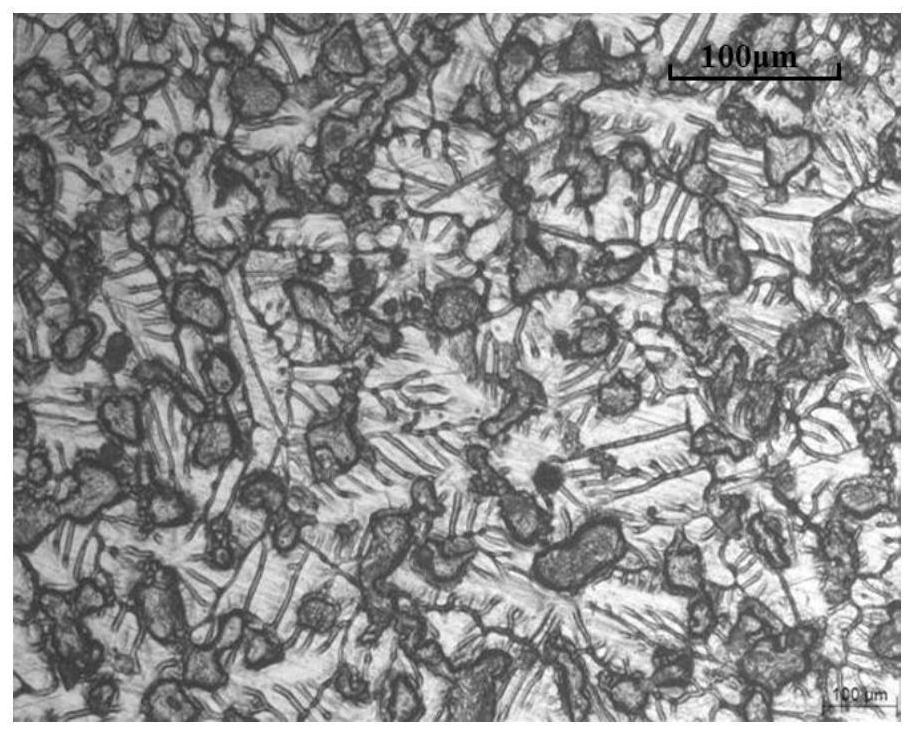

Environment-resistant electromagnetic protection composite conductive rubber and preparation method thereof

The invention relates to the technical field of functional composite rubbers in electronic materials, particularly to an environment-resistant electromagnetic protection composite conductive rubber and a preparation method thereof. The composite conductive rubber is formed by integrally vulcanizing a conductive part and a non-conductive part. According to the invention, the basic performance of the prepared composite rubber completely meets related standards of a conductive rubber gasket; a fluorosilicone conductive rubber is used as base rubber, so that the prepared composite rubber is stablein performance in an oil seal environment so as to resist oil corrosion; through a carbon nano-tube reinforcing agent, the mildew-proof characteristic and the flexibility of a composite strip are enhanced; through graphene oxide, the salt spray corrosion resistance of an aluminum-silver composite conductive rubber is enhanced; through glass micro-beads, the thermal stability of the composite strip in a high-temperature forming process is enhanced; the main function of the non-conductive part of the prepared composite conductive rubber strip is environment sealing, and the main function of theconductive part is electromagnetic sealing; and the environment-resistant special requirements of equipment operating in an extreme environment on the electromagnetic protection sealing strip are met.

Owner:NO 33 RES INST OF CHINA ELECTRONICS TECHNOOGY GRP

Preparation method of coated toughened glass

InactiveCN108373271AGood acid and alkali resistanceImprove salt spray corrosion resistanceCoatingsGlass tempering apparatusOrganosiliconCorrosion

The invention relates to the technical field of glass deep-processing in photovoltaic industry and discloses a preparation method of coated toughened glass. The preparation method includes providing aglass substrate and coating one side of the glass substrate with a titanium dioxide film layer; the preparation method is characterized by further coating the titanium dioxide film layer with an anti-reflective film layer and a diamond film layer sequentially; the anti-reflective film layer is prepared from a coating solution comprising isopropyl alcohol, silica solution, aluminium oxide, adhesion promoter, coupling agent of zirconium and organosilicon leveling agent. The light transmission rate of the coated toughened glass is increased by 3.5%; the coating solution refers to aqueous coatingsolution, is free of odor during use, and accordingly, physical health of users can be protected effectively; as a nano-scale silicon dioxide is taken as a basic system to prepare the inorganic hybrid film layer having porous structure, and nano-scale silicon dioxide has good binding performance with photovoltaic glass, the prepared coated toughened glass has high light-transmission rate and goodacid and alkali resistance, salt fog corrosion resistance and constant-temperature resistance performance.

Owner:JIANGXI GAN YUE PV GLASS

Industrial production method of galvanized IF steel with high salt spray corrosion resistance

PendingCN112647034AImprove cooling effectImprove densification performanceHot-dipping/immersion processesManufacturing convertersSteelmakingSalt spray test

The invention relates to an industrial production method of galvanized IF steel with high salt spray corrosion resistance, which comprises the steps of steelmaking, RH refining, continuous casting, hot rolling and galvanizing, in the galvanizing step, the speed of strip steel is controlled to be 120-130 m / min, the roughness of a working roll of a finishing machine is 2.5-3.5 [mu] m, the surface roughness Ra of a galvanized plate is controlled to be 1.2-1.6 [mu] m, the air knife spacing is 6-9 mm, and air knife pressure is 200-350 mbar; and a target zinc layer is accurately controlled at the upper limit of the zinc layer weight target value, and the salt spray corrosion resistance is improved. The IF steel plate galvanized sheet produced by the method can meet the requirement that the white rust area of the surface is less than 1% in a 120-hour salt spray test, and the salt spray corrosion resistance of the galvanized IF steel is greatly improved.

Owner:HANDAN IRON & STEEL GROUP +1

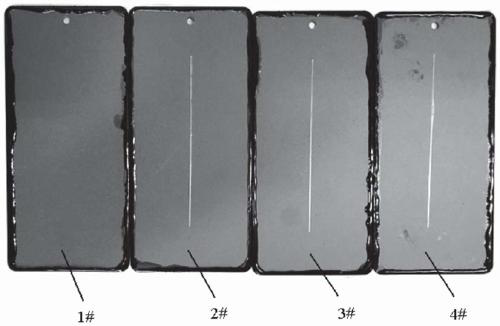

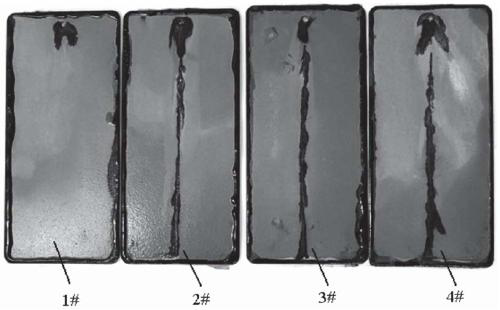

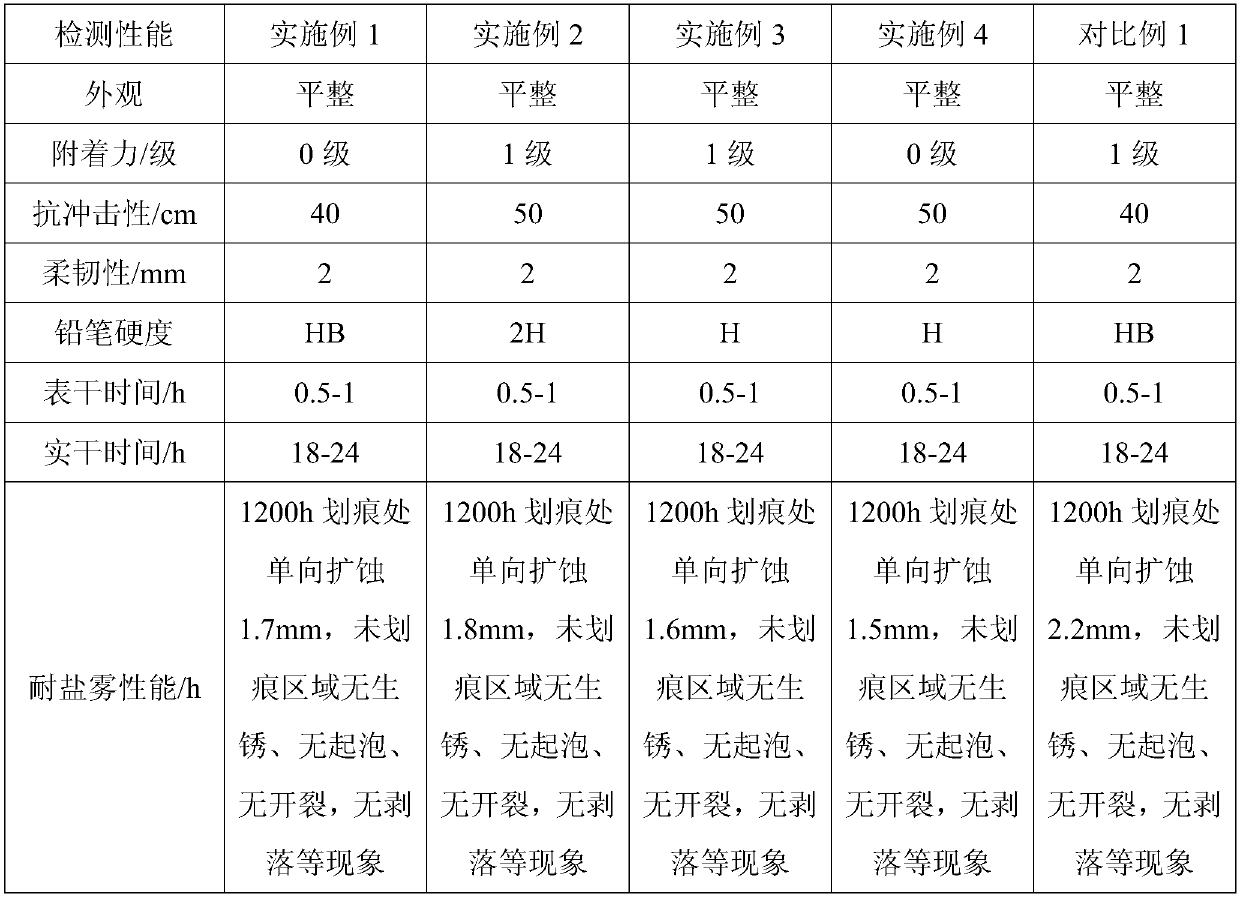

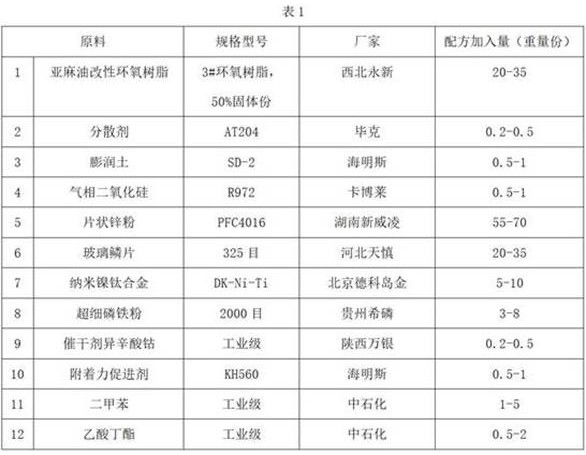

Single-component scale type epoxy zinc-rich anti-corrosive primer and preparation method thereof

ActiveCN112920687AImprove adhesionGood weather resistanceSiccativesAnti-corrosive paintsEpoxyXylylene

The invention discloses a single-component scale type epoxy zinc-rich anti-corrosive primer and a preparation method thereof, belongs to the field of industrial anti-corrosive coatings, and solves the problems of poor paint film flexibility, serious zinc powder precipitation and poor salt spray resistance of existing anti-corrosive coatings. The anti-corrosive primer comprises linseed oil modified epoxy resin, a dispersing agent, bentonite, fumed silica, flaky zinc powder, glass flakes, nano nickel-titanium alloy, superfine ferrophosphorus powder, a drier cobalt iso-octoate, an adhesion promoter, xylene and butyl acetate. The preparation method comprises the following steps: sequentially adding the linseed oil modified epoxy resin, the dispersing agent, the bentonite, the fumed silica, the flaky zinc powder, the glass flake, the nano nickel-titanium alloy and the superfine ferrophosphorus powder, and performing uniform stirring; increasing the rotating speed for high-speed dispersion; adding the drier cobalt iso-octoate, the adhesion promoter, the xylene and the butyl acetate while stirring; and performing filtering and packaging. The anti-corrosive primer is excellent in performance and convenient to prepare.

Owner:西北永新涂料有限公司

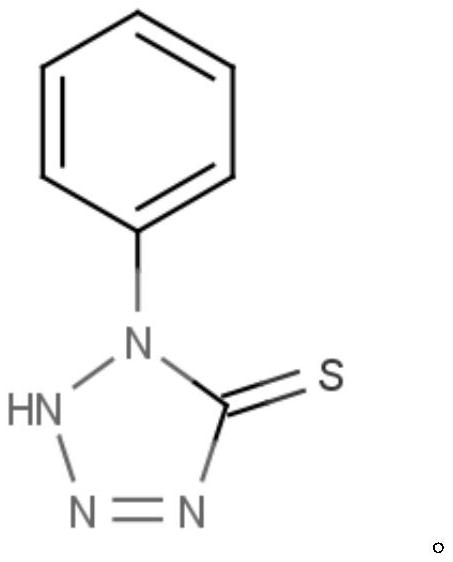

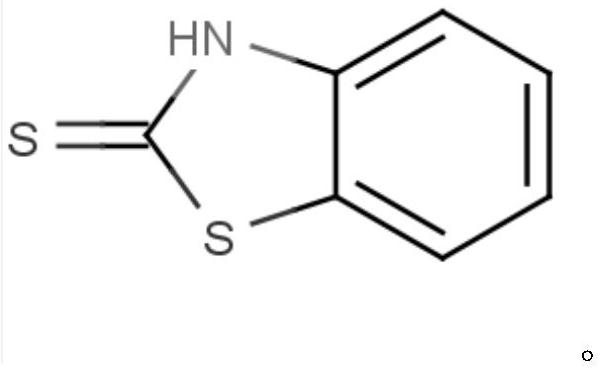

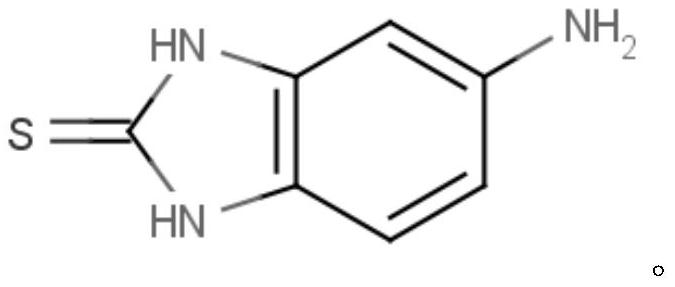

Water-based electronickelling sealing agent and preparation method thereof

The invention relates to the technical field of water-based electronickelling sealing agents, in particular to a water-based electronickelling sealing agent. The agent is prepared from the raw materials in parts: 30-150 parts of an alcohol solvent, 2-20 parts of a sulfydryl-containing fused heterocyclic compound, 30-150 parts of alkylol amine, 10-80 parts of an anionic surfactant, 1-8 parts of fatty amine polyoxyethylene ether, 30-150 parts of alcohol ether, 0.5-15 parts of a complexing agent, and 500-850 parts of water. The preparation method includes the steps of mixing the raw materials, and stirring to clarify. The water-based electronickelling sealing agent solves the problem of poor salt spray corrosion resistance of a water-based electronickelling sealing agent in the prior art, canform a bright and transparent adsorption film on the electronickelling surface, seals pores in the surface of a nickel layer, and remarkably improves the salt spray corrosion resistance of an electronickelling layer. In addition, after being sealed by the water-based electronickelling sealing agent, the electronickelling surface does not need to be heated and dried, and can directly enter a processing procedure after being naturally aired in air.

Owner:上海昕沐化学科技有限公司

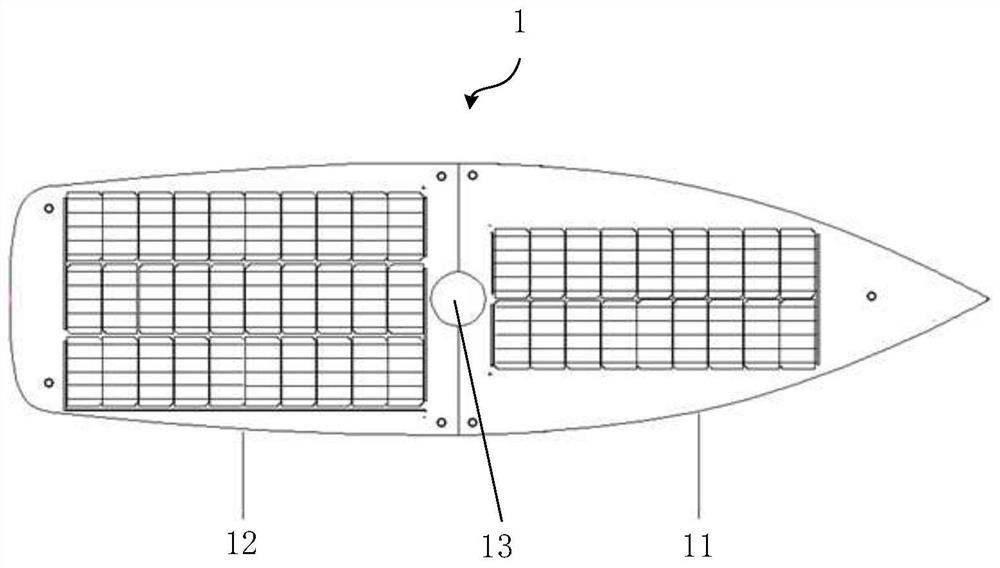

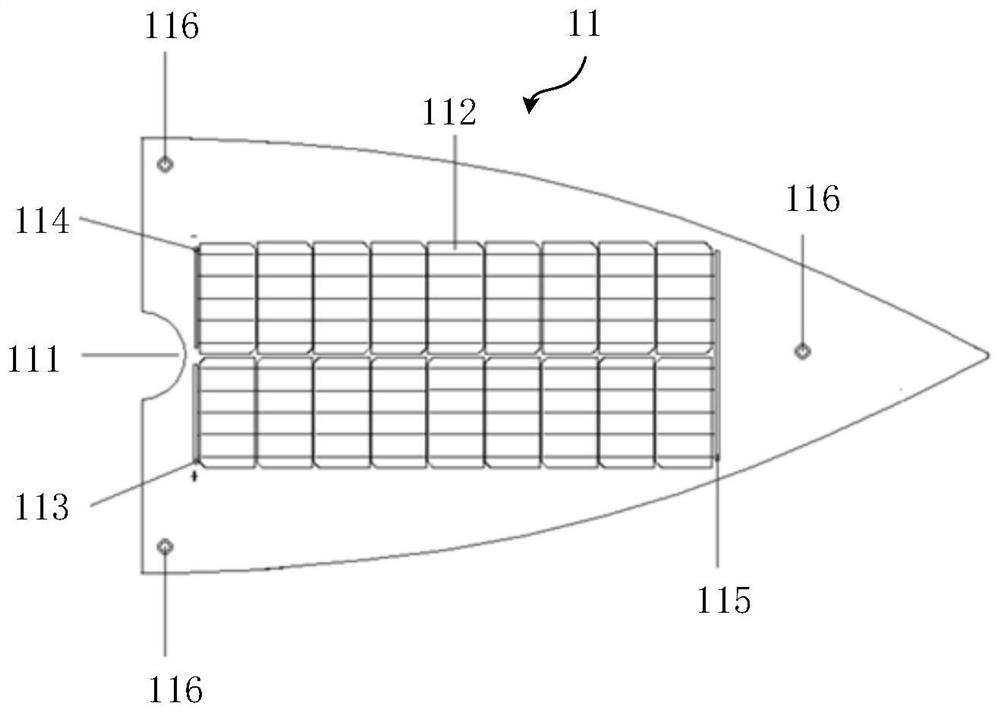

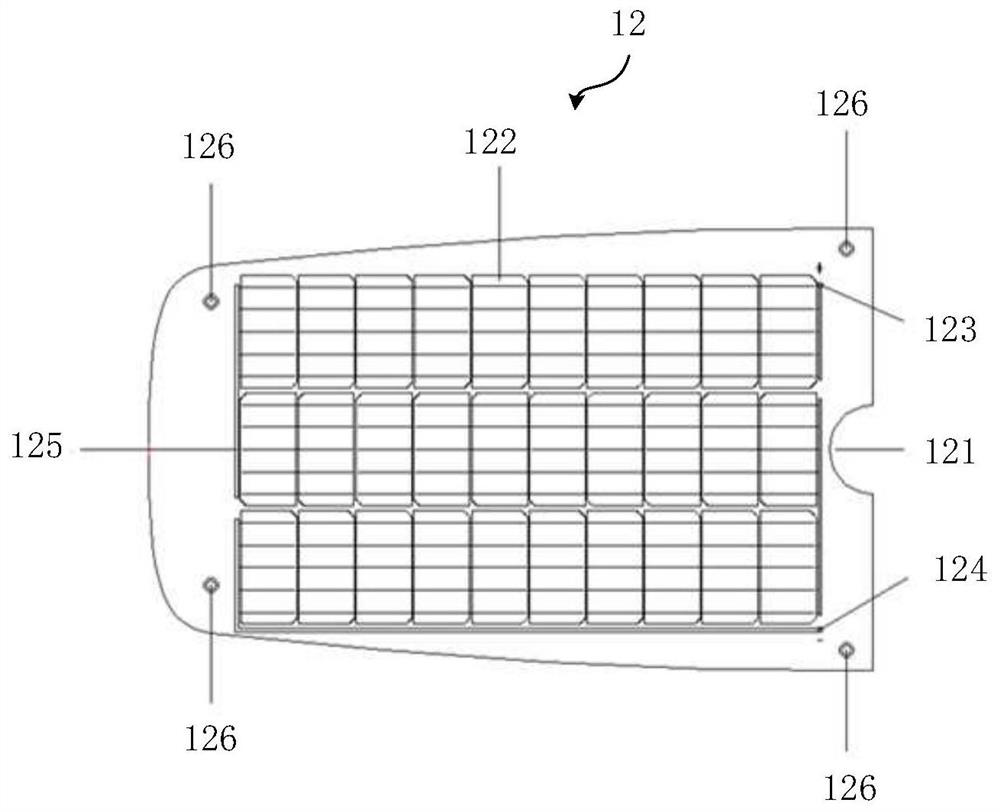

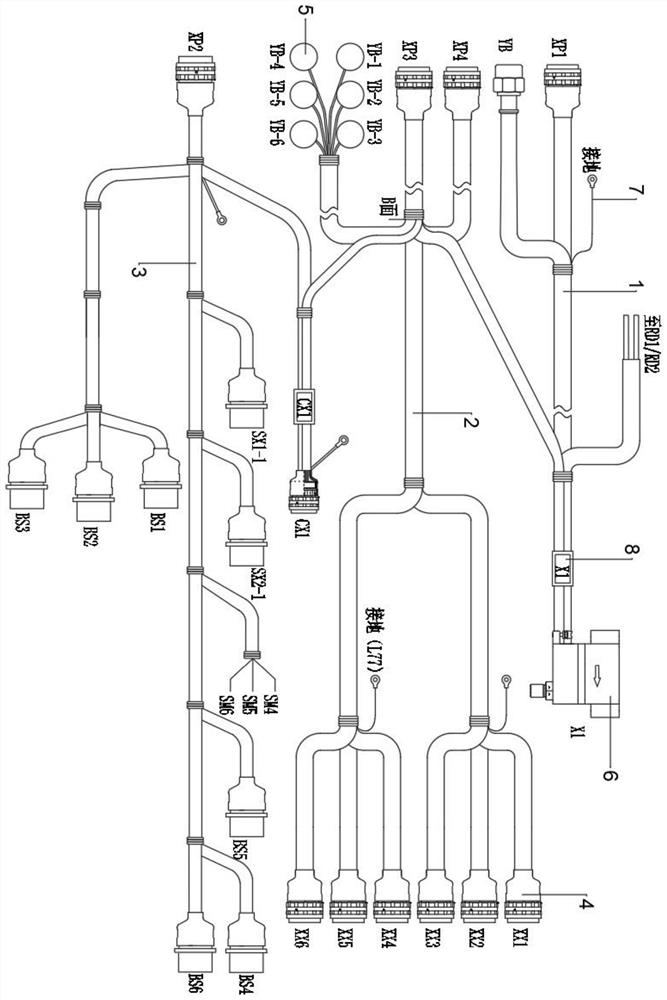

Photovoltaic module and unmanned sailing boat

PendingCN112271222AImprove flexibilityImprove waterproof performanceSteering ruddersPhotovoltaic energy generationSolar cellAluminum substrate

The invention relates to a photovoltaic module and an unmanned sailing boat, and aims at overcoming the problems of heavier weight and lower corrosion resistance of the photovoltaic module. The photovoltaic module is composed of an ETFE film, a first packaging adhesive film, a solar cell, a second packaging adhesive film, a thin aluminum substrate, a third packaging adhesive film and a photovoltaic backboard which are sequentially arranged in a stacked mode. The photovoltaic assembly is packaged with the thin aluminum substrate through the ETFE film, is high in flexibility, can be bent, and can be cut to customize various shapes. The weight is low and the thickness is low; and the thin aluminum substrate prevents water vapor and oxygen from permeating into the layer where the solar cell islocated from the back surface of the photovoltaic module, so that the water resistance, salt spray corrosion resistance, weather resistance such as aging resistance, use reliability and the like of the photovoltaic module are improved.

Owner:GREE ELECTRIC APPLIANCES INC

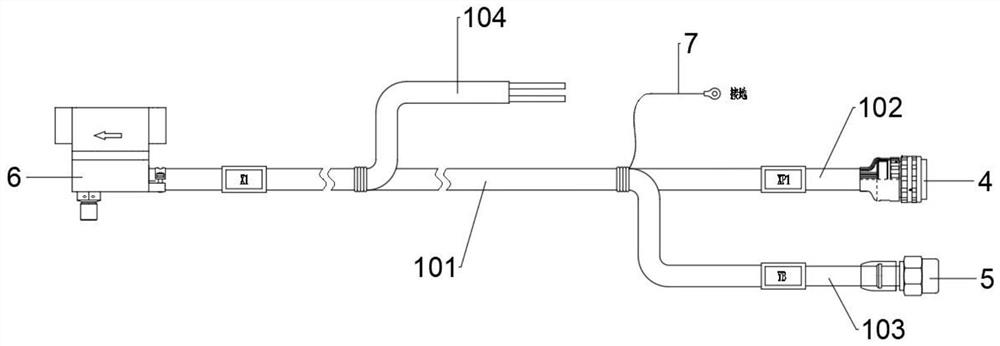

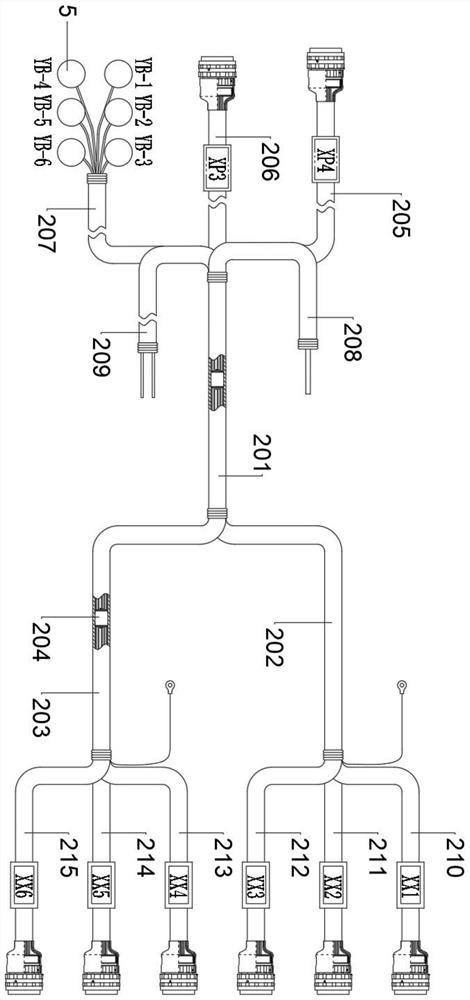

Hanger cable

PendingCN113507020AMeeting Electrical Interconnection NeedsAvoid enteringCouplings bases/casesCoupling protective earth/shielding arrangementsInterference resistanceControl signal

The invention discloses a hanger cable, and solves the problems that an existing hanger cable has fewer functions, only integrates one or two interfaces, is weaker in environment resistance and interference resistance of a cable body, is higher in integration degree, and is difficult to produce and process when the cable is complex in structure or longer, and the later maintenance process is tedious and the cost is increased. The cable provided by the invention can meet the requirement for electrical interconnection of various signals of an airplane and a hanging object in the high-speed flight process, and transmission of various signals such as a power supply signal, a monitoring control signal, a radio frequency signal and a 1553B data bus signal is integrated in the product; a titanium alloy external interface is selected as a connector, and an in-cabin interface connector is made of an aluminum alloy plated army green cadmium material, so that the salt mist resistance and corrosion resistance of the product can be effectively improved; the overall dimension of the connector is shortened according to the mounting environment of the hanger cable; meanwhile, the tail accessory is an external shrinkage sealing double-wall heat shrink tube, so water vapor, salt mist, dust and the like can be effectively prevented from entering the cable.

Owner:沈阳兴华航空电器有限责任公司

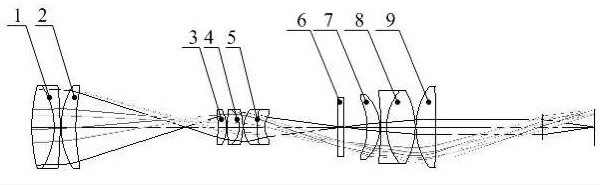

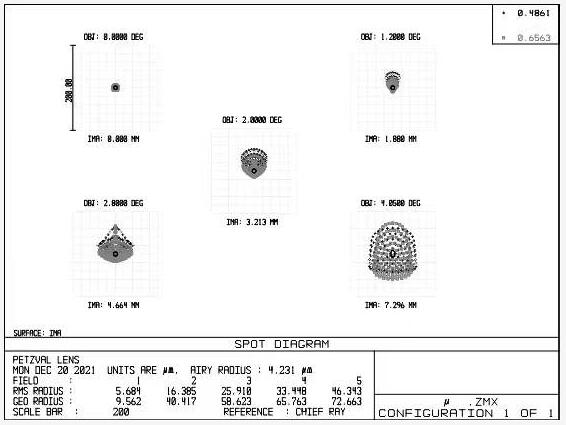

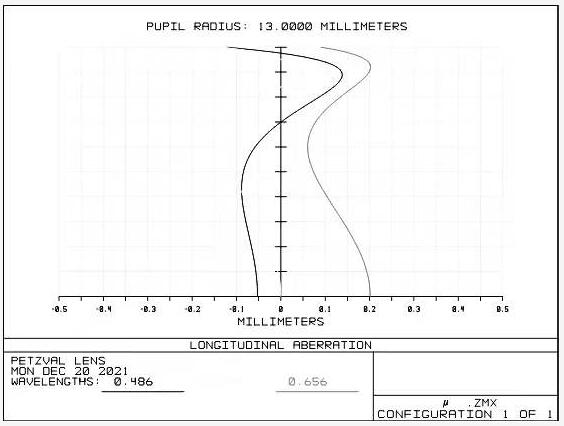

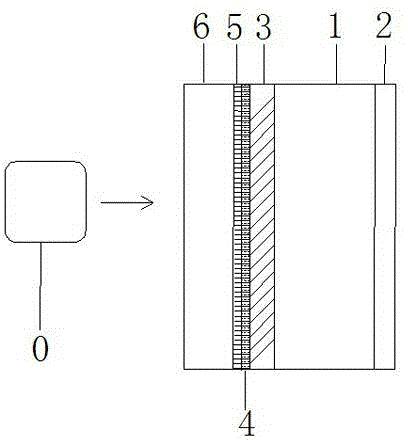

Compact wide-view-field white light sighting telescope optical system

The invention discloses a compact wide-field white light sighting telescope optical system, which adopts a Kepler telescope system and comprises an objective lens group, an image rotation group, a reticle and an eyepiece group, the objective lens group adopts two groups of three-piece spherical lenses, the image rotation group adopts three groups of five-piece spherical lenses, and the image rotation group is arranged behind an image plane of the objective lens group; the reticle is arranged behind the image rotation group, and the eyepiece group adopts three groups of five spherical lenses and comprises a first eyepiece lens group, a second eyepiece lens group and a third eyepiece lens group. The white light sighting telescope optical system is good in imaging quality, free of sensitive size, good in lens processing technology, reasonable in optical element arrangement, compact in structure, small in size and high in engineering realizability, and has practical application value.

Owner:湖南华南光电(集团)有限责任公司

A kind of high corrosion-resistant hot-dip galvanized alloy coating for steel components and its preparation process

ActiveCN103173707BSimple hot-dip plating processImprove salt spray corrosion resistanceHot-dipping/immersion processesIngotZinc alloys

The invention provides a hot-dipped galvanized alloy coating with high corrosion resistance for a steel member. The improvement is that, when the alloy coating is prepared, an adopted alloy ingot comprises the following components in percentage by weight: 0.01-2% of Al, 0.01-2% of Mg, 0.05-3% of Re, 0.002-1% of Cu and the balance of Zn. The alloy coating has the characteristics of high corrosion resistance, low zinc consumption, better economy and the like, which are suitable for the steel members of power transmission lines, and the alloy coating can effectively prolong the corrosion-resistant service life of the steel member of the power transmission line and prolong the corrosion-resistant service life by above 2 times in comparison with industrial hot-dipping of pure zinc while ensuring that the thickness of the coating is not increased.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

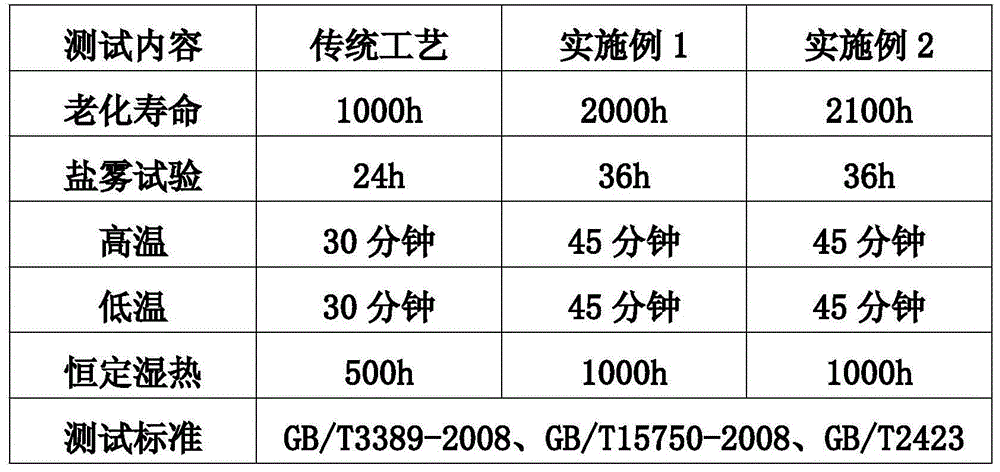

Surface treatment method for improving performance of piezoelectric ceramic

ActiveCN104876642AImprove salt spray corrosion resistanceGood high and low temperature resistanceElectricityMonocalcium phosphate

The invention discloses a surface treatment method for improving the performance of piezoelectric ceramic. The method comprises the following steps: (1) providing a piezoelectric ceramic body; (2) configuring a Ca(OH)2 solution and a mixed solution of boric acid and monocalcium phosphate for later use; (3) soaking the piezoelectric ceramic body into the Ca(OH)2 solution to obtain a product A; (4) taking the product A out, and heating and drying the product A to obtain a product B; (5) soaking the product B into the mixed solution of boric acid and monocalcium phosphate to obtain a product C; and (6) taking the product C out, drying the product C at first, and then performing heat treatment to generate a boron phosphate calcium glass film on the surface of the piezoelectric ceramic to obtain a finished product. By adopting the technical scheme, the surface treatment method provided by the invention has the advantages that the salt-spray corrosion resistance, high-low temperature resistance and moisture resistant performance of the surface of the piezoelectric ceramic are improved, and the aging service life of the piezoelectric ceramic is obviously prolonged.

Owner:GUIZHOU UNIV

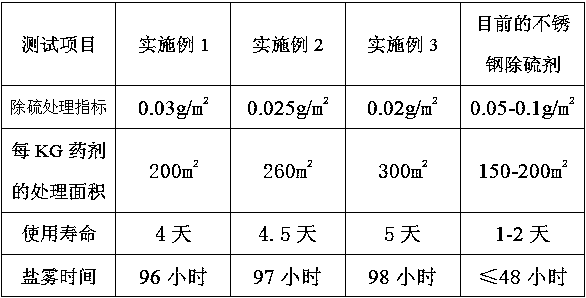

Stainless steel desulphurization agent

The invention relates to a stainless steel desulphurization agent. The stainless steel desulphurization agent comprises, by weight percentage, 10.4%-12.7% of wetting agents or polyhydric alcohol, 2.5%-5.0% of emulsifying agents, 7.7%-9.5% of complexing agents A, 0.5%-1.0% of penetrating agent or corrosion inhibitor, 5.8%-8.0% of complexing agents B, 5.5%-7.5% of complexing agents C and 56.3%-67.6%of deionized water. The stainless steel desulphurization agent is an agent which can effectively reduce the content of elemental sulfur and the content of sulfides on the surface of stainless steel,the content of elemental sulfur and the content of sulfides on the surface of the stainless steel per square meter can be reduced to 0.02g to 0.03g, the neutral salt fog testing time of the 304 stainless steel which is subjected to desulphurization treatment through the stainless steel desulphurization agent can be 96 hours or above, namely, the salt fog resistance testing capacity and the corrosion resistance capacity of the 304 stainless steel are remarkably improved, the desulphurization effect of the stainless steel desulphurization agent is better, and the stainless steel desulphurizationagent can achieve the purposes that the mechanical property of the surface of the stainless steel can be effectively improved, and the welding problem of the surface of the stainless steel can be effectively solved.

Owner:东莞市精诚环保科技有限公司

Radar safety guard

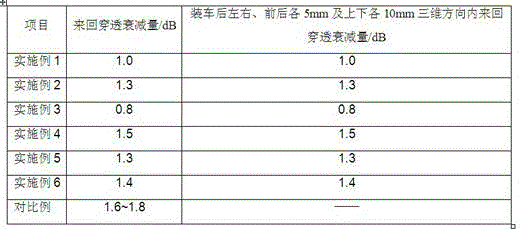

ActiveCN102637951BSmall back and forth penetration attenuationImprove salt spray corrosion resistanceRadiating element housingsUltrasound attenuationRadar

The invention discloses a radar safety guard, belonging to the surface technical field. The radar safety guard comprises a polycarbonate base. The radar safety guard is characterized by further comprising a transparent polycarbonate front cover connected with the polycarbonate base, one side of the transparent polycarbonate front cover, facing a radar, is sequentially provided with a primer layer, a colored layer, a vacuum plated nano metallic layer and a painting protective layer from inside to outside, and each of the vacuum plated nano metallic layer and the painting protective layer both has electromagnetic wave back-and-forth penetration attenuation being not more than 0.2dB. The radar safety guard is excellent in corrosion resistance, has very low wave back-and-forth penetration attenuation, and can be adapted to the reliability of the attenuation when the loading position is in a certain range of three-dimensional directions.

Owner:HUZHOU TIAHE AUTOMOBILE PART

Zinc-aluminum-titanium-rare earth alloy for hot dip galvanized steel sheets and preparation method thereof

ActiveCN102162048BImprove wettabilityImprove adhesionHot-dipping/immersion processesMischmetalSurface finish

The invention discloses a zinc-aluminum-titanium-rare earth alloy for hot dip galvanized steel sheets and a preparation method thereof, and belongs to the technical field of surface treatment of iron and steel materials. The hot dip galvanized alloy material comprises the following components in percentage by mass: 5.5 to 6.5 percent of aluminum (Al), 0.03 to 0.05 percent of titanium (Ti), 0.05 to 0.15 percent of rare earth (RE) metal, and the balance of zinc (Zn). The method for preparing the hot dip galvanized alloy material comprises the following steps of: heating and melting the aluminum, and adding the rare earth metal and titanium metal to prepare an aluminum-rare earth intermediate alloy with a certain mass ratio and an aluminum-titanium intermediate alloy with a certain mass ratio respectively; and heating and melting the zinc, adding the aluminum and the intermediate alloy materials according to the given proportion, and completely melting and stirring uniformly to obtain the required zinc-aluminum-titanium-rare earth alloy. The hot dip galvanized alloy material guarantees the surface finishment of hot dip galvanized layers and remarkably improves salt spray corrosion resistance of steel sheets; meanwhile, the preparation method has low process requirements, is easy to operate, and can meet the requirements of industrialized production.

Owner:张家港市凤凰科技开发有限公司

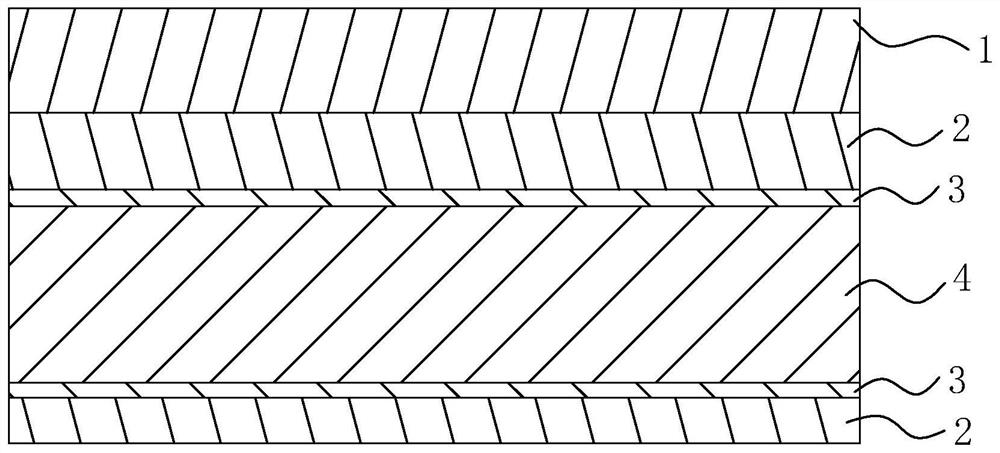

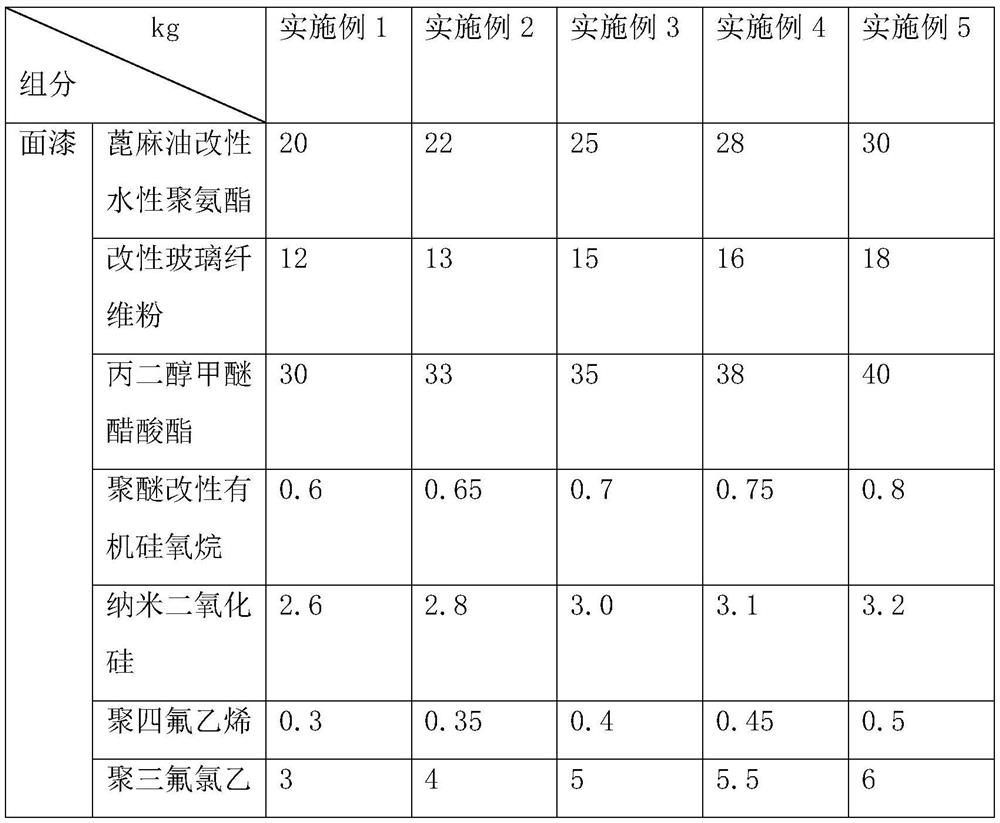

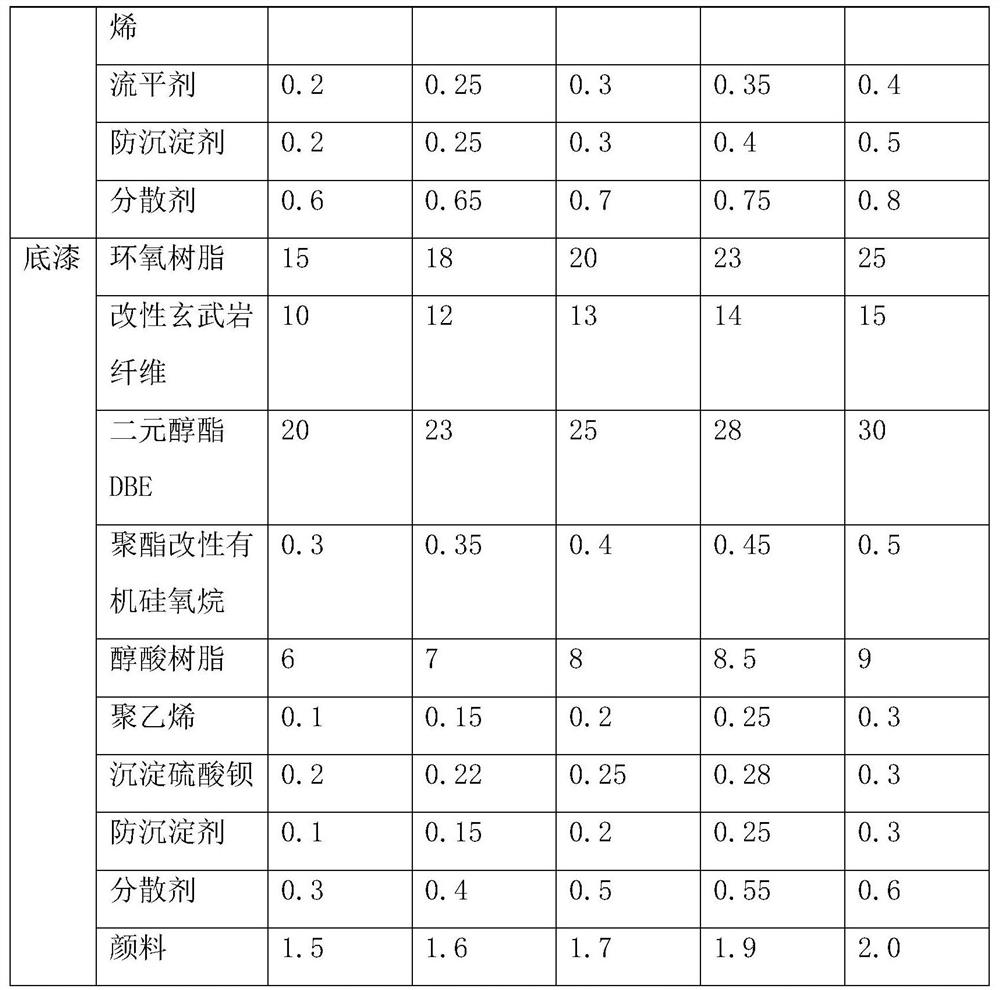

A kind of pcm board for elevator and its production process

ActiveCN110482380BImprove mechanical propertiesNot easy to stretch and breakPretreated surfacesAnti-corrosive paintsPolyesterEpoxy

The invention discloses a PCM board for an elevator and a production process of the PCM board. The PCM board for the elevator comprises a finish paint layer, a primer layer, a passivation layer, a substrate, another passivation layer and another primer layer, wherein the finish paint layer, the primer layer, the passivation layer, the substrate, the passivation layer and the primer layer are sequentially arranged layer by layer; the finish paint layer comprises raw materials: castor oil modified waterborne polyurethane, modified glass fiber powder, propylene glycol methyl ether acetate, polyether modified organosiloxane, nano silicon dioxide, polytetrafluoroethylene, polytrifluorochloroethylene, a flatting agent, an anti-precipitating agent and a dispersing agent; and the primer layer comprises the raw materials: epoxy resin, modified basalt fiber, dibasic acid ester DBE, polyester modified organosiloxane, alkyd resin, polyethylene, precipitated barium sulfate, an anti-precipitating agent, a dispersing agent and a pigment. The PCM board for the elevator has the advantages that the tensile property of coating is good, and when the PCM is bent, a gap is not easily formed in the coating, so that the PCM board has the advantage of good salt fog resistance.

Owner:杭州普络飞新材料科技有限公司

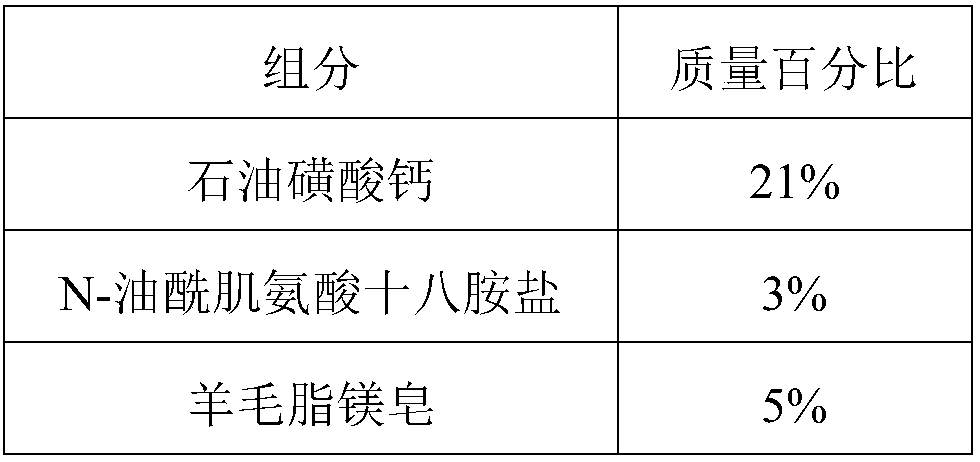

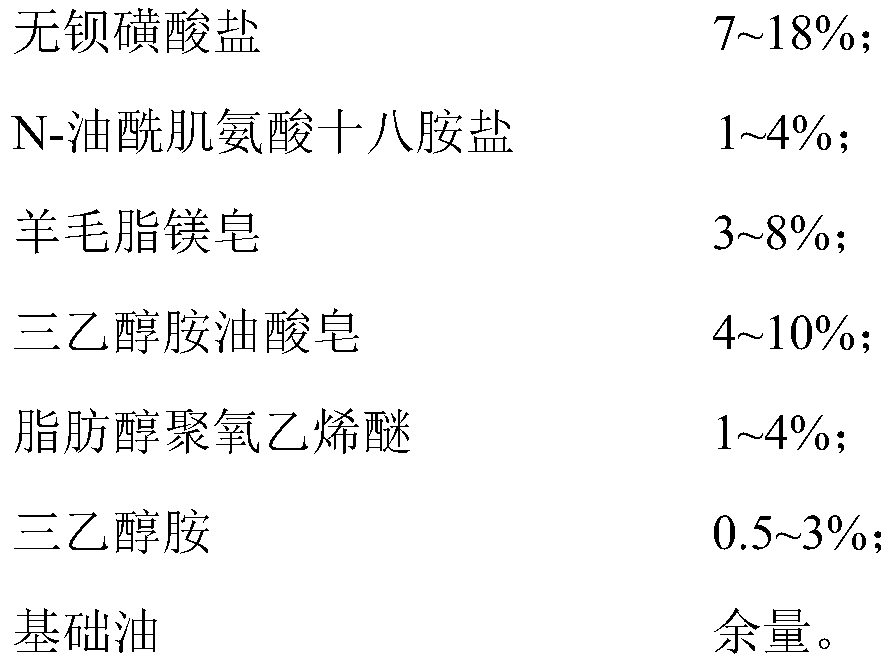

An environmentally friendly emulsified antirust oil

ActiveCN110591796BImprove rust resistanceImprove salt spray corrosion resistanceLubricant compositionSulfonateEnvironmental engineering

The invention discloses an environment-friendly emulsified antirust oil, which comprises the following components in terms of mass percentage: 5% to 20% of barium-free sulfonate; 0.5% to 5% of N-oleoyl sarcosine octadecylamine; wool 2-10% of fat magnesium soap; 2-10% of triethanolamine oleic acid soap; 0.5-5% of fatty alcohol polyoxyethylene ether; 0.5-5% of triethanolamine; the balance is base oil. The environment-friendly emulsified antirust oil provided by the present invention adopts an oil-soluble antirust agent that does not contain heavy metals such as barium and lead, and is environmentally friendly; Combining oil-soluble antirust agents such as lanolin magnesium soap with triethanolamine oleic acid soap, fatty alcohol polyoxyethylene ether, triethanolamine, and base oil can effectively improve the antirust performance of emulsified antirust oil, especially salt spray resistance corrosion performance.

Owner:NTIC (SHANGHAI) CO LTD

Protective coating for high-voltage and high-frequency power equipment

InactiveCN109161283AImprove salt spray corrosion resistanceImprove adhesion strengthFireproof paintsAnti-corrosive paintsSodium BentoniteHigh frequency power

The invention relates to the technical field of power protection materials, and particularly relates to a protective coating for high-voltage and high-frequency power equipment. The protective coatingcomprises the following components: a pure acrylic emulsion, fluorosilicone resin, polyvinylpyrrolidone, fillers, an anti-radiation additive, sodium nitrite, hydroxypropyl methyl cellulose ether, nonylphenol polyoxyethylene ether, an antiseptic bacteriostat and a defoamer, wherein the structure of the anti-radiation additive comprises a superhard base core composed of inorganic fillers, anti-radiation functional particles distributed on a surface of the base core, and a polyamide-imide film layer coating an outer layer of the anti-radiation functional particles; the fillers contain titanium dioxide, lithium-based bentonite and palygorskite powder; the antiseptic is isothiazolinone or thiophanate methyl; and the defoamer is a silicone defoamer or a mineral oil defoamer. The coating provided by the invention has advantages of high film strength, good adhesion, relatively good corrosion, rust and corrosion resistances, and excellent anti-radiation performance.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com