Isolated soybean protein chitosan nano gel and preparation method and application thereof

A nanotechnology of soybean protein isolate and chitosan, which is applied in the preparation method, application, and processing of plant protein, etc., can solve the problems of low solubility, limited stability and bioavailability, and achieve simple operation and easy use volume and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

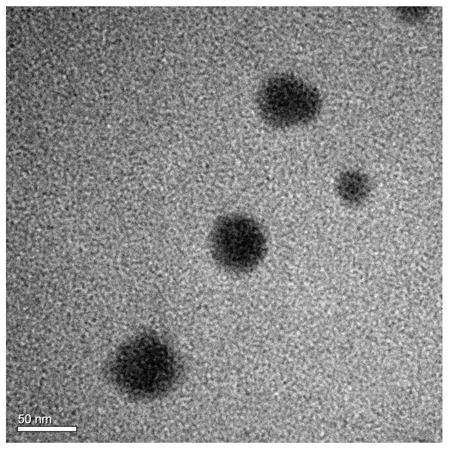

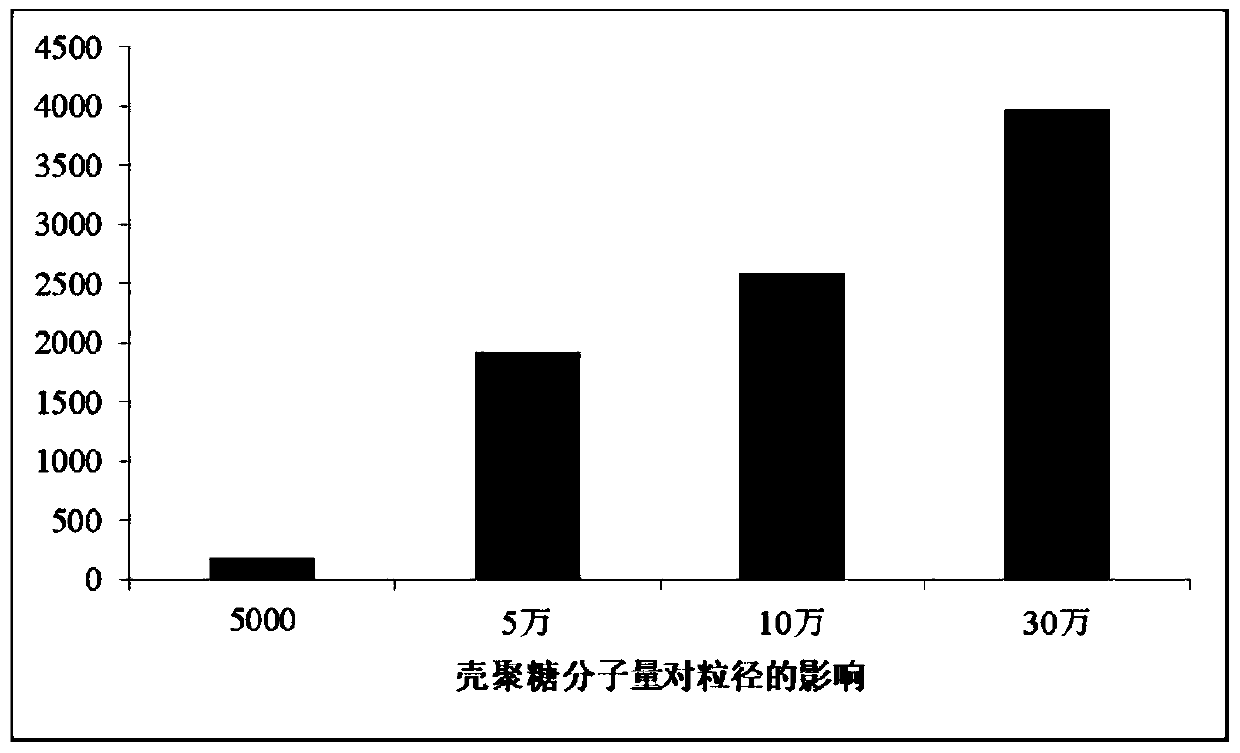

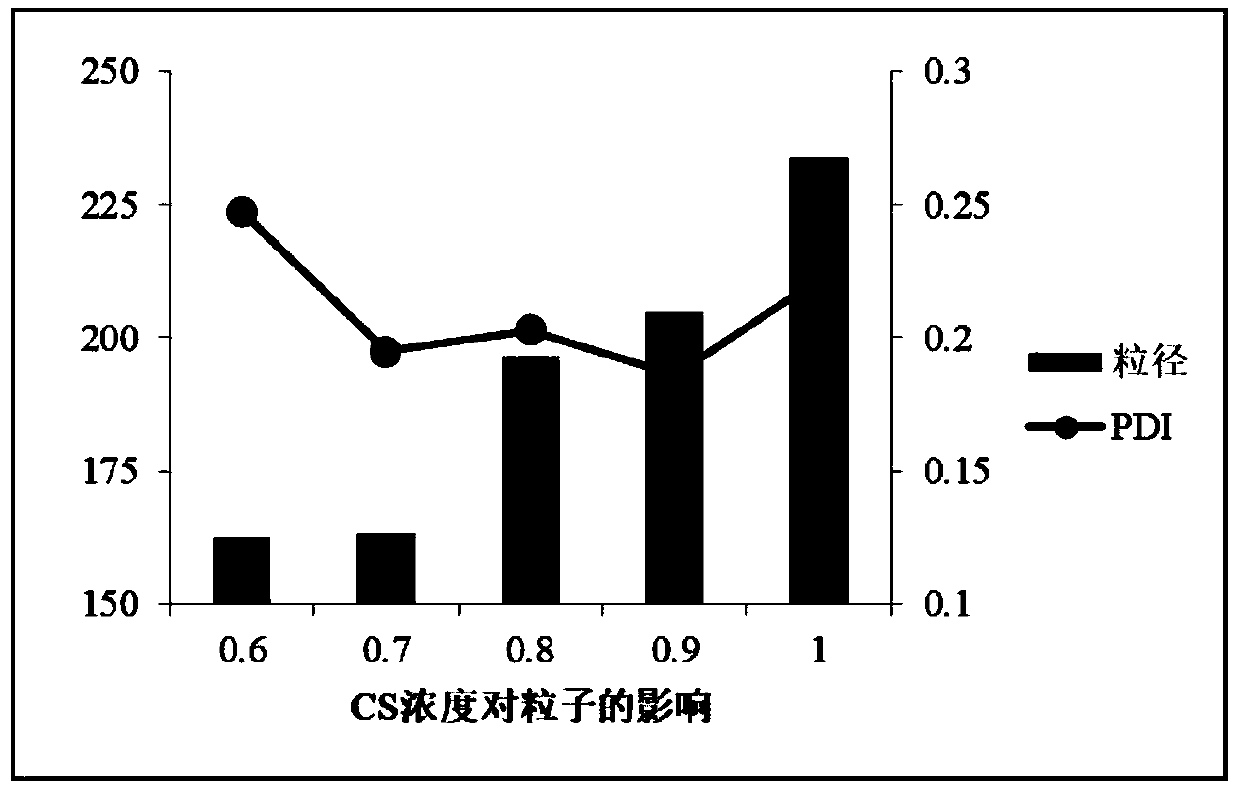

Image

Examples

Embodiment 1

[0037] A method for preparing soybean protein isolate chitosan nanogel and then preparing Pickering emulsion:

[0038] (1) Preparation of CS and SPI solutions:

[0039] Dissolve chitosan in 0.1% acetic acid solution and stir for 10 hours to make a chitosan solution with a concentration of 0.6 mg / ml, then adjust the pH of the chitosan solution to 5.1; dissolve soybean protein isolate in ultrapure water Prepare a 1.6% concentration of SPI solution, add 0.02% sodium azide, stir for 2 hours, put it in a refrigerator at 4°C for overnight hydration, and then centrifuge the soybean protein isolate solution at 8000r for 25 minutes, adjust its pH to 6.6, and further process membrane to remove insoluble material.

[0040] (2) Preparation of SPI / CS nanogel:

[0041] Under 700r / min magnetic stirring, the chitosan solution was continuously added dropwise to the soybean protein isolate solution at a speed of 1ml / min according to SPI:CS(v / v)=2:1, and stirred for 1h.

[0042] (3) Preparati...

Embodiment 2

[0045] A method for preparing soybean protein isolate chitosan nanogel and then preparing Pickering emulsion:

[0046] (1) Preparation of CS and SPI solutions:

[0047] Chitosan was dissolved in 0.1% acetic acid solution and stirred for 10h to make a chitosan solution with a concentration of 0.7mg / ml, and then the pH of the chitosan solution was adjusted to be 5.2; the soybean protein isolate was dissolved in ultrapure water 1.8% concentration of SPI solution was prepared in the mixture, 0.02% sodium azide was added, stirred for 2 hours, placed in a 4°C refrigerator for overnight hydration, and then the soy protein isolate solution was centrifuged at 8000r for 25 minutes to adjust its pH to 6.8, and further membrane to remove insoluble material.

[0048] (2) Preparation of SPI / CS nanogel:

[0049] Under 700r / min magnetic stirring, the chitosan solution was continuously added dropwise to the soybean protein isolate solution at a speed of 1ml / min according to SPI:CS(v / v)=1:1, ...

Embodiment 3

[0053] A method for preparing soybean protein isolate chitosan nanogel and then preparing Pickering emulsion:

[0054] (1) Preparation of CS and SPI solutions:

[0055] Dissolve chitosan in 0.1% acetic acid solution and stir for 10 hours to make a chitosan solution with a concentration of 0.8 mg / ml, then adjust the pH of the chitosan solution to 5.3; dissolve soybean protein isolate in ultrapure water Make a 2.0% concentration of SPI solution, add 0.02% sodium azide, stir for 2 hours, put it in a refrigerator at 4°C for overnight hydration, and then centrifuge the soybean protein isolate solution at 8000r for 25 minutes, adjust its pH to 7.0, and further process membrane to remove insoluble material.

[0056] (2) Preparation of SPI / CS nanogel:

[0057] Under 700r / min magnetic stirring, the chitosan solution was continuously added dropwise to the soybean protein isolate solution at a speed of 1ml / min according to SPI:CS(v / v)=5:8, and stirred for 1h.

[0058] (3) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com