Hydrophobic surface coating and preparation method thereof

A surface coating and hydrophobic technology, which is applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problems of cumbersome process and high production cost, and achieve good mechanical properties, high compactness, and heat saving Effect of annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

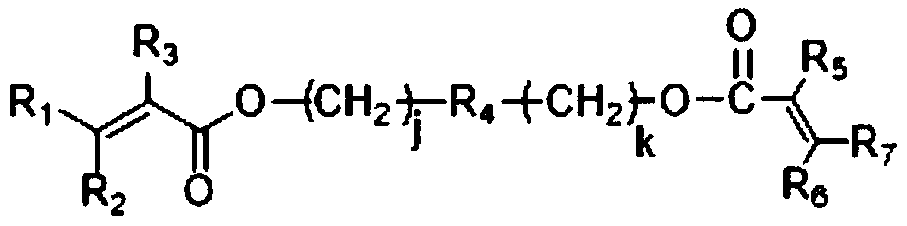

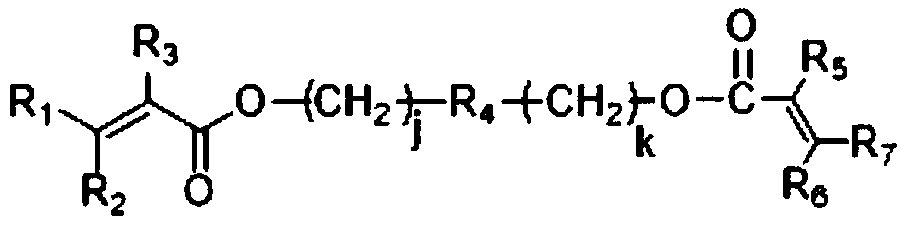

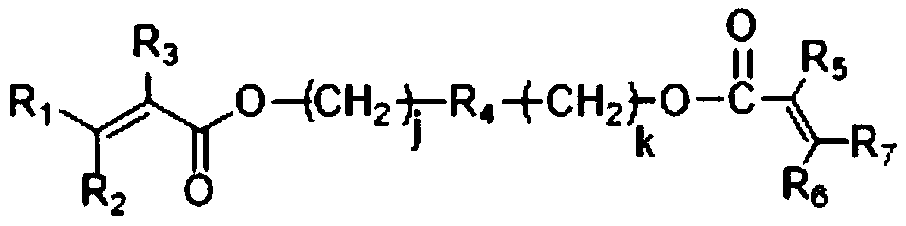

Method used

Image

Examples

Embodiment 1

[0060] A kind of hydrophobic surface coating and preparation method applied to PCB board among the present invention, through following steps:

[0061] Clean the PCB substrate with acetone or isopropanol first, dry it with a dust-free cloth, and then dry it in a drying oven for 24 hours.

[0062] Place the dried PCB board in the 300L plasma vacuum reaction chamber, and continuously evacuate the reaction chamber to make the vacuum degree reach 20 mTorr.

[0063] The plasma ion source gas helium is introduced, the flow rate is 20sccm, and the radio frequency discharge is turned on to pretreat the PCB board. The discharge power in the pretreatment stage is 120W, and the discharge time is 100s.

[0064] The reaction gas raw material perfluorohexyl alcohol is vaporized and introduced into the reaction chamber, and the hydrophobic surface coating is prepared by chemical vapor deposition on the surface of the substrate. During the coating preparation process, the monomer vapor flow ...

Embodiment 2

[0067] A kind of hydrophobic surface coating and preparation method applied to copper sheet among the present invention, through following steps:

[0068] First clean the copper substrate with acetone or isopropanol, dry it with a dust-free cloth, and then dry it in a drying oven for 24 hours.

[0069] The dried copper sheet is placed in a 500L plasma vacuum reaction chamber, and the reaction chamber is continuously evacuated to make the vacuum degree reach 80 mTorr.

[0070] The plasma ion source gas helium is introduced, the flow rate is 20 sccm, and the microwave plasma discharge is turned on to pretreat the copper sheet. The discharge power in the pretreatment stage is 500W, and the discharge lasts for 600s.

[0071] The reaction gas raw material perfluorobutyl alcohol is vaporized and introduced into the reaction chamber, and the nano-coating is prepared by chemical vapor deposition on the surface of the substrate. During the coating preparation process, the monomer vapo...

Embodiment 3

[0074] A kind of hydrophobic surface coating and preparation method applied to fabrics in the present invention, through the following steps:

[0075] Clean the fabric substrate with acetone or isopropanol first, dry it with a dust-free cloth, and then dry it in a drying oven for 24 hours.

[0076] The dried fabric was placed in a 1000L plasma vacuum reaction chamber, and the reaction chamber was continuously evacuated so that the vacuum degree reached 80 mTorr.

[0077] The plasma ion source gas helium is introduced, the flow rate is 40sccm, and the radio frequency discharge is turned on to pretreat the fabric. The discharge power in the pretreatment stage is 50W, and the discharge time is 300s.

[0078] First pass 1,2-epoxy-4-vinylcyclohexane (crosslinking agent), the flow rate is 320μL / min, and the passage time is 2000s; after the end, the reaction gas raw material perfluorohexyl alcohol is vaporized and introduced into the reaction The cavity is used to perform chemical v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com