Hanger cable

A cable and pylon technology, applied in the field of aircraft pylon cable assemblies, can solve the problems of weak environment resistance and anti-interference ability, high degree of cable integration, difficult production and processing, etc., so as to save processing time and improve salt spray resistance. Corrosion resistance, the effect of reducing the assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

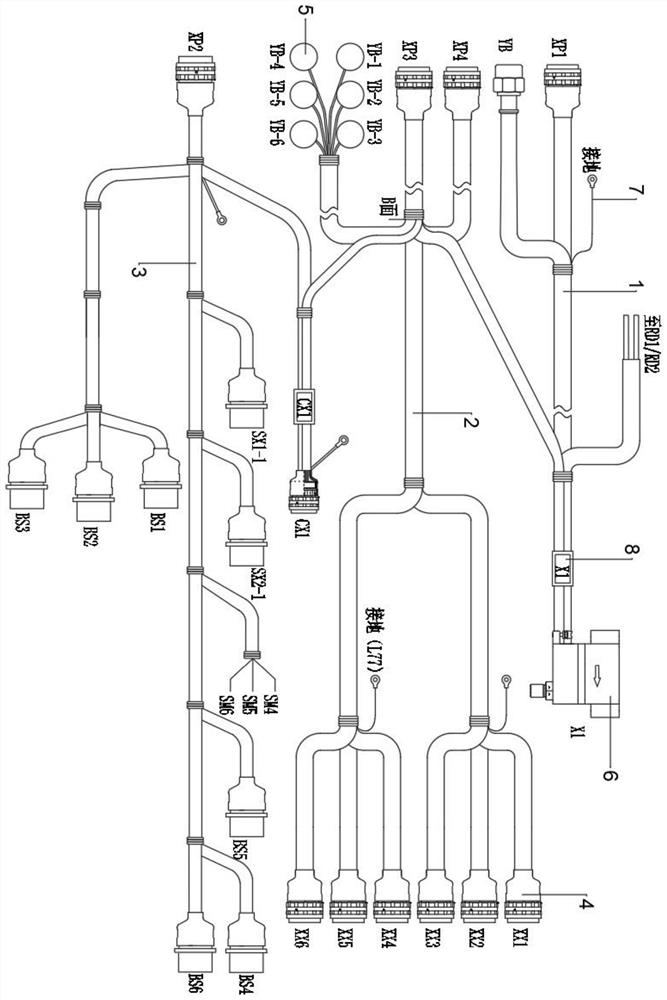

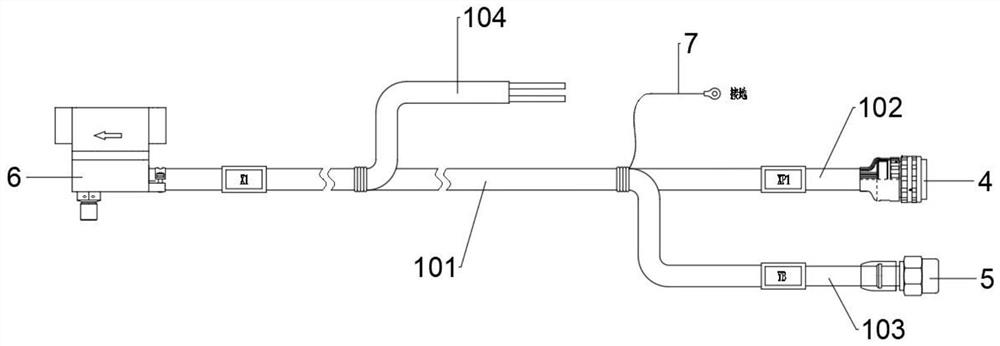

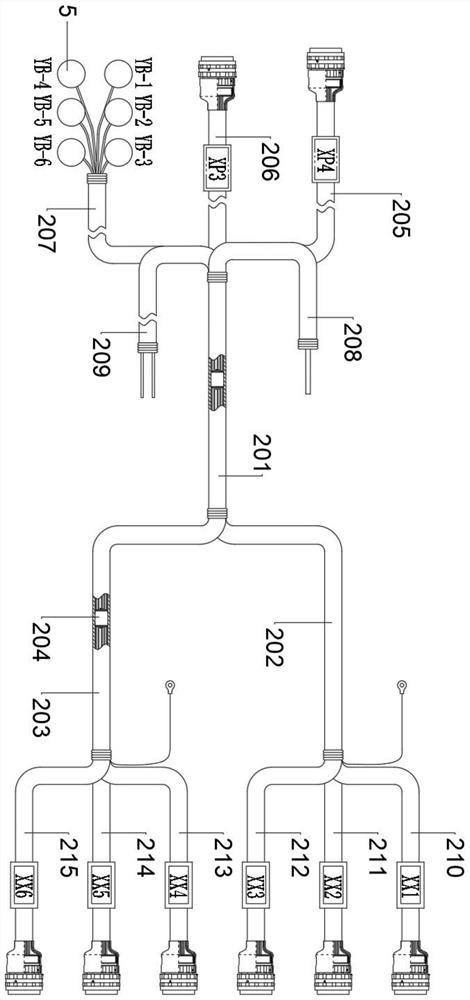

[0025] refer to Figure 1-Figure 5 , a hanger cable, including XP1 part cable assembly 1, XP2 part cable assembly 2, XP3 part cable assembly 3, connector 4, radio frequency connector 5, rectangular connector 6 and grounding terminal 7, said XP1 Part of the cable assembly 1, XP2 part of the cable assembly 2 and XP3 part of the cable assembly 3 are electrically connected through lines, and a plurality of the connectors 4, radio frequency connectors 5 and grounding terminals 7 are respectively assembled on the XP1 part of the cable The terminals of component 1, part of cable component 2 of XP2 and part of cable component 3 of XP3, the rectangular connector 6 is assembled on the terminal of part of cable component 1 of XP1.

[0026] The overall wire harness is split according to the shape installation and wiring relationship, and is divided into three wire harnesses: XP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com