Spent meal for treating surface of copper and copper alloy and method for preparing same

A surface treatment, copper alloy technology, applied in the field of degreasing powder for non-ferrous metal surface treatment, can solve the problems of unsatisfactory use effect, many pitting of electroplating products, slow degreasing speed, etc. The effect of period extension

Inactive Publication Date: 2008-10-15

JIANGSU DEMEI TECH

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although there are several degreasing powders used for non-ferrous metals at present, due to the limitations of their components, content and preparation methods, the degreasing treatment of copper and copper alloys generally has slow degreasing speed, easy discoloration, and slight corrosion to varying degrees. , resulting in many pitting defects in electroplating products, so the use effect is not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

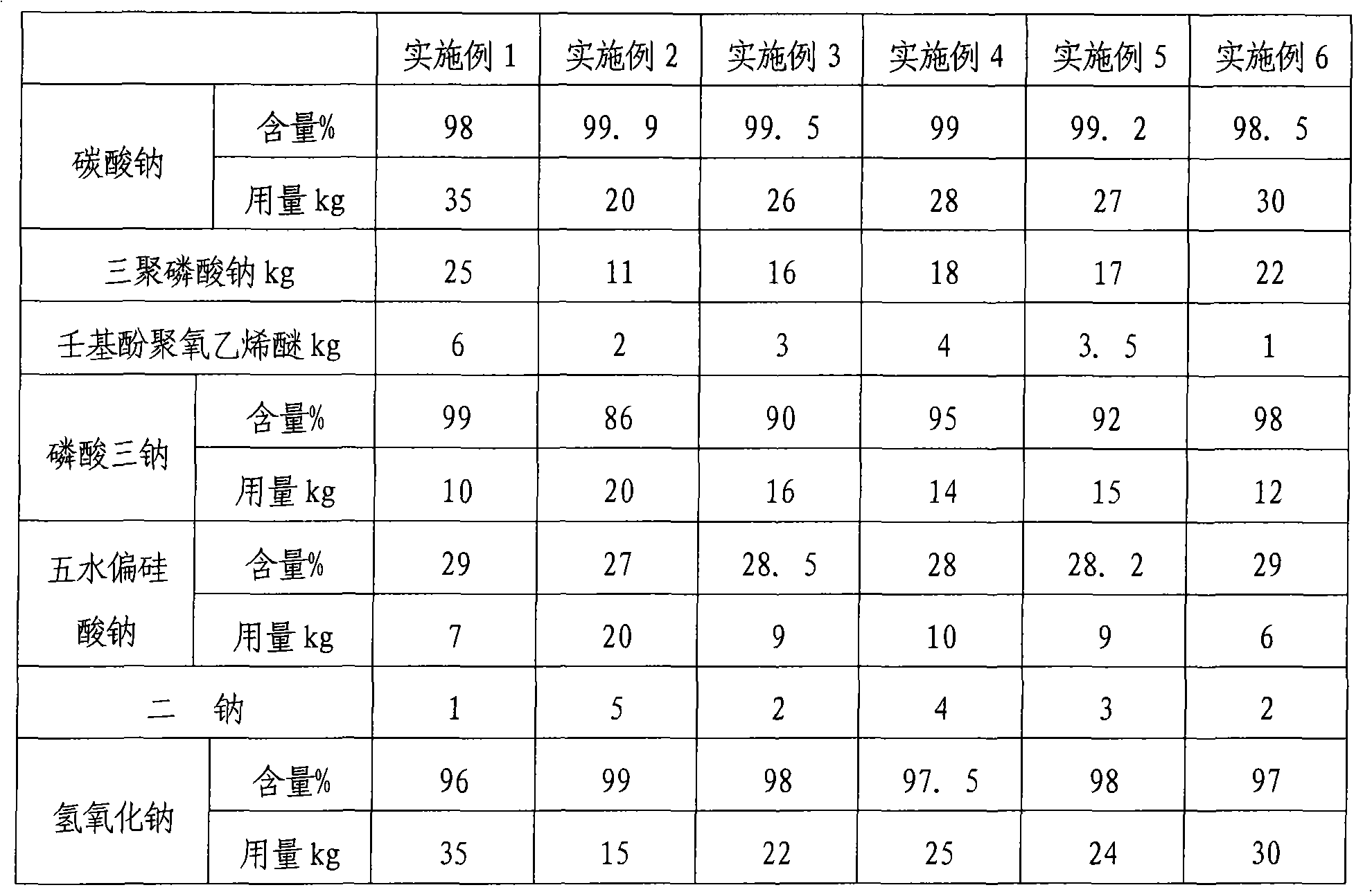

The invention discloses spent meal used for processing the surface of copper and copper alloy and a method for preparing the same. The compositions and the proportions of the spent meal are: 20 to 35 portions of sodium carbonate, 10 to 25 portions of trimeric sodium phosphate, 1 to 6 portions of nonylphenol polyoxyethylene ether, 10 to 20 portions of trisodium phosphate, 6 to 20 portions of sodium metasilicate pentahydrate, 1 to 5 portions of disodium, 15 to 35 portions of sodium hydroxide, and all the proportions being weight portions. The method for preparing the spent meal comprises the following steps of: evenly mixing and stirring the sodium carbonate and the trimeric sodium phosphate; adding the nonylphenol polyoxyethylene ether and evenly stirring; adding the trisodium phosphate and the sodium metasilicate pentahydrate and evenly stirring; and adding the disodium and the sodium hydroxide and evenly stirring to receive a finished product. The spent meal has strong emulsifying capacity and permeability, has the dirt dissolving capacity increased by 2 to 3 times and the cleaning period shortened by 1 to 3 times, does not discolor degreasing fluid during using, does not have corrodibility, does not destroy workpieces, is easily biodegraded and is advantageous to environmental protection.

Description

Degreasing powder for surface treatment of copper and copper alloy and preparation method thereof technical field The invention relates to a degreasing powder for surface treatment of nonferrous metals, in particular to a degreasing powder for surface treatment of copper and copper alloys, and also relates to a preparation method of the degreasing powder. Background technique Degreasing the surface of copper and copper alloys is an important process in workpiece processing, especially in electroplating production, which directly affects the processing and electroplating effect of workpieces. Although there are several degreasing powders used for non-ferrous metals at present, due to the limitations of their components, content and preparation methods, the degreasing treatment of copper and copper alloys generally has slow degreasing speed, easy discoloration, and slight corrosion to varying degrees. , resulting in many pitting defects in electroplating products, so the use...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D5/34C23G1/20

Inventor 瞿德勤

Owner JIANGSU DEMEI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com