A method for preparing anisaldehyde by catalytic liquid phase selective oxidation

A technology of phase selection and anisaldehyde, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of high cost of anisaldehyde, corrosion of equipment, large consumption of raw materials, etc., and achieve conversion rate of raw materials and The effect of high product selectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

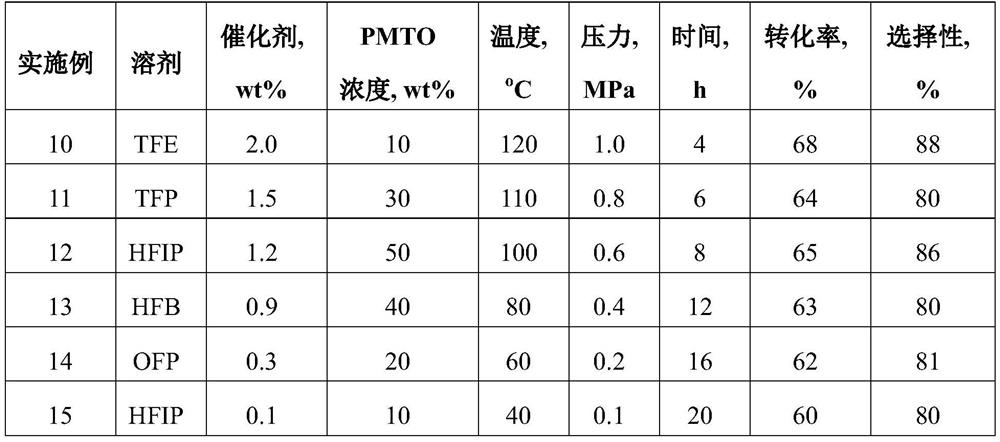

Examples

Embodiment 1

[0031] Dissolve 1 g of hydrated cobalt acetate in 100 ml of methanol, add 100 ml of methanol dissolved in 2 g of benzotriazole under stirring, continue to stir for 2 h, filter, wash the obtained solid with methanol, dry in the air, and roast at 700 °C for 4 h under nitrogen protection. Soak in 10% dilute hydrochloric acid for 8 h, filter and wash with water until neutral, and the obtained solid was vacuum dried at 80 °C for 8 h to obtain 1 g of nitrogen-doped carbon-supported cobalt catalyst (Co@N-C).

[0032] Take 20mg of the obtained catalyst (Co@N-C) and add it to the 50mL reactor containing 2g p-methoxytoluene and 8g 1,1,1,3,3,3-hexafluoro-2-propanol, stir, and heat up. to 80°C, charged with oxygen to a pressure of 0.4MPa, reacted for 8h, and qualitatively and quantitatively analyzed the reaction product by gas chromatography-mass spectrometry. The conversion rate of p-methoxytoluene was 70%, and the selectivity of anisaldehyde was 90%. .

Embodiment 2~3

[0034] In Examples 2-3, the effects of different metals on the reaction were studied, and the specific method was similar to that in Example 1. The reaction results are shown in Table 1.

Embodiment 2

[0035] The difference between the catalyst preparation process of Example 2 and Example 1 is that 1 g of hydrated ruthenium trichloride is dissolved in 100 ml of methanol to finally obtain a nitrogen-doped carbon-supported ruthenium catalyst (Ru@N-C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com