Aluminum alloy corrosion resistance two-dimensional code marking method based on laser cladding

A laser cladding, aluminum alloy technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of data loss, edge or module blur, DM code readability, etc., to improve the resistance to salt spray corrosion, The effect of avoiding pollution and improving the resistance to salt spray corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

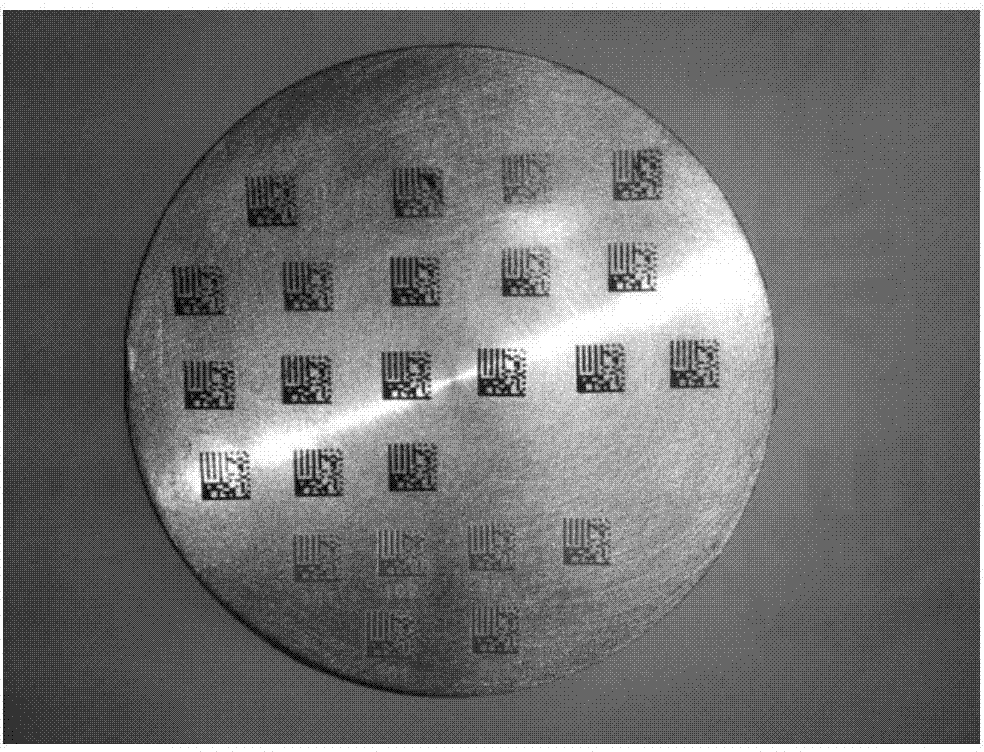

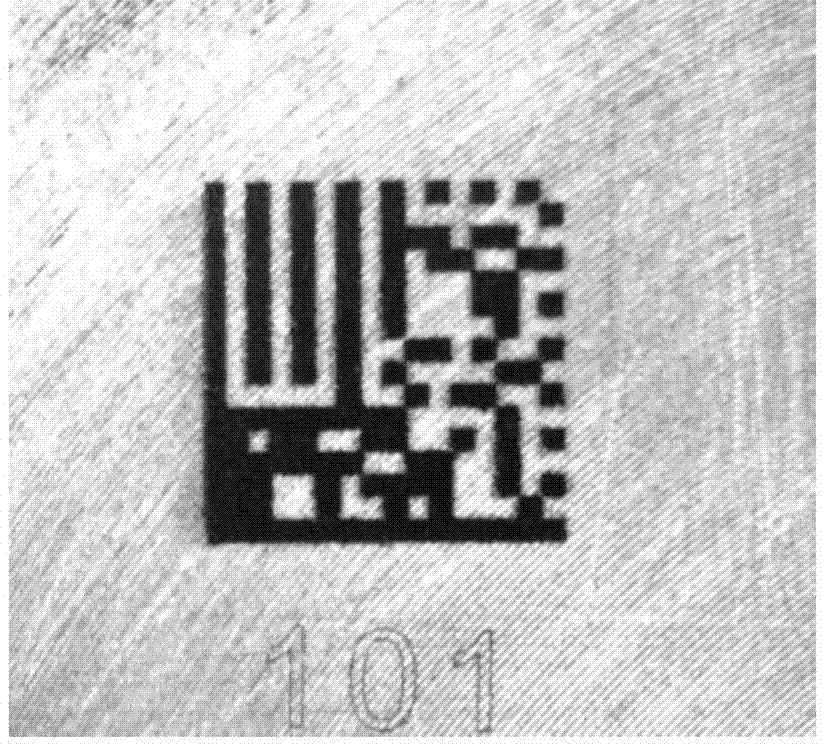

[0059] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

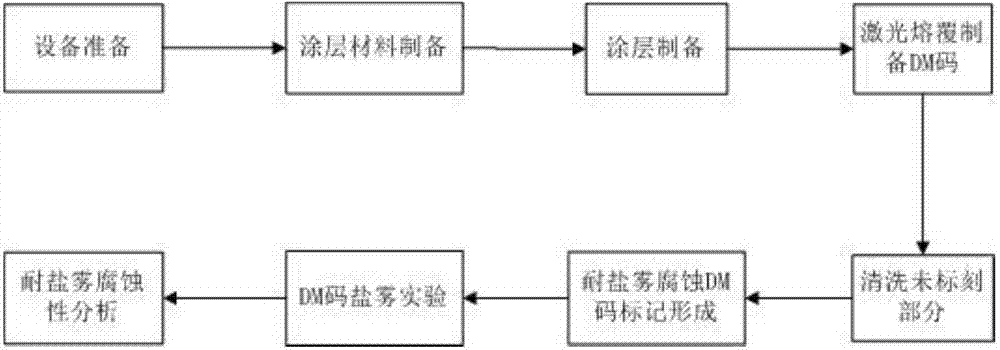

[0060] The steps of this embodiment are:

[0061] Step 1: Prepare laser cladding coating:

[0062] Step 1.1: Mix nickel-based alloy powder (nickel-based alloy powder grade is Ni20) and graphite powder in a mass ratio of 20:1 and place them in a ball mill to fully mix; mix the obtained mixed powder with absolute ethanol and varnish according to the mass ratio 20:2:1 ratio and fully stirred and mixed to obtain the coating material.

[0063] Step 1.2: Coat the coating material evenly on the surface of the aluminum alloy test piece, and then place the aluminum alloy test piece in an electric blast drying oven to dry at a drying temperature of 100 degrees Celsius and a drying time of 60 minutes. Before coating the coating material, it is necessary to grind the surface of the aluminum alloy specimen so th...

Embodiment 2

[0086] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

[0087] The steps of this embodiment are:

[0088] Step 1: Prepare laser cladding coating:

[0089]Step 1.1: Mix nickel-based alloy powder (nickel-based alloy powder grade is Ni20) and graphite powder in a mass ratio of 20:1 and place them in a ball mill to fully mix; mix the obtained mixed powder with absolute ethanol and varnish according to the mass ratio 20:2:1 ratio and fully stirred and mixed to obtain the coating material.

[0090] Step 1.2: Coat the coating material evenly on the surface of the aluminum alloy test piece, and then place the aluminum alloy test piece in an electric blast drying oven to dry at a drying temperature of 100 degrees Celsius and a drying time of 60 minutes. Before coating the coating material, it is necessary to grind the surface of the aluminum alloy specimen so tha...

Embodiment 3

[0113] In this embodiment, the aluminum alloy sheet material with the grade of 2A12 is selected as the aluminum alloy test piece to be marked, and its specification is Ф50*5mm.

[0114] The steps of this embodiment are:

[0115] Step 1: Prepare laser cladding coating:

[0116] Step 1.1: Mix nickel-based alloy powder (nickel-based alloy powder grade is Ni20) and graphite powder in a mass ratio of 20:1 and place them in a ball mill to fully mix; mix the obtained mixed powder with absolute ethanol and varnish according to the mass ratio 20:2:1 ratio and fully stirred and mixed to obtain the coating material.

[0117] Step 1.2: Coat the coating material evenly on the surface of the aluminum alloy test piece, and then place the aluminum alloy test piece in an electric blast drying oven to dry at a drying temperature of 100 degrees Celsius and a drying time of 60 minutes. Before coating the coating material, it is necessary to grind the surface of the aluminum alloy specimen so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com