Control method of surface cracks of passivated membrane of chromium-free passivated galvanized plate

A control method, chrome-free passivation technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of easy cracking or falling off, affecting the corrosion resistance of chrome-free passivated galvanized sheet, etc. problems, to achieve the effect of improving salt spray corrosion resistance, strong adhesion, and improving technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

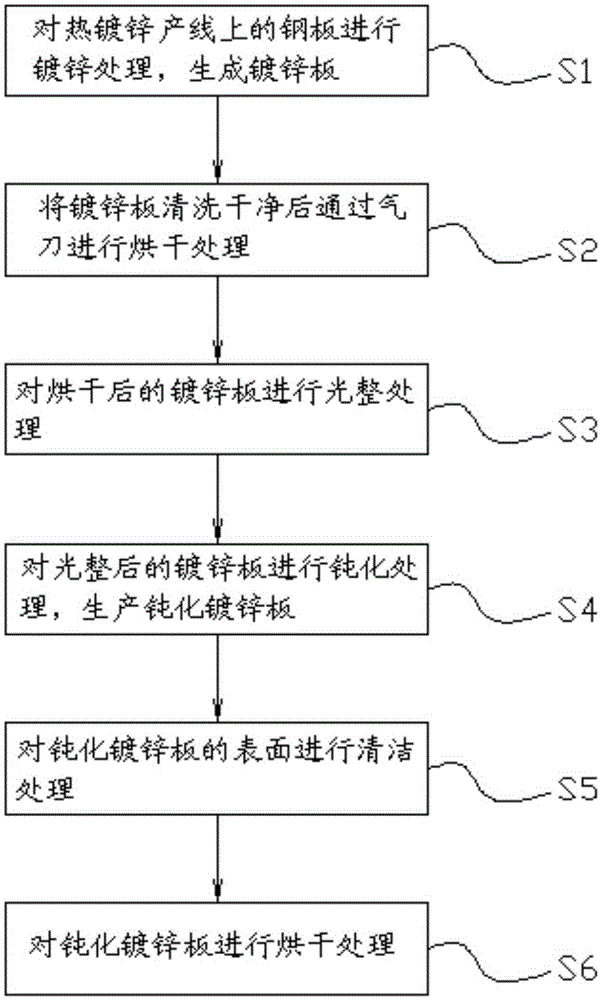

[0036] S1: Galvanize the steel plate on the hot-dip galvanizing line to produce a galvanized sheet.

[0037] S2: After cleaning the galvanized sheet, blow nitrogen gas through an air knife to dry it.

[0038] S3: skin pass treatment is performed on the dried galvanized sheet; wherein, the skin pass treatment is completed by a skin pass machine, and the conductivity of the skin pass solution sprayed out by the skin pass machine is 120 μS.

[0039] S4: Passivate the galvanized sheet after passivation to produce a passivated galvanized sheet; the strip tension during the passivation process is controlled at 15MPa; the pH value of the chromium-free passivation solution is controlled at 3; The temperature of the chemical solution was controlled at 25°C.

[0040] S5: Clean the surface of the passivated galvanized sheet by rinsing with clean water.

[0041] S6: Drying the passivated galvanized sheet; during the drying process, the temperature on the surface of the passivated galvan...

Embodiment 2

[0044] S1: Galvanize the steel plate on the hot-dip galvanizing line to produce a galvanized sheet.

[0045] S2: After cleaning the galvanized sheet, spray air to dry it.

[0046] S3: skin pass treatment is performed on the dried galvanized sheet; wherein, the skin pass treatment is completed by a skin pass machine, and the conductivity of the skin pass solution sprayed out by the skin pass machine is 80 μS.

[0047] S4: Passivate the galvanized sheet after passivation to produce a passivated galvanized sheet; the tension of the strip steel during the passivation treatment is controlled at 30MPa; the pH value of the chrome-free passivation solution is controlled at 3; The temperature of the chemical solution was controlled at 25°C.

[0048] S5: Clean the surface of the passivated galvanized sheet by rinsing with clean water.

[0049] S6: Drying the passivated galvanized sheet; during the drying process, the temperature on the surface of the passivated galvanized sheet is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com