Patents

Literature

37 results about "ALCOHOL/FLUORIDE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

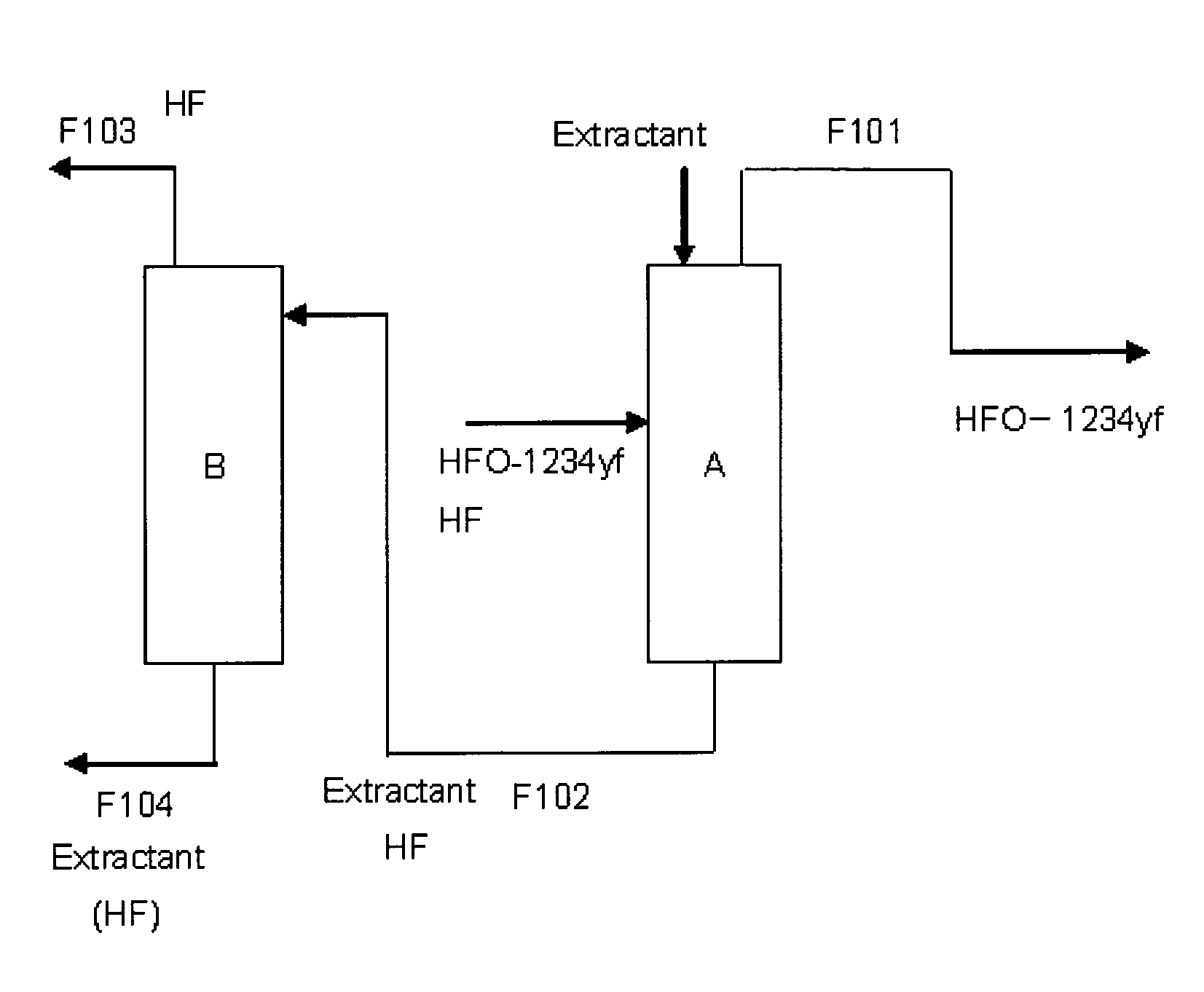

Purification method of 2,3,3,3-tetrafluoropropene

ActiveUS20130105296A1Efficient methodReduce the amount of wasteHydrogen fluorideHalogenated hydrocarbon separation/purificationPurification methodsExtractive distillation

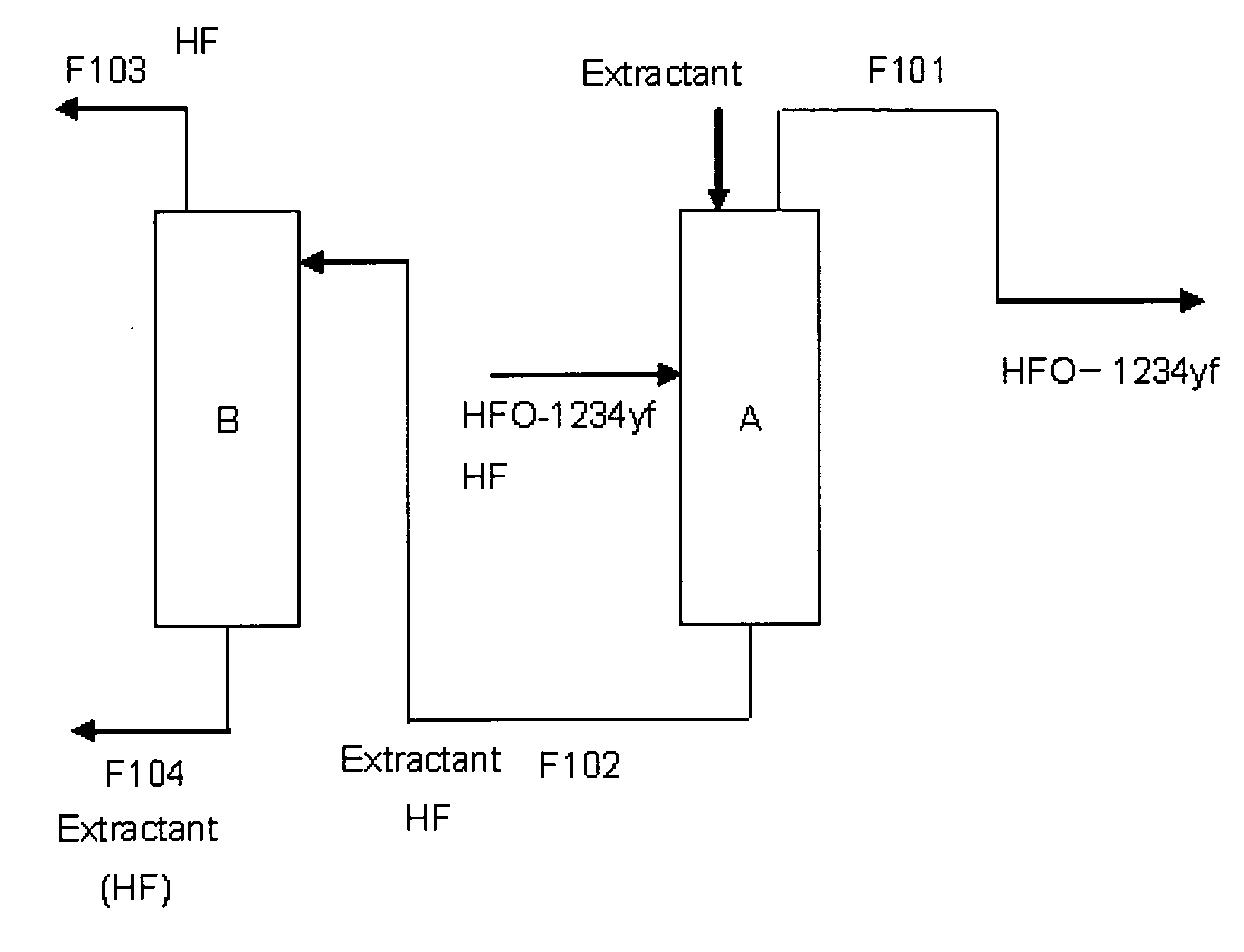

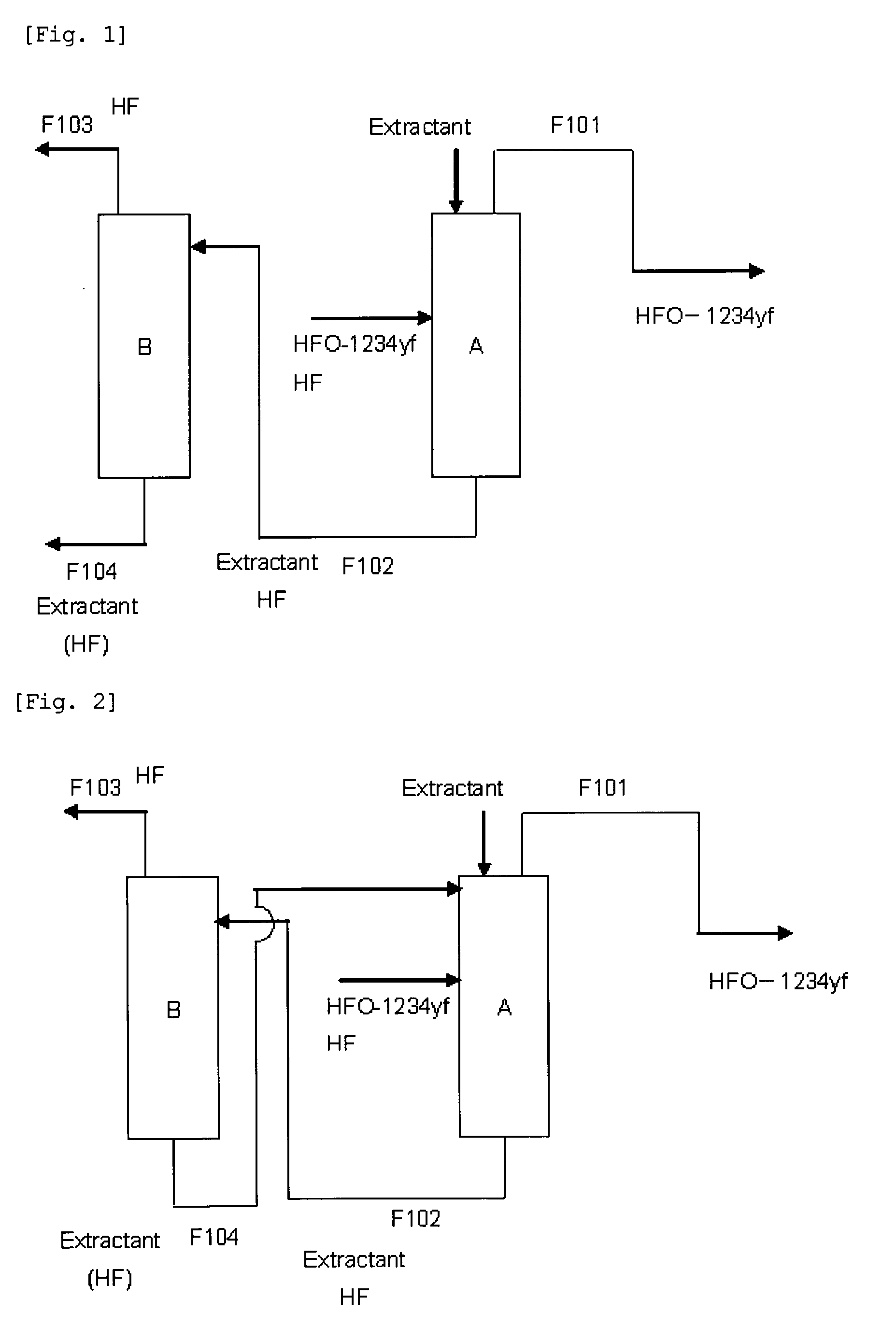

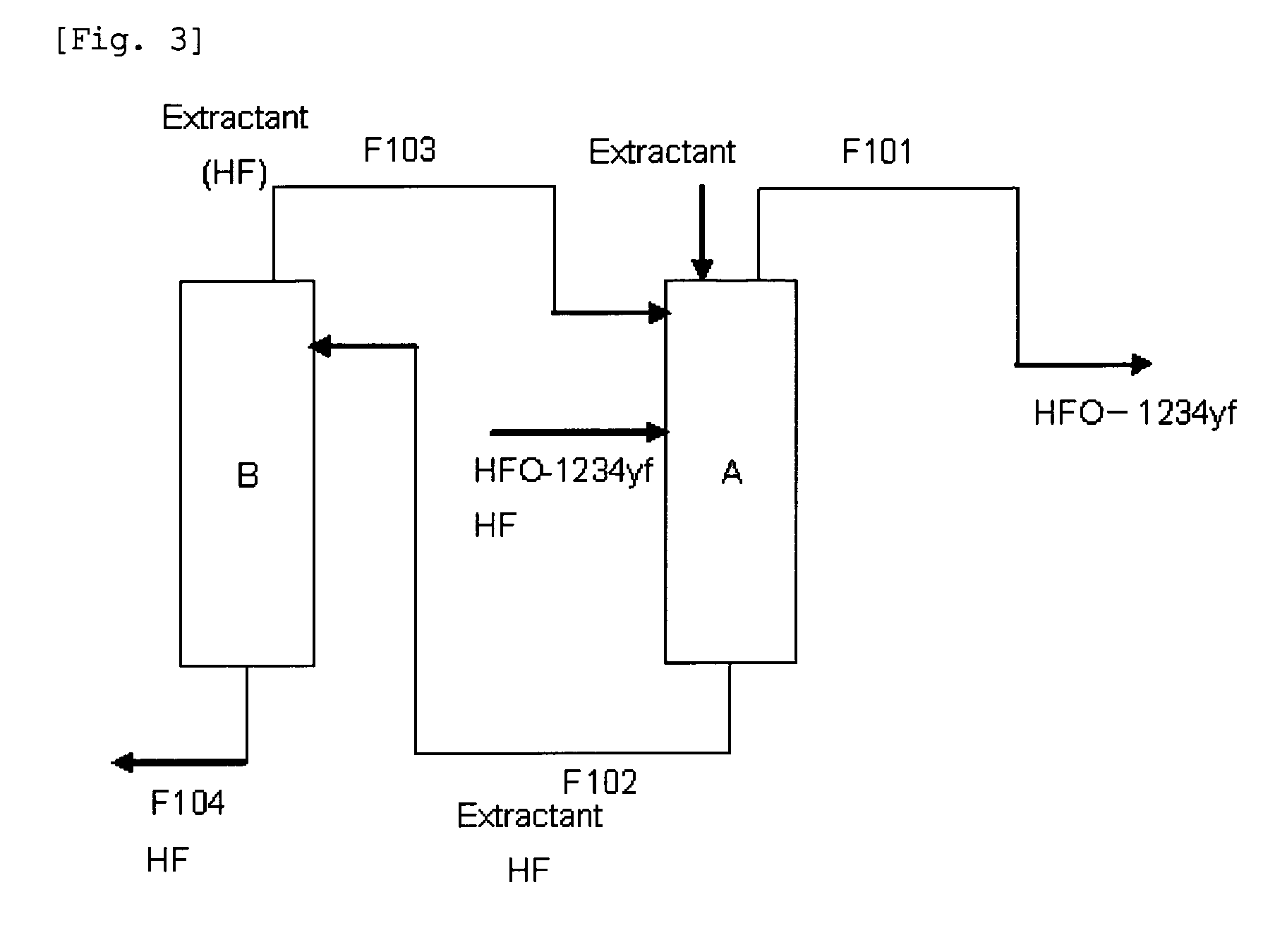

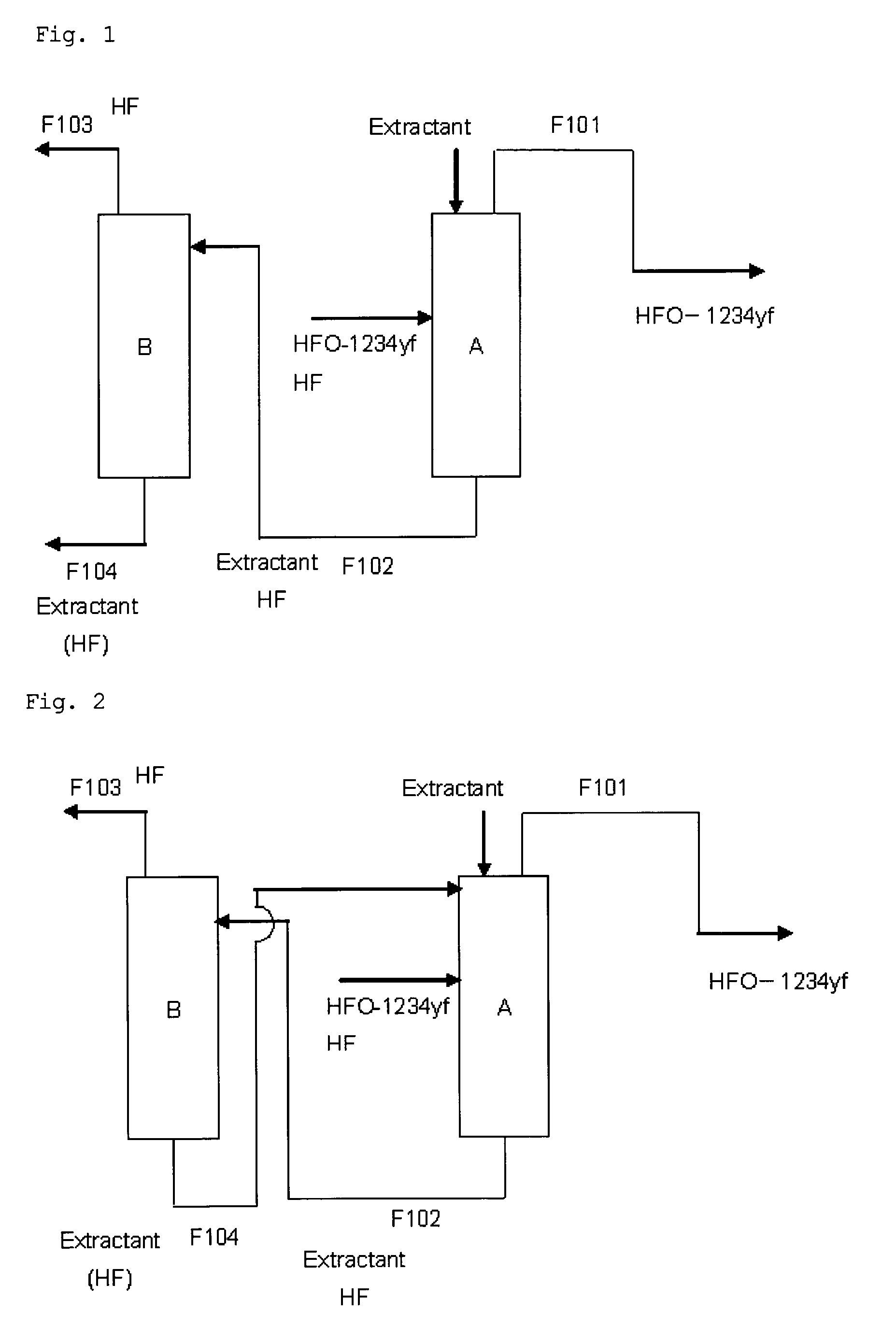

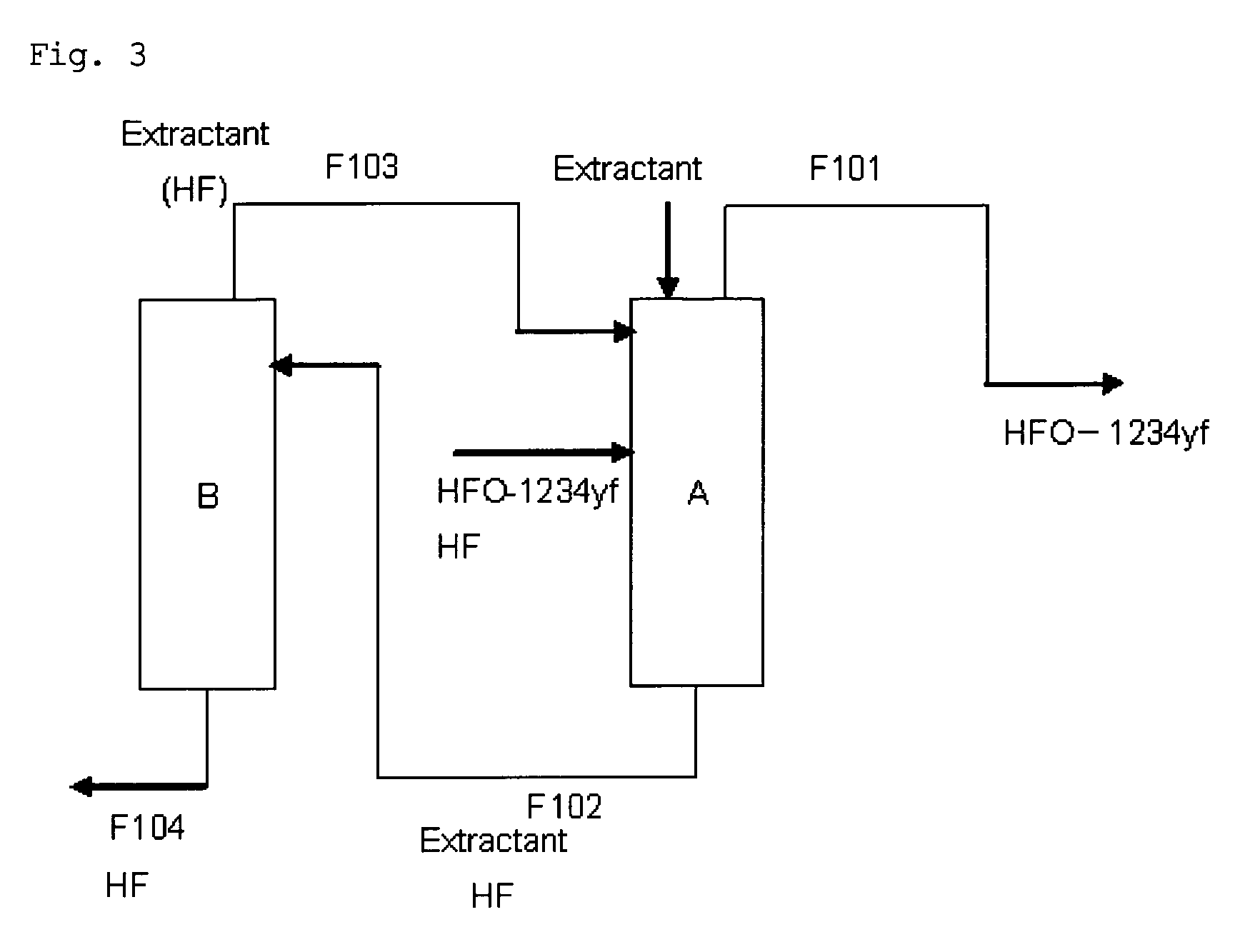

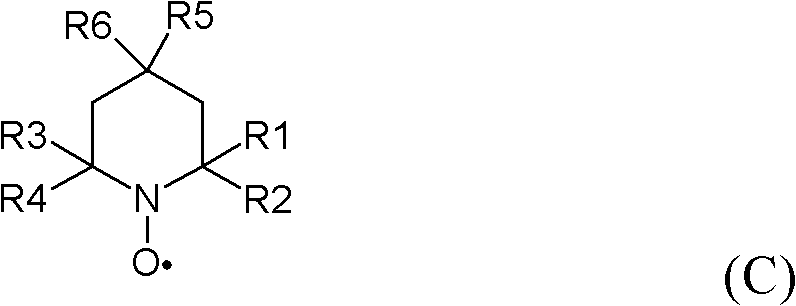

This invention provides a method for purifying HFO-1234yf by removing HF from a mixture of HFO-1234yf and HF under simple and economically advantageous conditions. According to the present invention, this is a purification method for 2,3,3,3-tetrafluoropropene, (1) the purification method comprising the step of subjecting a mixture comprising 2,3,3,3-tetrafluoropropene and hydrogen fluoride to extractive distillation in a distillation column A using an extractant, thereby obtaining a fraction I that contains 2,3,3,3-tetrafluoropropene and has a lower ratio of hydrogen fluoride to 2,3,3,3-tetrafluoropropene than that of the mixture, while obtaining a fraction II that contains hydrogen fluoride and has a lower ratio of 2,3,3,3-tetrafluoropropene to hydrogen fluoride than that of the mixture; (2) the extractant comprising at least one member selected from the group consisting of: (i) alcohols represented by ROH, wherein R is a C1-5 alkyl group, (ii) ethers represented by ROR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (iii) fluorinated alcohols represented by RfOH, wherein Rf is a C1-3 fluoroalkyl group, (iv) ketones represented by RCOR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (v) esters represented by RCOOR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (vi) polyols represented by R(OH)n, wherein R is a C1-4 alkyl group, and n is an integer of 2 to 3, and (vii) ethylene glycols represented by R1O(CH2CH2O)nR2, wherein R1 and R2 are the same or different, and each is hydrogen or a C1-4 alkyl group, and n is an integer of 1 to 3.

Owner:DAIKIN IND LTD

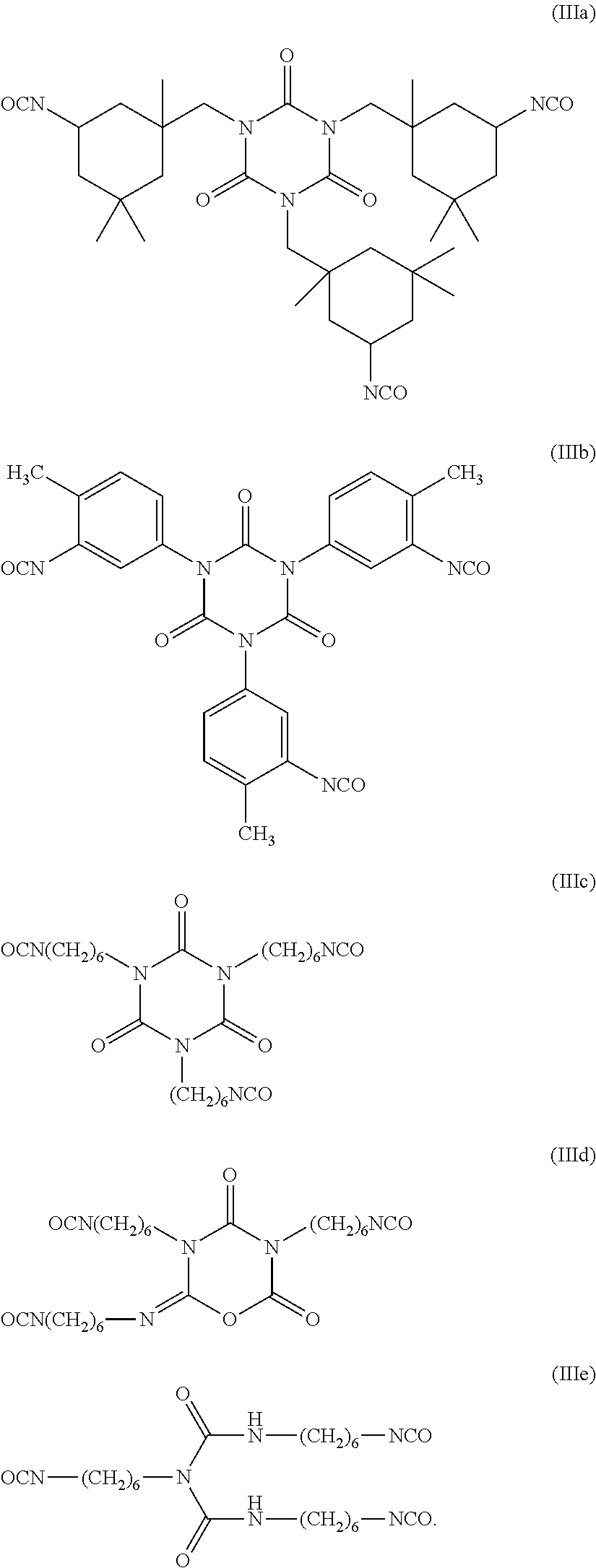

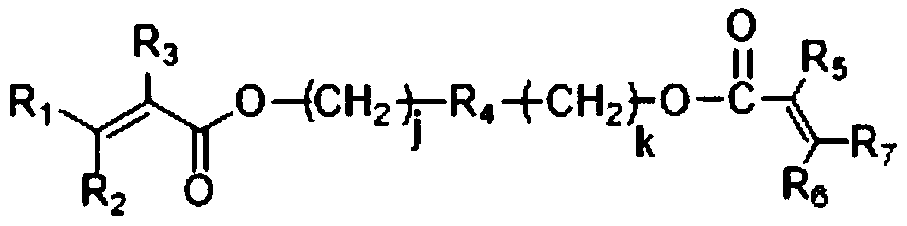

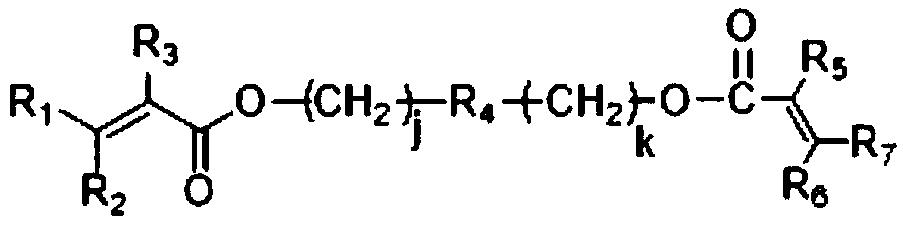

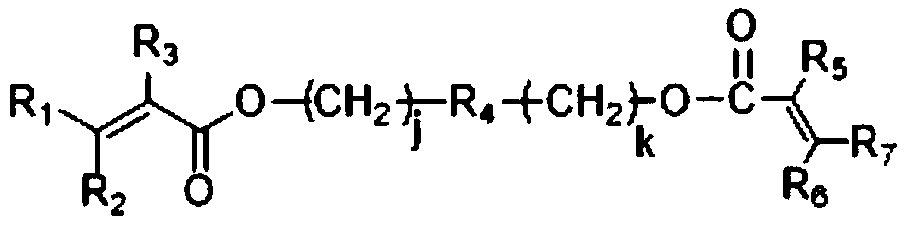

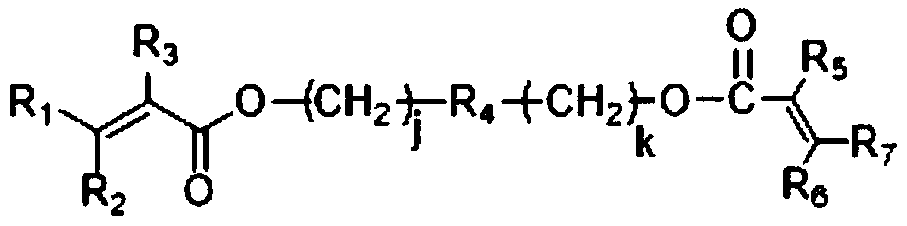

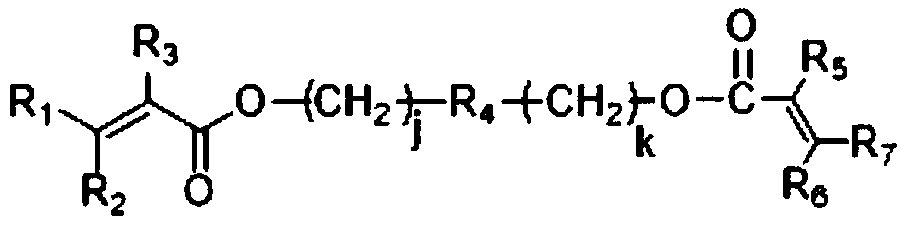

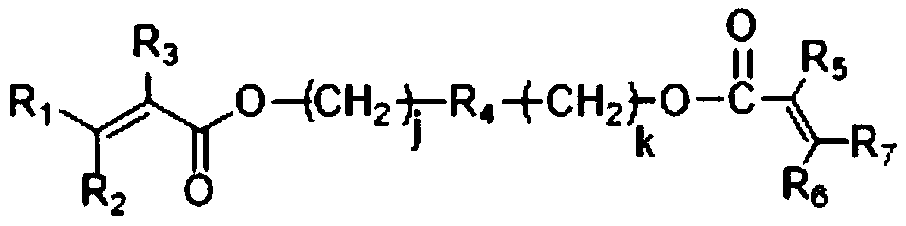

Method of making urethane based fluorinated monomers

Method of preparing urethane based fluorinated monomers comprising (i) reacting a fluorinated alcohol and an isocyanate functional non-fluorinated monomer or (ii) reacting in one or two steps a fluorinated alcohol, a polyisocyanate and an isocyanate reactive non-fluorinated monomer, wherein reactions (i) and (ii) are carried out in the presence of one or more reactive diluents, the reactive diluents having an ethylenically unsaturated group and being free of isocyanate reactive groups. The method does not require an inert organic solvent as a reaction medium, thus excluding volatile organic compounds (VOC's). The resulting compositions can be readily and conveniently used to prepare radiation curable coating compositions without the need to remove organic solvent from the composition.

Owner:3M INNOVATIVE PROPERTIES CO

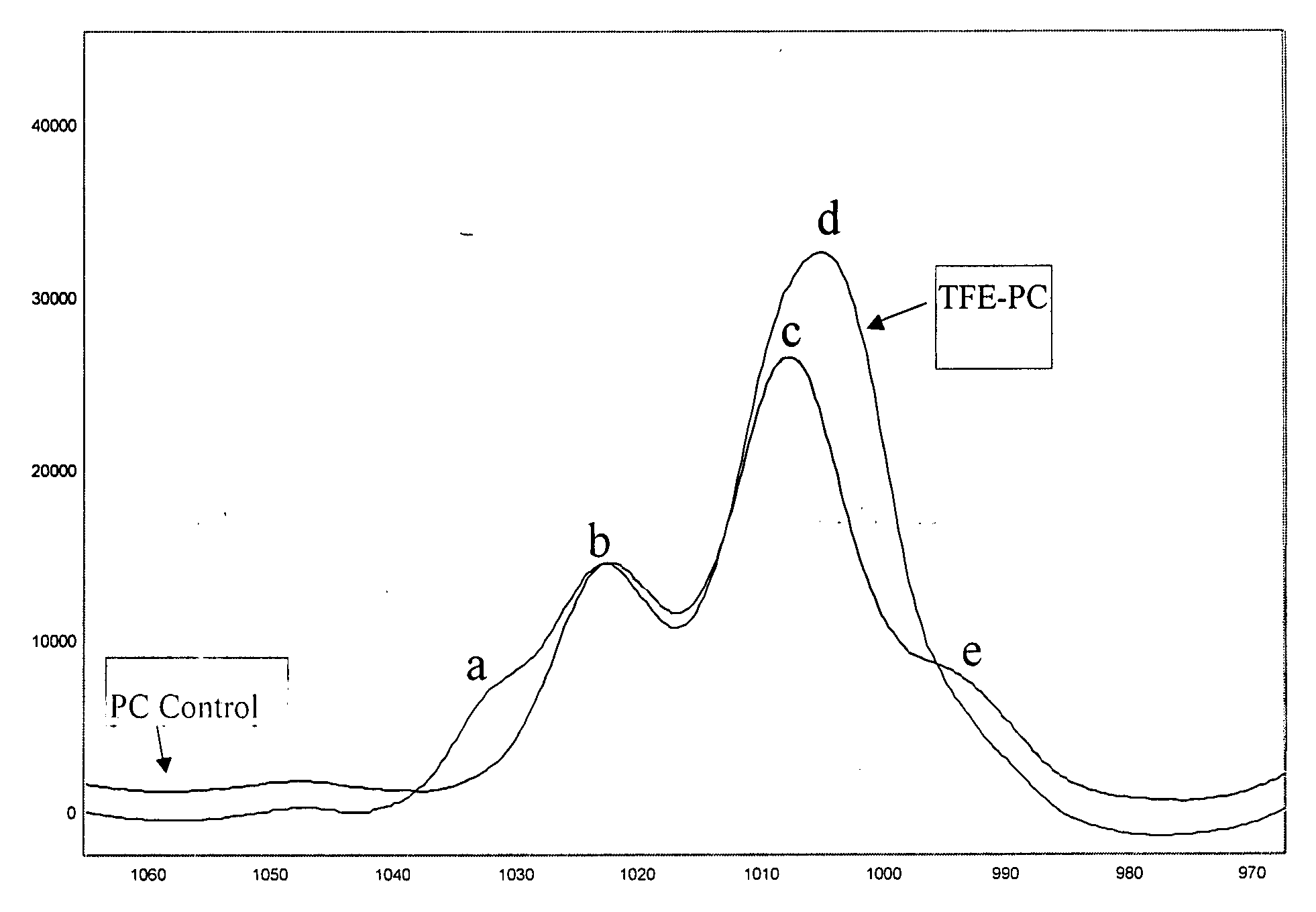

Polycarbonates with fluoroalkylene carbonate end groups

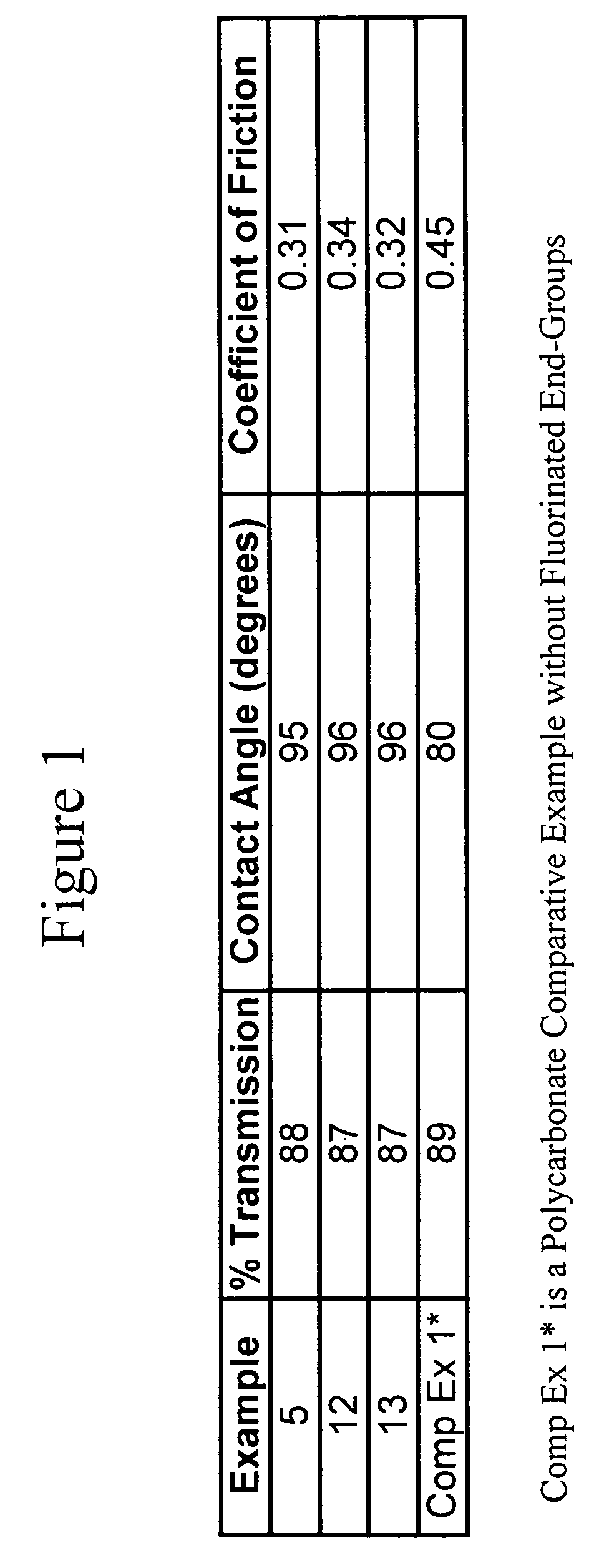

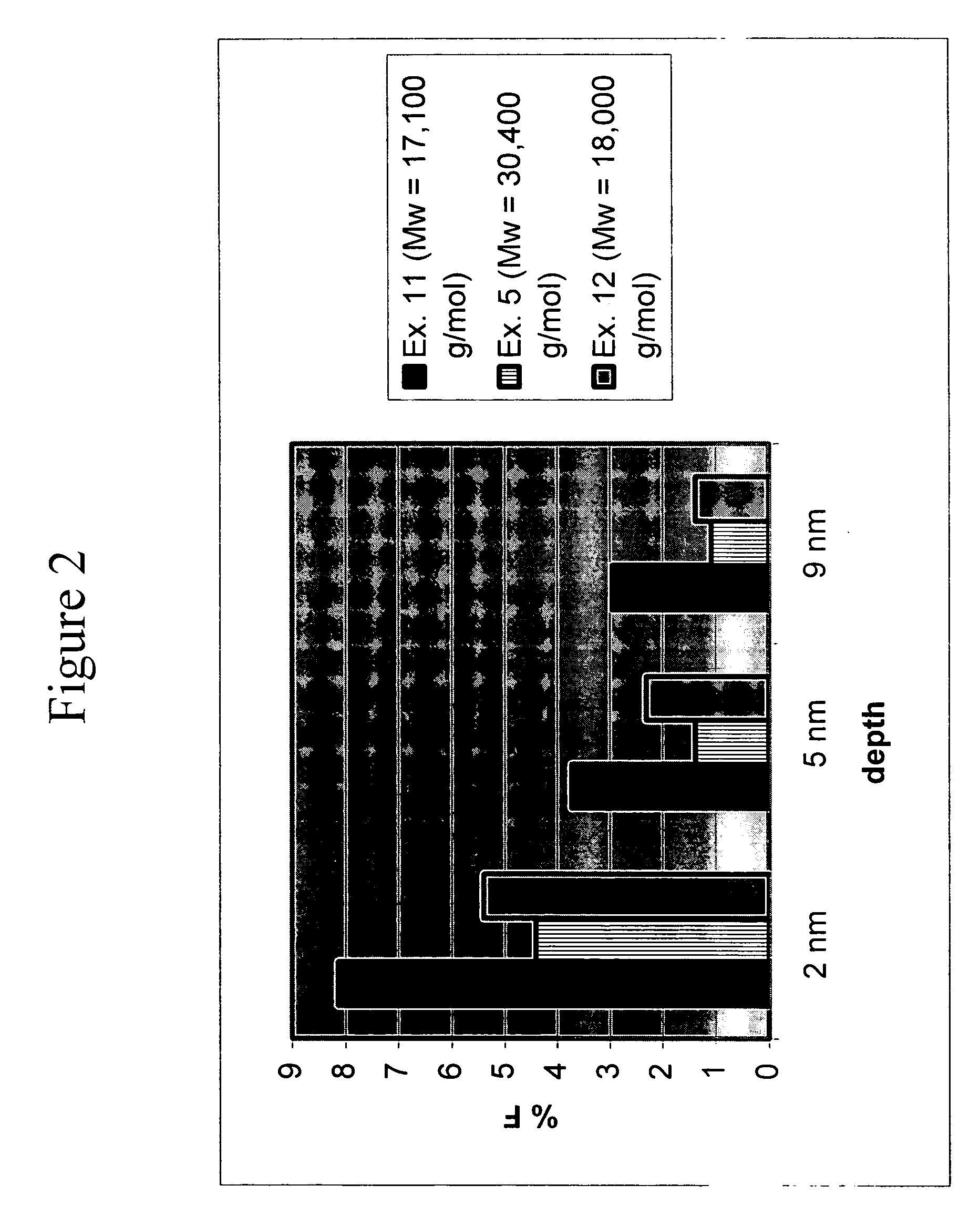

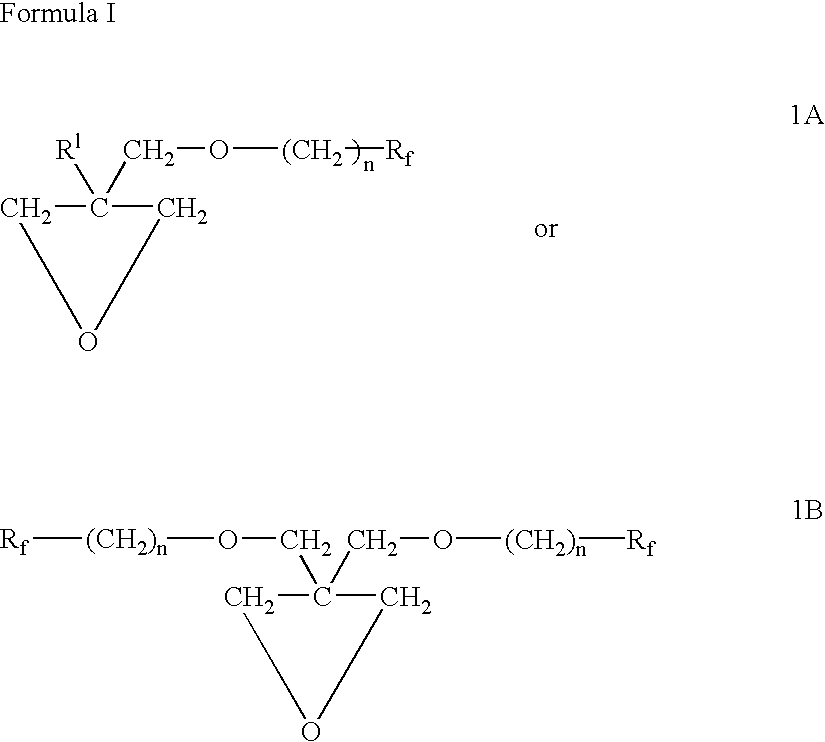

Polycarbonate compositions having an aromatic polycarbonate resin with 90% or greater fluoroalkylene carbonate end-groups are formed from a partially fluorinated alcohol or a partially fluorinated polymeric alcohol, and a bisphenol and a carbonate source using melt or interfacial polymerization methods. Copolymers and blends with a variety of other bisphenols and other thermoplastics are also described. The polycarbonate compositions show high water contact angles, fluorine enrichment on the surface layer of molded articles, and good flame retardant properties and are useful in a variety of applications including medical, automotive, telecommunication and weatherable applications.

Owner:SABIC INNOVATIVE PLASTICS IP BV

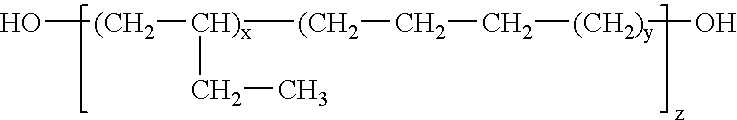

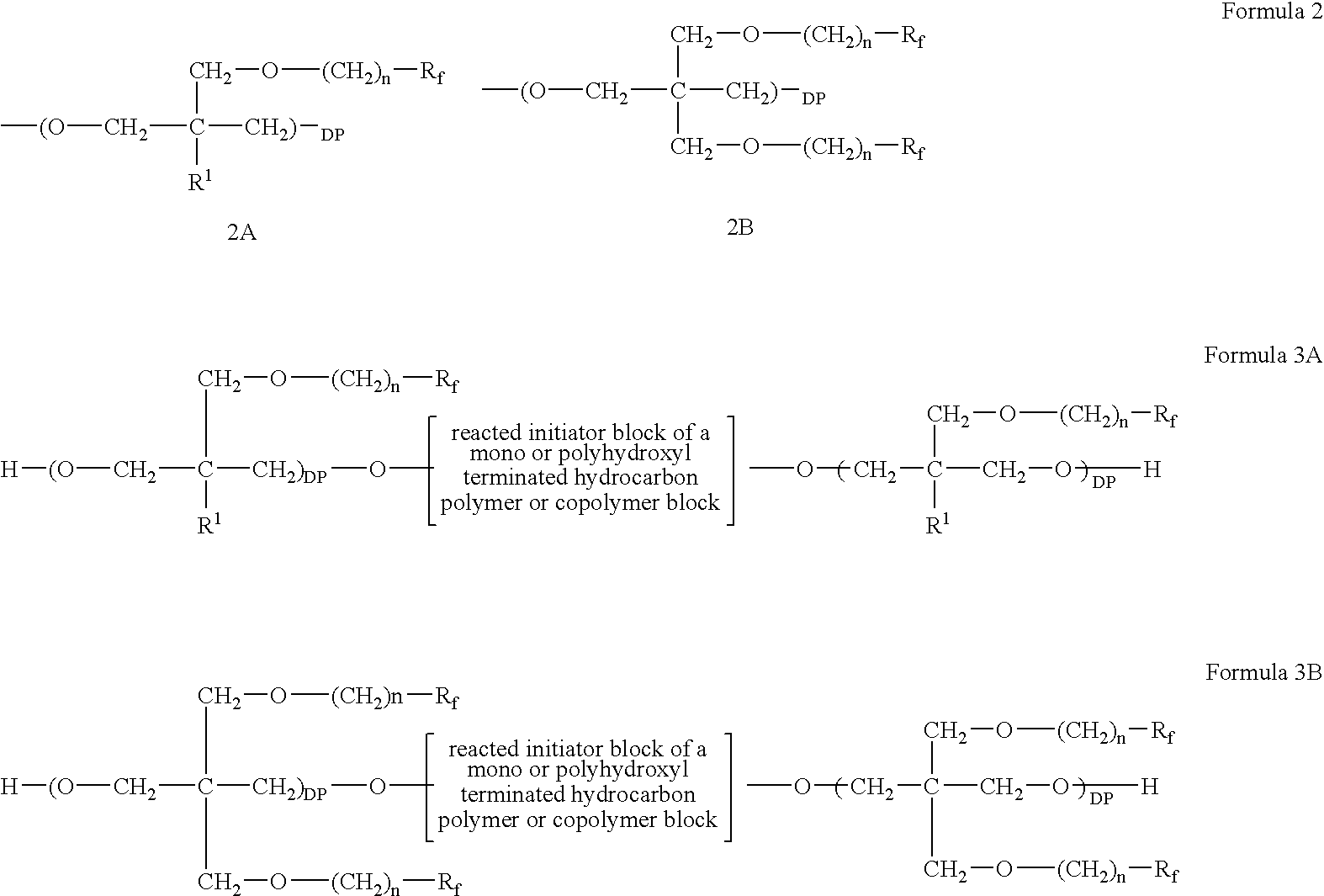

Polymeric blocks of an oxetane oligomer, polymer or copolymer, containing ether side chains terminated by fluorinated aliphatic groups, and hydrocarbon polymers or copolymers

A composition comprises an oxetane oligomer or polymer or copolymer block wherein each repeat group has at least one ether side chain which is terminated by a fluorinated aliphatic group and optionally with the proviso that at least two different repeat units of the oligomer or polymer or copolymer have different Rf groups. The oxetane block is connected to a hydrocarbon polymer block derived from a mono or polyhydroxyl initiator. The terminal fluorinated alkyl groups impart good stain resistance to the oligomer or polymer or copolymer. In another embodiment, a fluorinated aliphatic or alkyl alcohol is reacted with an amino dicarboxylic acid with the reaction product thereof being subsequently grafted to a maleated polyolefin or a maleated polymer derived from a vinyl substituted aromatic monomer. The fluorinated alcohol also imparts good stain resistance to the grafted copolymer. Both compounds can be utilized as an additive in polymers as for example various polyolefins.

Owner:OMNOVA SOLUTIONS INC

Purification of fluorinated alcohols

Owner:THE CHEMOURS CO FC LLC

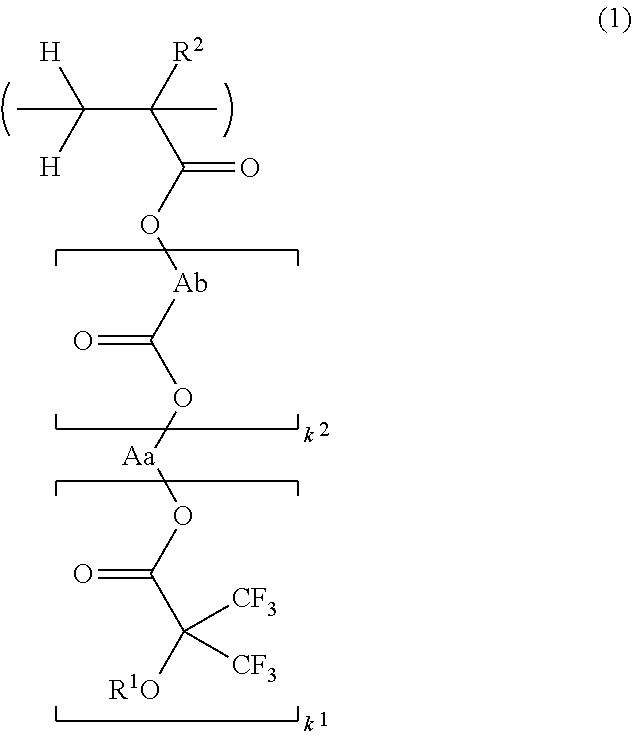

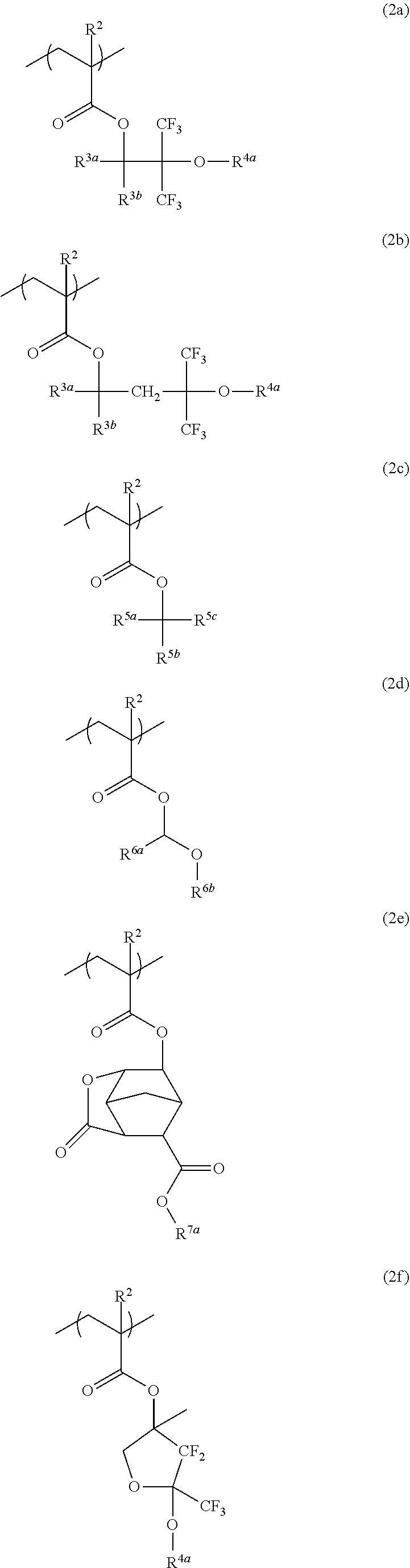

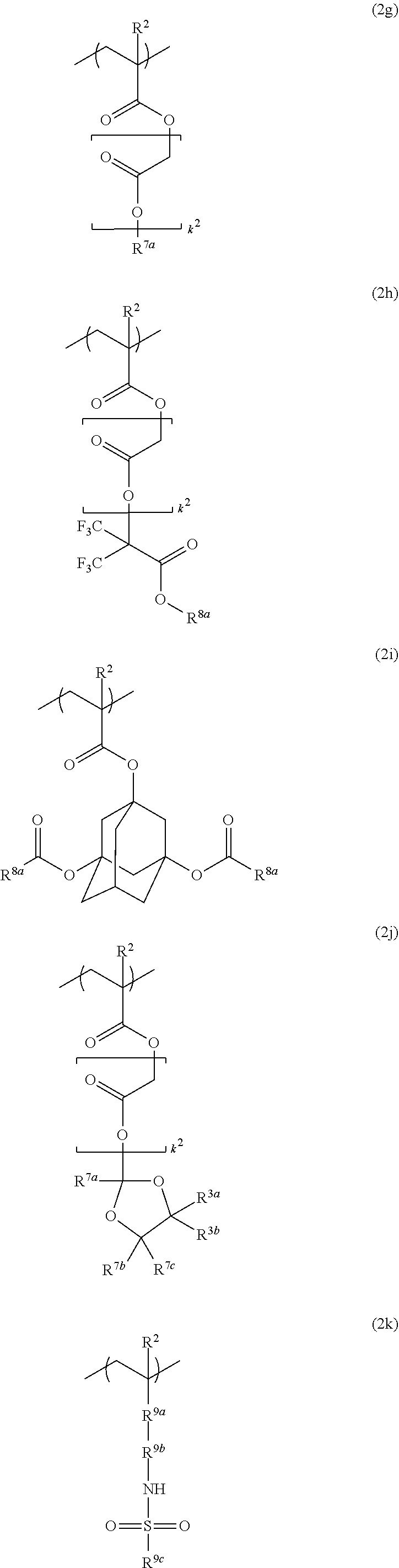

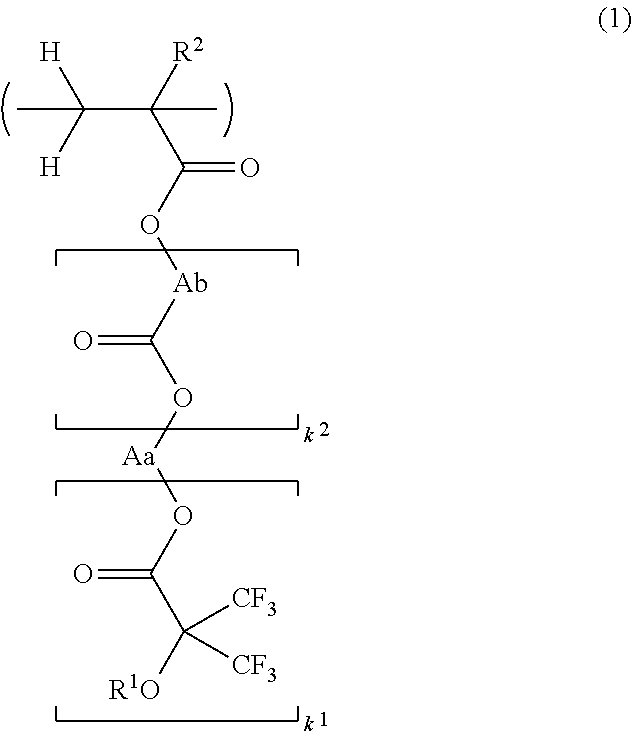

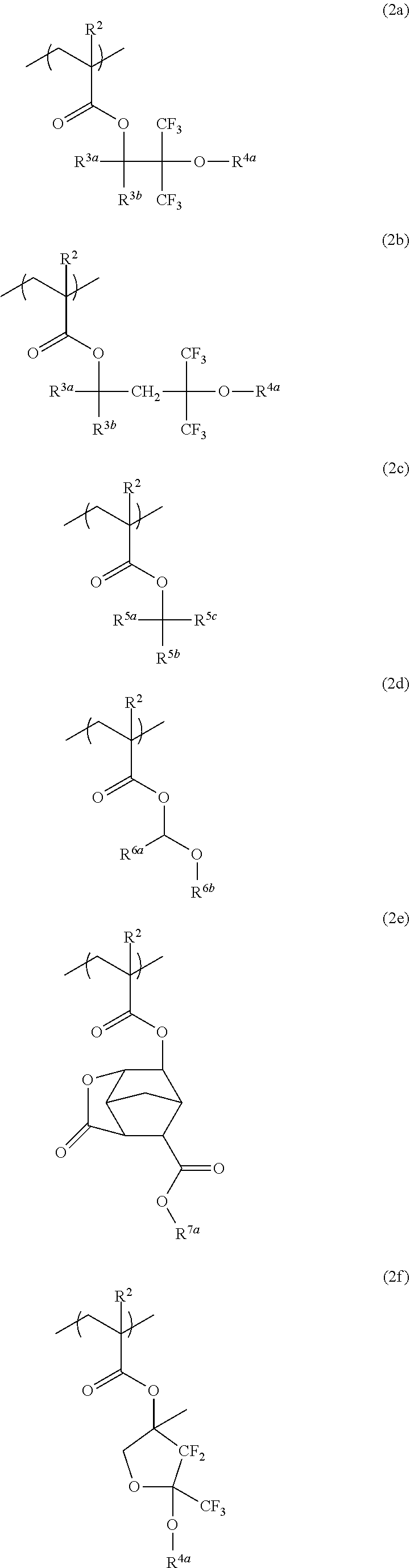

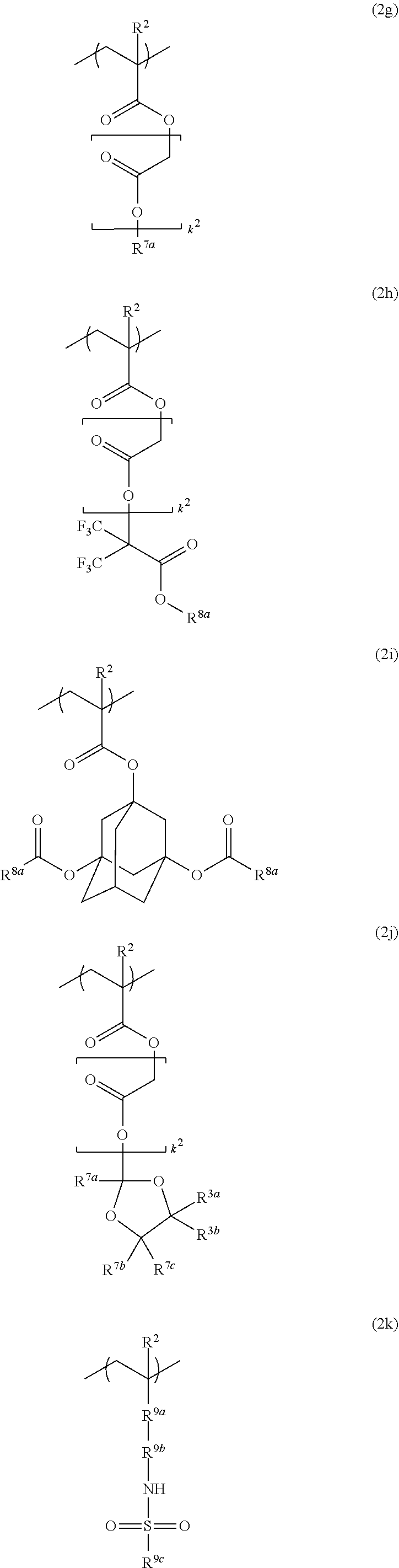

Resist protective film-forming composition and patterning process

ActiveUS20130084517A1Readily availableEasy to handlePhotomechanical exposure apparatusMicrolithography exposure apparatusPolymer scienceAlcohol

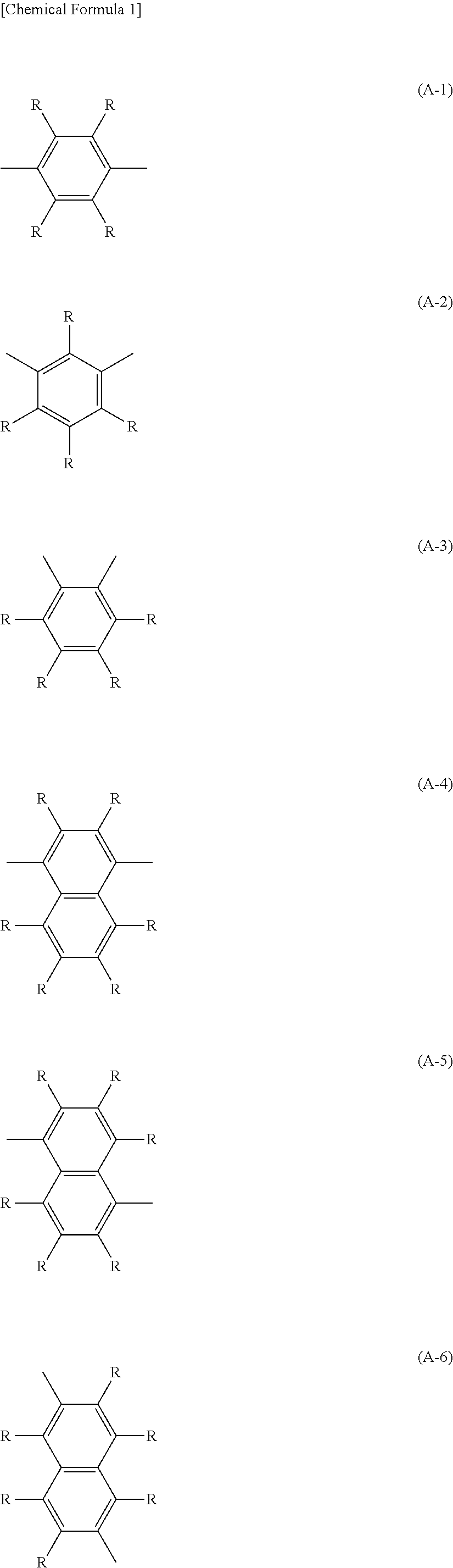

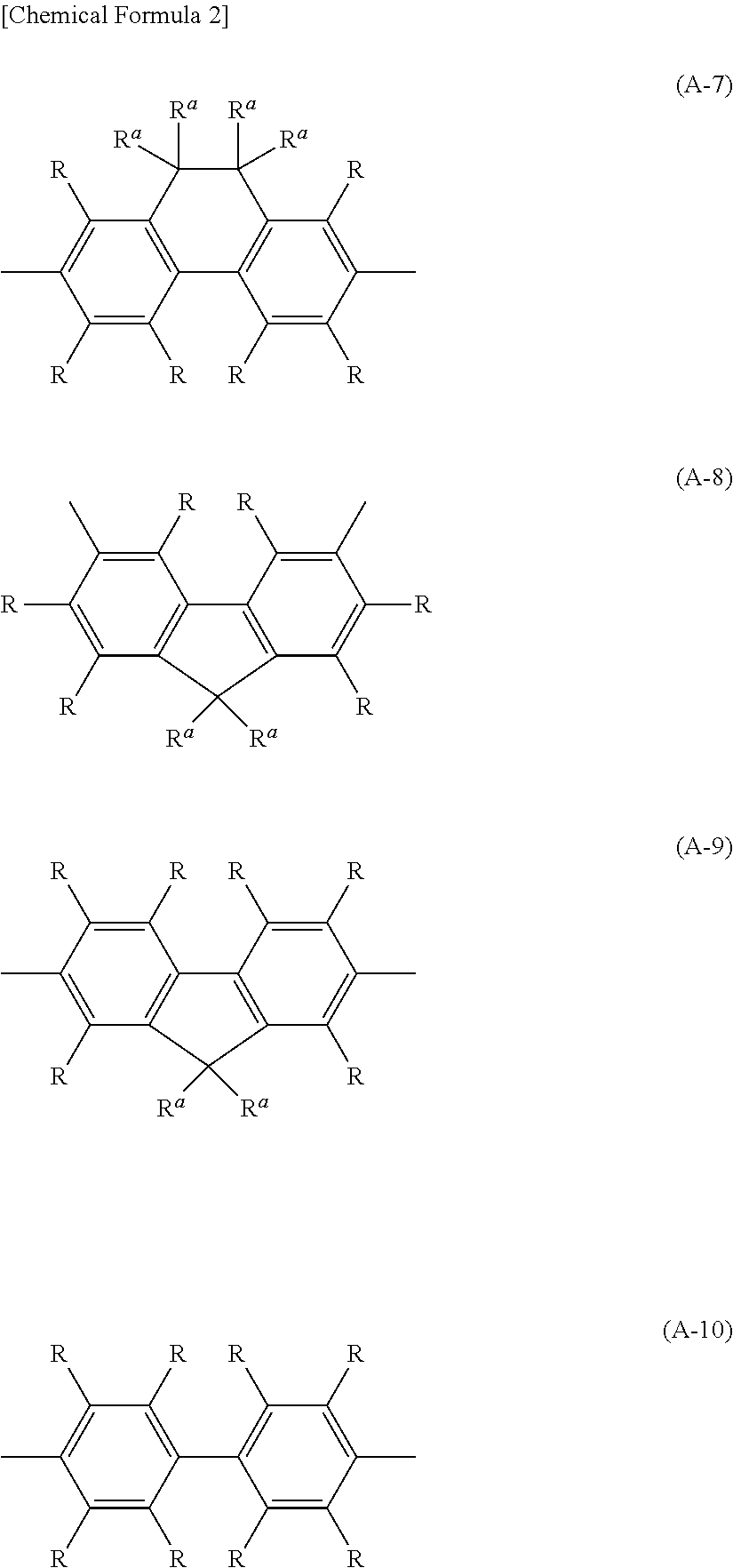

A protective film-forming composition comprising a polymer comprising fluorinated alcohol units of the structure: —C(CF3)2OR1 wherein R1 is H or a monovalent hydrocarbon group and having a Mw of 1,000-500,000 is applied onto a resist film to form a protective film thereon. The protective film-forming composition has high water repellent and water slip performance. The protective film exhibits barrier properties to water and prevents any resist components from being leached out in water.

Owner:SHIN ETSU CHEM IND CO LTD

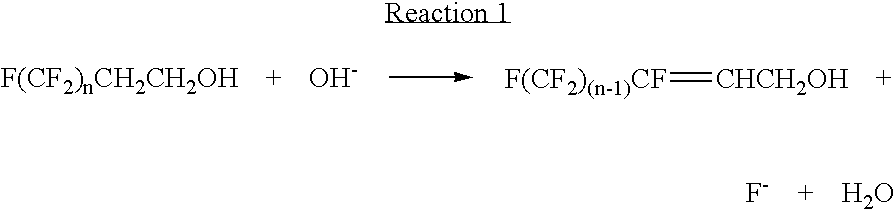

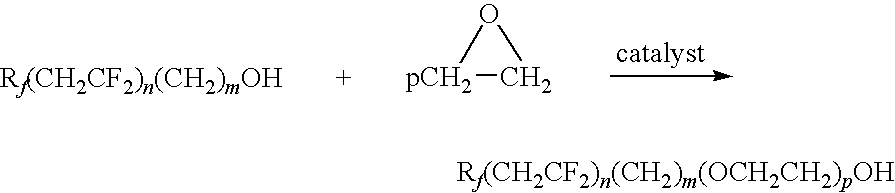

Alkoxylation of fluorinated alcohols

InactiveUS20100280281A1Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholALCOHOL/FLUORIDE

A fluorinated alkylalkoxylate, and a process for its preparation in which at least one fluorinated alcohol is contacted with at least one alkylene epoxide in the presence of a catalyst system comprising an alkali metal borohydride, and an organic quaternary salt.

Owner:EI DU PONT DE NEMOURS & CO

Catalysts for the preparation of fluorinated alcohols and process for the preparation of fluorinated alcohols

InactiveUS6664430B1High yieldLow reaction temperatureMolecular sieve catalystsOrganic compound preparationAlcoholReaction temperature

The present invention provides a catalyst for preparing a fluorine-containing alcohol compound, the catalyst having at least one component selected from elements in Group 1B, Group 2B, Group 6A, Group 7A and Group 8 of the periodic table, ions of these elements, oxides containing these elements, hydroxides containing these elements and salts containing these elements, said component being supported on at least one complex oxide selected from Si-Al complex oxides, Al-P complex oxides and Si-Al-P complex oxides; and a method for preparing a fluorine-containing alcohol compound, the method comprising reacting a halogenated fluorine compound with water in the presence of the catalyst.According to the present invention, a fluorine-containing alcohol compound can be prepared at a relatively low reaction temperature and in a high yield.

Owner:DAIKIN IND LTD

Purification method of 2,3,3,3-tetrafluoropropene

ActiveUS8900417B2Purified more economically and more safelyReduce the amount of wasteHydrogen fluorideHalogenated hydrocarbon separation/purificationPurification methodsExtractive distillation

This invention provides a method for purifying HFO-1234yf by removing HF from a mixture of HFO-1234yf and HF under simple and economically advantageous conditions. According to the present invention, this is a purification method for 2,3,3,3-tetrafluoropropene, (1) the purification method comprising the step of subjecting a mixture comprising 2,3,3,3-tetrafluoropropene and hydrogen fluoride to extractive distillation in a distillation column A using an extractant, thereby obtaining a fraction I that contains 2,3,3,3-tetrafluoropropene and has a lower ratio of hydrogen fluoride to 2,3,3,3-tetrafluoropropene than that of the mixture, while obtaining a fraction II that contains hydrogen fluoride and has a lower ratio of 2,3,3,3-tetrafluoropropene to hydrogen fluoride than that of the mixture; (2) the extractant comprising at least one member selected from the group consisting of: (i) alcohols represented by ROH, wherein R is a C1-5 alkyl group, (ii) ethers represented by ROR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (iii) fluorinated alcohols represented by RfOH, wherein Rf is a C1-3 fluoroalkyl group, (iv) ketones represented by RCOR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (v) esters represented by RCOOR′, wherein R and R′ are the same or different, and each is a C1-4 alkyl group, (vi) polyols represented by R(OH)n, wherein R is a C1-4 alkyl group, and n is an integer of 2 to 3, and (vii) ethylene glycols represented by R1O(CH2CH2O)nR2, wherein R1 and R2 are the same or different, and each is hydrogen or a C1-4 alkyl group, and n is an integer of 1 to 3.

Owner:DAIKIN IND LTD

Methods of preparing fluorinated carboxylic acids and their salts

A method for preparing fluorinated carboxylic acids and theirs salts is described comprising subjecting a fluorinated alcohol of the general formula (A): A-CH2-OH to at least one first and at least one second oxidizing agent to produce a highly fluorinated carboxylic acid or their salts of the general formula (B): A-COO M+, wherein M+ represents a cation and wherein A in formulas (A) and (B) is the same and A represents the residue: Rf-[0]p-CX"Y"-[0]m-CX'Y'-[0]n-CXY- wherein Rf represents a fluorinated alkyl residue which may or may not contain one or more catenary oxygen atoms, p, m and n are independently from each other either 1 or O, X, X', X", Y, Y' and Y" are independently from each other H, F, CF3, or C2F5 with the proviso that not all of X, X', X", Y, Y' and Y" are H; or A represents the residue: R-CFX- wherein X and R are independently selected from a hydrogen, a halogen, or an alkyl, alkenyl, cycloalkyl, or aryl residue, which may or may not contain one or more fluorine atoms and which may or may not contain one or more catenary oxygen atoms; wherein said at least one first oxidizing agent is a compound that can be converted, by action of the second oxidizing agent, into a reactive species capable of oxidizing the fluorinated alcohol.

Owner:3M INNOVATIVE PROPERTIES CO

Manufacture of fluorinated alcohols

InactiveUS20050256331A1Group 3/13 element organic compoundsPhosphorus organic compoundsAlcoholSolvent

Present invention relates to a process for the manufacture of fluorinated alcohols as well as borates which are employed in the manufacture of the fluorinated alcohols. Fluorinated alcohols of the formulae HOCHRCF(CF3)CHFCF(CF3)2 and HOCHRCF(CF(CF3)2)CHFCF3, HOCHRCF(CF2CF3)CH(CF3)2 and HOCHRC(CF3)2CHFCF2CF3 are made by heating a mixture of a borate of the formula (RCH2O)3B, wherein R═H or a C1 to C7 alkyl group, with perfluoro-4-methyl-2-pentene or perfluoro-2-methyl-2-pentene and a free-radical initiator to form a mixture of borates, optionally separating the mixture of borates from any reactants, solvents, and by-products; hydrolyzing the mixture of borates to form a hydrolysis product mixture; and separating the alcohols from the hydrolysis product mixture.

Owner:HONEYWELL INT INC

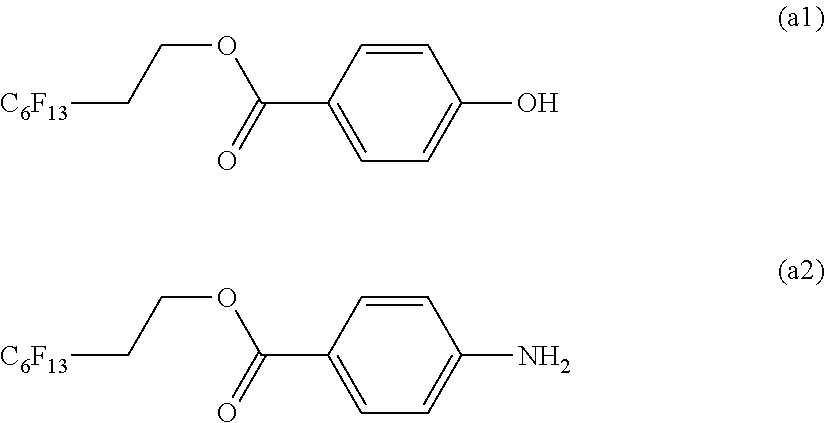

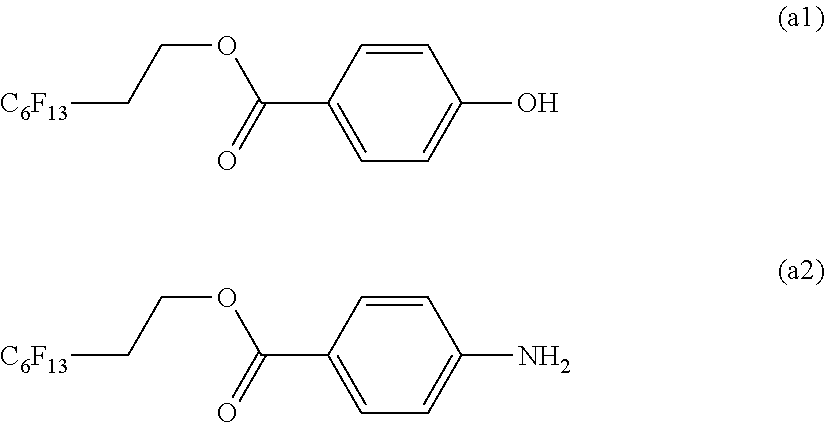

Fluorinated phosphate ester surfactant and fluorinated alcohol compositions

InactiveUS20080311053A1Foam stabilizationHigh organic solvent contentCosmetic preparationsHair cosmeticsOrganic solventPhosphate

Foaming compositions having high solvent content and compositions for foaming high solvent content formulations are disclosed having a fluorinated phosphate ester surfactant (“FPES”) of the formula (Ra—O)x—P(O)—(ORb)y in combination with a fluorinated alcohol (“FA”) of the formula RcOH, where x is 1 to 3, y is (3−x), Ra is a group R1-R2- with R1 being a fluorinated C6-18hydrocarbon optionally interrupted by groups of one or two non-fluorinated (or less fluorinated) carbons per interruption, and / or optionally interrupted by heteroatoms or functional groups, and Rb is selected from H and positively charged amines, and Rc is the same or different as Ra and if different is selected from the same group of Ra materials as well as from analogous groups to Ra except that they have only 1-3 carbons in the R1 portion of Ra instead of the Ra requirement of at least 4 carbons. The ratio of FA to FPES is at least 5% FA to not more than 95% FPES based on the total FA+FPES weight. The compositions are especially useful for foaming high organic solvent content (>20% by weight solvent) with the solvent being selected from lower aliphatic alcohol, C5-6cyclic saturated or unsaturated alcohols, lower alkyl-C(O)-lower alkyl, lower alkyl-O—C(O)-lower alkyl, lower alkylene glycols, and lower alkylene glycol-mono lower alkyl ethers.

Owner:MASON CHEM

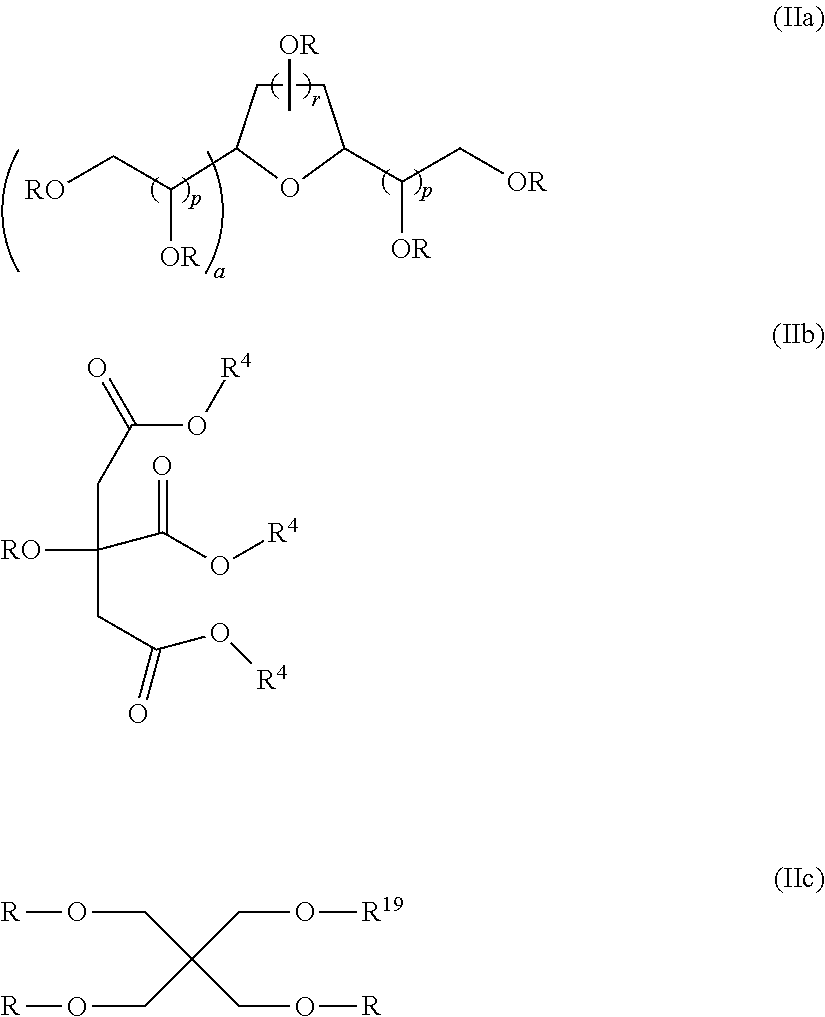

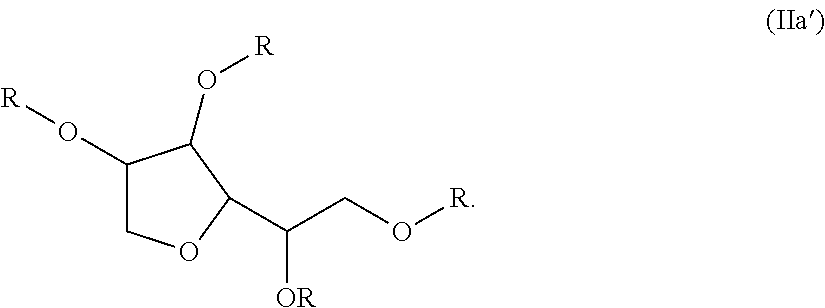

Sulfonated fluorinated, non-fluorinated or partially fluorinated urethanes

The invention relates to a compound prepared by (i) reacting (a) at least one compound selected from diisocyanate, polyisocyanate, or mixture thereof; (b) at least one isocyanate-reactive compound selected from a fluorinated alcohol; a cyclic or acyclic sugar alcohol which is substituted with at least one —R1, —C(O)R1, −(CH2CH2O)n(CH(CH3)CH2O)mR2, —(CH2CH2O)n(CH(CH3)CH2O)mC(O)R1, or mixtures thereof; or mixtures of a fluorinated alcohol and a substituted cyclic or acyclic sugar alcohol; and (c) at least one isocyanate-reactive ethylenically unsaturated compound; wherein each n is independently 0 to 20; each m is independently 0 to 20; m+n is greater than 0; each R1 is independently a linear or branched alkyl group having 5 to 29 carbons optionally comprising at least 1 unsaturated bond; each R2 is independently —H, or a linear or branched alkyl group having 6 to 30 carbons optionally comprising at least 1 unsaturated bond, or mixtures thereof; and (ii) reacting the reaction product of step (i) with a bisulfate source.

Owner:THE CHEMOURS CO FC LLC

Process for producing a fluorinated alcohol

InactiveCN1449366AHigh purityWon't mix inOrganic compound preparationHydroxy compound preparationAlcoholHexafluoropropylene

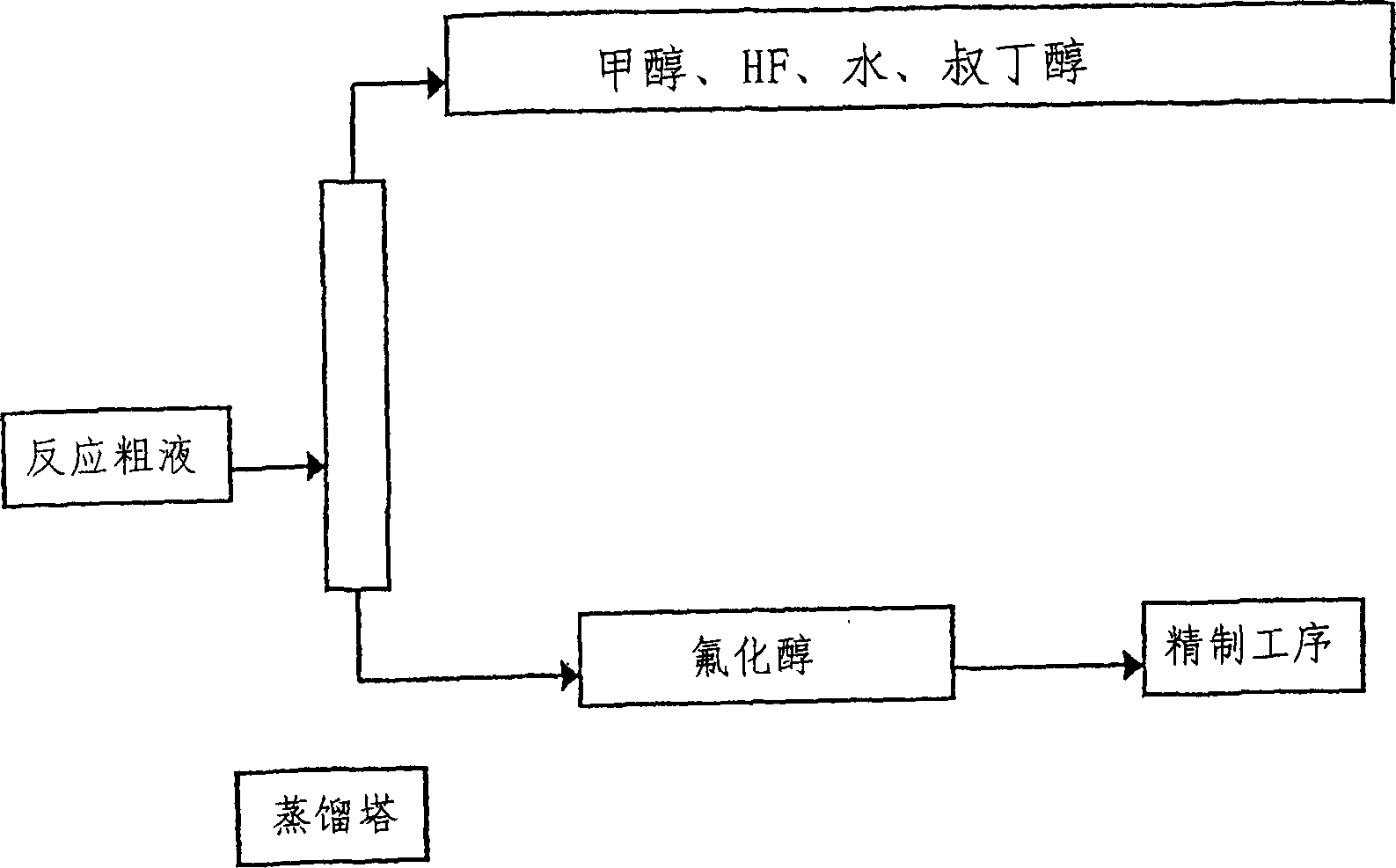

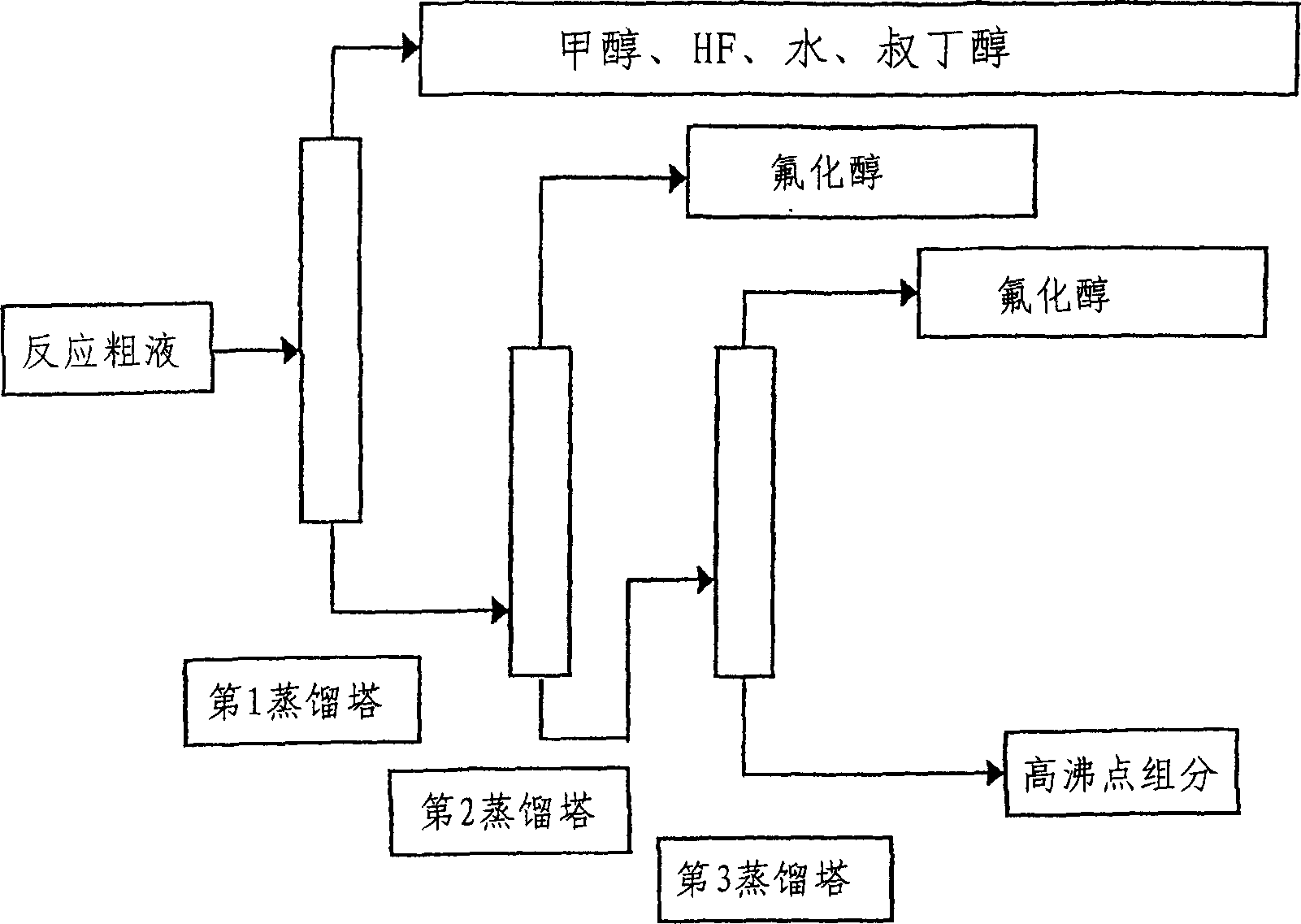

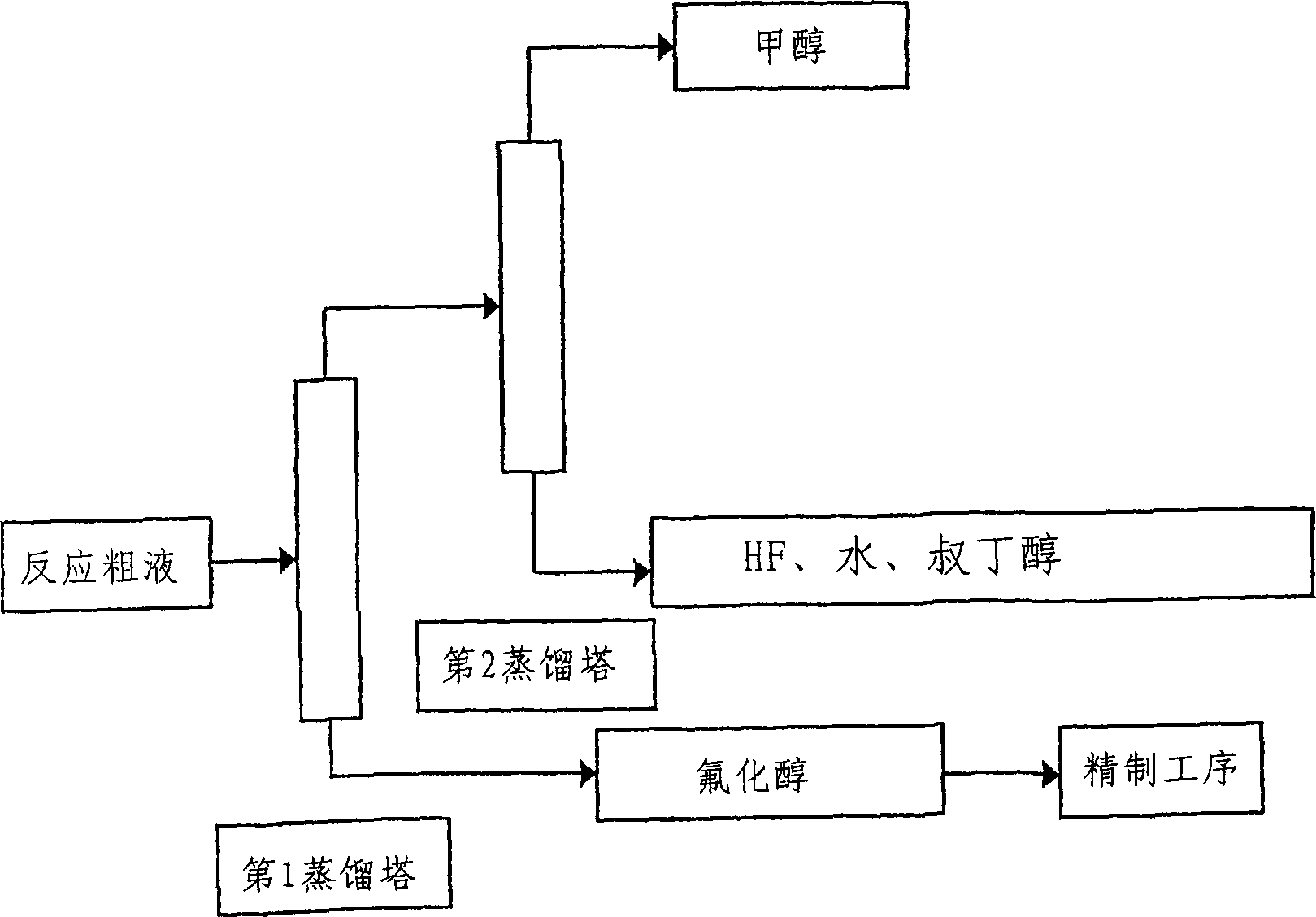

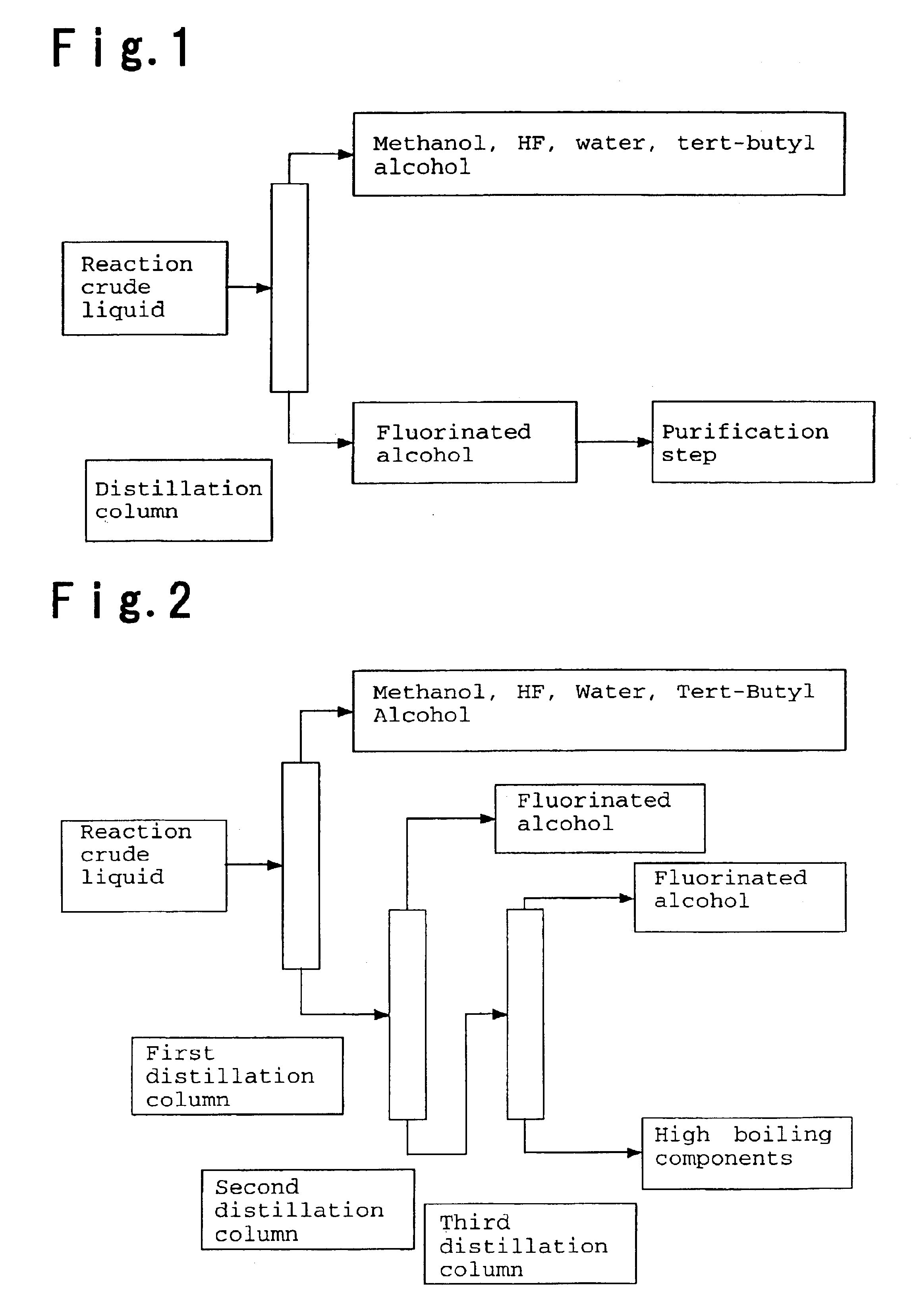

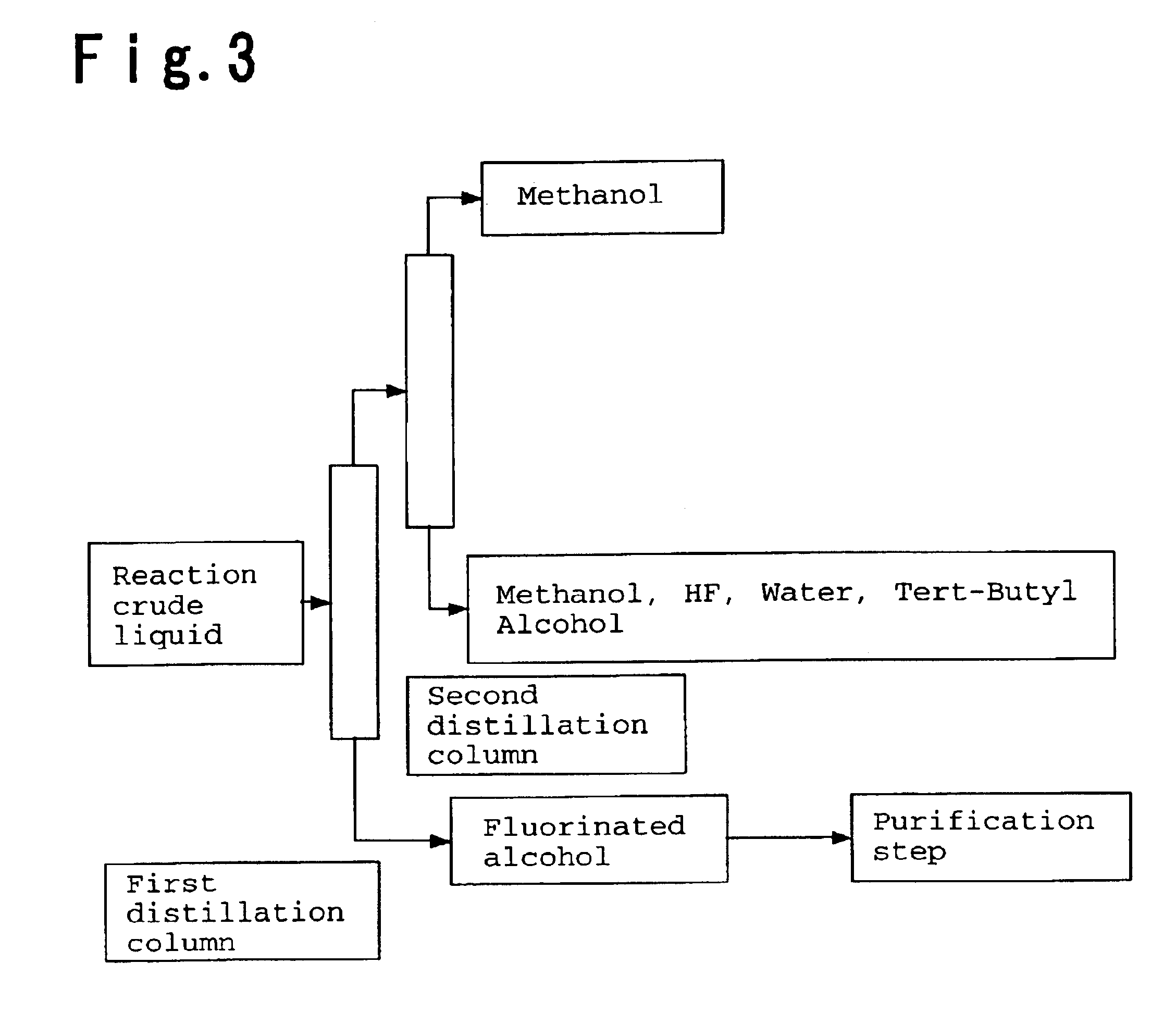

A process for producing a high-purity fluorinated alcohol in a satisfactory purification yield. The process comprises reacting methanol with tetrafluoroethylene or hexafluoropropylene in the presence of an alkyl peroxide to produce a fluorinated alcohol, wherein the liquid reaction mixture obtained after completion of the reaction is distilled in the presence of both water and HF to separate the mixture into a fraction containing an alcohol derived from the peroxide and a bottom containing the fluorinated alcohol and the bottom is purified to recover the fluorinated alcohol.

Owner:ASAHI GLASS CO LTD

Hydrophobic surface coating and preparation method thereof

The invention provides a hydrophobic surface coating and a preparation method thereof. The hydrophobic surface coating is formed by taking one or more fluorinated alcohol compounds as reaction gas rawmaterials on the surface of a base body through a plasma enhanced chemical vapor deposition method, the fluorinated alcohol compounds have the structural formula of OH-C<n>H<m>F<2n + 1-m>, wherein n>m+1, so that the hydrophobic performance of the surface of the base body is improved, and the hydrophobic surface coating is more suitable for a glass substrate.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Hydrophobic surface coating and preparation method thereof

ActiveCN111303673AImprove compactnessImprove mechanical propertiesPhysical treatmentVacuum evaporation coatingAlcoholWeather resistance

The invention provides a hydrophobic surface coating and a preparation method thereof, and the hydrophobic surface coating is formed on the surface of a substrate through a plasma enhanced chemical vapor deposition method by taking one or more fluorinated alcohol compounds as reaction gas raw materials, so as to improve the hydrophobicity, chemical corrosion resistance and weather resistance of the surface of the substrate.

Owner:JIANGSU FAVORED NANOTECHNOLOGY CO LTD

Purification of fluorinated alcohols

ActiveUS20060100464A1Lower Level RequirementsOrganic compound preparationHydroxy compound preparationAlcoholIodide

A process for reducing the level of perfluoroalkanoic acids, perfluoroalkanoic esters, and perfluoroalkyliodides in fluorinated alcohols comprising heating a fluorinated alcohol, or mixtures thereof, containing said acids, esters, or iodides to a temperature of at least 175° C. in the presence of water and a base additive is disclosed.

Owner:THE CHEMOURS CO FC LLC

Compositions for drying solid surfaces

A drying composition according to the invention is composed of a solution of a surface-active agent in a mixture of a fluorinated hydrocarbon and of a polyfluorinated alcohol of formula:Rf—(CH2)n—OH (I)in which n is equal to 1 or 2 and Rf represents a linear perfluoroalkyl radical containing from 2 to 8 carbon atoms.

Owner:ELF ATOCHEM SA

Water/oil repellent agent and water/oil repellent composition

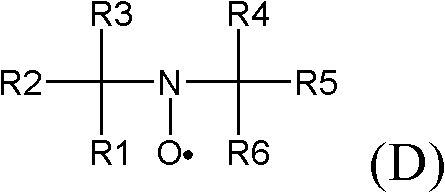

InactiveUS8754183B2Reduce environmental impactSufficient water/oil repellencyUrea derivatives preparationOther chemical processesAlcoholEnvironment effect

To provide a water / oil repellent agent and a water / oil repellent composition which are capable of imparting sufficient water / oil repellency to the surface of an article and which have low environmental impact. One comprising a reaction product obtained by reacting a fluorinated alcohol or amine having a polyfluoroalkyl moiety having at most 6 carbon atoms with a polyisocyanate compound, which is, when applied to an article, capable of imparting sufficient water / oil repellency, while presenting little environmental impact. When applied to an article, the water / oil repellent composition of the present invention is capable of imparting a high quality water / oil repellency to the article.

Owner:ASAHI GLASS CO LTD

Process for producing a fluorinated alcohol

InactiveUS6894196B2High yieldOrganic compound preparationHydroxy compound preparationAlcoholHexafluoropropylene

A process for producing a high-purity fluorinated alcohol in a good purification yield, is provided.In a process for producing a fluorinated alcohol, which comprises reacting methanol with tetrafluoroethylene or hexafluoropropylene in the presence of an alkyl peroxide, the reaction liquid after completion of the reaction is distilled in the presence of water and HF to separate it into a fraction containing an alcohol derived from the alkyl peroxide and a bottom liquid containing the fluorinated alcohol, and then, the bottom liquid is purified to recover the fluorinated alcohol.

Owner:ASAHI GLASS CO LTD

Method for cleaning chamber of deposition apparatus for organic EL device production

InactiveUS20050155632A1Hollow article cleaningDetergent mixture composition preparationAlcoholCleaning methods

A compound such as Alq3 accumulated on the inner surface of a chamber at the time of organic EL device production and wasted is recovered and recycled, whereby the production cost is reduced. The inner surface of a chamber or the surface of components in the chamber to which a compound such as Alq3 has adhered is cleaned with a fluorinated alcohol such as 2,2,3,3,4,4,5,5-octafluoropentanol to recover Alq3.

Owner:ASAHI GLASS CO LTD

Process for producing fluorinated alcohol

InactiveUS6894197B2Minimizes undesirable side reactionImprove production yieldOrganic compound preparationGroup 5/15 element organic compoundsHydroxybutyric acidSolvent

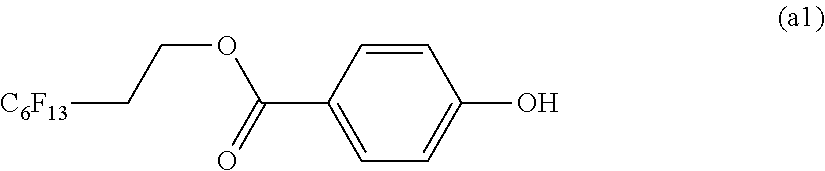

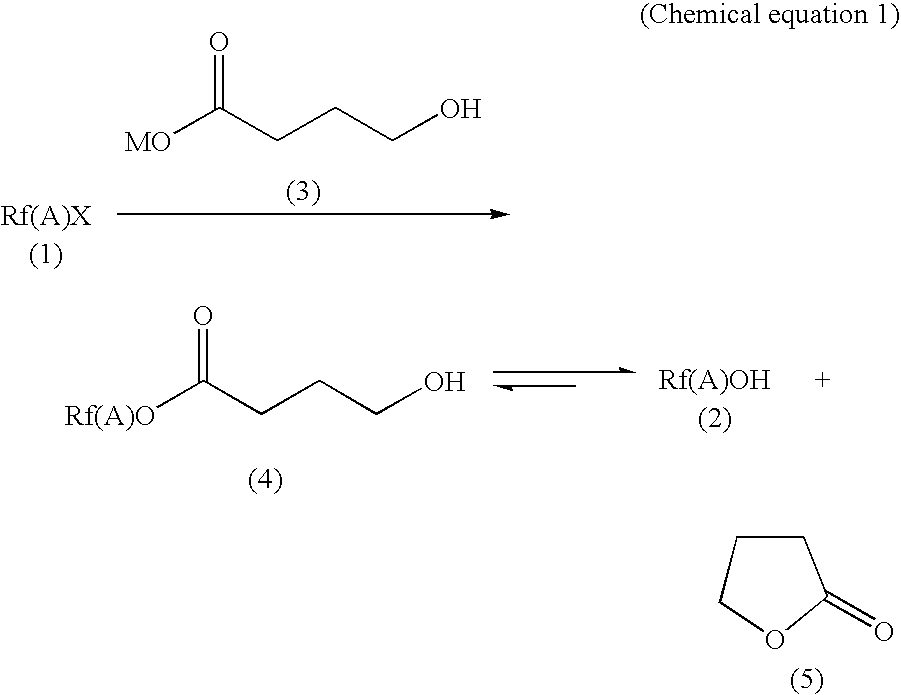

A method for producing fluorinated alcohols from fluorinated alkyl halides can produce fluorinated alcohols at high product yield and at high selectivity in a single-step reaction. The method eliminates the need to use heavy metals and other toxic compounds that are difficult to handle or process.Specifically, the method produces a fluorinated alcohol represented by the following general formula (2):Rf(A)OH (2)wherein Rf represents a perfluoroalkyl group having 1 to 10 carbon atoms; and A represents a straight-chained or branched saturated hydrocarbon group having 3 to 10 carbon atoms. The method is characterized in that it allows a fluorinated alkyl halide represented by the following general formula (1) to react with an alkali metal salt of 4-hydroxybutyrate in a gamma-butyrolactone solvent:Rf(A)X (1)wherein Rf and A are as defined above; and X represents a halogen atom.

Owner:TOSOH F TECH INC

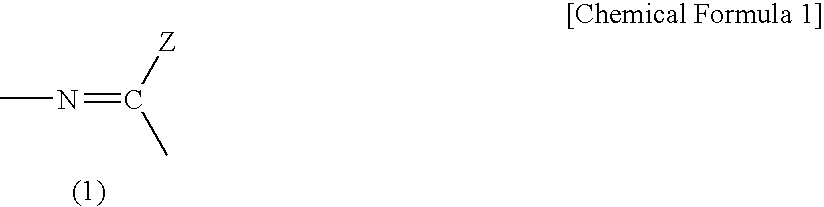

Process for Production of Amides or Lactams

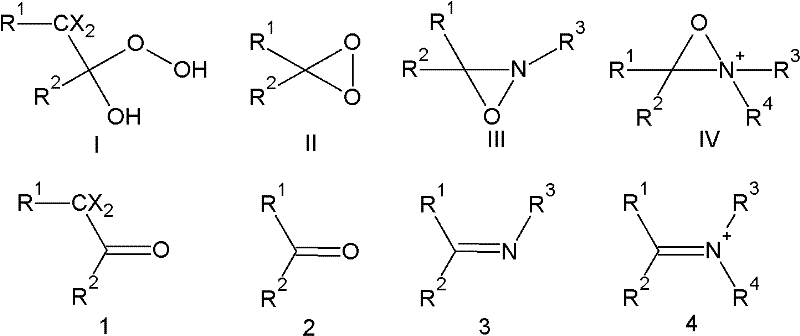

InactiveUS20090093628A1Easy to produceEliminate the problemLactams preparationOrganic compound preparationCyclic compoundPhotochemistry

An amide or lactam is produced by conducting a rearrangement of a corresponding oxime compound in the presence of a cyclic compound containing a structure represented by following Formula (1) as a ring constituent and a fluorinated alcohol:wherein Z represents a halogen atom or an —OR group, where R represents an organic group.Z is preferably chlorine atom. Exemplary fluorinated alcohols include fluorine-containing branched-chain aliphatic alcohols represented by following Formula (3):wherein Rf1 and Rf2 may be the same as or different from each other and each represent a perfluoroalkyl group having one to eight carbon atoms; and “n” denotes an integer of 0 to 8.According to this process, amides or lactams can be simply produced in high yields without causing large amounts of by-products.

Owner:DAICEL CHEM IND LTD

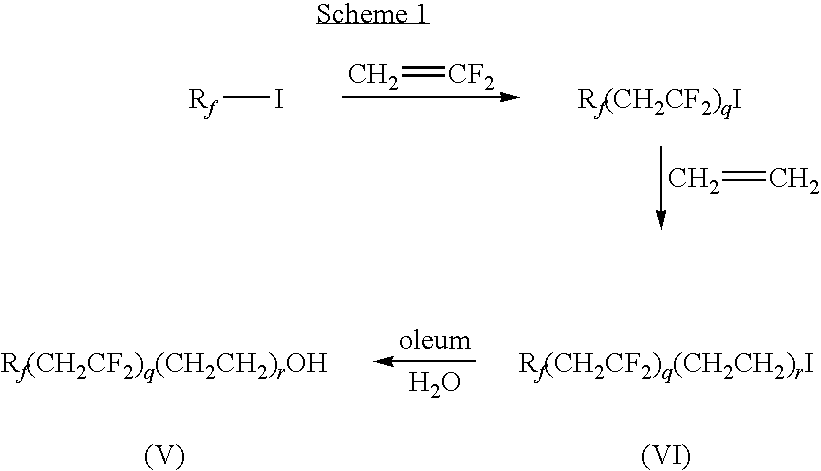

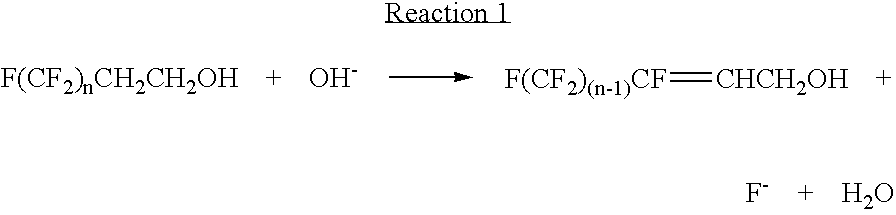

Process for producing fluorinated alcohols

InactiveUS20140163262A1Less costlyMild reaction conditionsOrganic compound preparationPreparation by OH group eliminationVinyl etherAlcohol

The present invention is directed to a process for preparation of fluorinated alcohols of Formula (I)RfCH2CH2OH (I)by contacting a fluorinated iodide with an alkyl vinyl ether in the presence of an initiator and a base to generate an intermediate hemi-acetal or aldehyde or a mixture thereof, followed by hydrogenation of the hemi-acetal of Formula (II)RfCH2CH(OCxH2x+1)m(OH)p (II)or aldehyde of Formula (III)RfCH2CHO (III)or a mixture thereof, to yield a compound of Formula (I).

Owner:THE CHEMOURS CO FC LLC

Resist protective film-forming composition and patterning process

ActiveUS9086628B2Readily availableEasy to handlePhotomechanical exposure apparatusMicrolithography exposure apparatusPolymer scienceAlcohol

A protective film-forming composition comprising a polymer comprising fluorinated alcohol units of the structure: —C(CF3)2OR1 wherein R1 is H or a monovalent hydrocarbon group and having a Mw of 1,000-500,000 is applied onto a resist film to form a protective film thereon. The protective film-forming composition has high water repellent and water slip performance. The protective film exhibits barrier properties to water and prevents any resist components from being leached out in water.

Owner:SHIN ETSU CHEM CO LTD

Method for preparation of fluorinated acrylic ester from fluorinated alcohol

ActiveCN111393289AGood compatibilityLow reaction temperatureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAlcohol

The invention discloses a method for preparation of fluorinated acrylic ester from fluorinated alcohol. The method includes: in a reaction kettle provided with a packed tower and a rectification separator, reacting fluorinated alcohol with acrylic ester in the presence of a self-made fluorine-containing catalyst, a solvent and an assistant, performing step-by-step rectification in the reaction process to remove generated methanol, excessive acrylic ester and the solvent, and then conducting rectification to obtain a high-purity target product. According to the method, the used self-made fluorine-containing catalyst has good compatibility with the reaction system, the reaction temperature is low, the reaction speed is high, and few impurities are generated; the product manufacturing mode issimpler, and industrial production is facilitated.

Owner:安徽灵达高新材料有限公司

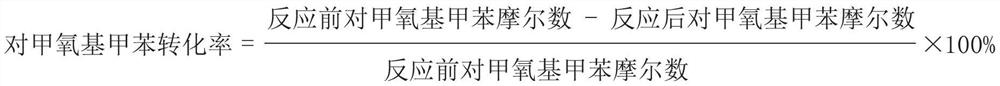

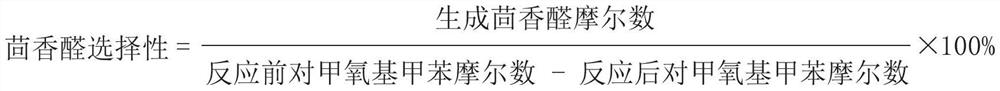

A method for preparing anisaldehyde by catalytic liquid phase selective oxidation

ActiveCN112778106BImprove conversion rateHigh selectivityPhysical/chemical process catalystsOrganic compound preparationPtru catalystAlcohol

The application discloses a method for preparing anisaldehyde by catalytic liquid-phase selective oxidation. In this method, the material containing fluorinated alcohol compounds and p-methoxytoluene is contacted with a catalyst in the presence of an oxygen source to react to obtain anisaldehyde; wherein, air or oxygen is used as an oxygen source, and Nitrogen-doped carbon-supported metals were used as catalysts, and fluorinated alcohols were used as solvents to catalyze the liquid-phase selective oxidation of p-methoxytoluene to produce anisaldehyde. The method has the advantages of mild reaction conditions, high raw material conversion rate and product selectivity, recyclable catalyst, etc. The conversion rate of p-methoxytoluene can reach more than 70%, and the selectivity of anisaldehyde can reach more than 90%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

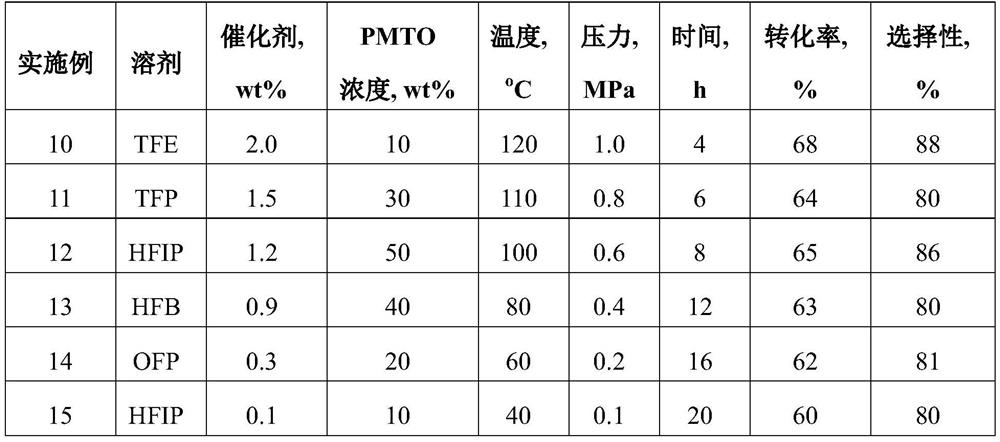

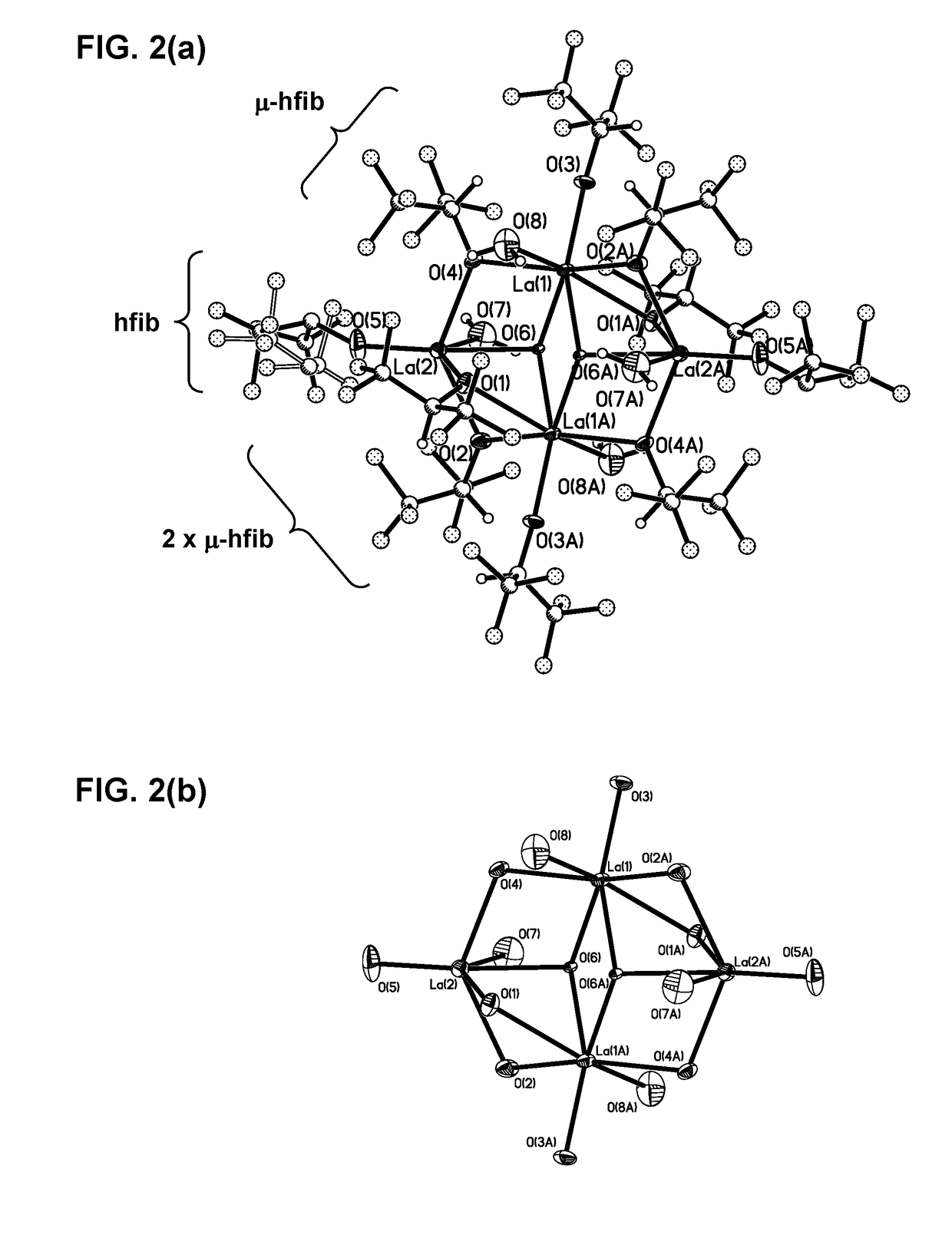

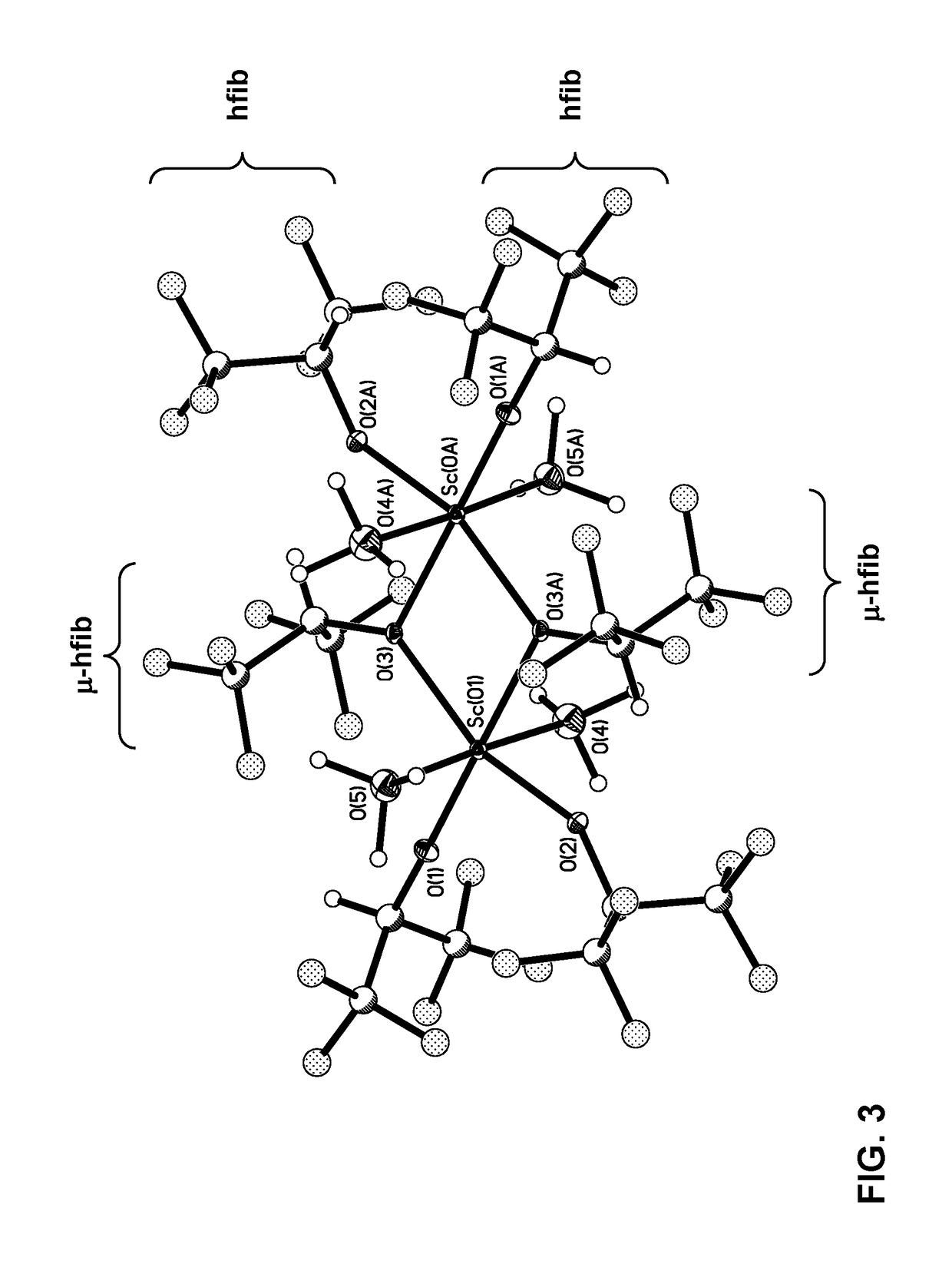

Method to synthesize lanthanide fluoride materials from lanthanide fluorinated alkoxides

Lanthanide fluorinated alkoxide derivatives can be synthesized from the alcoholysis reaction of the lanthanide bis-trimethylsilyl amide and an excess amount of hexafluoro iso-propanol. Nanoparticles can be formed from the lanthanide fluorinated alkoxide derivatives by a solvothermal or solution precipitation process.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Composition, film production method, and light emitting device

ActiveUS10916706B2Improve discharge performanceReduce cloggingDuplicating/marking methodsElectroluminescent light sourcesAlcoholALCOHOL/FLUORIDE

Owner:SUMITOMO CHEM CO LTD

Manufacture of fluorinated alcohols

Present invention relates to a process for the manufacture of fluorinated alcohols as well as borates which are employed in the manufacture of the fluorinated alcohols. Fluorinated alcohols of the formulae HOCHRCF(CF3)CHFCF(CF3)2 and HOCHRCF(CF(CF3)2)CHFCF3, HOCHRCF(CF2CF3)CH(CF3)2 and HOCHRC(CF3)2CHFCF2CF3 are made by heating a mixture of a borate of the formula (RCH2O)3B, wherein R═H or a C1 to C7 alkyl group, with perfluoro-4-methyl-2-pentene or perfluoro-2-methyl-2-pentene and a free-radical initiator to form a mixture of borates, optionally separating the mixture of borates from any reactants, solvents, and by-products; hydrolyzing the mixture of borates to form a hydrolysis product mixture; and separating the alcohols from the hydrolysis product mixture.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com