High-solubility piglet milk powder and processing method thereof

A processing method and reconstitution technology, which is applied in the field of pig feed to achieve the effects of solving poor solubility, promoting acid environment and improving reconstitution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

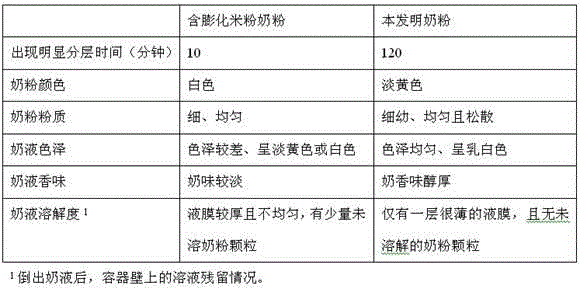

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A milk powder for suckling piglets with high brewability, including the following raw materials in weight ratio: 300 parts of medium-fat milk powder, 100 parts of low-protein whey powder, 50 parts of lactose, 80 parts of fermented rice paste, 30 parts of soybean protein isolate, plasma 50 parts of protein powder, 50 parts of coconut oil, 20 parts of glucose, 5 parts of lysine, 1 part of methionine, 1 part of threonine, 1 part of tryptophan, 1 part of arginine, 0.1 part of vitamin C, 0.1 part of vitamin E 0.1 part of ethoxyquinoline, 2 parts of organic acid, 0.5 part of probiotics for feed, 0.2 part of functional oligosaccharide, 2 parts of vitamin premix, 2 parts of organic trace element premix, 0.01 part of α-amylase 1 part, 1 part linseed gum.

Embodiment 2

[0038] A milk powder for suckling piglets with high brewability, including raw materials in the following weight ratio: 600 parts of medium-fat milk powder, 300 parts of low-protein whey powder, 150 parts of lactose, 280 parts of fermented rice paste, 200 parts of soybean protein isolate, plasma 150 parts of protein powder, 150 parts of coconut oil, 40 parts of glucose, 50 parts of sucrose, 15 parts of lysine, 5 parts of methionine, 5 parts of threonine, 8 parts of tryptophan, 5 parts of arginine, 0.3 parts of vitamin C , 0.3 parts of vitamin E, 1 part of ethoxyquinoline, 5 parts of organic acid, 2 parts of feed probiotics, 4 parts of functional oligosaccharides, 3 parts of vitamin premix, 3 parts of organic trace element premix, α - 1 part of amylase, 0.5 parts of milk flavoring agent, 10 parts of linseed gum.

[0039] Described organic acid is 99% benzoic acid.

Embodiment 3

[0041] A milk powder for suckling piglets with high brewability, including the following raw materials in weight ratio: 400 parts of medium-fat milk powder, 200 parts of low-protein whey powder, 100 parts of lactose, 120 parts of fermented rice paste, 120 parts of soybean protein isolate, plasma 80 parts of protein powder, 85 parts of coconut oil, 30 parts of glucose, 10 parts of sucrose, 10 parts of lysine, 2 parts of methionine, 2 parts of threonine, 4 parts of tryptophan, 3 parts of arginine, 0.2 parts of vitamin C , 0.2 parts of vitamin E, 0.15 parts of ethoxyquinoline, 3 parts of organic acid, 1 part of feed probiotics, 2 parts of functional oligosaccharides, 2.5 parts of vitamin premix, 2.3 parts of organic trace element premix, α - 0.05 parts of amylase, 0.2 parts of milk flavoring agent, 5 parts of linseed gum.

[0042] The described coconut oil contains an emulsifier with a mass fraction of 0.15%.

[0043] Described organic acid is 99% benzoic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com