Stainless steel desulphurization agent

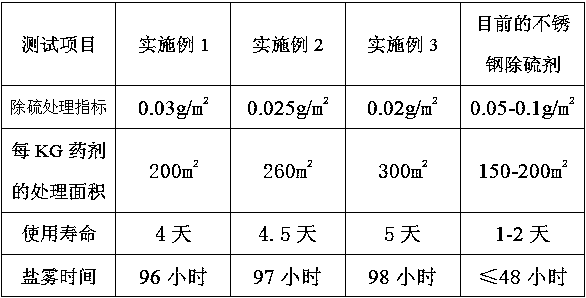

A technology of stainless steel and complexing agent, applied in the field of stainless steel desulfurizer, it can solve the problems of loose weld, reduced plasticity and toughness, service life of only 1-2 days, and salt spray time of less than or equal to 48 hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A stainless steel desulfurizer, consisting of the following components by weight: wetting agent or polyol 11%, emulsifier 3%, complexing agent A: 8%, penetrating agent or corrosion inhibitor 0.7%, complexing agent B: 6%, complexing agent C: 6% and deionized water 65.3%.

[0024] Wherein, the wetting agent or polyhydric alcohol is 2-methyl-2,4-pentanediol.

[0025] Wherein, the emulsifier is isomerized tridecanol polyoxyethylene ether E-1310.

[0026] Wherein, the complexing agent A is sodium α-glucoheptonate.

[0027] Wherein, the penetrating agent or corrosion inhibitor is BEROL 226 SA, and BEROL 226 SA is a strong degreasing surfactant.

[0028] Wherein, complexing agent B is sodium citrate.

[0029] Wherein, complexing agent C is sodium potassium tartrate.

Embodiment 2

[0031] A stainless steel desulfurizer, consisting of the following components by weight: wetting agent or polyol 12%, emulsifier 4%, complexing agent A: 9%, penetrating agent or corrosion inhibitor 0.8%, complexing agent B: 7%, complexing agent C: 7% and deionized water 60.2%.

[0032] Wherein, the wetting agent or polyhydric alcohol is 2-methyl-2,4-pentanediol.

[0033] Wherein, the emulsifier is isomerized tridecanol polyoxyethylene ether E-1310.

[0034] Wherein, the complexing agent A is sodium α-glucoheptonate.

[0035] Wherein, the penetrating agent or corrosion inhibitor is BEROL 226 SA, and BEROL 226 SA is a strong degreasing surfactant.

[0036] Wherein, complexing agent B is sodium citrate.

[0037] Wherein, complexing agent C is sodium potassium tartrate.

Embodiment 3

[0039] A stainless steel desulfurizer, consisting of the following components by weight: wetting agent or polyol 12%, emulsifier 5%, complexing agent A: 9.3%, penetrating agent or corrosion inhibitor 1%, complexing agent B: 8%, complexing agent C: 7.5% and deionized water 57.2%.

[0040] Wherein, the wetting agent or polyhydric alcohol is 2-methyl-2,4-pentanediol.

[0041] Wherein, the emulsifier is isomerized tridecanol polyoxyethylene ether E-1310.

[0042] Wherein, the complexing agent A is sodium α-glucoheptonate.

[0043] Wherein, the penetrating agent or corrosion inhibitor is BEROL 226 SA, and BEROL 226 SA is a strong degreasing surfactant.

[0044] Wherein, complexing agent B is sodium citrate.

[0045] Wherein, complexing agent C is sodium potassium tartrate.

[0046] In one of the examples, the formulas and weight ratios of Examples 1-3 are prepared respectively using the preparation method of the stainless steel desulfurizer of the present invention. Pour deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com