Environment-resistant electromagnetic protection composite conductive rubber and preparation method thereof

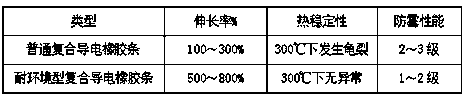

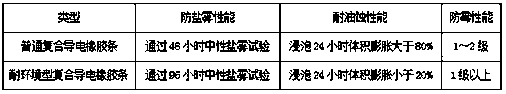

An electromagnetic protection and composite conductive technology, applied in the field of functional composite rubber, can solve problems such as being easily corroded, affecting the electromagnetic sealing and environmental sealing performance of conductive rubber sealing strips, and electrochemical corrosion of conductive rubber, and achieving enhanced mildew resistance and flexibility. properties, enhanced salt spray corrosion resistance, and enhanced thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1. Weigh the raw materials of the conductive part and the non-conductive part respectively according to the formula; the material formula of the conductive part is 100 parts of silicone rubber, 248 parts of glass silver-plated powder, 1.0 parts of carbon nanotube reinforcing agent, 1.2 parts of silane coupling agent, 0.62 parts of hydroxyl silicone oil, 1.31 parts of hydrogen-containing silicone oil as a vulcanizing agent, and 0.62 parts of chloroplatinic acid as a vulcanization accelerator; the material formula of the non-conductive part is 100 parts of silicone rubber, 18 parts of glass microspheres, 0.41 parts of hydroxyl silicone oil, and hydrogen-containing silicone oil as a vulcanizing agent 0.58 parts, 0.52 parts of vulcanization accelerator chloroplatinic acid;

[0030] S2. Add the conductive rubber base material, hydroxy silicone oil and silane coupling agent into the internal mixer for 10-15 minutes of mixing;

[0031] S3. Add glass silver-plated powder and r...

Embodiment 2

[0040] S1. Weigh the raw materials of the conductive part and the non-conductive part respectively according to the formula; the material formula of the conductive part is 100 parts of fluorosilicone rubber, 268 parts of aluminum silver-plated powder, 0.85 parts of graphene oxide, 0.56 parts of hydroxyl silicone oil, and hydrogen-containing vulcanizing agent 1.28 parts of silicone oil, 0.665 parts of vulcanization accelerator; the material formula of the non-conductive part is 100 parts of fluorosilicone rubber, 16 parts of glass microspheres, 3.8 parts of silane coupling agent, 0.42 parts of hydroxyl silicone oil, and 0.58 parts of hydrogen-containing silicone oil as a vulcanizing agent , 0.48 parts of vulcanization accelerator;

[0041] S2. Add the conductive rubber base material, hydroxy silicone oil and silane coupling agent into the internal mixer for 10-15 minutes of mixing;

[0042] S3. Add aluminum silver-plated powder and reinforcing agent to the internal mixer, conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com